A SOP Template for Equipment Maintenance in Manufacturing outlines standardized procedures to ensure consistent and efficient upkeep of machinery. This template helps reduce downtime, extend equipment lifespan, and maintain safety standards across production lines. Clear instructions and documentation within the template facilitate compliance and streamline maintenance operations.

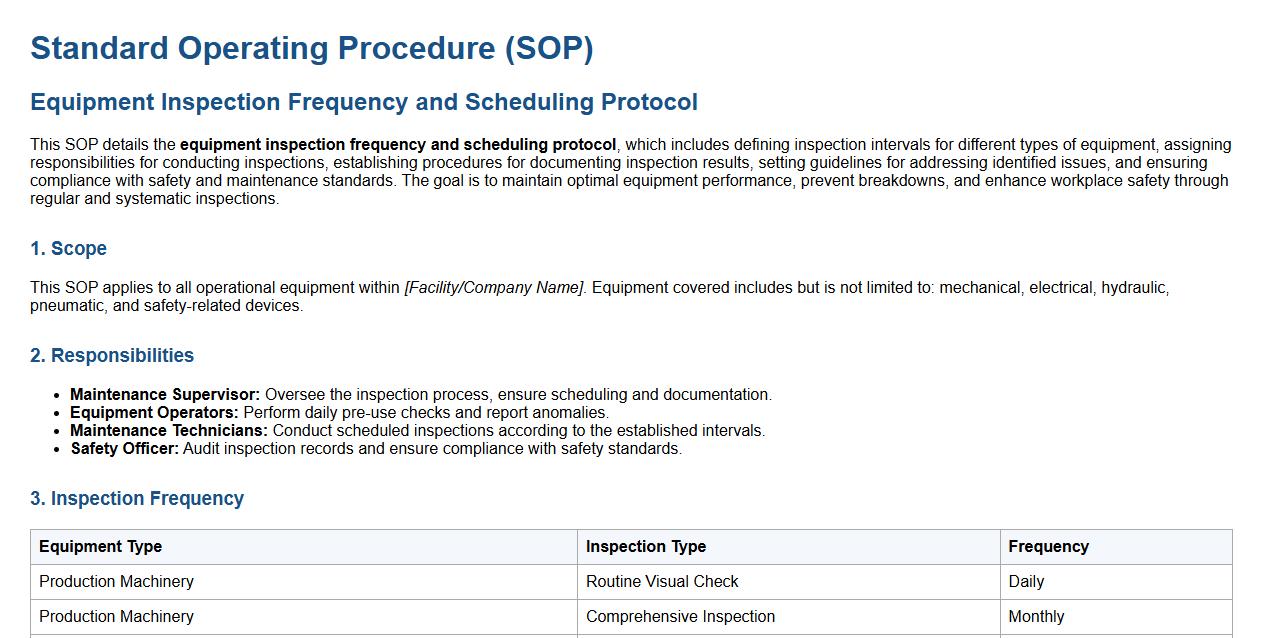

Equipment inspection frequency and scheduling protocol.

This SOP details the equipment inspection frequency and scheduling protocol, which includes defining inspection intervals for different types of equipment, assigning responsibilities for conducting inspections, establishing procedures for documenting inspection results, setting guidelines for addressing identified issues, and ensuring compliance with safety and maintenance standards. The goal is to maintain optimal equipment performance, prevent breakdowns, and enhance workplace safety through regular and systematic inspections.

