A SOP Template for Retail Equipment Maintenance outlines standardized procedures to ensure the timely servicing and repair of retail store machinery. It helps maintain operational efficiency by minimizing equipment downtime and extending asset lifespan. This template guides staff in performing routine checks, troubleshooting issues, and documenting maintenance activities accurately.

Scheduled preventative maintenance routines.

This SOP describes the scheduled preventative maintenance routines designed to ensure the reliability and longevity of equipment and facilities. It includes detailed procedures for regular inspections, cleaning, lubrication, adjustments, and component replacements to prevent unexpected breakdowns and minimize downtime. The goal is to maintain optimal operational performance, enhance safety, and reduce repair costs by proactively addressing potential issues before they result in equipment failure.

Equipment inspection and assessment procedures.

This SOP details equipment inspection and assessment procedures, covering regular maintenance checks, identification of wear and damage, safety compliance verification, functionality testing, documentation of inspection results, and scheduling of repairs or replacements. The goal is to ensure all equipment operates safely and efficiently, minimizing downtime and preventing accidents through timely assessments and corrective actions.

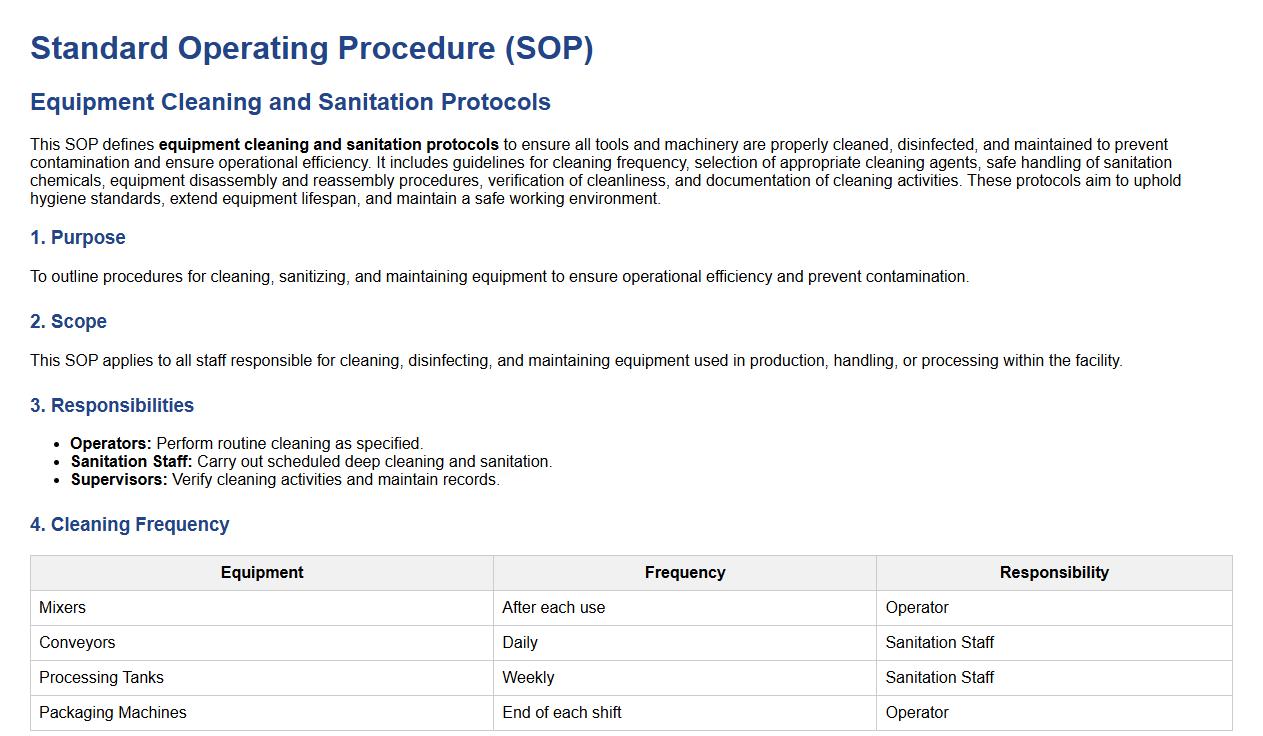

Equipment cleaning and sanitation protocols.

