A SOP Template for Manufacturing Process Control ensures consistent quality and efficiency by standardizing operational procedures. This template outlines step-by-step instructions for monitoring, controlling, and optimizing manufacturing activities. It helps reduce errors, maintain compliance, and improve overall production performance.

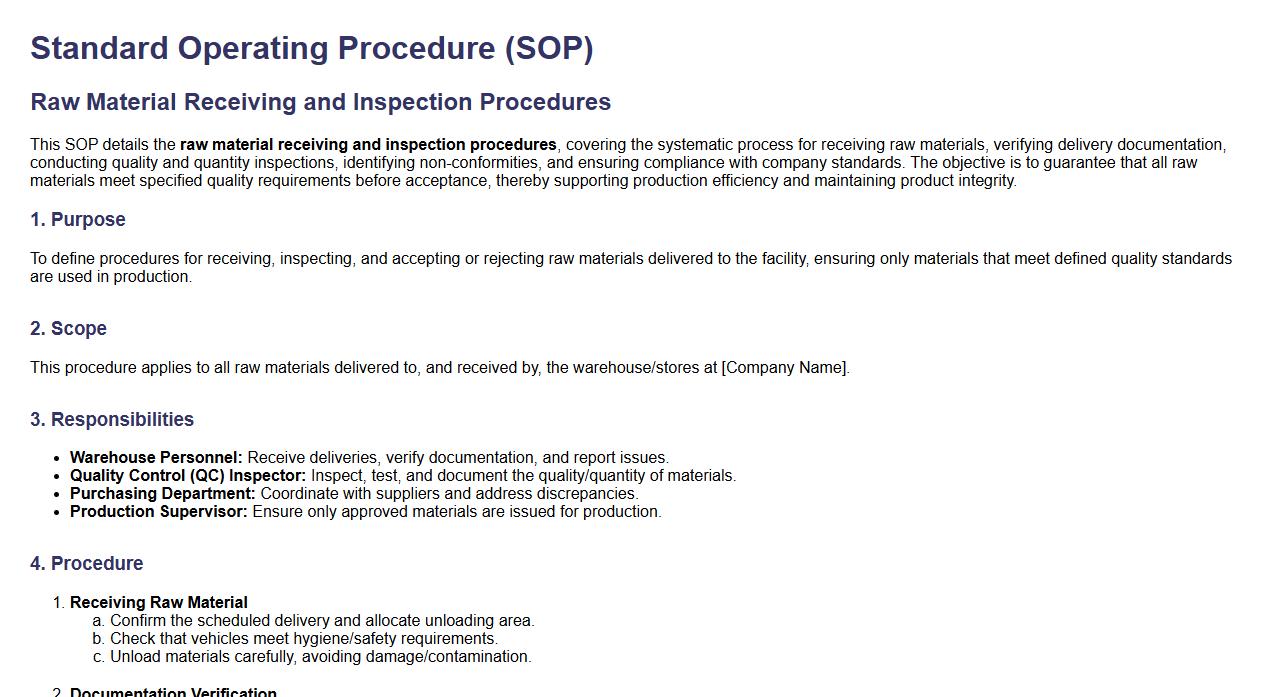

Raw material receiving and inspection procedures.

This SOP details the raw material receiving and inspection procedures, covering the systematic process for receiving raw materials, verifying delivery documentation, conducting quality and quantity inspections, identifying non-conformities, and ensuring compliance with company standards. The objective is to guarantee that all raw materials meet specified quality requirements before acceptance, thereby supporting production efficiency and maintaining product integrity.