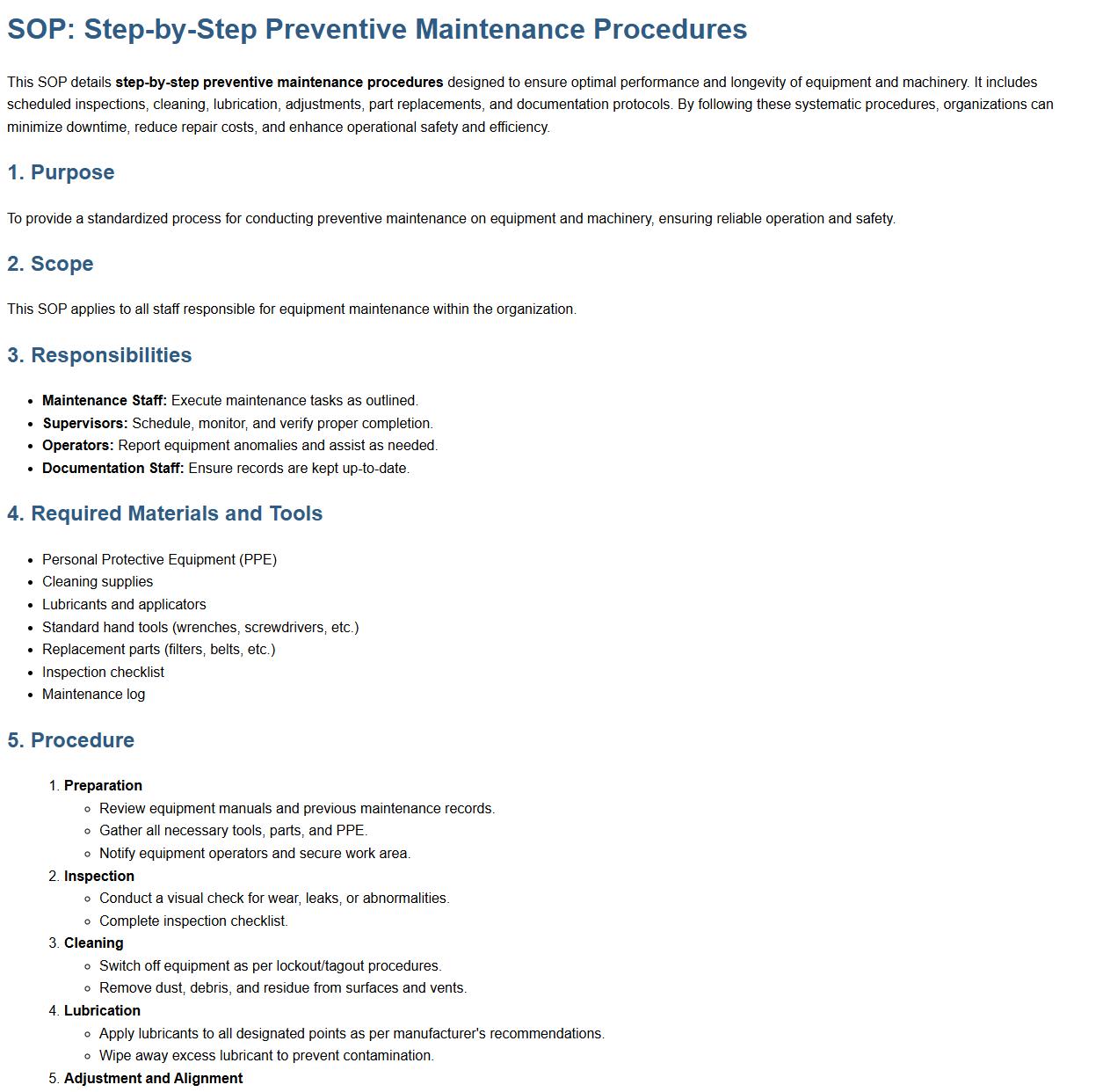

Step-by-step preventive maintenance procedures.

This SOP details step-by-step preventive maintenance procedures designed to ensure optimal performance and longevity of equipment and machinery. It includes scheduled inspections, cleaning, lubrication, adjustments, part replacements, and documentation protocols. By following these systematic procedures, organizations can minimize downtime, reduce repair costs, and enhance operational safety and efficiency.