This SOP defines equipment cleaning and sanitation protocols to ensure all tools and machinery are properly cleaned, disinfected, and maintained to prevent contamination and ensure operational efficiency. It includes guidelines for cleaning frequency, selection of appropriate cleaning agents, safe handling of sanitation chemicals, equipment disassembly and reassembly procedures, verification of cleanliness, and documentation of cleaning activities. These protocols aim to uphold hygiene standards, extend equipment lifespan, and maintain a safe working environment.

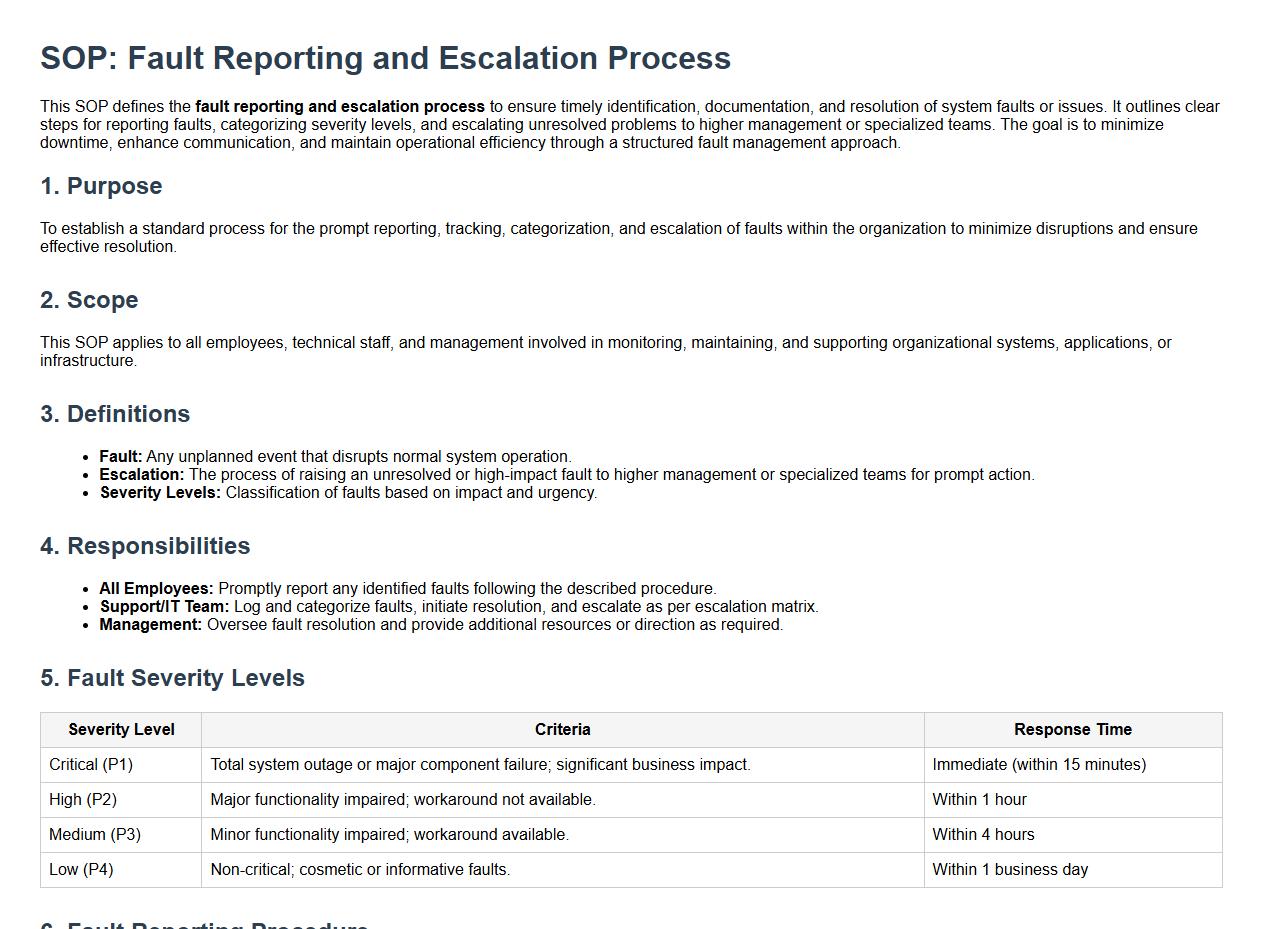

Fault reporting and escalation process.

