A SOP Template for Manufacturing Packaging and Labeling ensures consistent and compliant procedures for product packaging and accurate label application. It outlines step-by-step instructions to maintain quality control and regulatory standards throughout the manufacturing process. This template helps streamline operations, minimize errors, and enhance overall production efficiency.

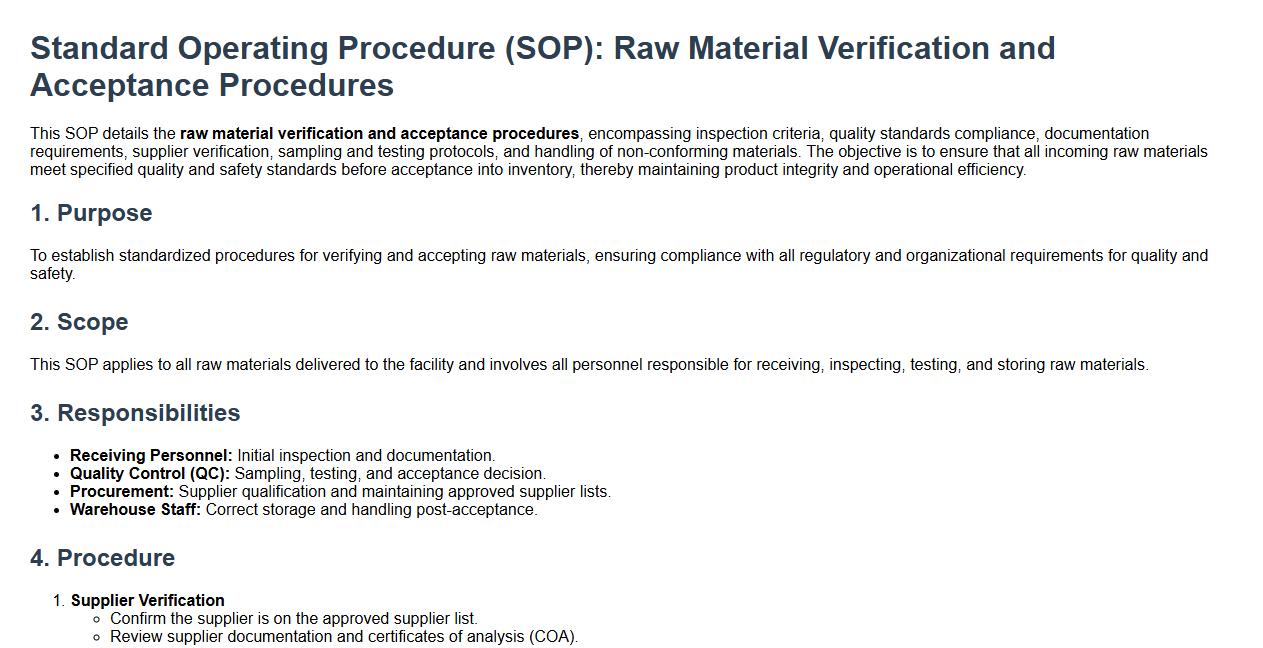

Raw material verification and acceptance procedures.

This SOP details the raw material verification and acceptance procedures, encompassing inspection criteria, quality standards compliance, documentation requirements, supplier verification, sampling and testing protocols, and handling of non-conforming materials. The objective is to ensure that all incoming raw materials meet specified quality and safety standards before acceptance into inventory, thereby maintaining product integrity and operational efficiency.

