A SOP Template for Manufacturing Inventory Management provides a standardized framework to streamline inventory tracking, control, and replenishment processes within a manufacturing facility. It ensures accuracy in recording stock levels, reduces waste, and enhances operational efficiency by defining clear procedures for handling materials. This template is essential for maintaining consistent inventory practices and optimizing production workflows.

Inventory receiving and inspection procedures.

This SOP details the inventory receiving and inspection procedures, outlining the steps for accurate receipt, verification, and quality assessment of incoming goods. It includes protocols for checking shipment accuracy, inspecting items for damage or defects, documenting discrepancies, and ensuring compliance with purchase orders. The purpose is to maintain inventory integrity, prevent errors, and ensure timely reporting of issues to support efficient supply chain management.

Inventory storage and organization guidelines.

This SOP provides comprehensive inventory storage and organization guidelines, covering proper inventory categorization, storage methods, space optimization, labeling and tracking systems, handling procedures to prevent damage, regular inventory audits, and safety practices. The aim is to enhance inventory management efficiency, minimize loss or damage, and ensure easy access and accurate record-keeping.

Raw material requisition and issuance process.

This SOP defines the raw material requisition and issuance process, detailing the procedures for requesting, authorizing, and distributing raw materials within the organization. It ensures accurate documentation, inventory control, and timely supply of materials to production departments while maintaining compliance with quality standards and minimizing material wastage. The objective is to streamline material flow, promote accountability, and support efficient production operations.

Production batch tracking and inventory allocation.

This SOP details the process for production batch tracking and inventory allocation. It covers the methods for accurately recording production batches, assigning unique batch numbers, monitoring batch status throughout the production cycle, and ensuring traceability. Additionally, it outlines inventory allocation procedures to manage stock levels efficiently, allocate materials to specific batches, and maintain accurate inventory records. The goal is to enhance production transparency, improve inventory control, and support quality assurance and regulatory compliance.

Stock level monitoring and reorder point protocols.

This SOP details stock level monitoring and reorder point protocols, including procedures for regularly tracking inventory levels, establishing minimum stock thresholds, and defining reorder points to prevent stockouts. It encompasses guidelines for accurate stock counting, data recording, and timely communication with suppliers to ensure continuous supply. The goal is to optimize inventory management, reduce holding costs, and maintain efficient operational flow by ensuring adequate stock availability at all times.