This SOP defines the fault reporting and escalation process to ensure timely identification, documentation, and resolution of system faults or issues. It outlines clear steps for reporting faults, categorizing severity levels, and escalating unresolved problems to higher management or specialized teams. The goal is to minimize downtime, enhance communication, and maintain operational efficiency through a structured fault management approach.

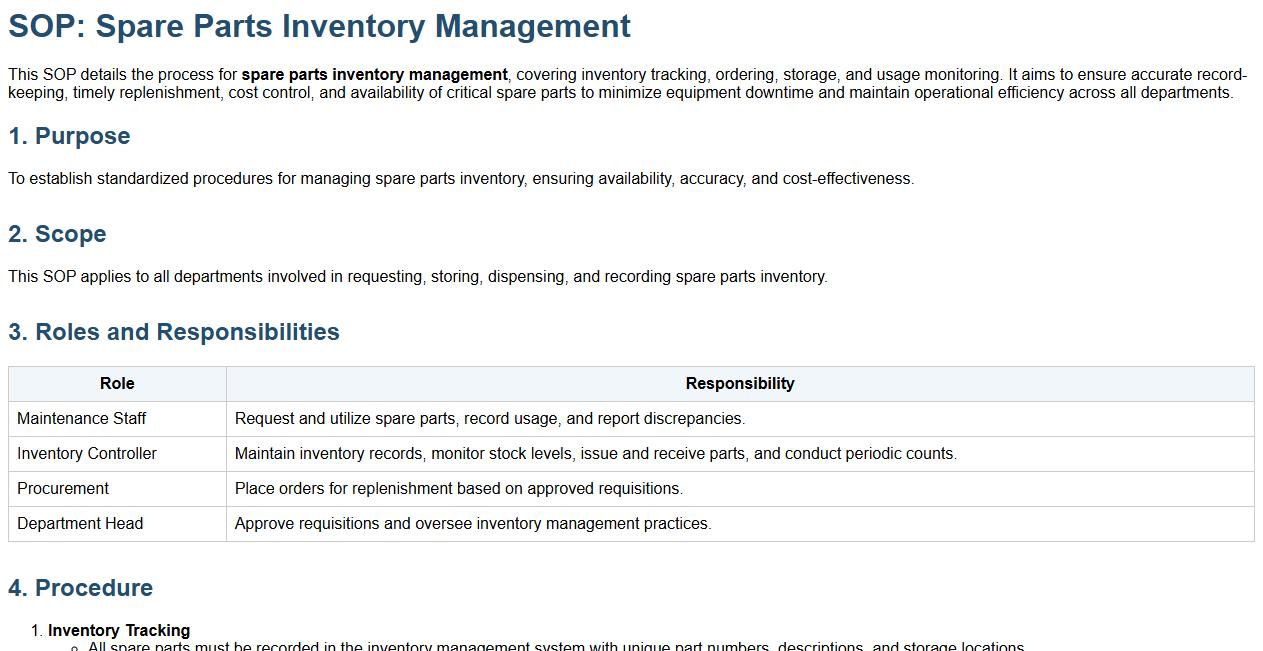

Spare parts inventory management.

This SOP details the process for spare parts inventory management, covering inventory tracking, ordering, storage, and usage monitoring. It aims to ensure accurate record-keeping, timely replenishment, cost control, and availability of critical spare parts to minimize equipment downtime and maintain operational efficiency across all departments.