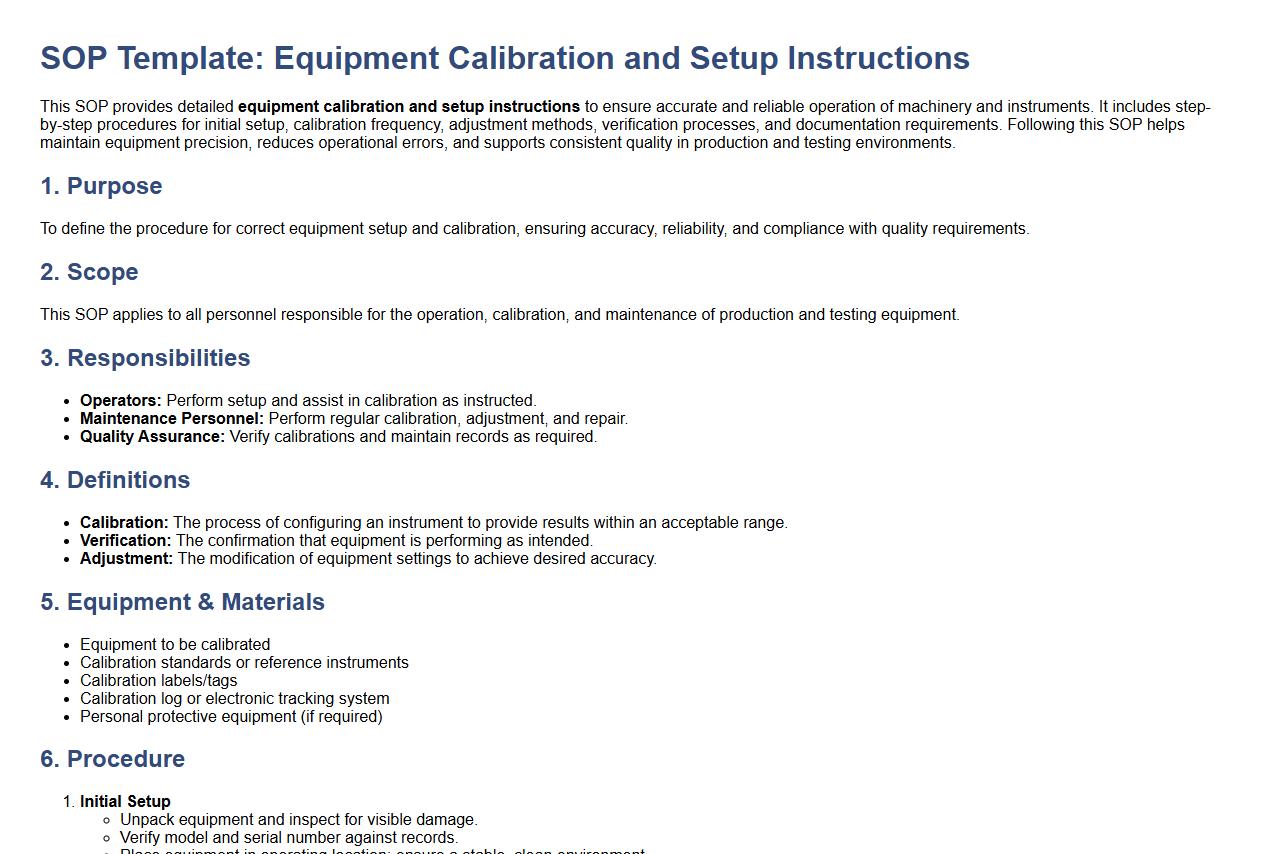

Equipment calibration and setup instructions.

This SOP provides detailed equipment calibration and setup instructions to ensure accurate and reliable operation of machinery and instruments. It includes step-by-step procedures for initial setup, calibration frequency, adjustment methods, verification processes, and documentation requirements. Following this SOP helps maintain equipment precision, reduces operational errors, and supports consistent quality in production and testing environments.

