A SOP template for manufacturing shipment preparation outlines standardized procedures to ensure accuracy and efficiency in packaging, labeling, and documentation before dispatch. It establishes clear guidelines for quality checks, inventory verification, and compliance with shipping regulations. This template helps streamline operations, minimize errors, and enhance customer satisfaction.

Order verification and documentation check.

This SOP defines the process for order verification and documentation check, ensuring accuracy and completeness of orders before processing. It includes verification of order details, validation of customer information, cross-checking invoicing and shipping documents, confirmation of product specifications, and authorization approval to prevent errors and discrepancies. The procedure aims to enhance order accuracy, streamline workflow, and maintain reliable records for auditing and customer satisfaction.

Product quality inspection and conformity assessment.

This SOP details the procedures for product quality inspection and conformity assessment, covering the criteria for quality standards, inspection methods, sampling techniques, testing protocols, documentation requirements, non-conformance management, corrective actions, and final product approval. The goal is to ensure that all products meet specified quality requirements and regulatory standards, guaranteeing customer satisfaction and maintaining compliance throughout the production process.

Labeling and packaging specifications adherence.

This SOP ensures strict adherence to labeling and packaging specifications to maintain product quality, compliance with regulatory requirements, and brand consistency. It covers procedures for accurate labeling, correct packaging materials selection, proper sealing and handling techniques, inspection protocols, and documentation standards to prevent errors and ensure customer satisfaction.

Packing list creation and itemization.

This SOP details the process of packing list creation and itemization, covering the accurate documentation of items to be shipped, specifying quantities, descriptions, and item codes, verifying the completeness and correctness of the list, and ensuring proper labeling for efficient handling and tracking. The goal is to enhance shipment accuracy, facilitate inventory control, and improve overall logistics efficiency by providing a clear and organized packing list.