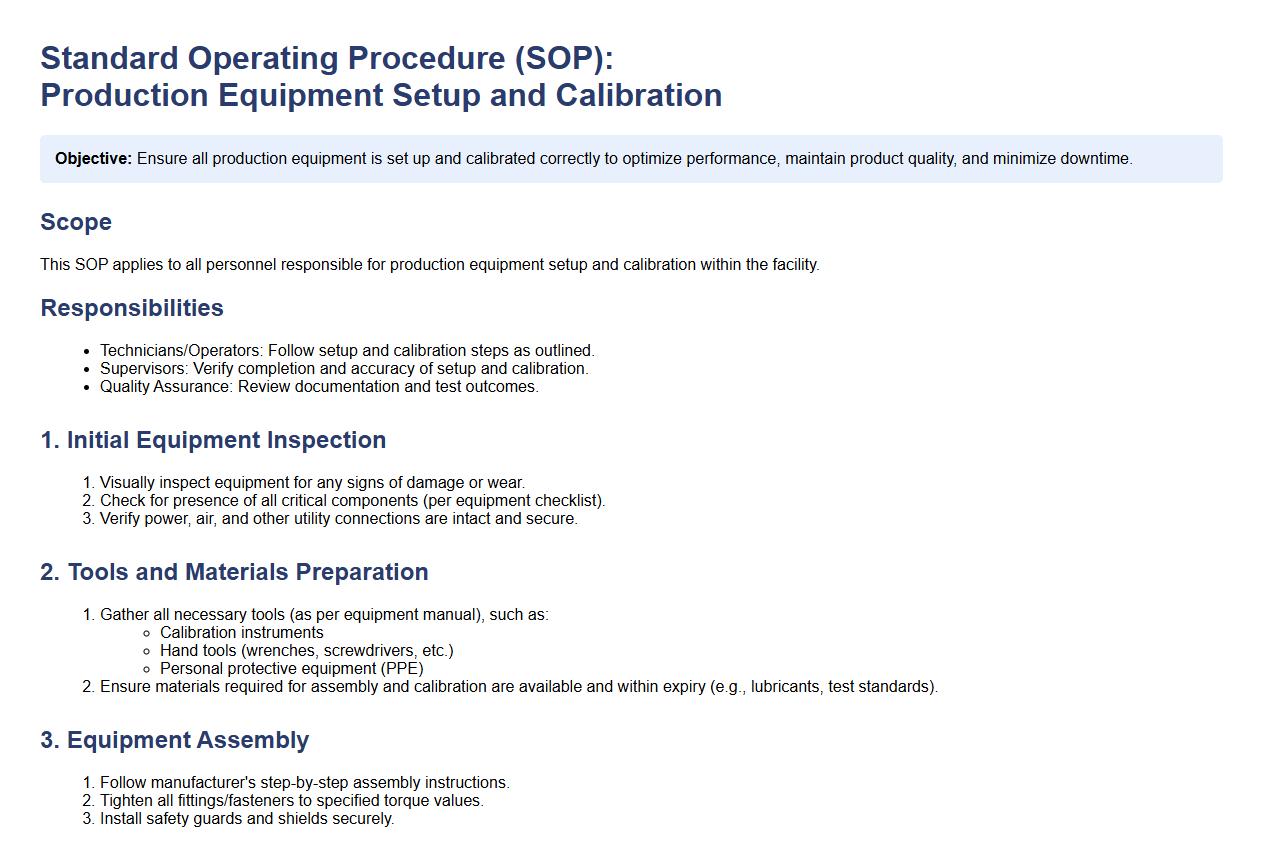

Production equipment setup and calibration steps.

This SOP details the production equipment setup and calibration steps, including initial equipment inspection, necessary tools and materials preparation, step-by-step assembly instructions, calibration procedures for accuracy and precision, verification and testing protocols, safety checks, documentation of setup parameters, and routine maintenance guidelines. The objective is to ensure that all production equipment is correctly set up and calibrated to optimize performance, maintain product quality, and reduce downtime.

