A SOP Template for Inventory Management in Manufacturing streamlines the process of tracking raw materials, work-in-progress, and finished goods to ensure accuracy and efficiency. It establishes standardized procedures for stock counting, order replenishment, and inventory audits, minimizing errors and reducing downtime. Implementing this template improves inventory control, enhances supply chain coordination, and supports overall production performance.

Inventory receiving and inspection procedures.

This SOP details the inventory receiving and inspection procedures, covering the systematic approach to receiving goods, verifying order accuracy, inspecting items for quality and damage, documenting discrepancies, and ensuring proper storage. The objective is to maintain inventory accuracy, prevent losses, and guarantee that received products meet quality standards before being integrated into the inventory system.

Inventory labeling and barcoding standards.

This SOP defines inventory labeling and barcoding standards to ensure accurate identification, tracking, and management of inventory items. It covers labeling materials and formats, barcode symbologies, placement guidelines, scanning procedures, and quality control measures. Adhering to these standards improves inventory accuracy, streamlines stock management, reduces errors, and enhances overall operational efficiency within the supply chain and warehouse environments.

Materials storage and shelving protocols.

This SOP establishes materials storage and shelving protocols to ensure the safe, organized, and efficient handling, storage, and retrieval of materials. It includes guidelines for proper shelving installation, weight limits, labeling, inventory management, safe stacking practices, and regular inspection schedules. The protocol aims to minimize damage, prevent accidents, maximize space utilization, and maintain a safe working environment for all personnel.

Inventory issuing and withdrawal documentation.

This SOP details the procedures for inventory issuing and withdrawal documentation, including accurate recording of inventory items, authorization protocols, withdrawal approval processes, and proper documentation to maintain inventory control. The goal is to ensure accountability, prevent discrepancies, and streamline inventory management by establishing standardized practices for issuing and withdrawing materials.

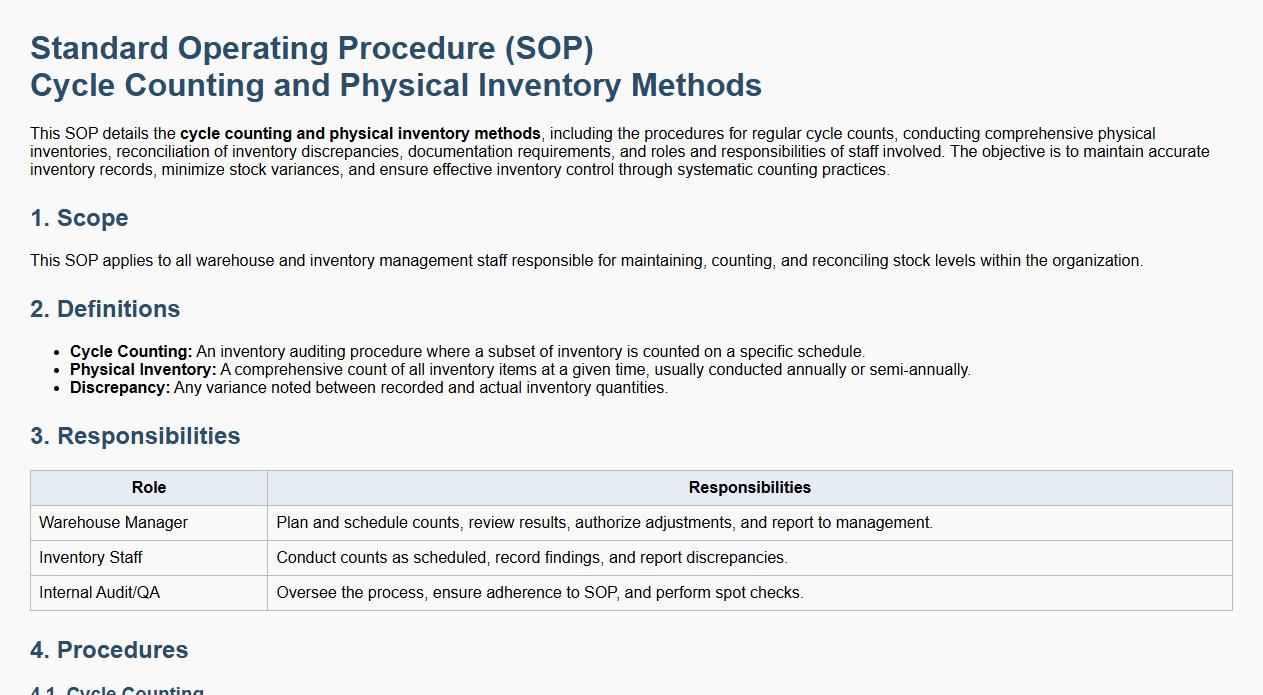

Cycle counting and physical inventory methods.