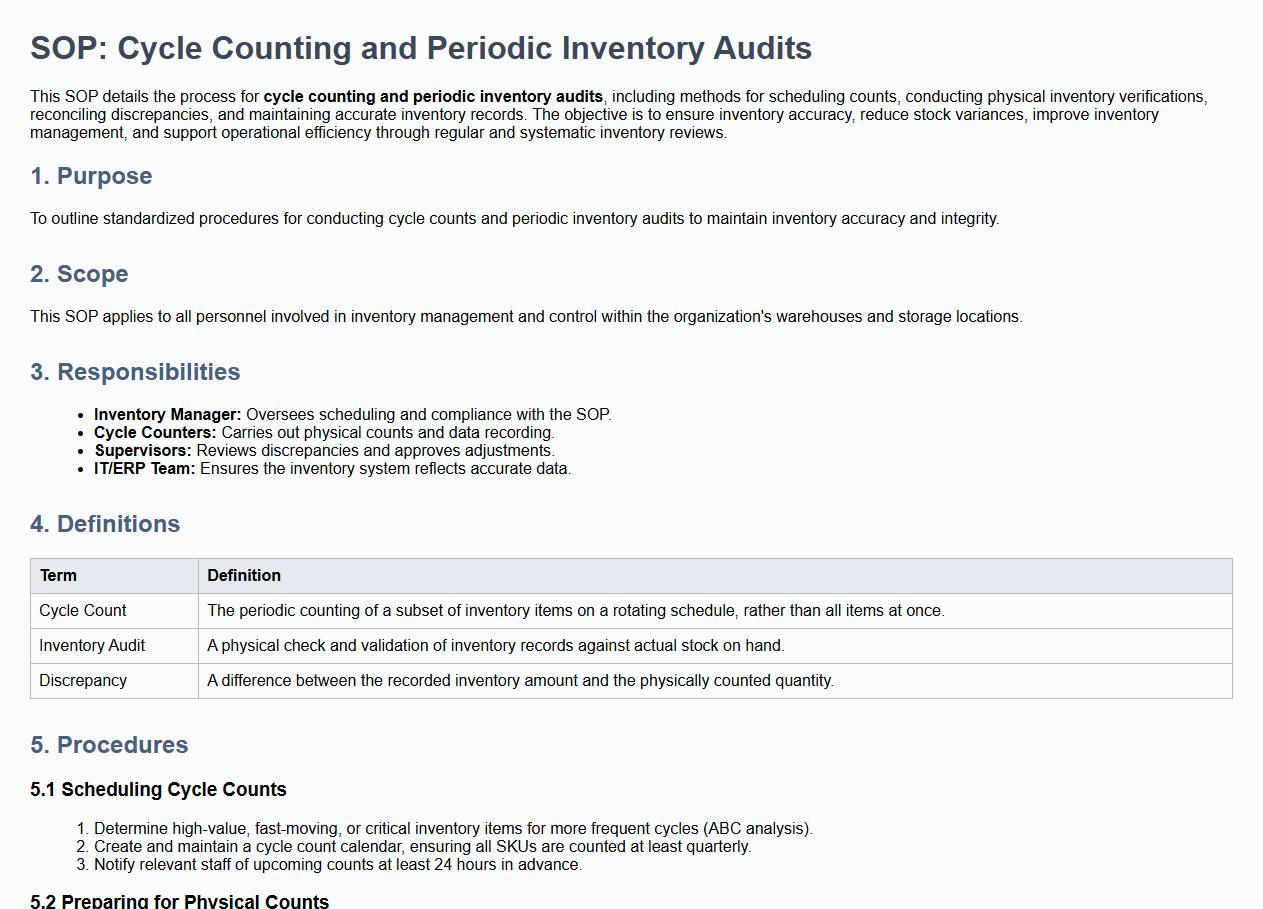

Cycle counting and periodic inventory audits.

This SOP details the process for cycle counting and periodic inventory audits, including methods for scheduling counts, conducting physical inventory verifications, reconciling discrepancies, and maintaining accurate inventory records. The objective is to ensure inventory accuracy, reduce stock variances, improve inventory management, and support operational efficiency through regular and systematic inventory reviews.