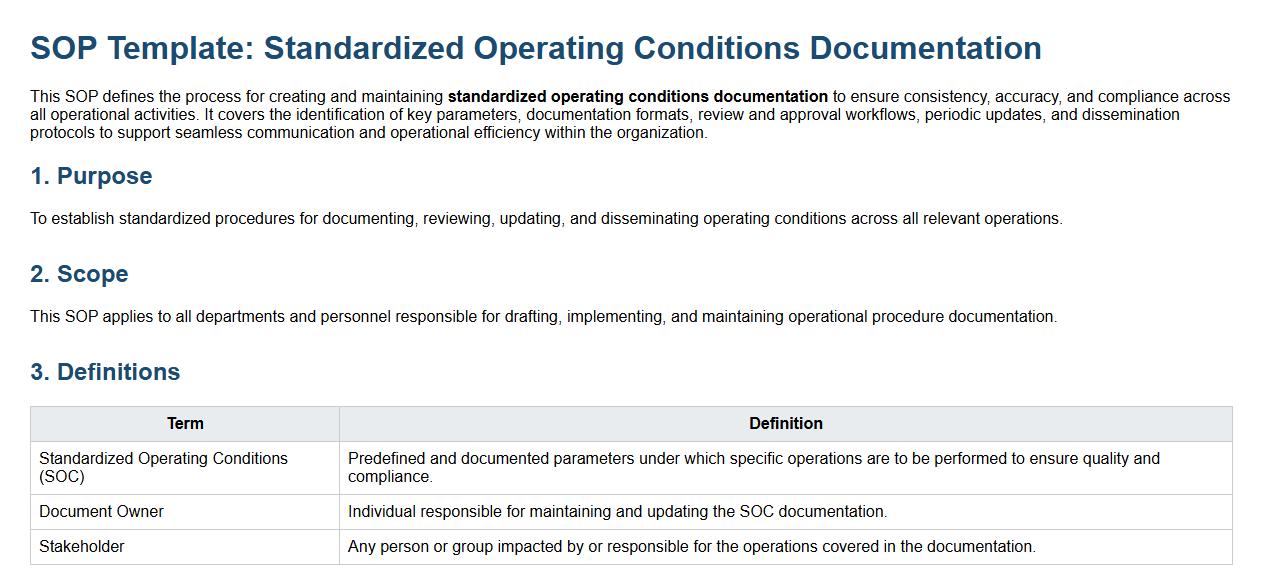

Standardized operating conditions documentation.

This SOP defines the process for creating and maintaining standardized operating conditions documentation to ensure consistency, accuracy, and compliance across all operational activities. It covers the identification of key parameters, documentation formats, review and approval workflows, periodic updates, and dissemination protocols to support seamless communication and operational efficiency within the organization.

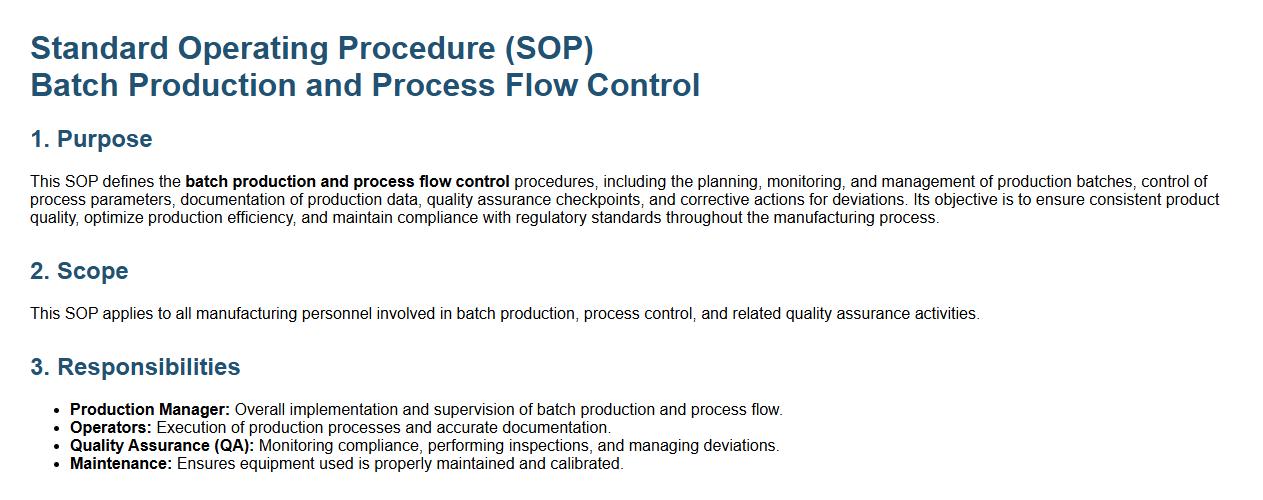

Batch production and process flow control.

