A SOP Template for Retail Product Receiving ensures standardized procedures for inspecting, verifying, and logging incoming inventory. This template helps minimize errors, maintain accurate records, and streamline the receiving process for retail operations. Clear guidelines in the template support consistent training and compliance across all receiving staff.

Pre-arrival notification and scheduling of deliveries.

This SOP details the pre-arrival notification and scheduling of deliveries process, ensuring timely communication with suppliers and efficient coordination of delivery times. It covers procedures for notifying receiving personnel ahead of delivery, verifying order details, scheduling delivery windows to minimize disruptions, and maintaining accurate records of all scheduled arrivals. The goal is to optimize workflow, enhance operational efficiency, and prevent bottlenecks at the receiving area.

Receiving area preparation and safety checks.

This SOP details the receiving area preparation and safety checks, including the setup of receiving zones, inspection of equipment, verification of safety protocols, hazard identification and mitigation, proper signage placement, and communication of safety guidelines to personnel. The goal is to ensure a safe, efficient, and organized receiving process that minimizes risks and maintains compliance with safety standards.

Verification of delivery documentation (PO, packing list, invoices).

This SOP details the verification of delivery documentation process, including the thorough examination and cross-checking of purchase orders (PO), packing lists, and invoices. It ensures accuracy and consistency between ordered items and delivered goods, supports proper inventory management, prevents discrepancies, facilitates timely payments, and maintains compliance with procurement policies and financial controls.

Inspection and counting of incoming products for quantity and quality.

This SOP details the inspection and counting of incoming products to ensure both quantity accuracy and quality standards are met. It covers procedures for receiving shipments, verifying product counts against purchase orders, conducting quality checks for defects or damages, documenting findings, and reporting discrepancies. The goal is to maintain inventory accuracy, uphold product quality, and support efficient supply chain operations.