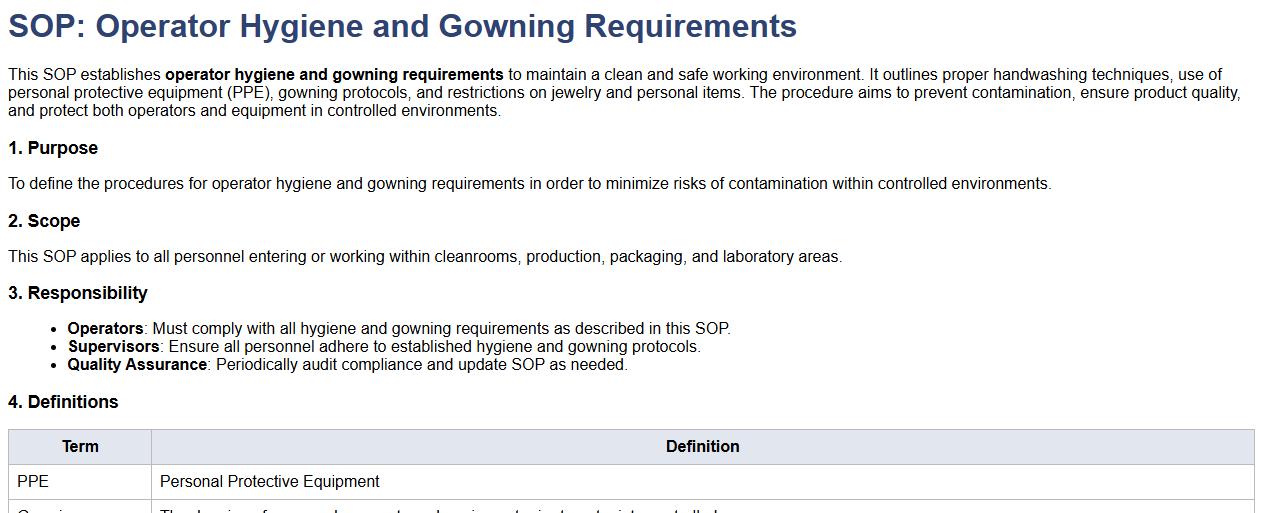

Operator hygiene and gowning requirements.

This SOP establishes operator hygiene and gowning requirements to maintain a clean and safe working environment. It outlines proper handwashing techniques, use of personal protective equipment (PPE), gowning protocols, and restrictions on jewelry and personal items. The procedure aims to prevent contamination, ensure product quality, and protect both operators and equipment in controlled environments.

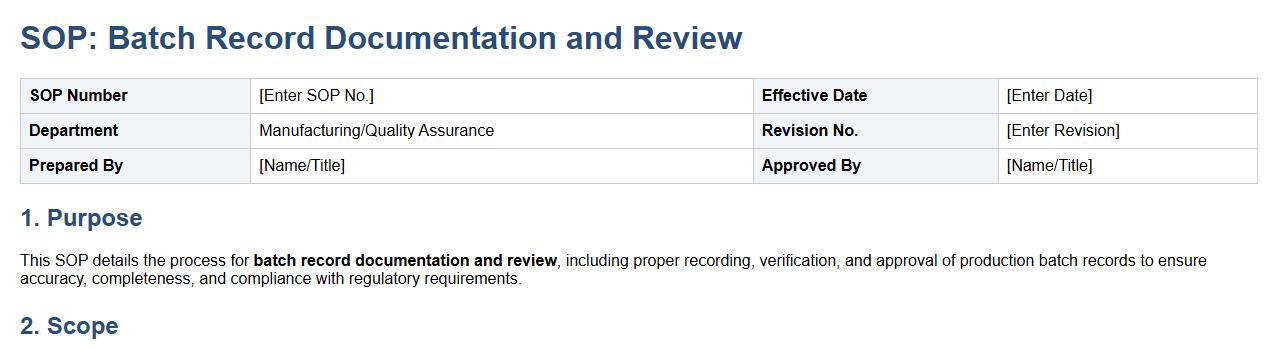

Batch record documentation and review.

This SOP details the process for batch record documentation and review, covering the proper recording, verification, and approval of production batch records. It ensures accuracy, completeness, and compliance with regulatory standards throughout the manufacturing process. The procedure includes guidelines for data entry, review timelines, discrepancy management, and final documentation approval to maintain product quality and traceability.