This SOP defines the batch production and process flow control procedures, including the planning, monitoring, and management of production batches, control of process parameters, documentation of production data, quality assurance checkpoints, and corrective actions for deviations. Its objective is to ensure consistent product quality, optimize production efficiency, and maintain compliance with regulatory standards throughout the manufacturing process.

In-process quality assurance checks and sampling.

This SOP details in-process quality assurance checks and sampling to ensure consistent product quality during manufacturing. It covers procedures for regular inspection, testing, and sampling at defined stages of the production process, criteria for acceptance and rejection, documentation requirements, and corrective actions to address deviations. The purpose is to maintain high-quality standards, detect and resolve issues promptly, and comply with regulatory and customer specifications throughout the production cycle.

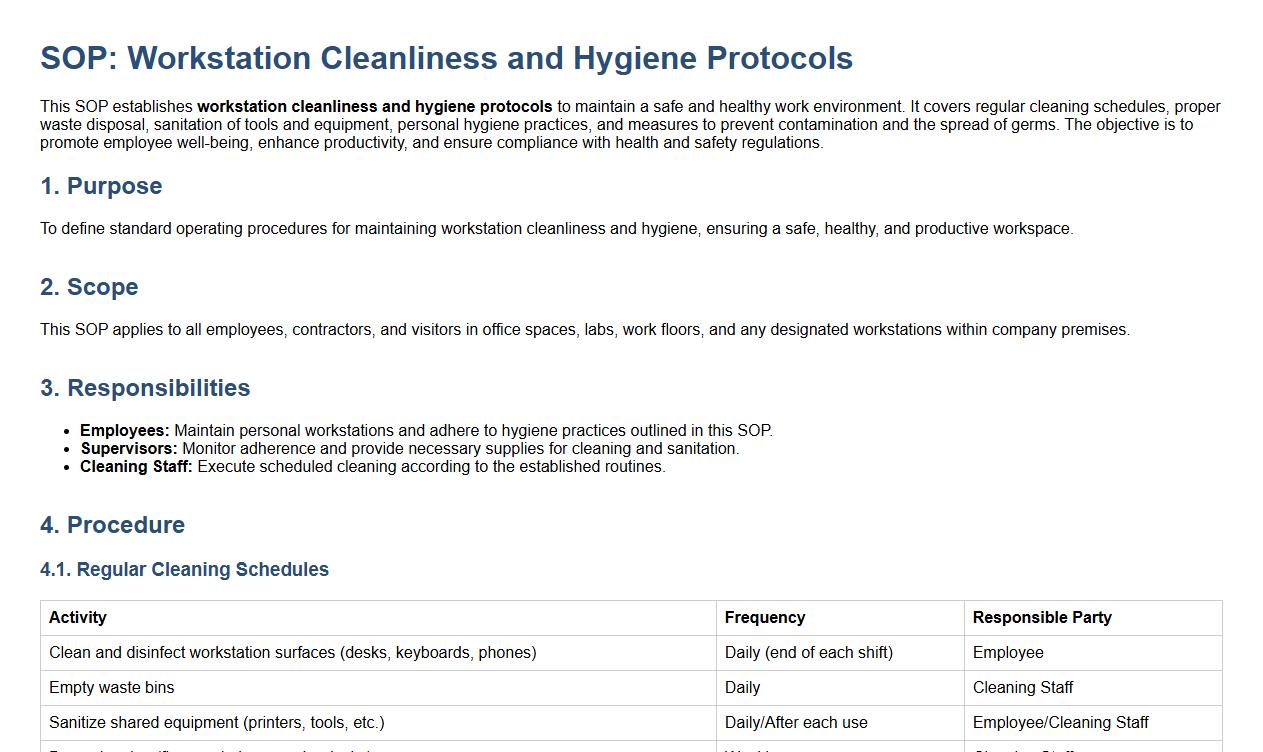

Workstation cleanliness and hygiene protocols.

