A SOP Template for Manufacturing Cleaning and Sanitation ensures consistent and effective cleaning protocols, minimizing contamination risks in production environments. This template outlines step-by-step procedures, including cleaning agents, equipment handling, and safety measures to maintain hygiene standards. Implementing this SOP enhances product quality, regulatory compliance, and workplace safety.

Personnel hygiene and handwashing procedures.

This SOP details personnel hygiene and handwashing procedures essential for maintaining a clean and safe environment. It covers proper handwashing techniques, the use of sanitizers, timing and frequency of handwashing, guidelines for personal cleanliness, and the importance of preventing contamination in workplace settings. The objective is to promote health, reduce the spread of infections, and ensure compliance with hygiene standards among all personnel.

Pre-operational cleaning checklist for manufacturing areas.

This SOP details the pre-operational cleaning checklist for manufacturing areas, covering essential cleaning tasks before production begins. It ensures all equipment, work surfaces, and floors are thoroughly cleaned to maintain hygiene and prevent contamination. The checklist includes verification of cleaning supplies, inspection for residues or debris, proper disposal of waste, and documentation of cleaning activities. Adhering to this SOP promotes a safe and efficient manufacturing environment, reducing downtime and maintaining product quality.

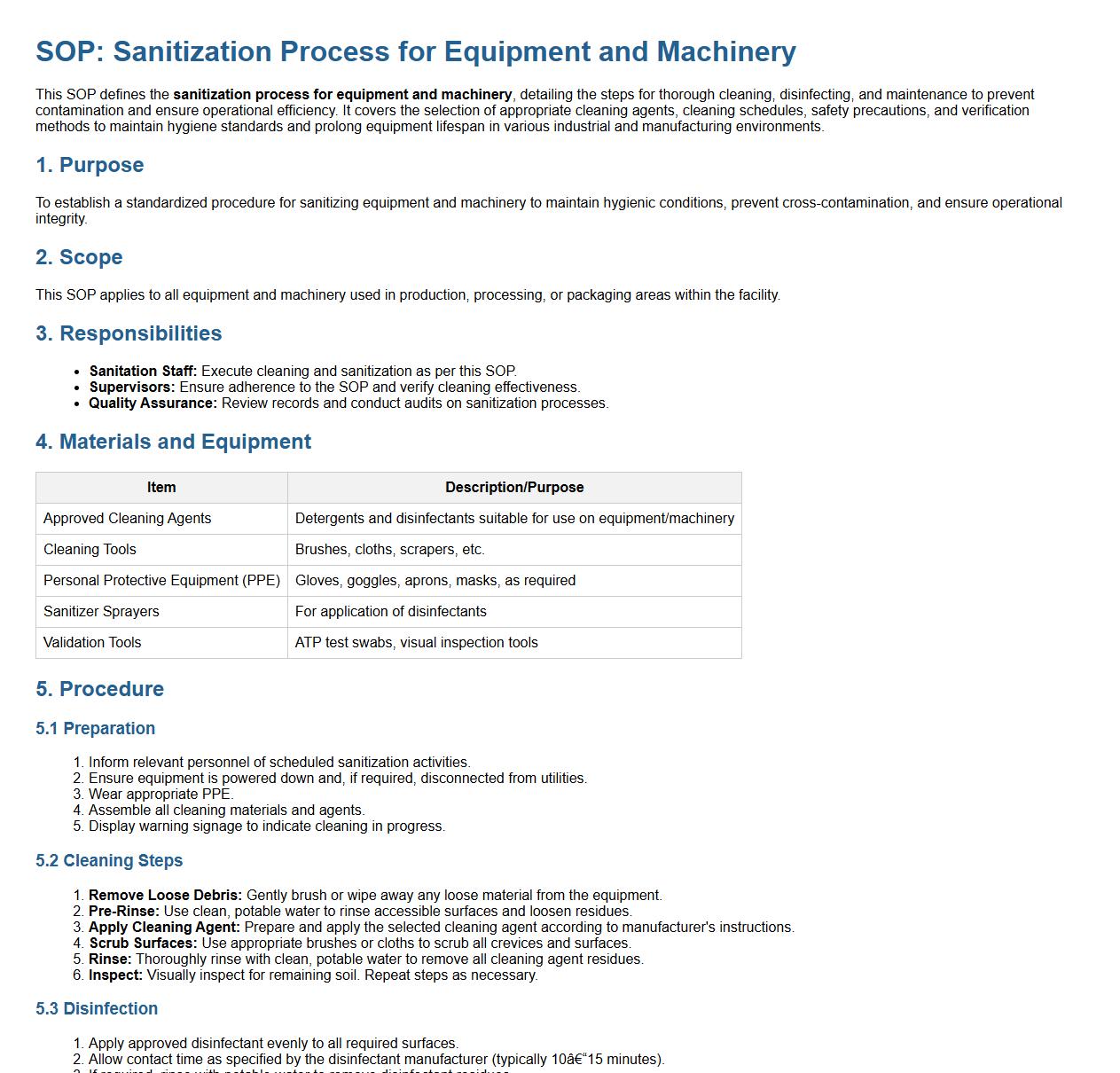

Sanitization process for equipment and machinery.

This SOP defines the sanitization process for equipment and machinery, detailing the steps for thorough cleaning, disinfecting, and maintenance to prevent contamination and ensure operational efficiency. It covers the selection of appropriate cleaning agents, cleaning schedules, safety precautions, and verification methods to maintain hygiene standards and prolong equipment lifespan in various industrial and manufacturing environments.

Cleaning frequency schedule for production zones.

This SOP defines the cleaning frequency schedule for production zones, detailing the required cleaning intervals, methods, and responsibilities to maintain hygiene and prevent contamination. It covers daily, weekly, and monthly cleaning tasks, specifies cleaning agents and equipment, and outlines documentation procedures to ensure compliance with safety and quality standards in production environments.