This SOP details the cycle counting and physical inventory methods, including the procedures for regular cycle counts, conducting comprehensive physical inventories, reconciliation of inventory discrepancies, documentation requirements, and roles and responsibilities of staff involved. The objective is to maintain accurate inventory records, minimize stock variances, and ensure effective inventory control through systematic counting practices.

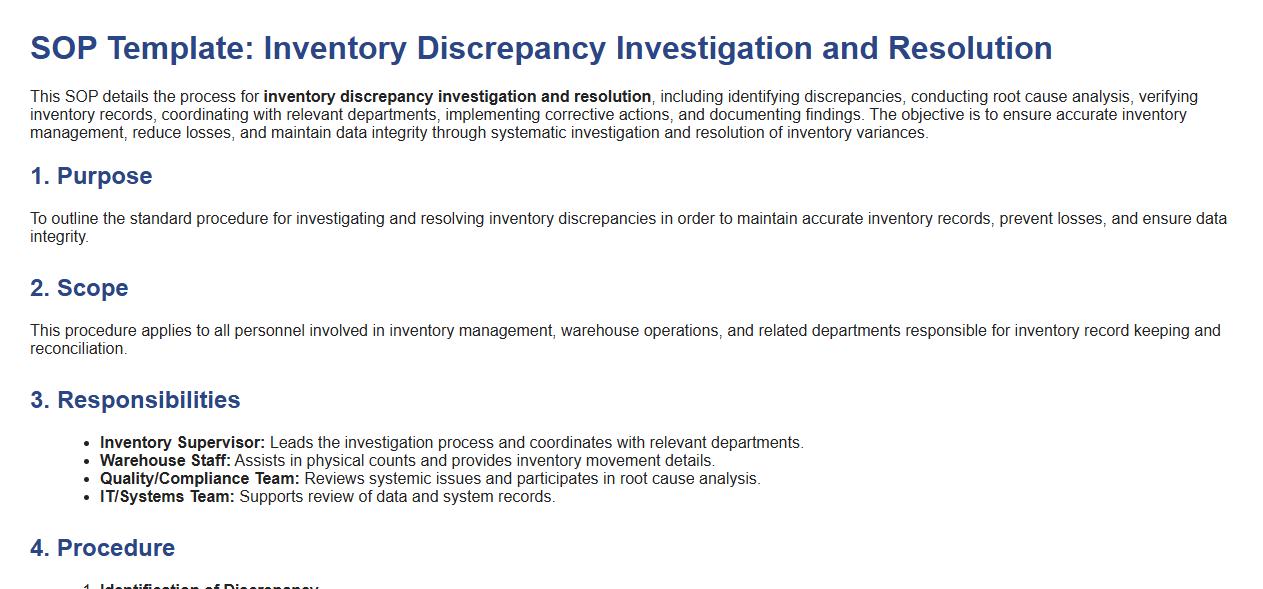

Inventory discrepancy investigation and resolution.

This SOP details the process for inventory discrepancy investigation and resolution, including identifying discrepancies, conducting root cause analysis, verifying inventory records, coordinating with relevant departments, implementing corrective actions, and documenting findings. The objective is to ensure accurate inventory management, reduce losses, and maintain data integrity through systematic investigation and resolution of inventory variances.