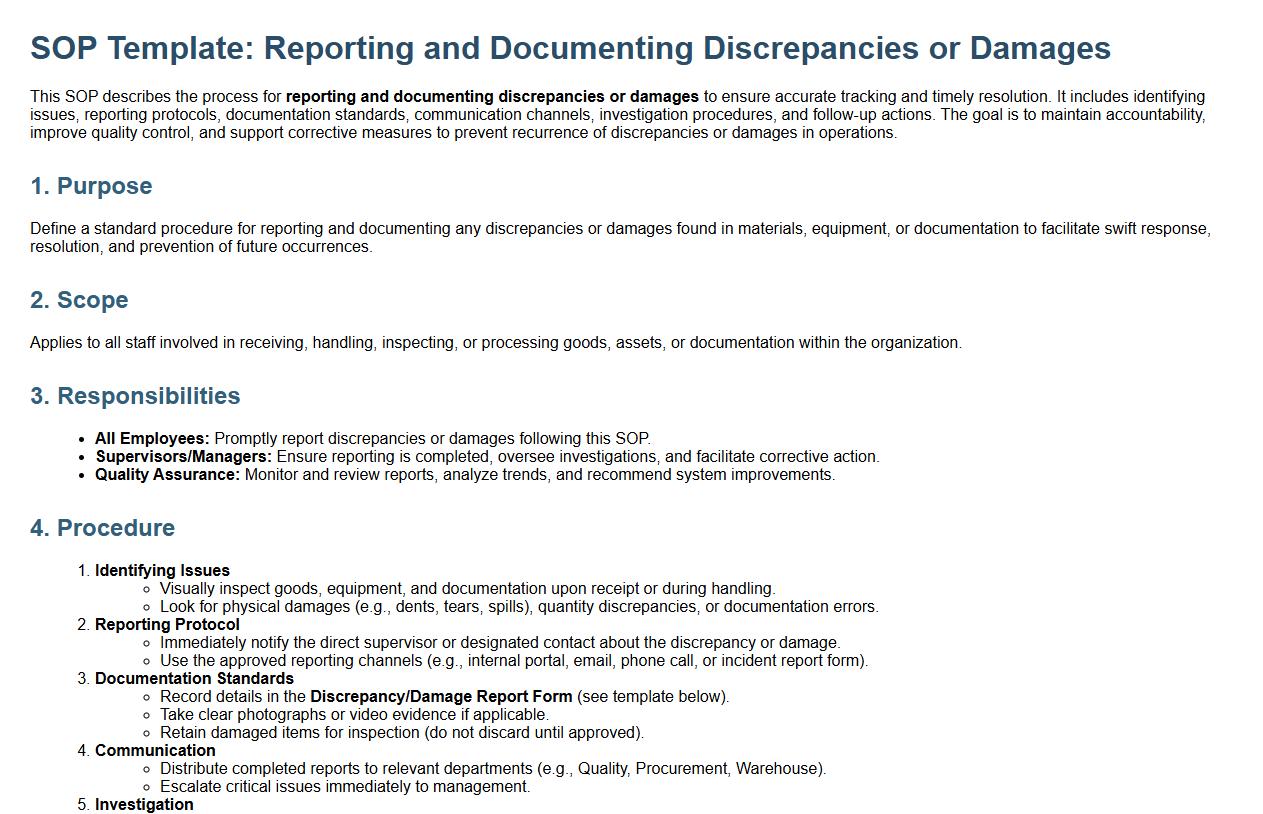

Reporting and documenting discrepancies or damages.

This SOP describes the process for reporting and documenting discrepancies or damages to ensure accurate tracking and timely resolution. It includes identifying issues, reporting protocols, documentation standards, communication channels, investigation procedures, and follow-up actions. The goal is to maintain accountability, improve quality control, and support corrective measures to prevent recurrence of discrepancies or damages in operations.

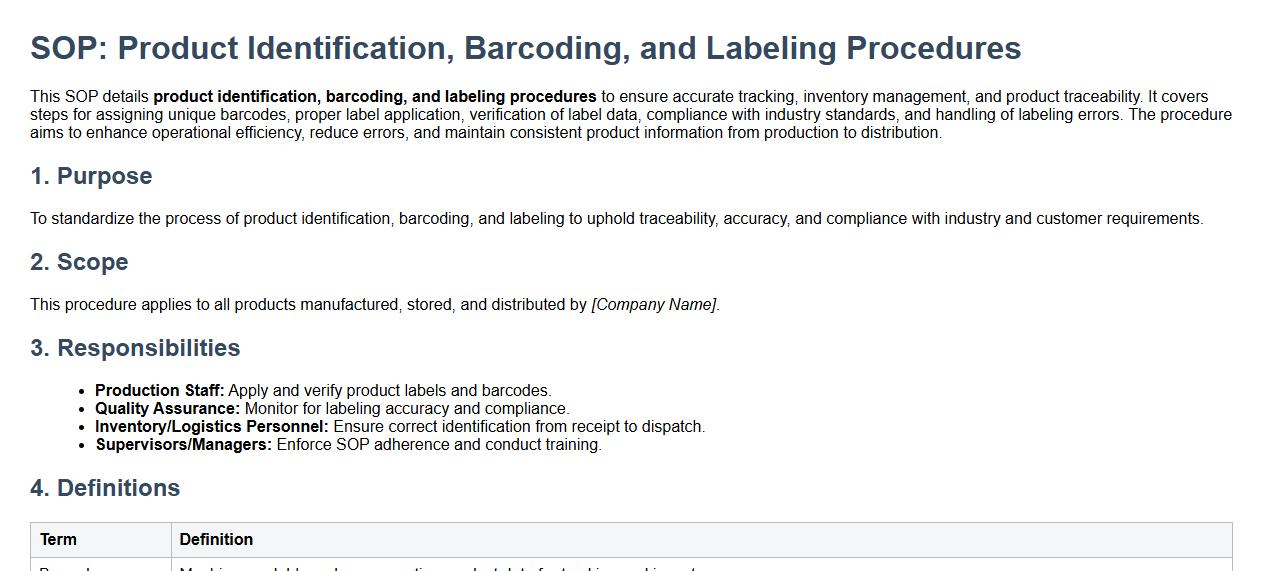

Product identification, barcoding, and labeling procedures.

This SOP details product identification, barcoding, and labeling procedures to ensure accurate tracking, inventory management, and product traceability. It covers steps for assigning unique barcodes, proper label application, verification of label data, compliance with industry standards, and handling of labeling errors. The procedure aims to enhance operational efficiency, reduce errors, and maintain consistent product information from production to distribution.