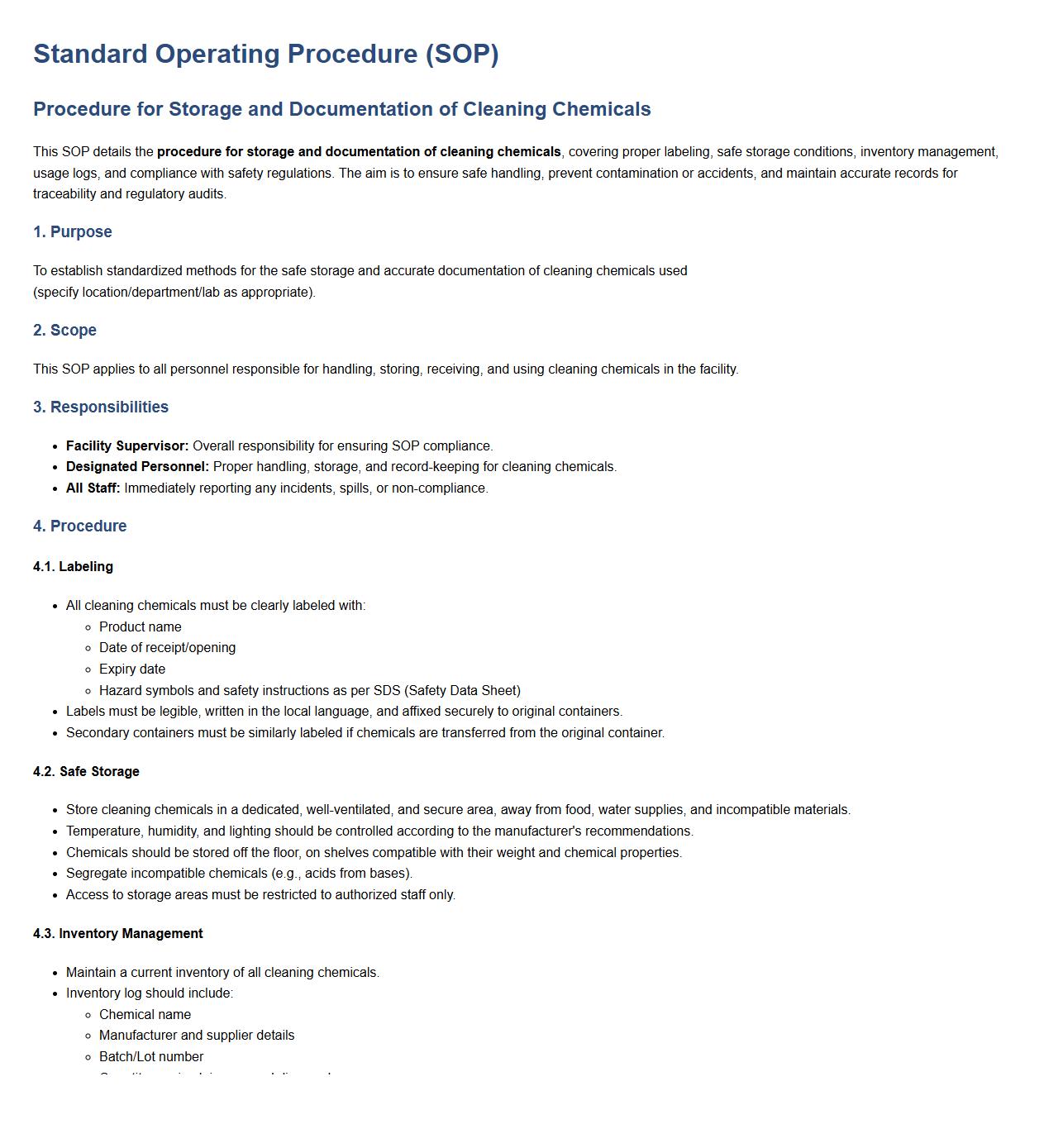

Procedure for storage and documentation of cleaning chemicals.

This SOP details the procedure for storage and documentation of cleaning chemicals, covering proper labeling, safe storage conditions, inventory management, usage logs, and compliance with safety regulations. The aim is to ensure safe handling, prevent contamination or accidents, and maintain accurate records for traceability and regulatory audits.