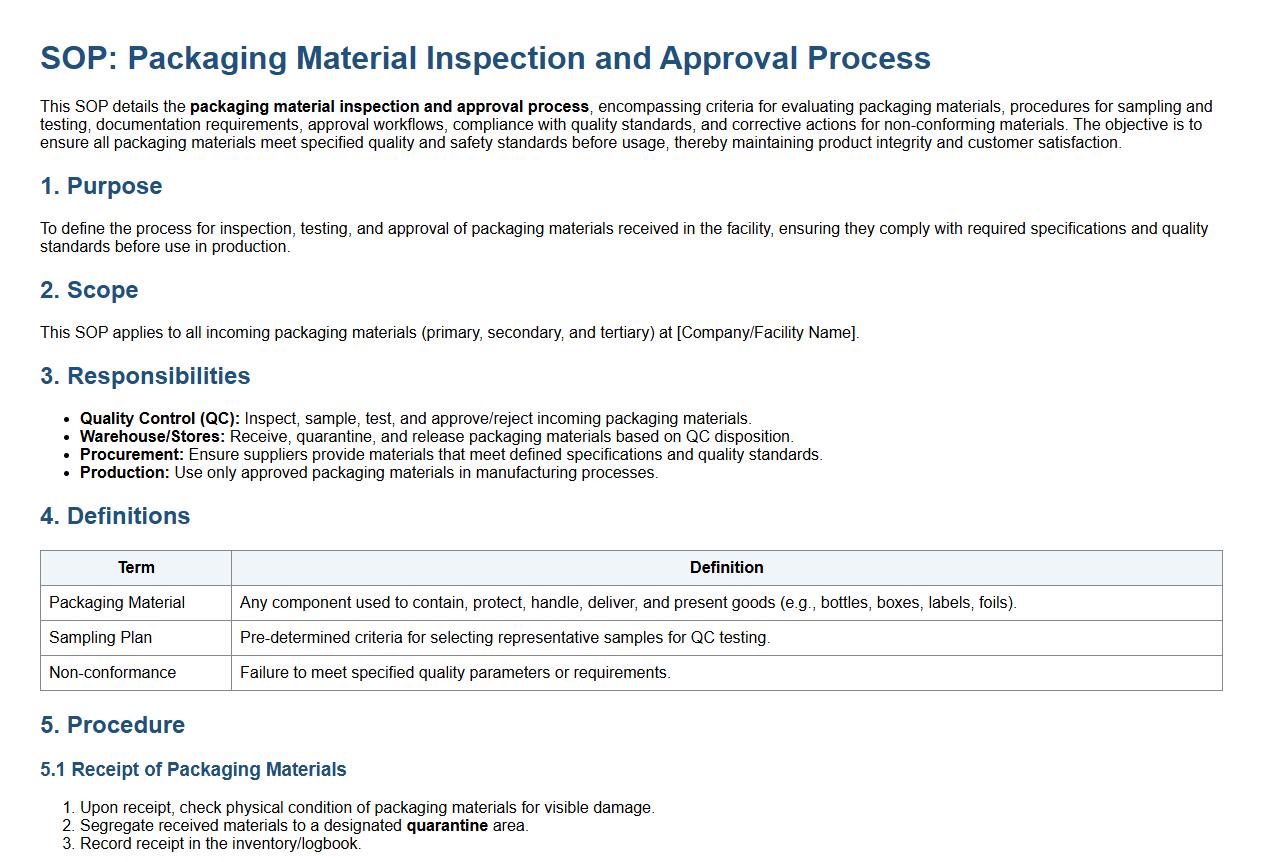

Packaging material inspection and approval process.

This SOP details the packaging material inspection and approval process, encompassing criteria for evaluating packaging materials, procedures for sampling and testing, documentation requirements, approval workflows, compliance with quality standards, and corrective actions for non-conforming materials. The objective is to ensure all packaging materials meet specified quality and safety standards before usage, thereby maintaining product integrity and customer satisfaction.