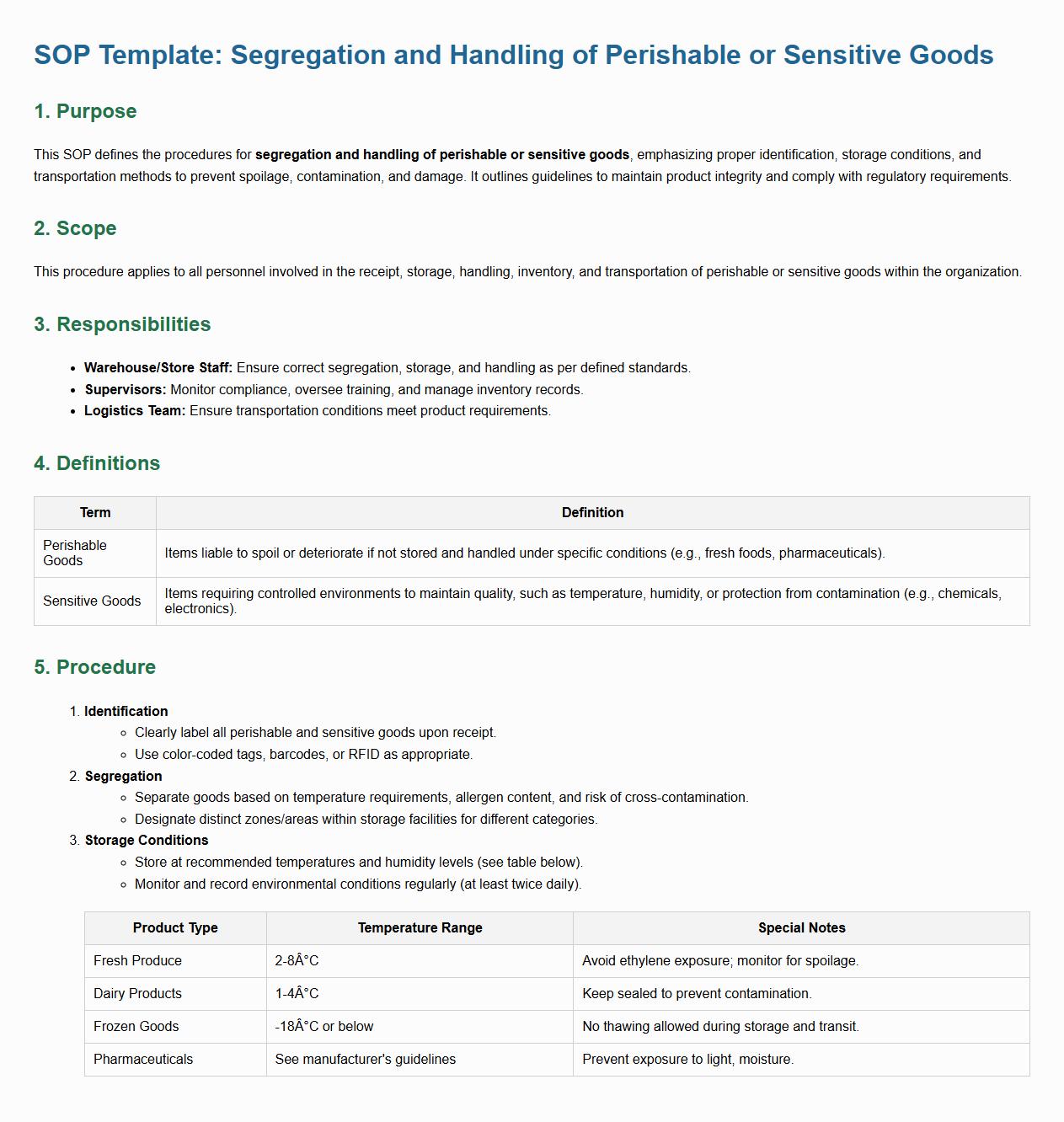

Segregation and handling of perishable or sensitive goods.

This SOP defines the procedures for segregation and handling of perishable or sensitive goods, emphasizing proper identification, storage conditions, and transportation methods to prevent spoilage, contamination, and damage. It includes guidelines for temperature control, packaging standards, inventory management, and staff training to ensure product quality and safety throughout the supply chain. The objective is to maintain the integrity and freshness of delicate items while minimizing waste and ensuring compliance with regulatory requirements.