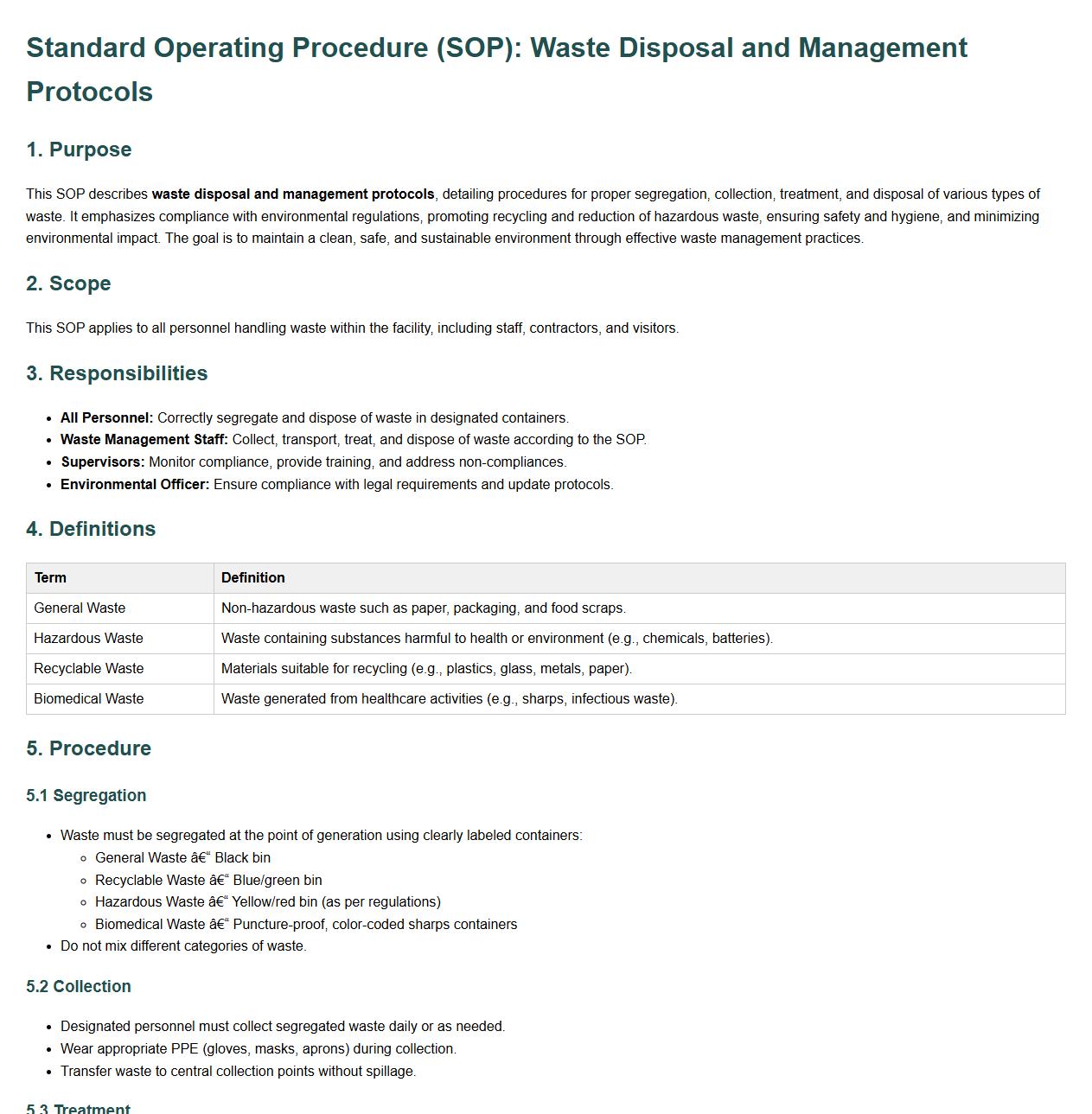

Waste disposal and management protocols.

This SOP describes waste disposal and management protocols, detailing procedures for proper segregation, collection, treatment, and disposal of various types of waste. It emphasizes compliance with environmental regulations, promoting recycling and reduction of hazardous waste, ensuring safety and hygiene, and minimizing environmental impact. The goal is to maintain a clean, safe, and sustainable environment through effective waste management practices.