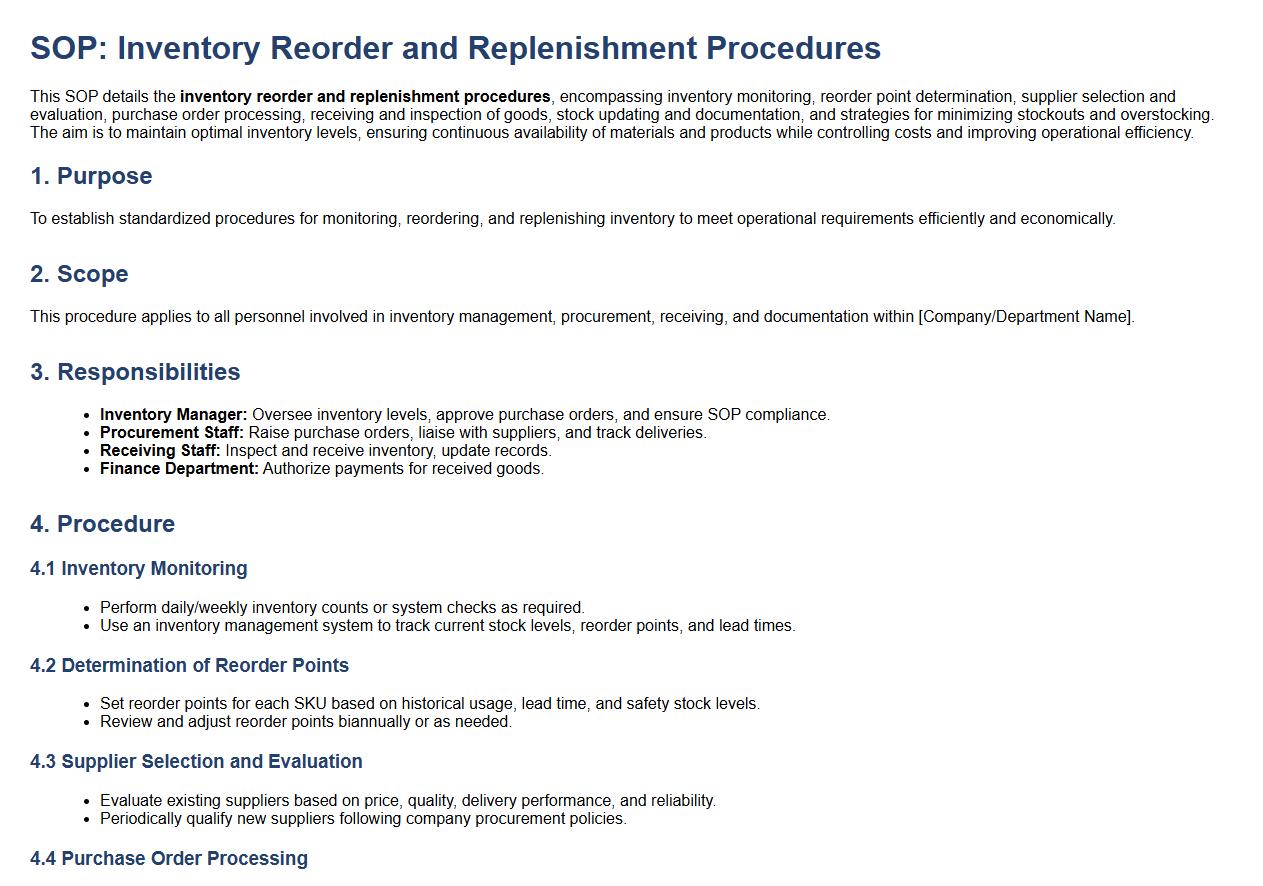

Inventory reorder and replenishment procedures.

This SOP details the inventory reorder and replenishment procedures, encompassing inventory monitoring, reorder point determination, supplier selection and evaluation, purchase order processing, receiving and inspection of goods, stock updating and documentation, and strategies for minimizing stockouts and overstocking. The aim is to maintain optimal inventory levels, ensuring continuous availability of materials and products while controlling costs and improving operational efficiency.