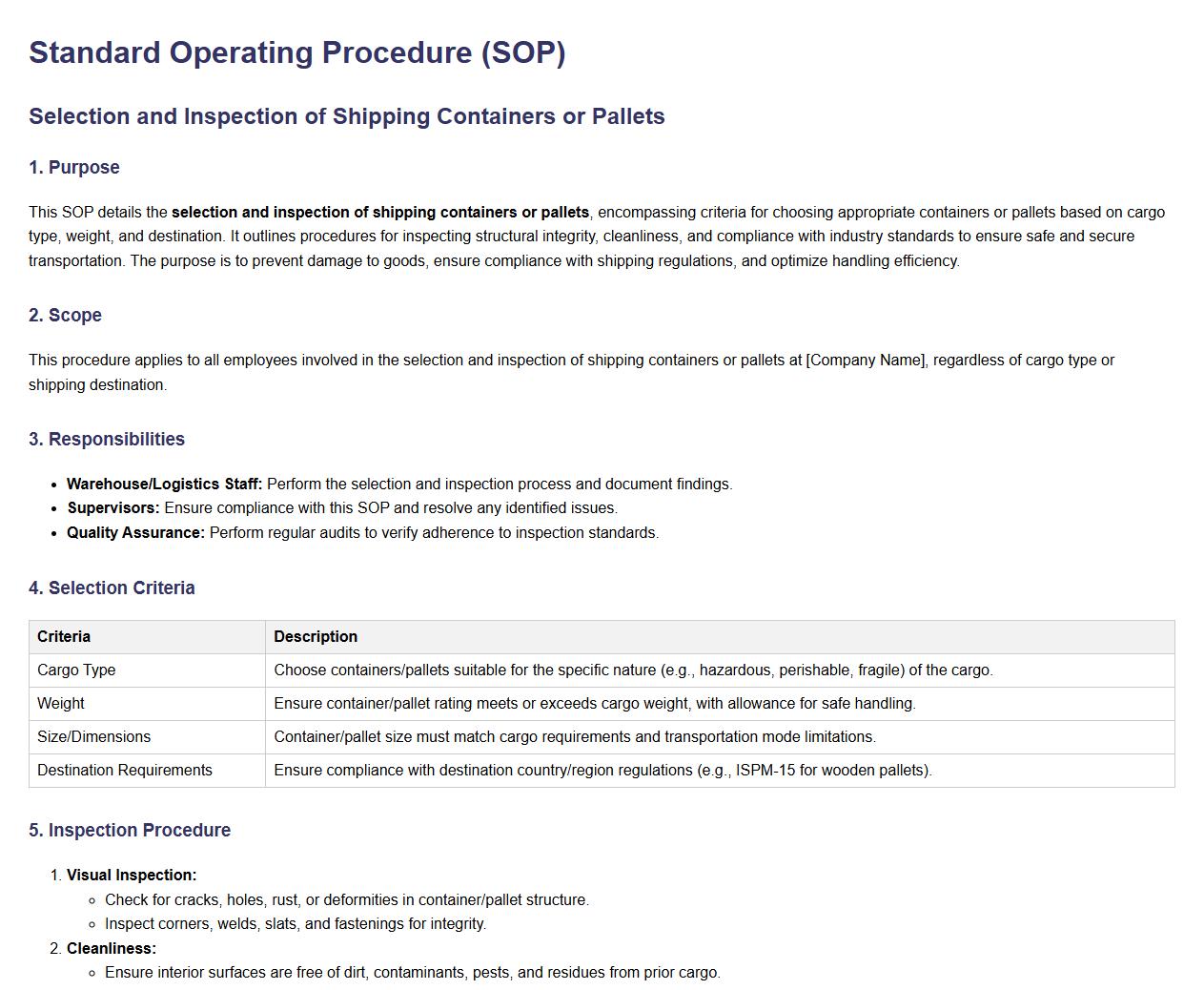

Selection and inspection of shipping containers or pallets.

This SOP details the selection and inspection of shipping containers or pallets, encompassing criteria for choosing appropriate containers or pallets based on cargo type, weight, and destination. It outlines procedures for inspecting structural integrity, cleanliness, and compliance with industry standards to ensure safe and secure transportation. The purpose is to prevent damage to goods, ensure compliance with shipping regulations, and optimize handling efficiency.