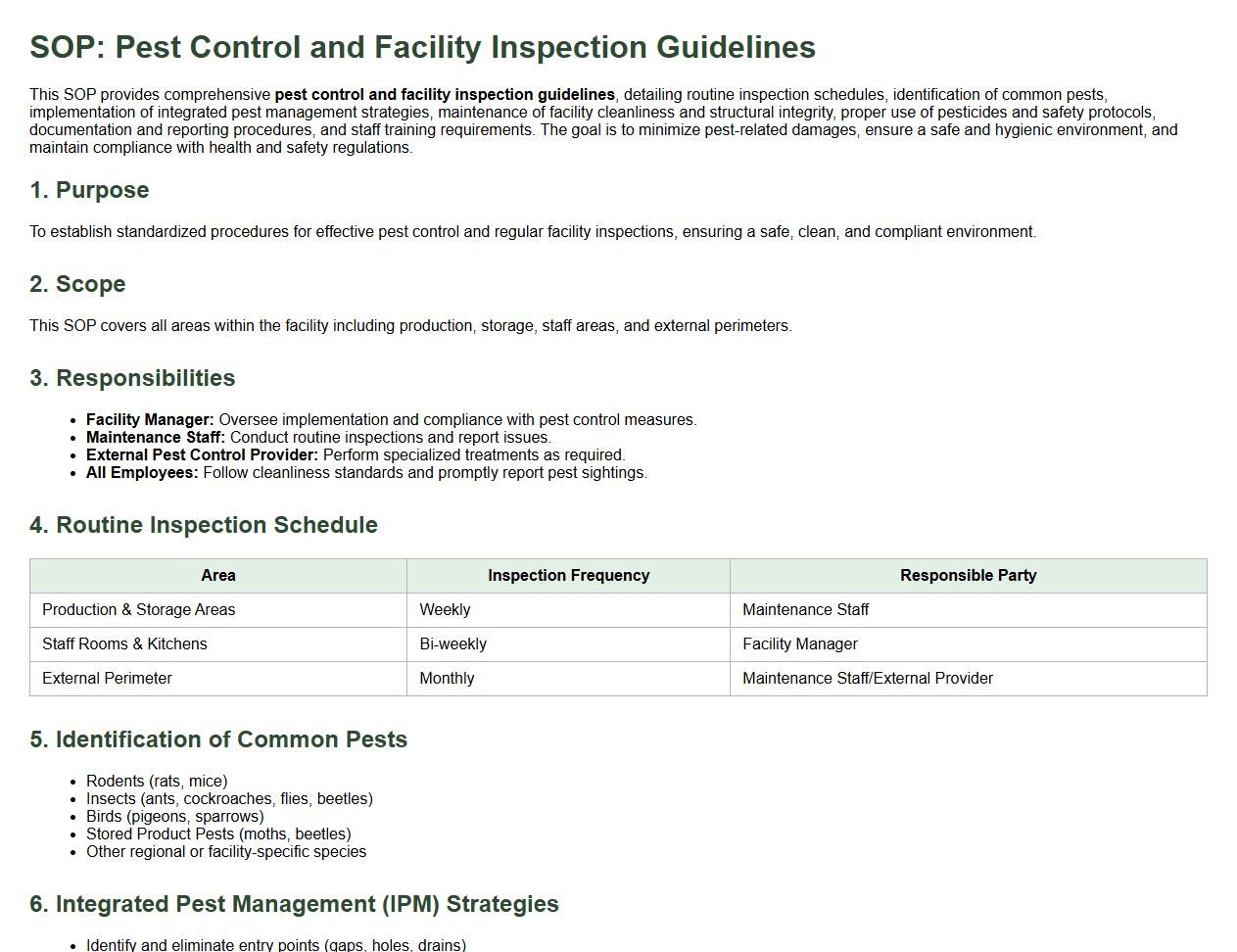

Pest control and facility inspection guidelines.

This SOP provides comprehensive pest control and facility inspection guidelines, detailing routine inspection schedules, identification of common pests, implementation of integrated pest management strategies, maintenance of facility cleanliness and structural integrity, proper