Work order generation and tracking.

This SOP details the process of work order generation and tracking, covering the creation, assignment, monitoring, and completion of work orders. It ensures accurate documentation, timely updates, and effective communication among team members to enhance productivity, resource allocation, and project management efficiency.

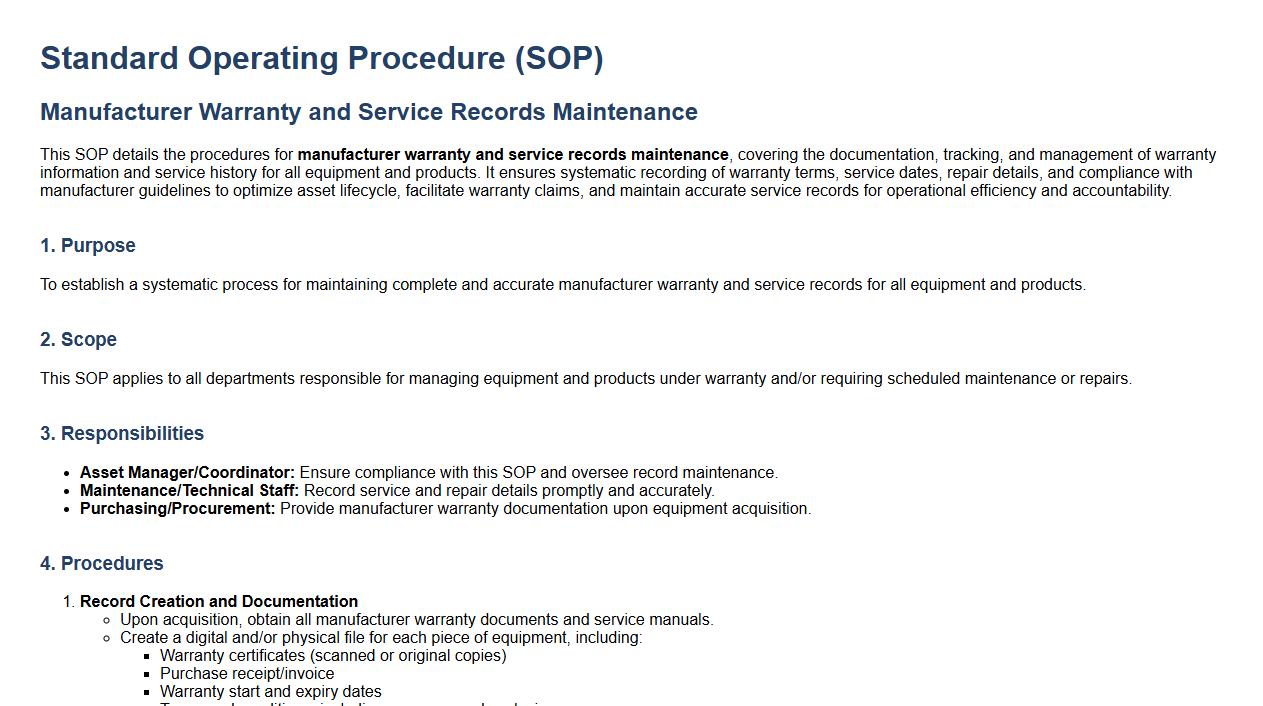

Manufacturer warranty and service records maintenance.

This SOP details the procedures for manufacturer warranty and service records maintenance, covering the documentation, tracking, and management of warranty information and service history for all equipment and products. It ensures systematic recording of warranty terms, service dates, repair details, and compliance with manufacturer guidelines to optimize asset lifecycle, facilitate warranty claims, and maintain accurate service records for operational efficiency and accountability.

