A SOP Template for Manufacturing Waste Management provides a structured framework to ensure efficient handling, segregation, and disposal of waste generated during manufacturing processes. It outlines clear procedures for compliance with environmental regulations and promotes sustainable practices to minimize ecological impact. This template helps standardize waste management operations, enhancing workplace safety and reducing operational costs.

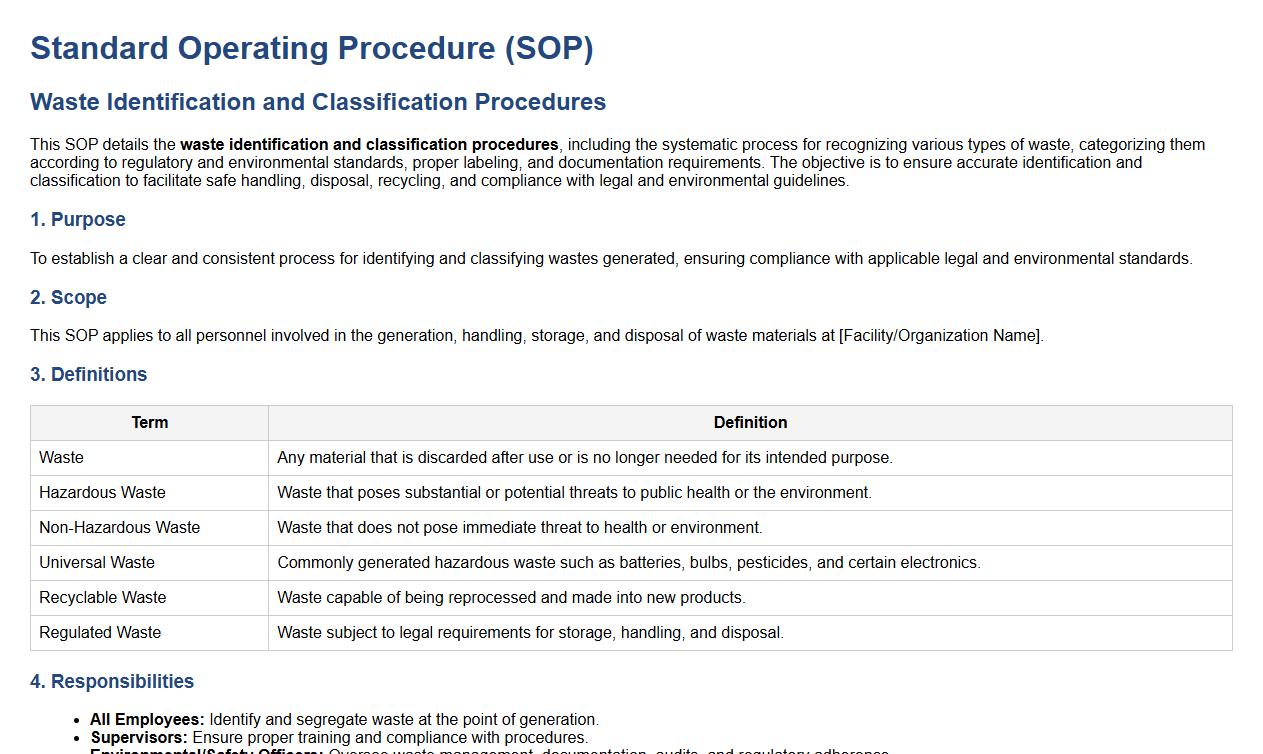

Waste identification and classification procedures.

This SOP details the waste identification and classification procedures, including the systematic process for recognizing various types of waste, categorizing them according to regulatory and environmental standards, proper labeling, and documentation requirements. The objective is to ensure accurate identification and classification to facilitate safe handling, disposal, recycling, and compliance with legal and environmental guidelines.

Waste segregation and collection guidelines.

This SOP provides detailed waste segregation and collection guidelines, outlining proper procedures for sorting different types of waste to promote recycling and minimize environmental impact. It includes instructions on categorizing waste into recyclables, organics, hazardous materials, and general waste, as well as best practices for waste collection, storage, and disposal. The aim is to ensure effective waste management, compliance with environmental regulations, and the safety of personnel handling waste materials.