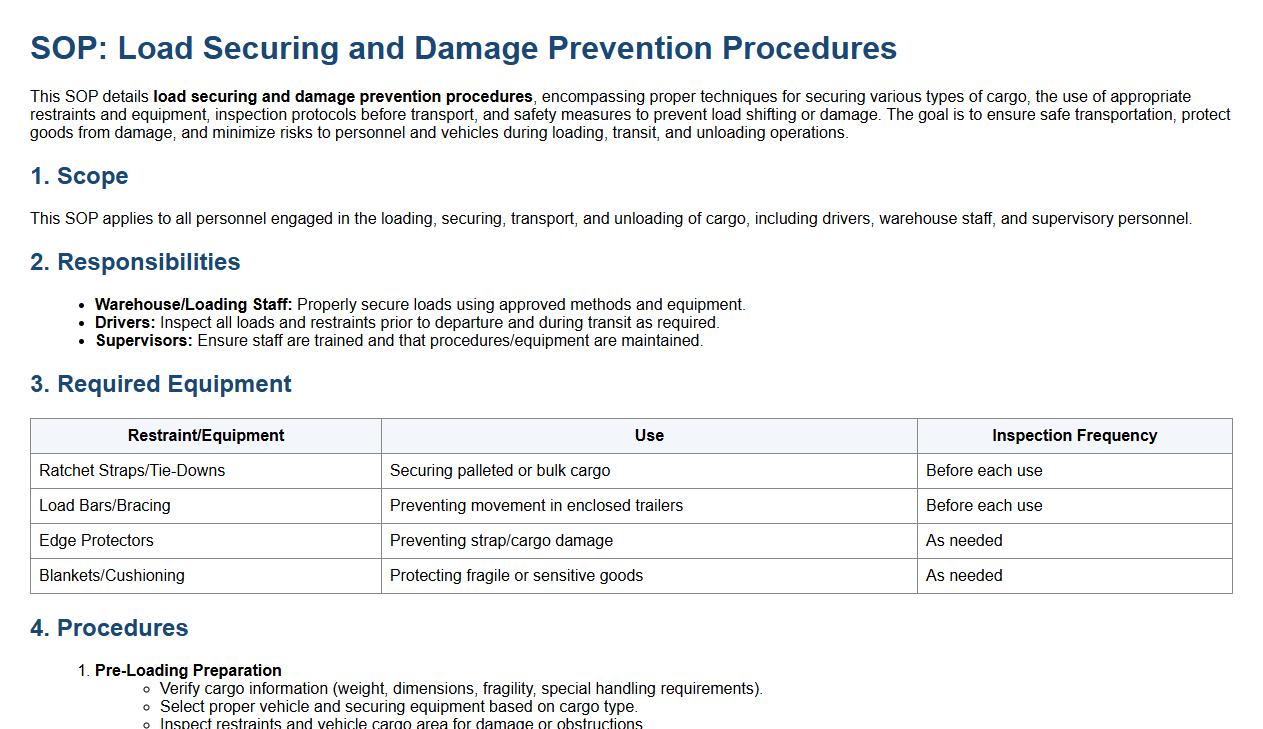

Load securing and damage prevention procedures.

This SOP details load securing and damage prevention procedures, encompassing proper techniques for securing various types of cargo, the use of appropriate restraints and equipment, inspection protocols before transport, and safety measures to prevent load shifting or damage. The goal is to ensure safe transportation, protect goods from damage, and minimize risks to personnel and vehicles during loading, transit, and unloading operations.

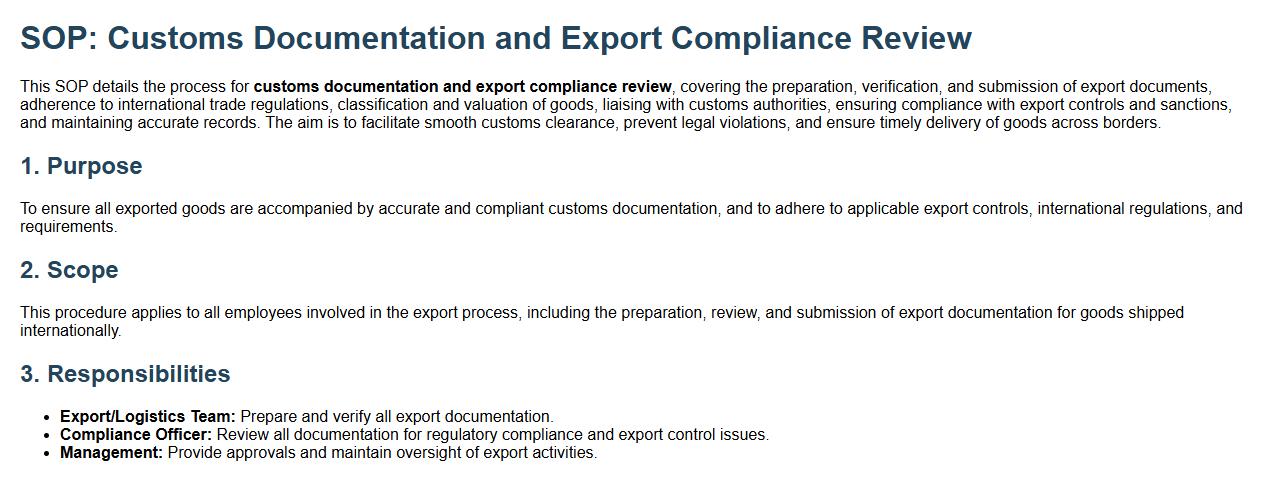

Customs documentation and export compliance review.

This SOP details the process for customs documentation and export compliance review, covering the preparation, verification, and submission of export documents, adherence to international trade regulations, classification and valuation of goods, liaising with customs authorities, ensuring compliance with export controls and sanctions, and maintaining accurate records. The aim is to facilitate smooth customs clearance, prevent legal violations, and ensure timely delivery of goods across borders.