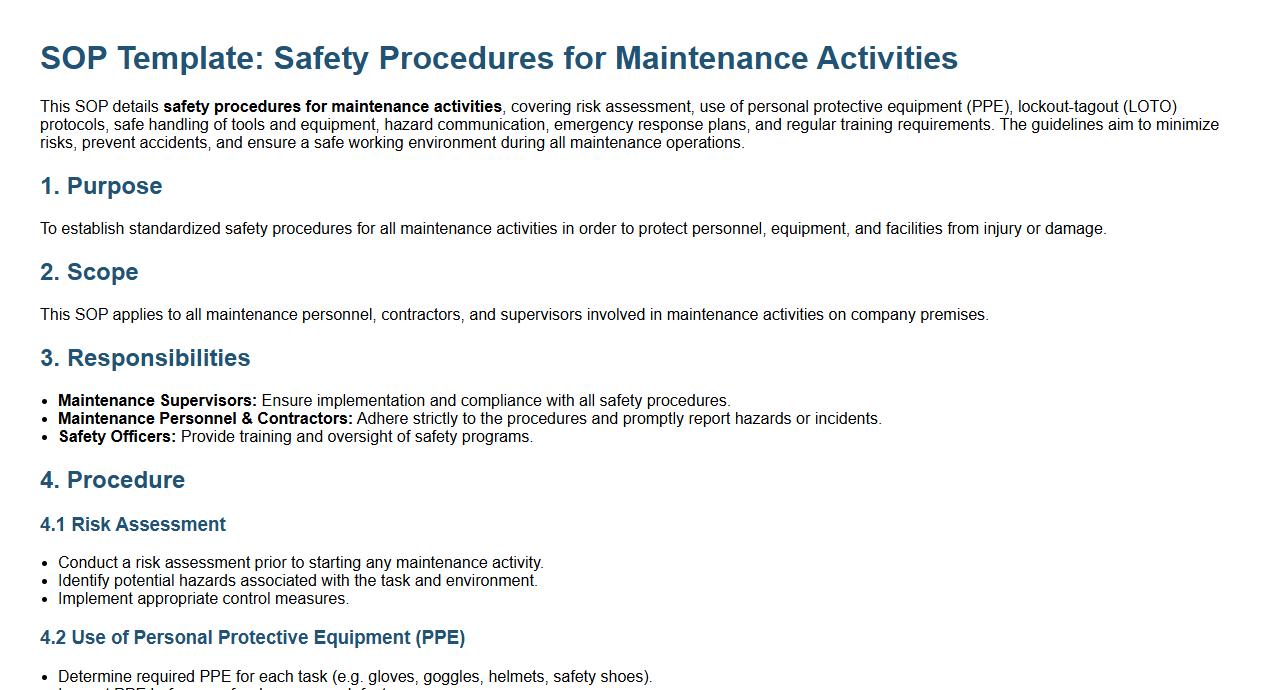

Safety procedures for maintenance activities.

This SOP details safety procedures for maintenance activities, covering risk assessment, use of personal protective equipment (PPE), lockout-tagout (LOTO) protocols, safe handling of tools and equipment, hazard communication, emergency response plans, and regular training requirements. The guidelines aim to minimize risks, prevent accidents, and ensure a safe working environment during all maintenance operations.