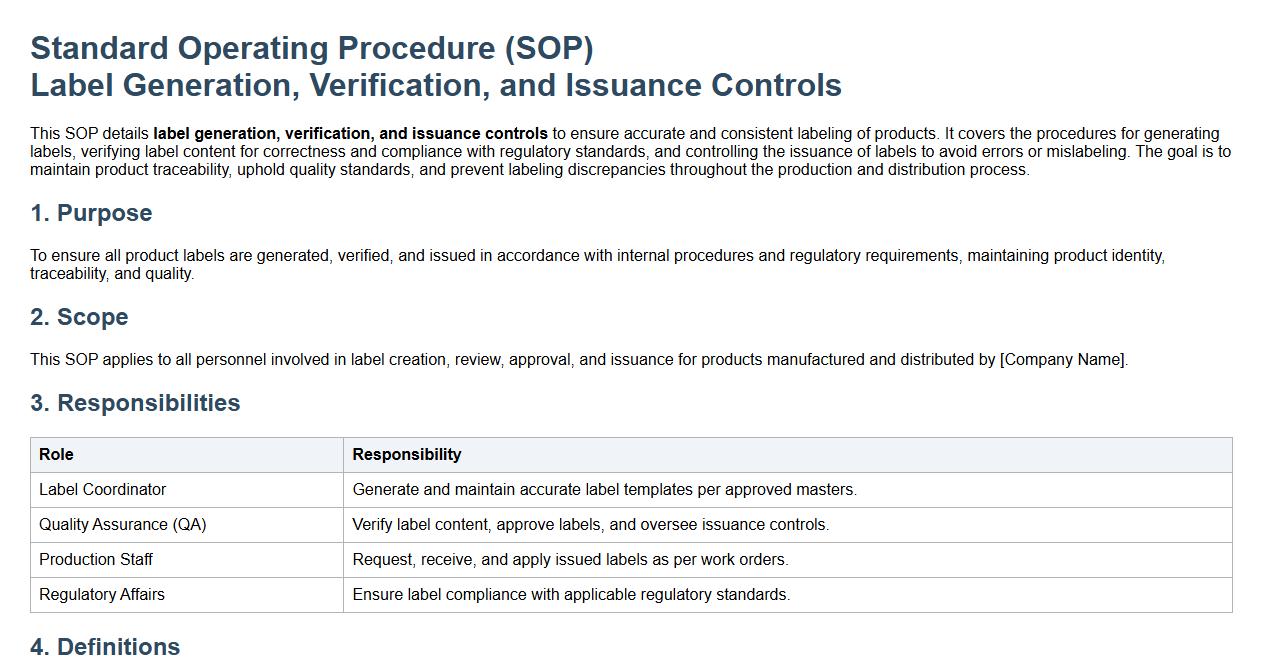

Label generation, verification, and issuance controls.

This SOP details label generation, verification, and issuance controls to ensure accurate and consistent labeling of products. It covers the procedures for generating labels, verifying label content for correctness and compliance with regulatory standards, and controlling the issuance of labels to avoid errors or mislabeling. The goal is to maintain product traceability, uphold quality standards, and prevent labeling discrepancies throughout the production and distribution process.