This SOP establishes workstation cleanliness and hygiene protocols to maintain a safe and healthy work environment. It covers regular cleaning schedules, proper waste disposal, sanitation of tools and equipment, personal hygiene practices, and measures to prevent contamination and the spread of germs. The objective is to promote employee well-being, enhance productivity, and ensure compliance with health and safety regulations.

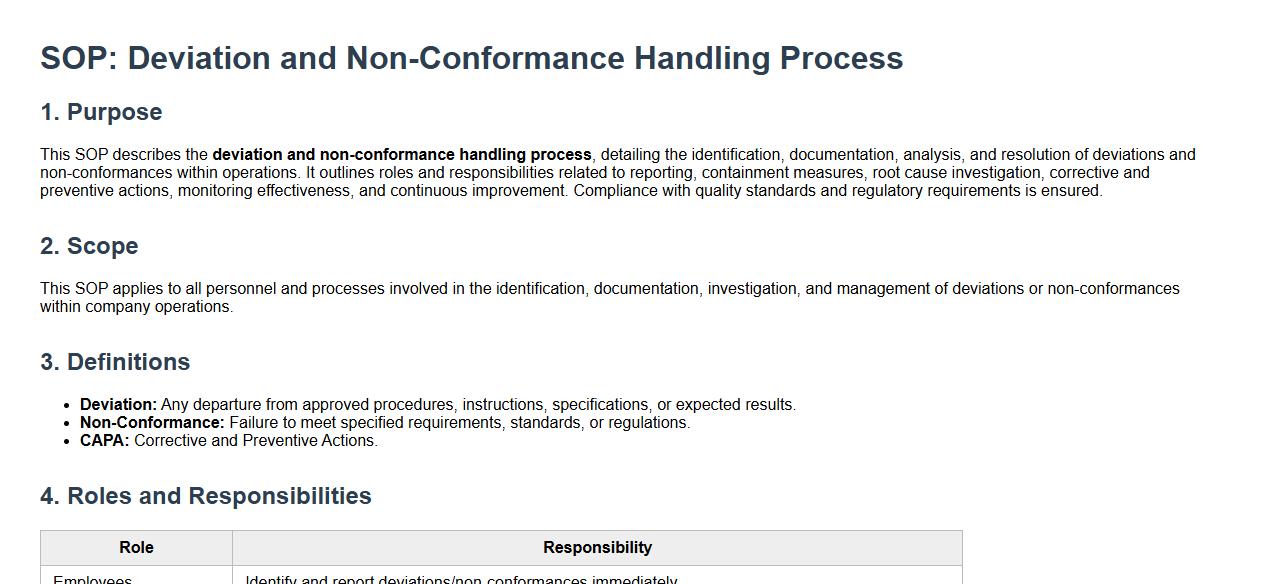

Deviation and non-conformance handling process.

This SOP describes the deviation and non-conformance handling process, detailing the identification, documentation, analysis, and resolution of deviations and non-conformances within operations. It covers roles and responsibilities for reporting, containment measures, root cause investigation, corrective and preventive actions, monitoring effectiveness, and continuous improvement strategies to ensure compliance with quality standards and regulatory requirements.

Packaging and labeling verification procedures.

This SOP details packaging and labeling verification procedures to ensure accuracy, compliance, and quality control. It covers the systematic inspection of packaging materials, label content verification against product specifications, regulatory compliance checks, and proper documentation. The procedure aims to prevent errors, maintain product integrity, and uphold brand consistency by implementing thorough verification steps before product release.

Finished goods release and storage guidelines.

This SOP defines the finished goods release and storage guidelines, focusing on the procedures for inspecting, approving, and releasing finished products for distribution. It includes proper storage conditions to maintain product quality, inventory management, handling practices, and documentation requirements. The goal is to ensure that only products meeting quality standards are released while optimizing storage efficiency and traceability.