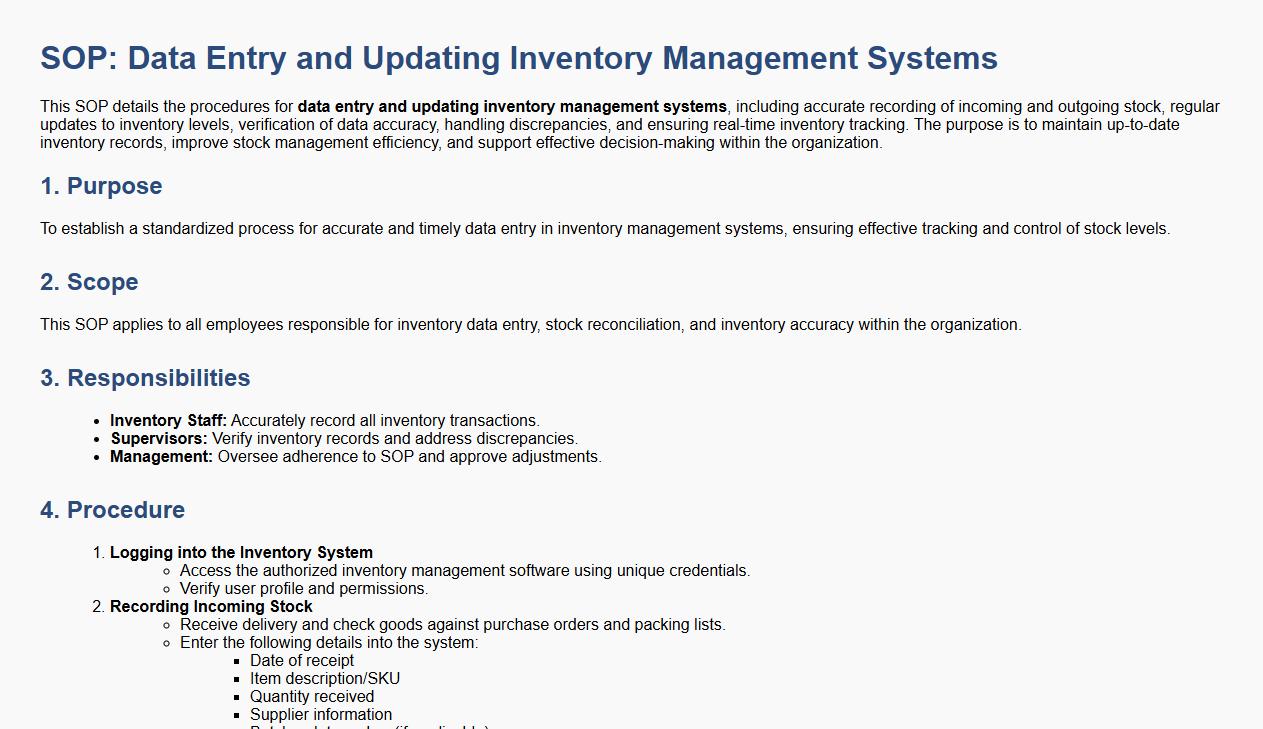

Data entry and updating inventory management systems.

This SOP details the procedures for data entry and updating inventory management systems, including accurate recording of incoming and outgoing stock, regular updates to inventory levels, verification of data accuracy, handling discrepancies, and ensuring real-time inventory tracking. The purpose is to maintain up-to-date inventory records, improve stock management efficiency, and support effective decision-making within the organization.

Proper storage and shelving of received products.

This SOP details the procedures for the proper storage and shelving of received products, including guidelines for inspecting incoming items, organizing inventory based on product type and safety requirements, using appropriate shelving and storage equipment, maintaining clean and accessible storage areas, and ensuring accurate labeling and inventory tracking to preserve product quality and facilitate efficient retrieval.

Cleaning up receiving area and finalizing receiving log/documentation.

This SOP details the process for cleaning up the receiving area and finalizing receiving log/documentation, including proper disposal of waste, sanitizing surfaces, organizing received materials, verifying and recording accurate shipment details, and ensuring all documentation is complete and correctly filed. The objective is to maintain a clean and efficient receiving area while ensuring accurate record-keeping for inventory and compliance purposes.

Key Steps for Verifying and Documenting Received Retail Products

The SOP emphasizes the importance of thorough inspection of all received retail products to ensure accuracy and quality. Staff must cross-check delivery documents against purchase orders to verify quantities and specifications. Accurate documentation is required, including logging batch numbers and expiration dates.

Handling Discrepancies or Damaged Items During Product Receiving

The SOP mandates immediate reporting of any discrepancies or damaged items to the supervisor for further evaluation. A formal discrepancy report must be completed, detailing the nature and extent of the issue. Damaged products are isolated to prevent distribution and follow established return or disposal procedures.

Safety and Compliance Procedures for Retail Product Receiving

Strict adherence to safety protocols is outlined to protect staff during the receiving process. Compliance with regulatory requirements, such as proper labeling and handling of hazardous materials, is mandatory. Personal protective equipment (PPE) must be worn as specified to prevent workplace injuries.

Roles and Responsibilities in the Receiving Process

The SOP clearly designates roles including receiving clerks, quality inspectors, and supervisors, each with distinct responsibilities. Receiving clerks handle initial product checks and logging, while inspectors verify product condition. Supervisors oversee the process and resolve any issues that arise.

Protocols for Recording and Tracking Inventory Upon Receipt

The SOP requires detailed inventory recording using electronic systems to ensure real-time accuracy. Each product entry must include quantities, supplier details, and storage location. Regular updates and audits are conducted to maintain inventory integrity and accountability.