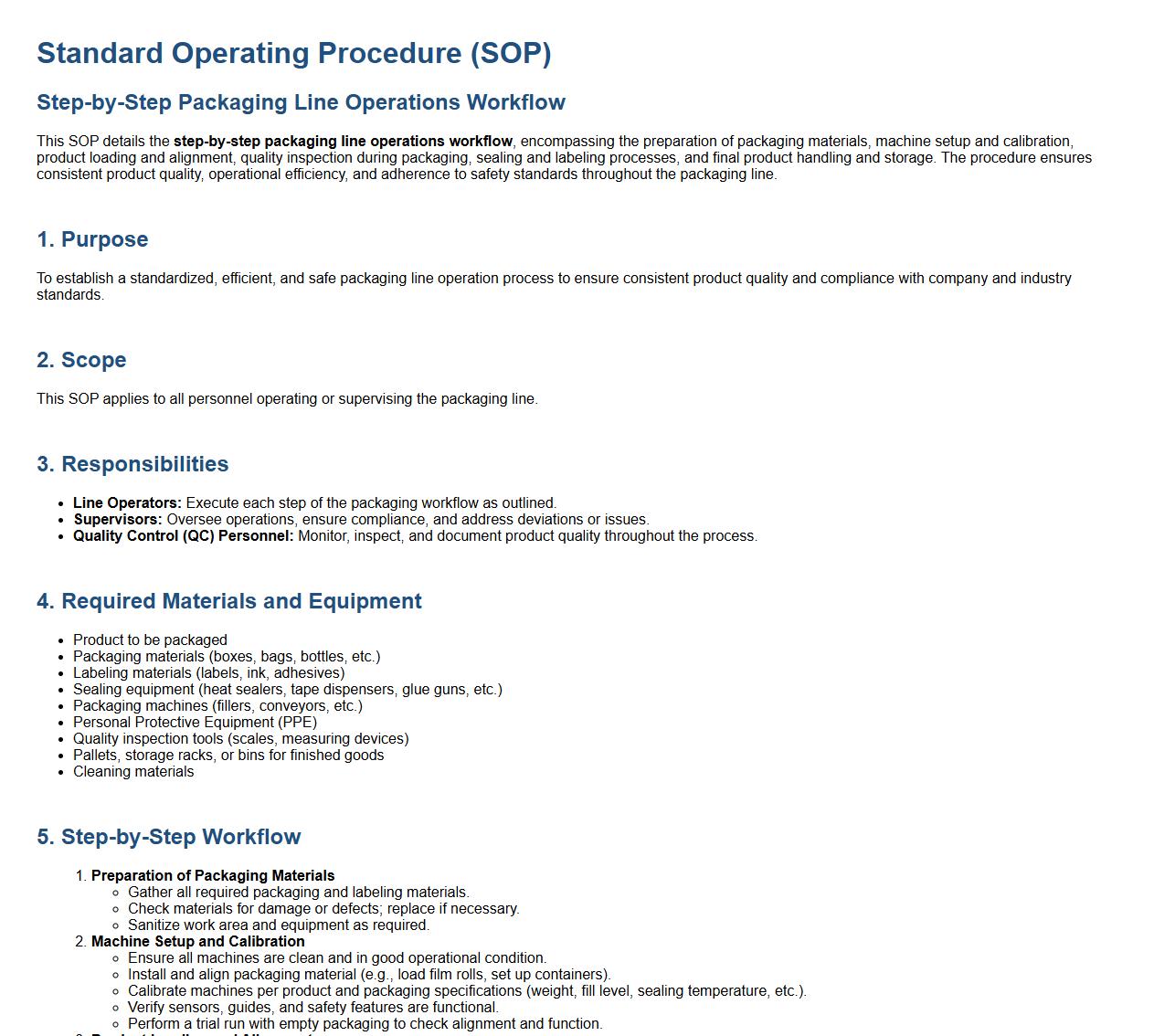

Step-by-step packaging line operations workflow.

This SOP details the step-by-step packaging line operations workflow, encompassing the preparation of packaging materials, machine setup and calibration, product loading and alignment, quality inspection during packaging, sealing and labeling processes, and final product handling and storage. The procedure ensures consistent product quality, operational efficiency, and adherence to safety standards throughout the packaging line.