use of pesticides and safety protocols, documentation and reporting procedures, and staff training requirements. The goal is to minimize pest-related damages, ensure a safe and hygienic environment, and maintain compliance with health and safety regulations.

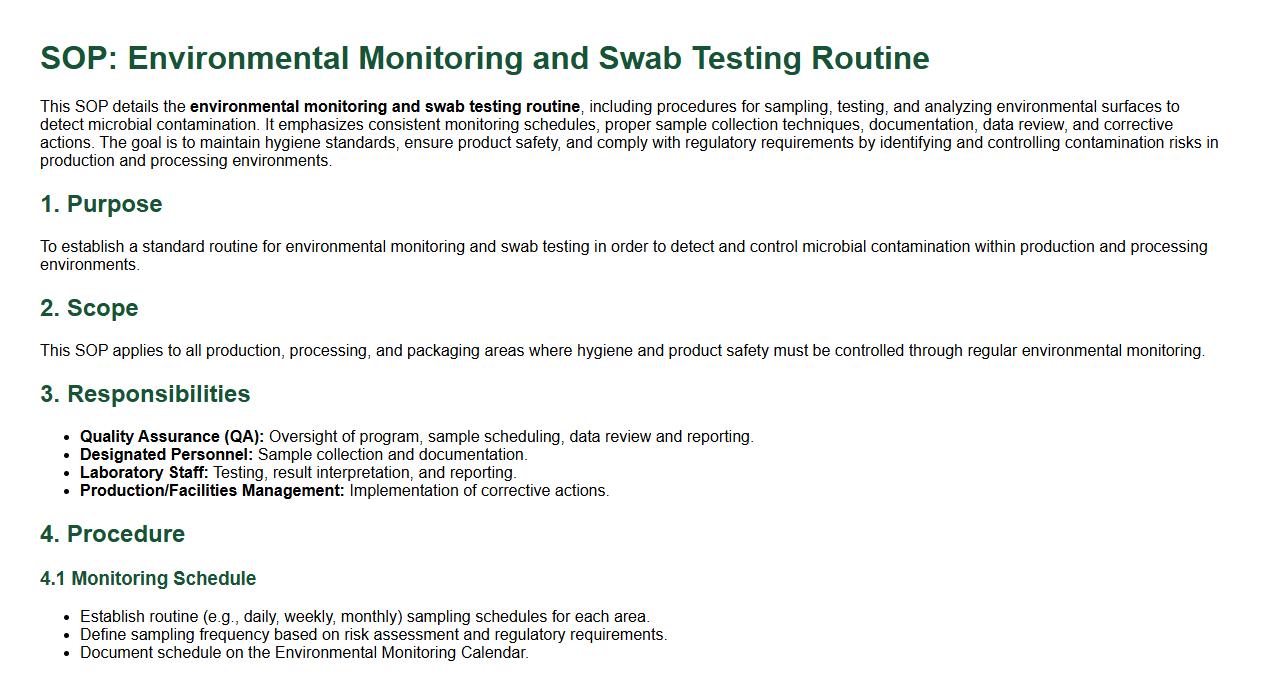

Environmental monitoring and swab testing routine.