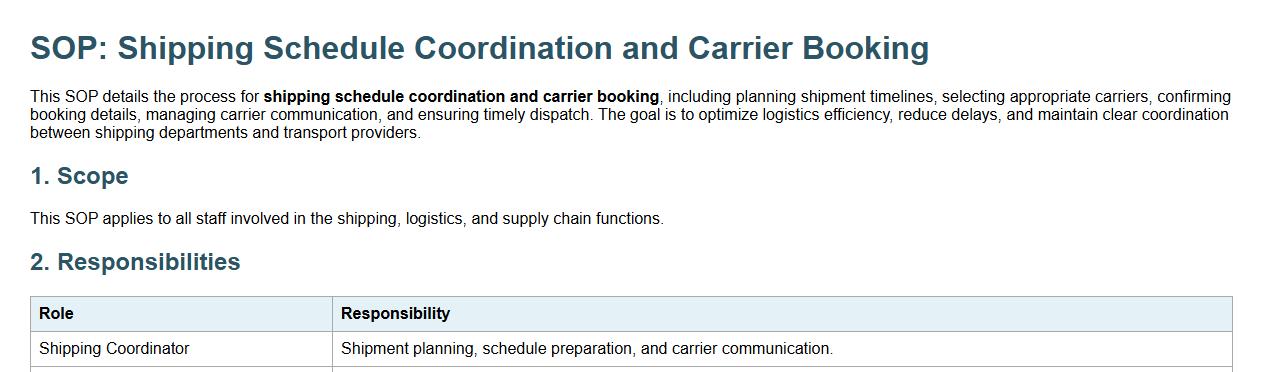

Shipping schedule coordination and carrier booking.

This SOP details the process for shipping schedule coordination and carrier booking, including planning shipment timelines, selecting appropriate carriers, confirming booking details, managing carrier communication, and ensuring timely dispatch. The goal is to optimize logistics efficiency, reduce delays, and maintain clear coordination between shipping departments and transport providers.

Final review and management approval before dispatch.

This SOP details the process for final review and management approval before dispatch, ensuring that all products or documents undergo thorough quality checks, compliance verification, and authorization by designated management personnel prior to shipment or release. The procedure aims to prevent errors, maintain standards, and guarantee customer satisfaction by confirming that all dispatch requirements are met.

Shipment tracking initiation and customer notification.

This SOP details the process for shipment tracking initiation and customer notification, covering steps to accurately record shipment details, generate tracking information, and promptly inform customers about their order status. The procedure ensures transparency, improves customer satisfaction, and facilitates timely updates throughout the delivery process.

Key Steps Outlined in the SOP for Preparing Shipments in the Manufacturing Process

The SOP emphasizes systematic packaging and labeling to ensure product integrity during shipment. It mandates verification of order accuracy before dispatch to avoid shipment errors. Finally, the procedure includes scheduling and coordinating with logistics partners for timely delivery.

Safety and Quality Checks Mandated by the Shipment Preparation SOP

Safety inspections are required to confirm packaging materials meet industry standards to prevent damage. Quality control ensures all products comply with specifications and are free from defects. Additionally, the SOP mandates final product checks prior to shipment to maintain customer satisfaction.

Documentation Required for Compliance According to the Shipment Preparation SOP

The SOP requires generation of packing lists detailing the contents of each shipment for traceability. Shipping labels and compliance certificates must accompany the goods to meet regulatory standards. Also, shipment logs are maintained to record dispatch times and condition of goods.

How the Shipment Preparation SOP Defines Roles and Responsibilities of Involved Personnel

The SOP clearly assigns responsibility to warehouse staff for product inspection and packaging accuracy. Logistics personnel are accountable for coordinating transportation and managing shipment documentation. Supervisors ensure adherence to SOP protocols and handle any operational issues.

Procedures for Handling Discrepancies or Damaged Goods Specified in the SOP

The SOP mandates immediate reporting of any discrepancies or damages identified during shipment preparation. A documented investigation process follows to determine cause and corrective action. Additionally, damaged goods are isolated and handled according to company policy to prevent further issues.