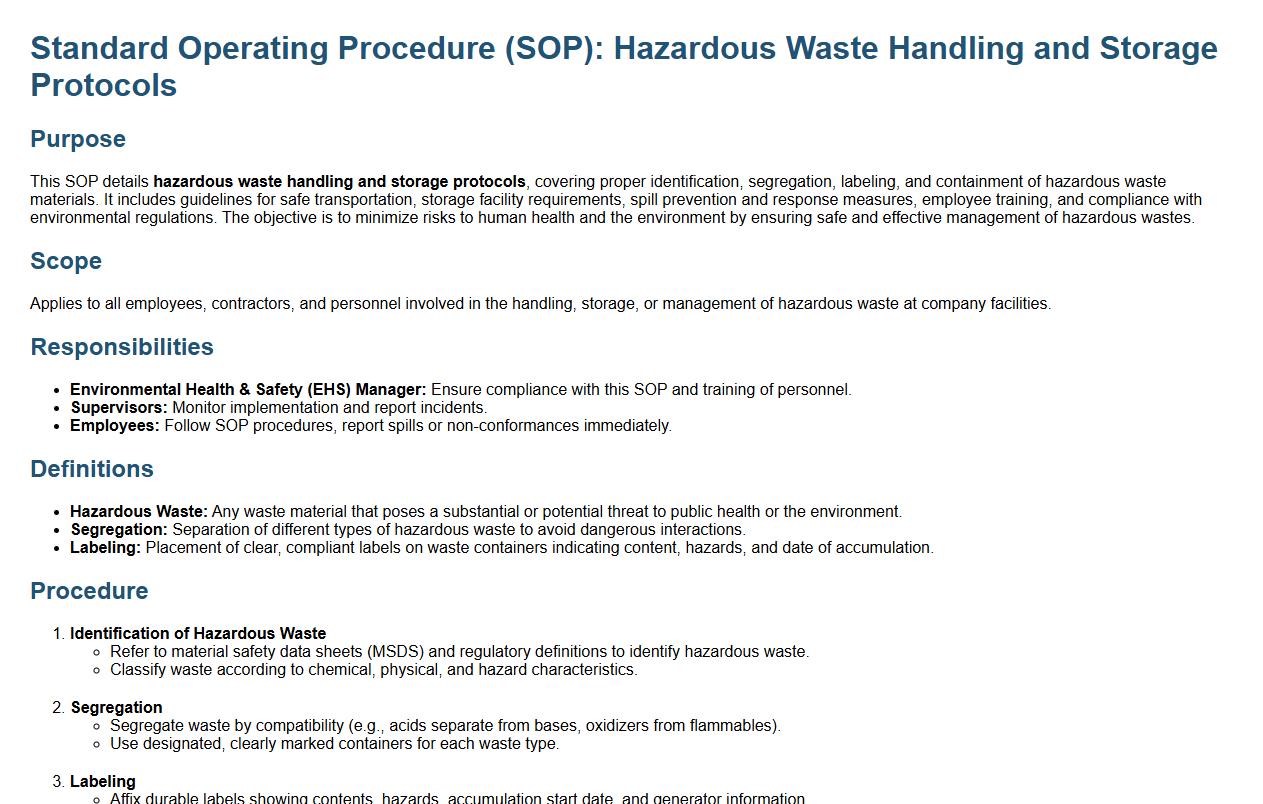

Hazardous waste handling and storage protocols.

This SOP details hazardous waste handling and storage protocols, covering the proper identification, segregation, labeling, and containment of hazardous waste materials. It includes guidelines for safe transportation, storage facility requirements, spill prevention and response measures, employee training, and compliance with environmental regulations. The objective is to minimize risks to human health and the environment by ensuring safe and effective management of hazardous wastes.