This SOP details the environmental monitoring and swab testing routine, including procedures for sampling, testing, and analyzing environmental surfaces to detect microbial contamination. It emphasizes consistent monitoring schedules, proper sample collection techniques, documentation, data review, and corrective actions. The goal is to maintain hygiene standards, ensure product safety, and comply with regulatory requirements by identifying and controlling contamination risks in production and processing environments.

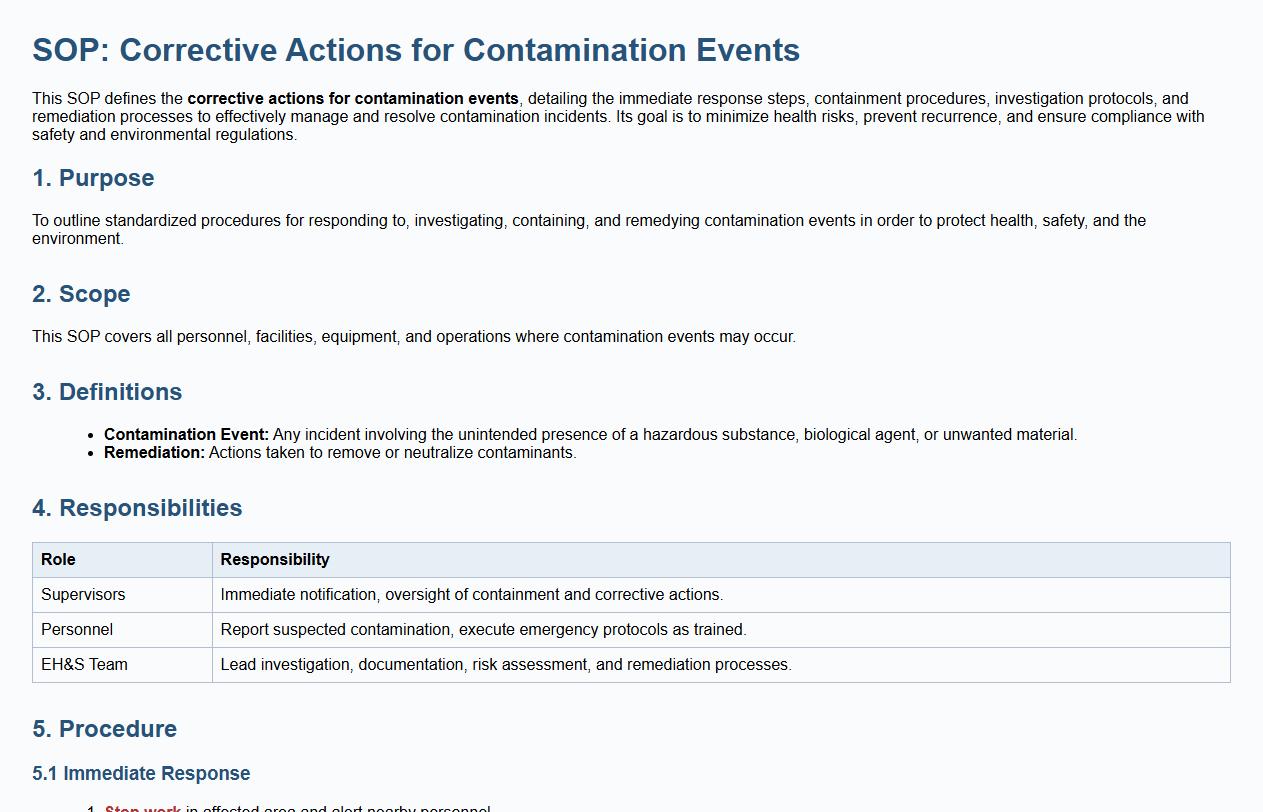

Corrective actions for contamination events.

This SOP defines the corrective actions for contamination events, detailing the immediate response steps, containment procedures, investigation protocols, and remediation processes to effectively manage and resolve contamination incidents. Its goal is to minimize health risks, prevent recurrence, and ensure compliance with safety and environmental regulations.