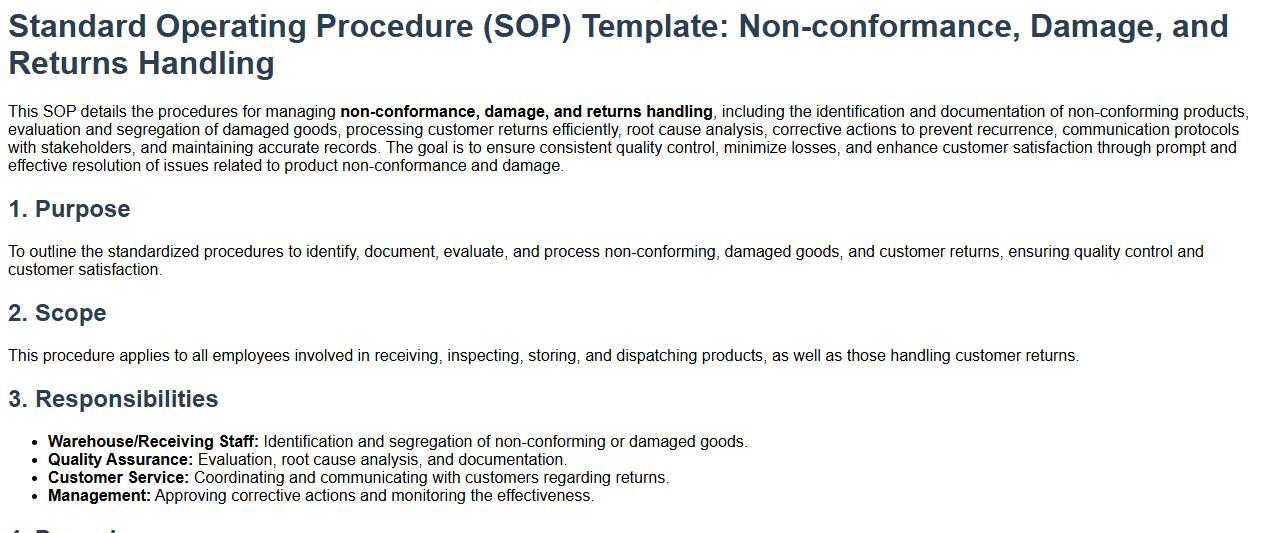

Non-conformance, damage, and returns handling.

This SOP details the procedures for managing non-conformance, damage, and returns handling, including the identification and documentation of non-conforming products, evaluation and segregation of damaged goods, processing customer returns efficiently, root cause analysis, corrective actions to prevent recurrence, communication protocols with stakeholders, and maintaining accurate records. The goal is to ensure consistent quality control, minimize losses, and enhance customer satisfaction through prompt and effective resolution of issues related to product non-conformance and damage.

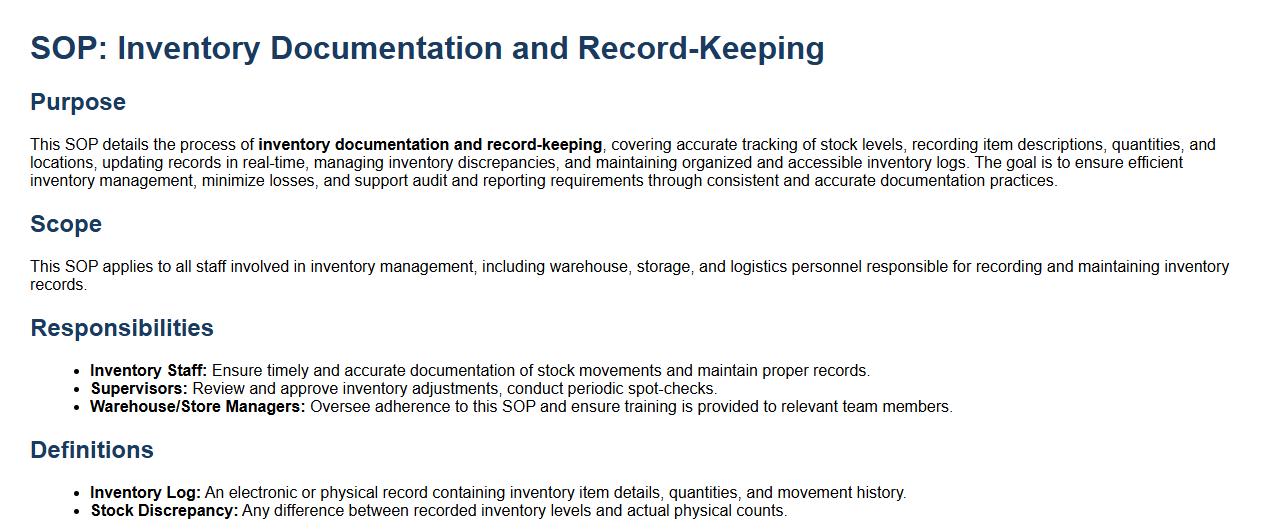

Inventory documentation and record-keeping.

This SOP details the process of inventory documentation and record-keeping, covering accurate tracking of stock levels, recording item descriptions, quantities, and locations, updating records in real-time, managing inventory discrepancies, and maintaining organized and accessible inventory logs. The goal is to ensure efficient inventory management, minimize losses, and support audit and reporting requirements through consistent and accurate documentation practices.