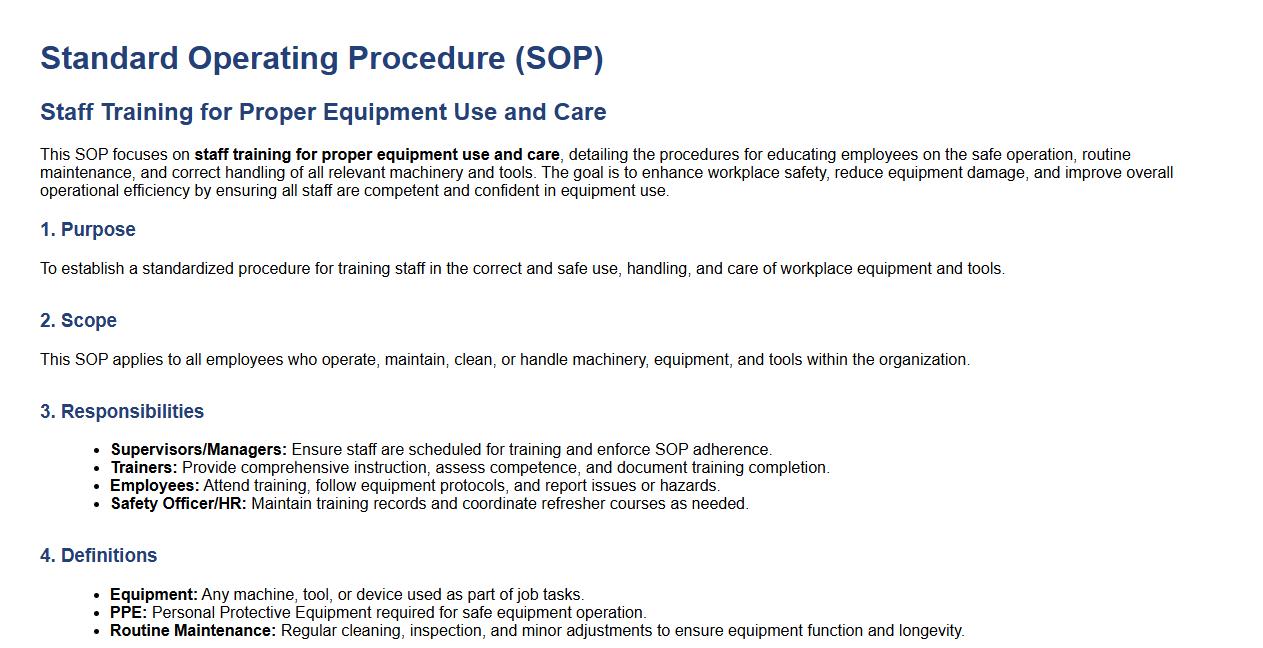

Staff training for proper equipment use and care.

This SOP focuses on staff training for proper equipment use and care, detailing the procedures for educating employees on the safe operation, routine maintenance, and correct handling of all relevant machinery and tools. The goal is to enhance workplace safety, reduce equipment damage, and improve overall operational efficiency by ensuring all staff are competent and confident in equipment use.

Documentation and logging of all maintenance activities.

This SOP details the documentation and logging of all maintenance activities, ensuring accurate and timely records of routine inspections, repairs, replacements, and preventive maintenance tasks. It promotes accountability, facilitates tracking of equipment performance, supports compliance with regulatory requirements, and helps in scheduling future maintenance to minimize downtime and extend the lifespan of assets.

What are the primary objectives defined in the Retail Equipment Maintenance SOP?

The primary objectives of the Retail Equipment Maintenance SOP focus on ensuring operational efficiency and minimizing equipment downtime. It aims to enhance the lifespan of retail equipment through regular inspections and maintenance. Additionally, the SOP seeks to uphold safety standards and compliance with regulatory guidelines.

Which specific procedures must be followed for scheduled preventive maintenance?

Scheduled preventive maintenance procedures involve systematic inspections, cleaning, and calibration of retail equipment at designated intervals. Technicians must adhere to detailed checklists that outline every step to prevent equipment failure. These procedures are designed to detect potential issues early and maintain optimal performance.

What are the documentation and reporting requirements outlined in the SOP?

The SOP mandates comprehensive documentation and reporting for all maintenance activities, including checklists, service records, and incident reports. Accurate logs ensure traceability and help in monitoring equipment health over time. Reports must be submitted to designated supervisors promptly to facilitate timely decision-making.

Who are the designated personnel responsible for executing maintenance tasks according to the SOP?

The SOP assigns maintenance responsibilities to trained and certified technicians and engineers familiar with retail equipment. Supervisors oversee the coordination of maintenance schedules and verify task completion. Furthermore, all personnel must comply with safety protocols and report any anomalies immediately.

How does the SOP address emergency repair situations and escalation protocols?

In emergency repair situations, the SOP requires immediate assessment and rapid response to mitigate operational disruptions. It outlines a clear escalation protocol, specifying when issues must be reported to higher management or external service providers. This structured approach ensures swift resolution and minimizes impact on retail operations.