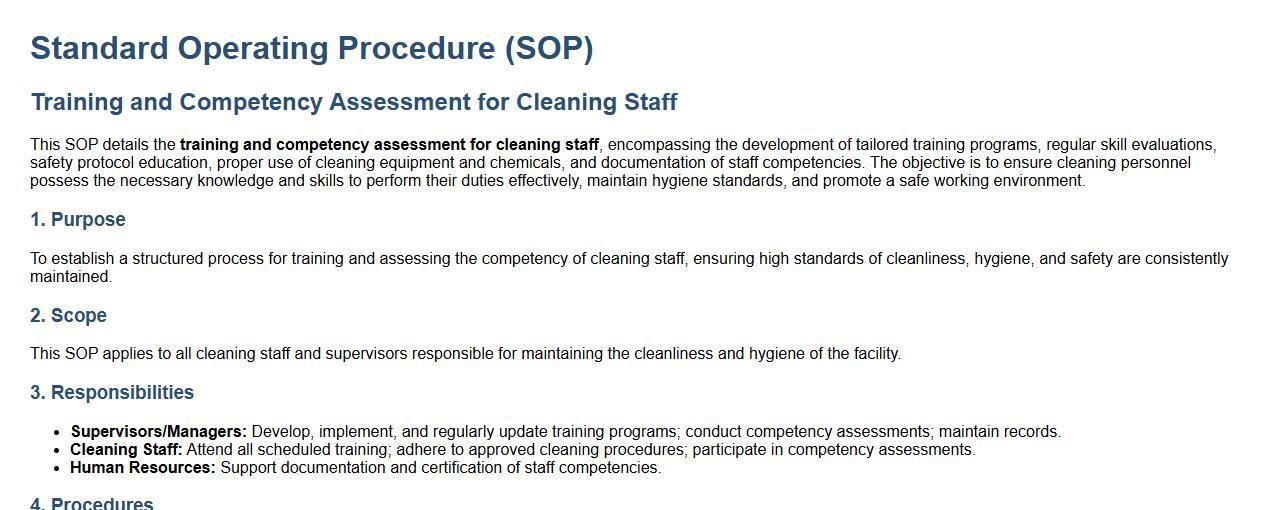

Training and competency assessment for cleaning staff.

This SOP details the training and competency assessment for cleaning staff, encompassing the development of tailored training programs, regular skill evaluations, safety protocol education, proper use of cleaning equipment and chemicals, and documentation of staff competencies. The objective is to ensure cleaning personnel possess the necessary knowledge and skills to perform their duties effectively, maintain hygiene standards, and promote a safe working environment.

What are the primary objectives outlined in the SOP for Manufacturing Cleaning and Sanitation?

The primary objectives of the SOP focus on ensuring a safe and hygienic manufacturing environment. It aims to prevent contamination and maintain product quality through rigorous cleaning practices. Additionally, the SOP seeks to comply with regulatory standards and promote operational efficiency.

Which specific areas, equipment, or surfaces must be cleaned and sanitized according to the SOP?

The SOP mandates cleaning of critical manufacturing areas such as production floors, storage rooms, and packaging zones. Specific equipment including mixers, conveyors, and filling machines must receive thorough sanitation. All contact surfaces that interact with raw materials or finished products are also included.

What approved cleaning agents and sanitizers are specified in the document, and what are their correct usage procedures?

The document lists approved cleaning agents like alkaline detergents, acid cleaners, and disinfectants such as quaternary ammonium compounds. Usage procedures involve dilution ratios, contact times, and application methods unique to each agent. Proper PPE and ventilation requirements during application are strictly outlined to ensure safety and efficacy.

What are the required frequencies and schedules for each cleaning and sanitation activity as per the SOP?

The SOP specifies cleaning frequencies based on operational needs, ranging from daily sanitation of high-touch surfaces to weekly deep cleaning protocols. Equipment cleaning is scheduled after each production batch or shift change. Periodic audits and unscheduled cleanings are also part of the maintenance plan.

What are the verification, documentation, and record-keeping requirements stated in the SOP for cleaning and sanitation processes?

The SOP requires detailed verification procedures including visual inspections and microbial testing to confirm cleanliness. Documentation must capture the date, time, personnel involved, and methods used for each cleaning activity. Records are maintained systematically to support traceability and regulatory compliance audits.