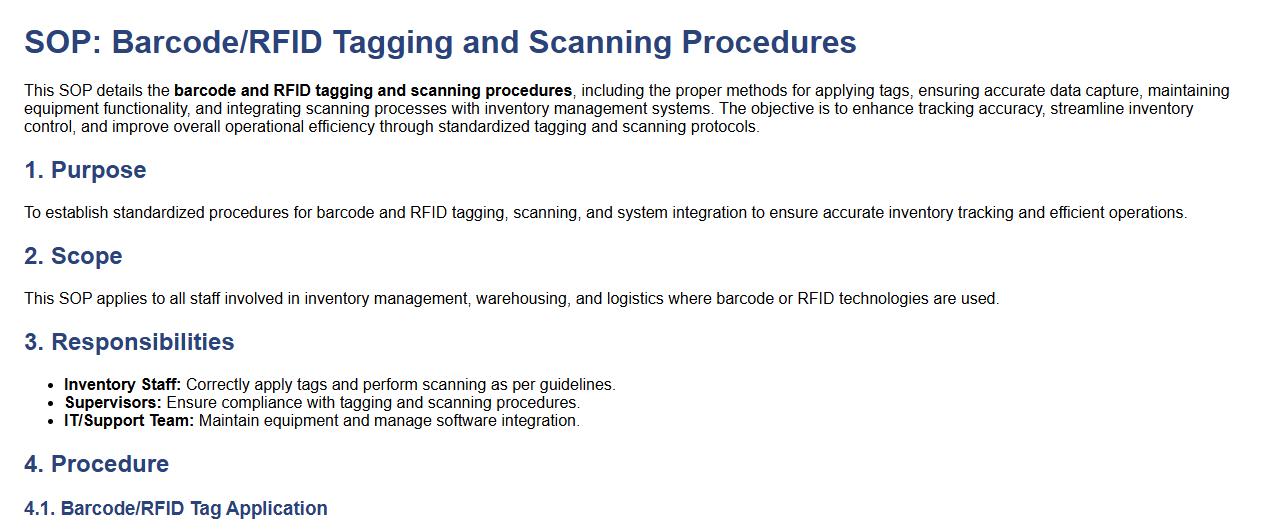

Barcode/RFID tagging and scanning procedures.

This SOP details the barcode and RFID tagging and scanning procedures, including the proper methods for applying tags, ensuring accurate data capture, maintaining equipment functionality, and integrating scanning processes with inventory management systems. The objective is to enhance tracking accuracy, streamline inventory control, and improve overall operational efficiency through standardized tagging and scanning protocols.