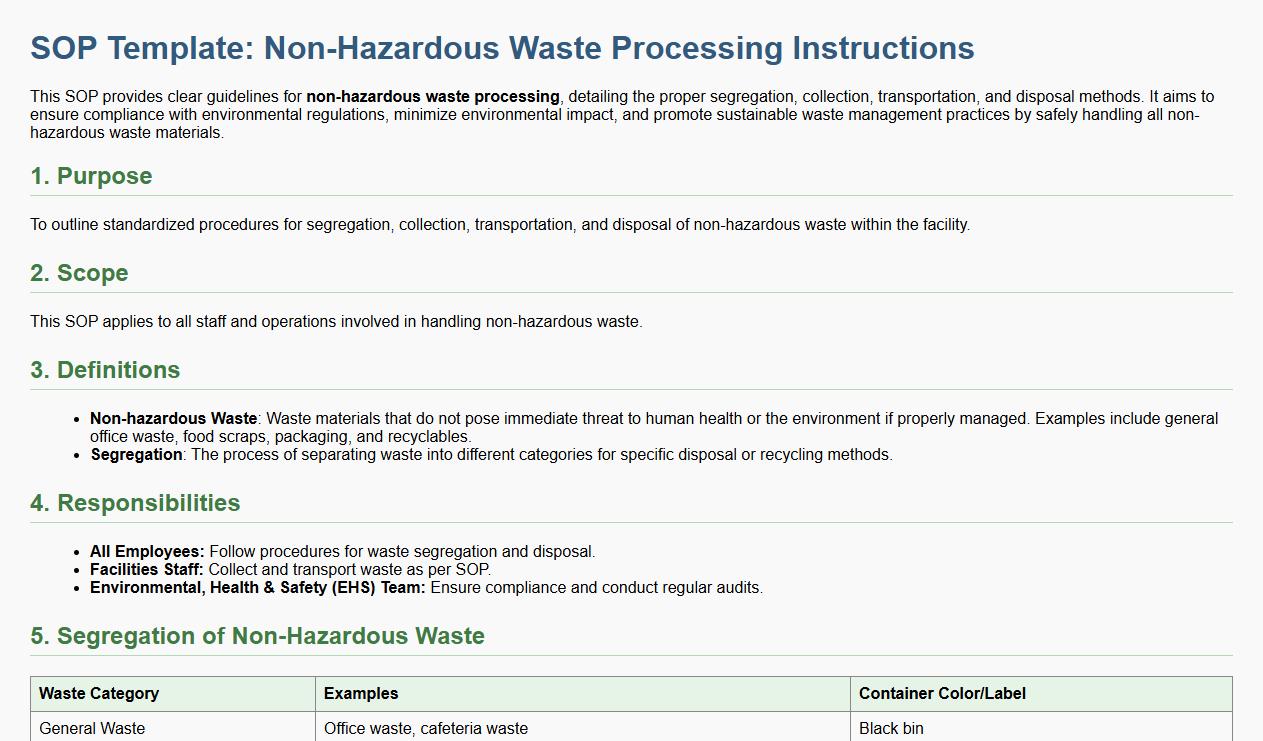

Non-hazardous waste processing instructions.

This SOP provides clear guidelines for non-hazardous waste processing, detailing the proper segregation, collection, transportation, and disposal methods. It aims to ensure compliance with environmental regulations, minimize environmental impact, and promote sustainable waste management practices by safely handling all non-hazardous waste materials.

Recycling and reuse procedures for materials.

This SOP details recycling and reuse procedures for materials, including the identification and segregation of recyclable materials, proper cleaning and preparation for reuse, guidelines for safe storage and handling, methods to minimize waste generation, and protocols for tracking and reporting recycling efforts. The objective is to promote sustainable practices, reduce environmental impact, and optimize resource utilization through effective recycling and reuse strategies.

Waste transportation and disposal methods.

This SOP details waste transportation and disposal methods, including procedures for safe and compliant waste collection, handling, transportation, and final disposal. It covers waste segregation, container requirements, labeling, transport vehicle standards, regulatory compliance, environmental protection measures, and emergency response in case of spills or accidents. The objective is to ensure efficient waste management while minimizing environmental impact and adhering to legal regulations.

Personal protective equipment (PPE) requirements.

This SOP defines the personal protective equipment (PPE) requirements necessary for maintaining safety and health in the workplace. It covers the selection, proper use, maintenance, and replacement of PPE to protect employees from hazards such as chemical exposure, physical injuries, and environmental risks. The goal is to ensure compliance with safety regulations and to minimize workplace accidents by providing clear guidelines on PPE protocols.

Spill response and cleanup actions.

This SOP details the spill response and cleanup actions to effectively manage and mitigate the impact of hazardous and non-hazardous spills. It covers immediate containment measures, notification protocols, safe cleanup procedures, proper disposal of waste materials, use of appropriate personal protective equipment (PPE), environmental protection considerations, and documentation requirements. The objective is to minimize health risks, environmental contamination, and operational disruptions through prompt and systematic spill response.

Documentation and waste tracking systems.

This SOP details the implementation and management of documentation and waste tracking systems, covering proper recording of waste generation, handling, storage, transportation, and disposal. It emphasizes maintaining accurate logs, ensuring regulatory compliance, minimizing environmental impact, and promoting accountability across all operational stages. The objective is to streamline waste management processes, enhance traceability, and support sustainability initiatives within the organization.