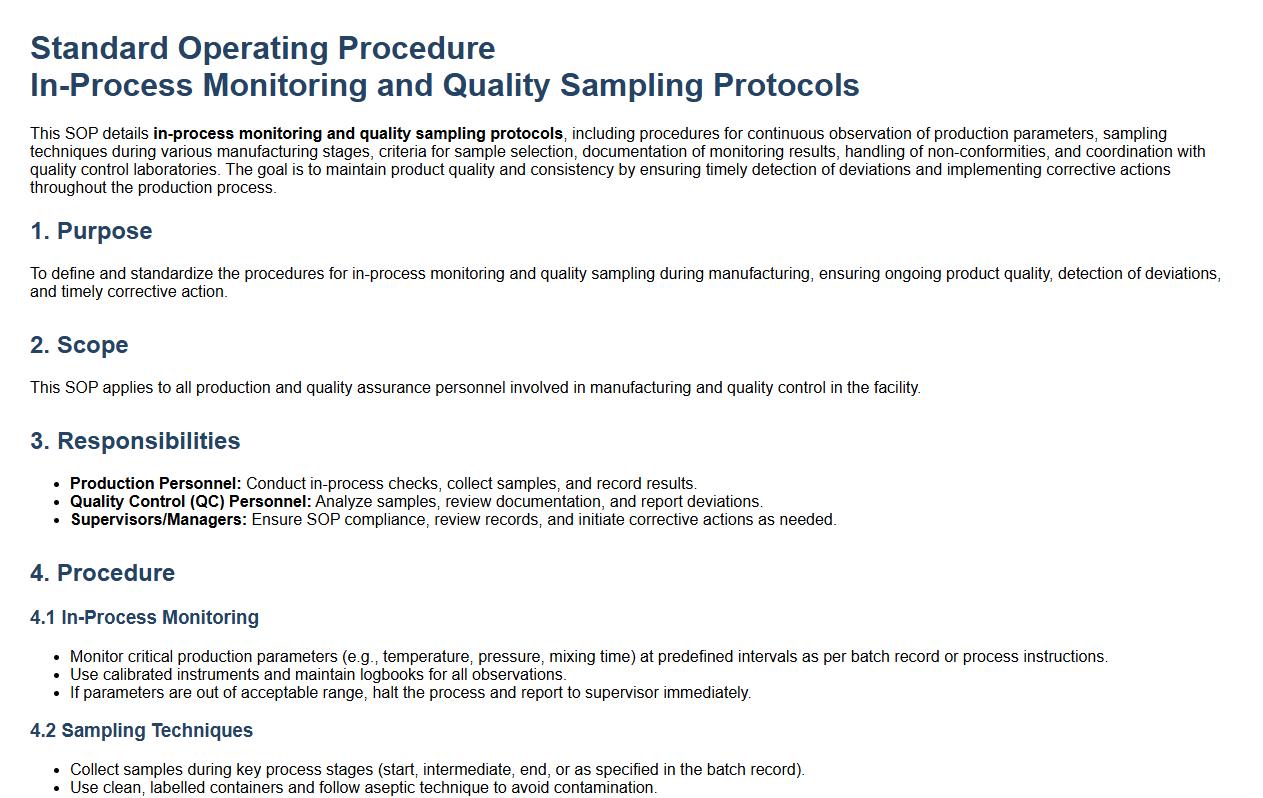

In-process monitoring and quality sampling protocols.

This SOP details in-process monitoring and quality sampling protocols, including procedures for continuous observation of production parameters, sampling techniques during various manufacturing stages, criteria for sample selection, documentation of monitoring results, handling of non-conformities, and coordination with quality control laboratories. The goal is to maintain product quality and consistency by ensuring timely detection of deviations and implementing corrective actions throughout the production process.

Finished product inspection, reconciliation, and rejection handling.

This SOP defines the process for finished product inspection, reconciliation, and rejection handling to ensure that all products meet quality standards before distribution. It includes criteria for product inspection, identification and documentation of non-conformities, procedures for product reconciliation to account for discrepancies, and guidelines for the appropriate handling, segregation, and disposition of rejected items. The goal is to maintain product integrity, minimize defects, and ensure compliance with regulatory and company quality requirements.

Room and equipment cleaning, line clearance, and changeover procedures.

This SOP details room and equipment cleaning, line clearance, and changeover procedures to ensure hygiene, prevent cross-contamination, and maintain production efficiency. It covers step-by-step cleaning protocols, verification of line clearance, proper equipment sanitation, and systematic changeover steps to comply with safety and quality standards in manufacturing environments.

What are the critical steps and controls outlined in the SOP for manufacturing, packaging, and labeling operations?

The SOP details critical steps such as raw material verification, in-process controls, and final product inspection to ensure quality. It mandates precise control points to prevent contamination and mix-ups during manufacturing, packaging, and labeling. These controls are designed to maintain consistent product integrity and compliance with industry standards.

How does the SOP ensure traceability and compliance with regulatory requirements during packaging and labeling?

The SOP requires comprehensive traceability through batch numbers, lot tracking, and barcode usage on packaging labels. It aligns all procedures with applicable regulatory guidelines to ensure full compliance during labeling and packaging. Electronic and manual logs are maintained to provide an audit trail for every product unit.

Which personnel responsibilities and training requirements are specified in the SOP for each stage of the process?

The SOP clearly defines the responsibilities of all personnel involved, from manufacturing operators to quality control staff. It enforces mandatory training programs focused on good manufacturing practices (GMP) and specific operational tasks. Continuous assessment and retraining ensure that all staff remain competent and aware of procedural updates.

What documentation and record-keeping procedures are mandated by the SOP for packaging and labeling activities?

The SOP mandates detailed documentation including batch records, label reconciliation forms, and deviation logs to maintain accurate records. All packaging and labeling activities must be recorded in real-time to ensure data integrity. These records are critical for retrospective review and regulatory inspections.

How does the SOP address inspection, quality assurance, and deviation management throughout manufacturing, packaging, and labeling?

The SOP incorporates inspection steps at multiple stages to identify defects and ensure product quality. It outlines quality assurance protocols that include routine audits and validation checks to uphold standards. Any deviations detected are rigorously documented, investigated, and corrected as per established procedures to prevent recurrence.