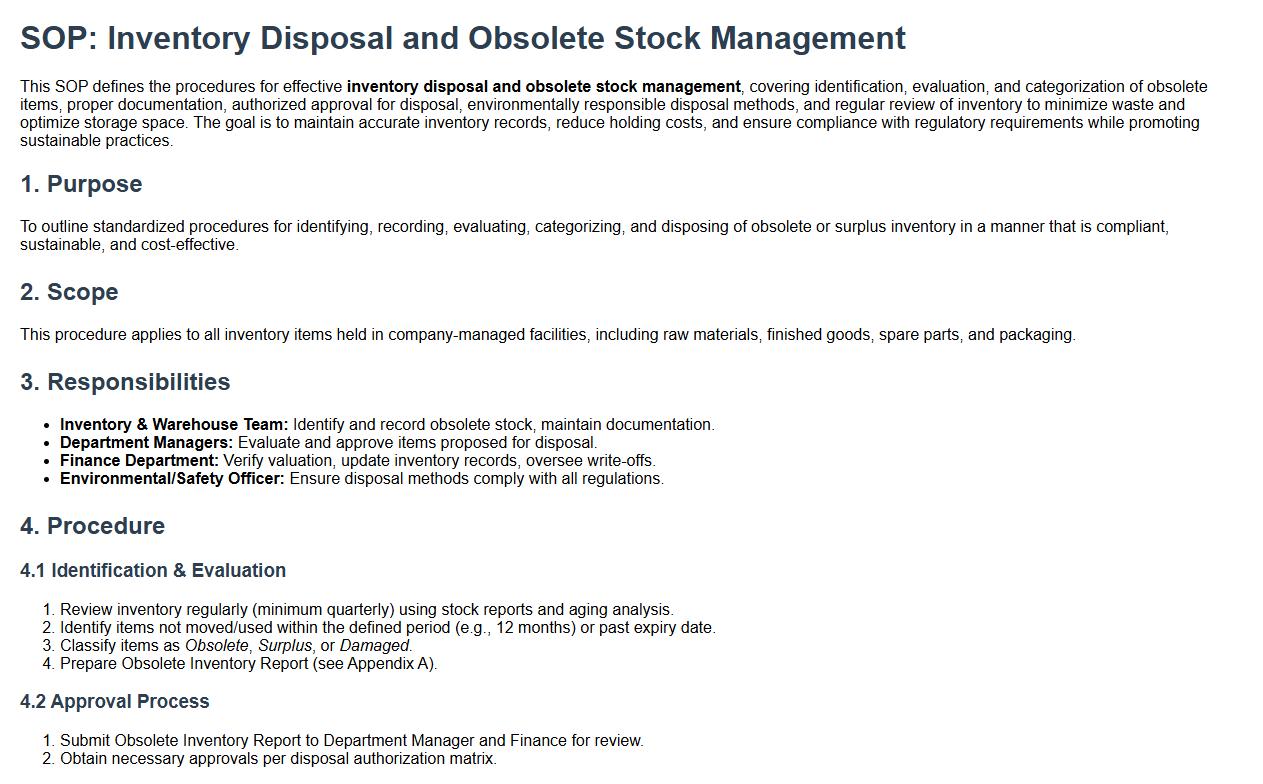

Inventory disposal and obsolete stock management.

This SOP defines the procedures for effective inventory disposal and obsolete stock management, covering identification, evaluation, and categorization of obsolete items, proper documentation, authorized approval for disposal, environmentally responsible disposal methods, and regular review of inventory to minimize waste and optimize storage space. The goal is to maintain accurate inventory records, reduce holding costs, and ensure compliance with regulatory requirements while promoting sustainable practices.

What are the key steps outlined in the SOP for managing raw material inventory within the manufacturing process?

The SOP begins with the receipt and inspection of raw materials to ensure they meet quality standards. It then outlines proper storage procedures to maintain material integrity. Finally, the SOP details the systematic inventory rotation to minimize waste and optimize material usage.

How does the SOP specify procedures for recording and tracking inventory movement?

The SOP mandates the use of a centralized inventory management system to record all raw material transactions. Each inventory movement must be logged with accurate timestamps and batch numbers. This ensures real-time tracking and traceability of materials throughout the manufacturing process.

Which roles and responsibilities are defined in the SOP for maintaining accurate inventory records?

The SOP assigns the inventory control manager with overall responsibility for record accuracy and system updates. Warehouse staff are tasked with documenting material receipt and dispatch precisely. Quality assurance personnel perform periodic audits to verify inventory records against physical stock.

What are the standard protocols for reporting and addressing inventory discrepancies according to the SOP?

Any inventory discrepancies must be immediately reported to the inventory control manager for investigation. The SOP requires a thorough reconciliation process to identify the root cause and implement corrective actions. All discrepancy reports and resolutions must be documented in the inventory system for future reference.

How does the SOP ensure compliance with safety and quality standards during inventory handling?

The SOP enforces strict adherence to personal protective equipment (PPE) usage and safe material handling practices. Materials are stored in conditions that comply with defined quality control parameters to prevent contamination or damage. Regular training sessions are conducted to keep staff updated on safety and quality protocols.