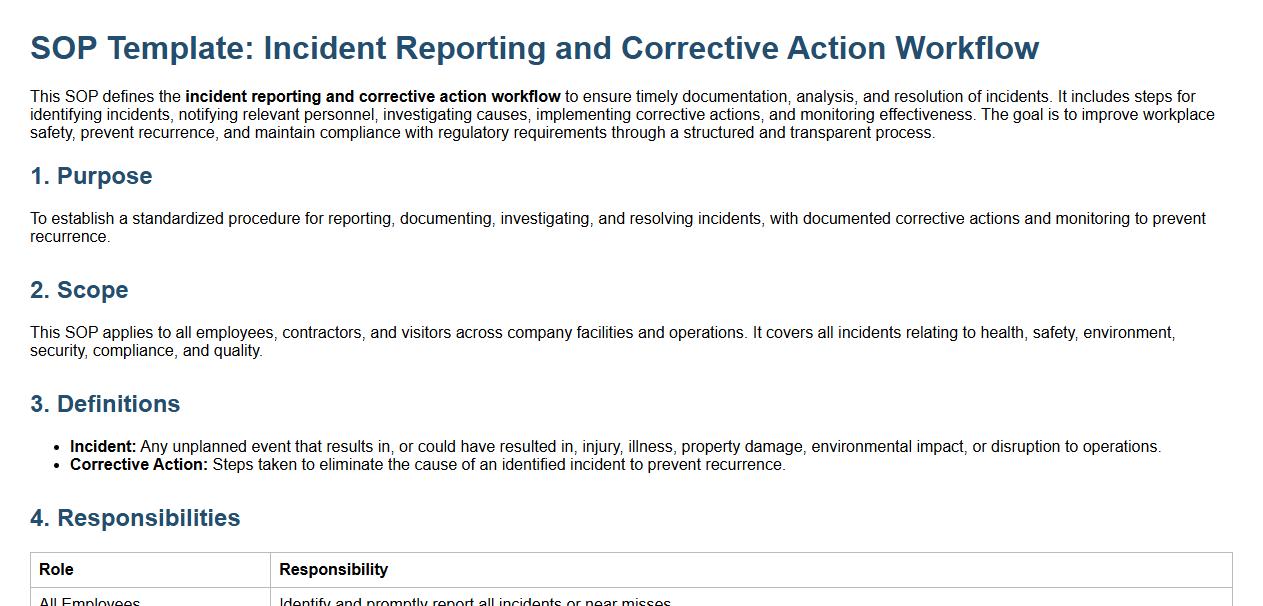

Incident reporting and corrective action workflow.

This SOP defines the incident reporting and corrective action workflow to ensure timely documentation, analysis, and resolution of incidents. It includes steps for identifying incidents, notifying relevant personnel, investigating causes, implementing corrective actions, and monitoring effectiveness. The goal is to improve workplace safety, prevent recurrence, and maintain compliance with regulatory requirements through a structured and transparent process.

What are the primary objectives outlined in the SOP for Manufacturing Process Control?

The primary objectives of the SOP for Manufacturing Process Control are to ensure consistent product quality and adherence to regulatory standards. It aims to minimize variability in the manufacturing process by setting clear control limits and procedures. Additionally, the SOP focuses on maintaining process efficiency while safeguarding product safety and compliance.

Which critical parameters are monitored and controlled according to the SOP?

The SOP specifies monitoring critical parameters such as temperature, pressure, and humidity during the manufacturing process. It also controls variables like batch size, mixing speed, and reaction time to ensure process stability. These parameters are regularly tracked to prevent deviations and maintain product specifications.

What specific documentation and records are required as per the SOP guidelines?

The SOP mandates detailed documentation and record-keeping for all manufacturing activities to ensure traceability and accountability. Batch records, calibration logs, and deviation reports must be maintained accurately and updated in real time. These documents are critical for audits, quality reviews, and regulatory compliance.

How does the SOP define roles and responsibilities for process control activities?

The SOP clearly defines roles and responsibilities for all personnel involved in process control, including operators, supervisors, and quality assurance staff. Each role outlines specific tasks such as monitoring parameters, documenting data, and responding to deviations. This structure ensures accountability and effective communication across the manufacturing team.

What procedures does the SOP specify for handling deviations and non-conformities during manufacturing?

The SOP outlines strict procedures for handling deviations and non-conformities, including immediate reporting and investigation protocols. Corrective and preventive actions (CAPA) must be documented and implemented to resolve issues promptly. This ensures continuous improvement and maintains the integrity of the manufacturing process.