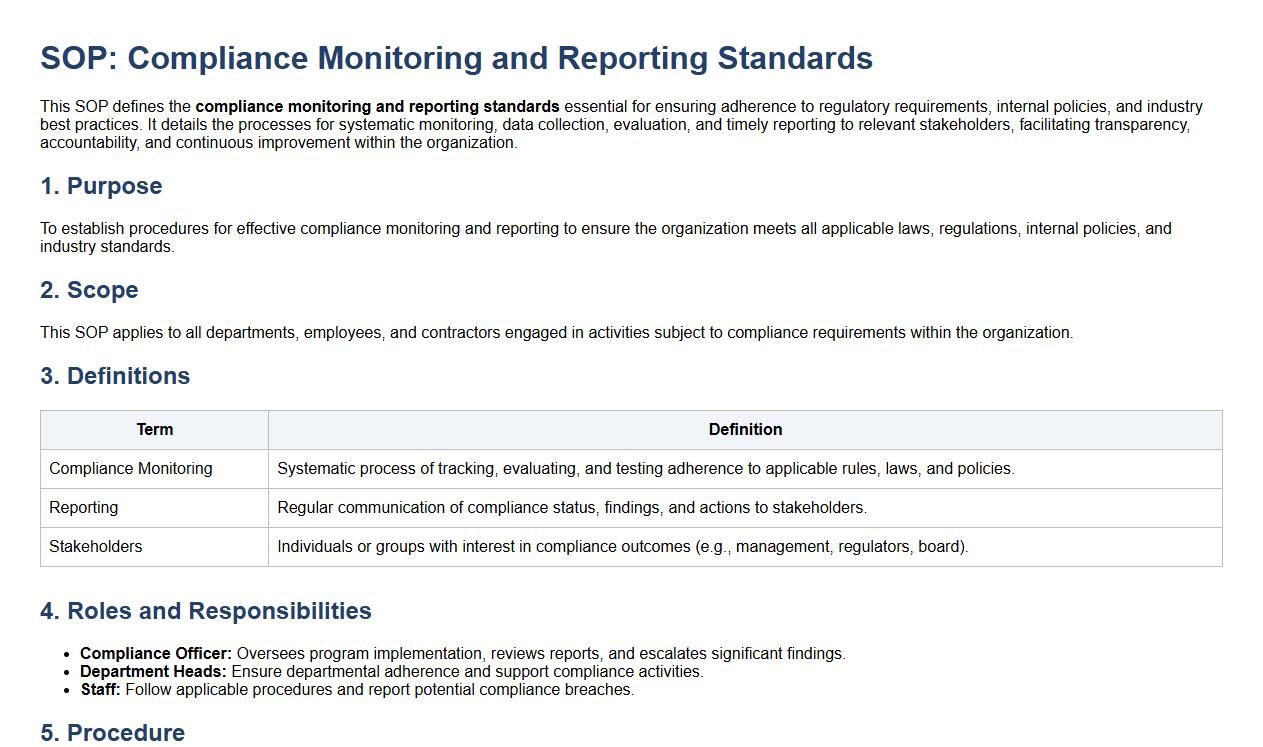

Compliance monitoring and reporting standards.

This SOP defines the compliance monitoring and reporting standards essential for ensuring adherence to regulatory requirements, internal policies, and industry best practices. It details the processes for systematic monitoring, data collection, evaluation, and timely reporting to relevant stakeholders, facilitating transparency, accountability, and continuous improvement within the organization.

What are the key steps outlined in the SOP for segregating manufacturing waste?

The SOP highlights the identification and classification of waste into categories such as hazardous, non-hazardous, and recyclable. It mandates the use of designated containers clearly labeled with waste type to prevent cross-contamination. Additionally, staff must be trained on proper segregation techniques to ensure compliance and environmental safety.

Which types of manufacturing waste require special handling procedures according to the SOP?

The SOP specifies that hazardous waste such as chemical solvents, heavy metals, and biohazard materials require specialized handling. These wastes must be managed using protective equipment and stored in secure, leak-proof containers. Non-hazardous waste, while less critical, still requires proper disposal to avoid environmental impact.

What documentation is mandated by the SOP for tracking and recording waste disposal activities?

The SOP requires maintenance of detailed waste disposal logs including the type, quantity, and disposal method of each waste item. Additionally, transfer receipts and disposal certificates from authorized vendors must be recorded. This documentation ensures traceability and regulatory compliance throughout the waste management process.

Who is responsible for regularly inspecting compliance with the waste management SOP?

The SOP designates the Waste Management Officer or an appointed Environmental Compliance Officer to conduct routine inspections. These inspections verify adherence to segregation, storage, and disposal protocols. Regular audits help identify gaps and improve overall waste management effectiveness.

What corrective actions does the SOP specify in the event of accidental waste spillage?

In case of waste spillage, the SOP mandates immediate containment using absorbent materials and spill kits. The incident must be reported to the supervisor and documented with details of the spill and cleanup actions. Corrective measures include reviewing procedures and retraining personnel to prevent recurrence.