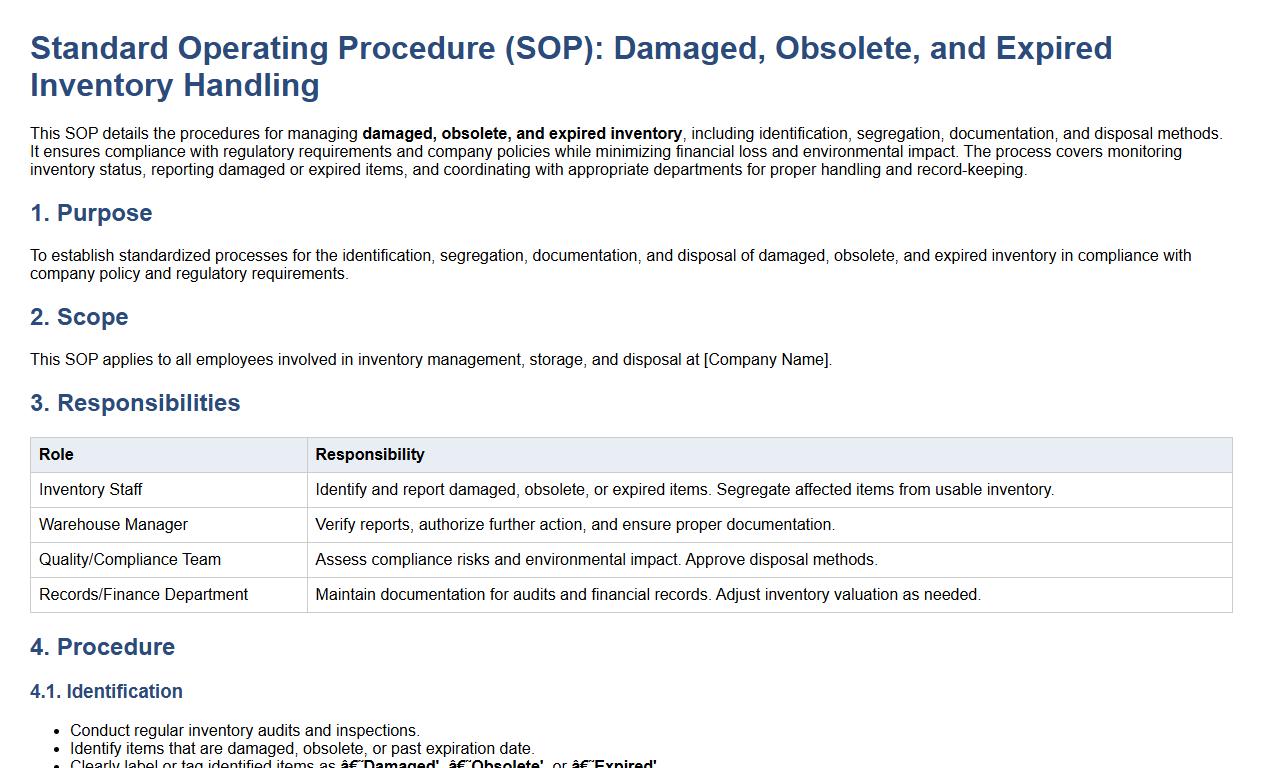

Damaged, obsolete, and expired inventory handling.

This SOP details the procedures for managing damaged, obsolete, and expired inventory, including identification, segregation, documentation, and disposal methods. It ensures compliance with regulatory requirements and company policies while minimizing financial loss and environmental impact. The process covers monitoring inventory status, reporting damaged or expired items, and coordinating with appropriate departments for proper handling and record-keeping.

Inventory record-keeping and reporting requirements.

This SOP defines the inventory record-keeping and reporting requirements to ensure accurate tracking, management, and accountability of all inventory items. It covers procedures for documenting inventory receipts, adjustments, transfers, and disposals, as well as maintaining up-to-date records in accordance with company policies and regulatory standards. The SOP also outlines reporting protocols for inventory status, discrepancies, and periodic audits to support operational efficiency and financial integrity.

Inventory security and access control guidelines.

This SOP establishes inventory security and access control guidelines to safeguard company assets, prevent unauthorized access, and maintain accurate inventory records. It includes procedures for controlling entry to storage areas, employee access permissions, monitoring and auditing inventory movements, secure handling of stock, and incident response protocols to ensure the integrity and security of inventory at all times.

What defines the procedures for inventory receipt, storage, and issuance in the SOP document?

The SOP document outlines standardized procedures for inventory receipt, ensuring all items are checked and verified upon arrival. It specifies proper storage methods to maintain organization and product integrity. Additionally, it details issuance protocols to ensure accurate distribution and record-keeping.

How are inventory discrepancies identified and resolved according to the protocol?

The protocol includes regular inventory audits to detect discrepancies between recorded and physical stock. Discrepancies are documented and investigated immediately to identify causes such as errors or theft. Resolution steps involve adjustments, reporting to management, and implementing corrective actions.

What are the documented methods for tracking inventory levels and movements?

Inventory tracking methods in the SOP encompass the use of inventory management systems and detailed logbooks. Movements are recorded at each stage, from receipt to issuance, to maintain real-time stock visibility. Periodic reviews ensure data integrity and update records as needed.

Which roles and responsibilities are outlined for personnel managing inventory?

The SOP clearly defines roles such as inventory clerks, supervisors, and auditors, assigning specific duties to each. Personnel are responsible for accurate recording, monitoring stock levels, and conducting regular checks. Accountability is emphasized to maintain operational efficiency and control.

What are the documented controls for ensuring inventory accuracy and preventing loss or theft?

Controls include secure storage areas, authorization protocols, and surveillance measures documented in the SOP. Regular audits and inventory reconciliations are mandated to detect irregularities. Training employees on compliance and security procedures further minimizes risks of loss or theft.