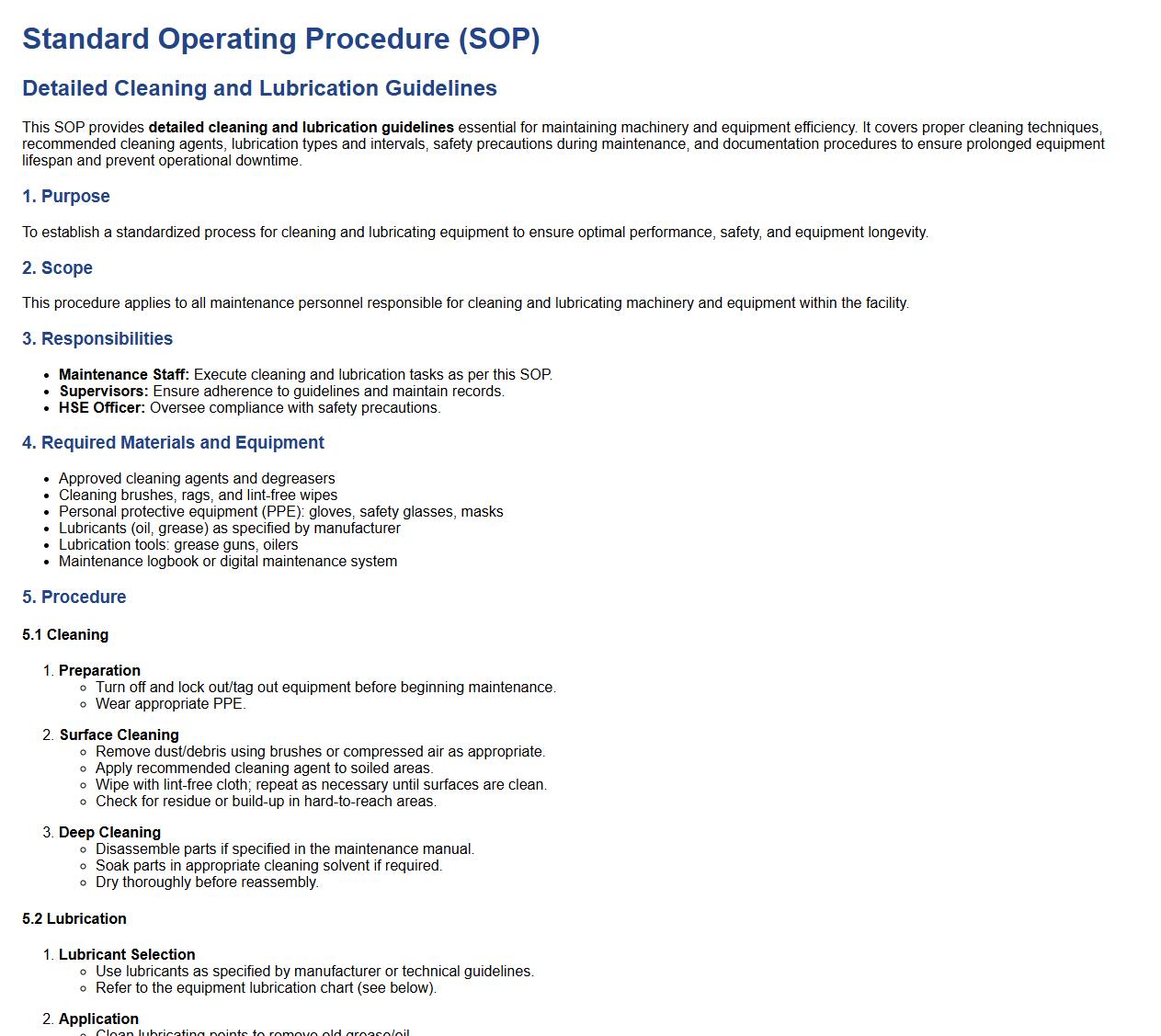

Detailed cleaning and lubrication guidelines.

This SOP provides detailed cleaning and lubrication guidelines essential for maintaining machinery and equipment efficiency. It covers proper cleaning techniques, recommended cleaning agents, lubrication types and intervals, safety precautions during maintenance, and documentation procedures to ensure prolonged equipment lifespan and prevent operational downtime.

Standard process for reporting equipment faults and malfunctions.

This SOP details the standard process for reporting equipment faults and malfunctions, including identification of issues, proper documentation, immediate notification protocols, troubleshooting steps, and escalation procedures. The goal is to ensure timely and efficient handling of equipment problems to minimize downtime, maintain safety standards, and support continuous operational productivity.

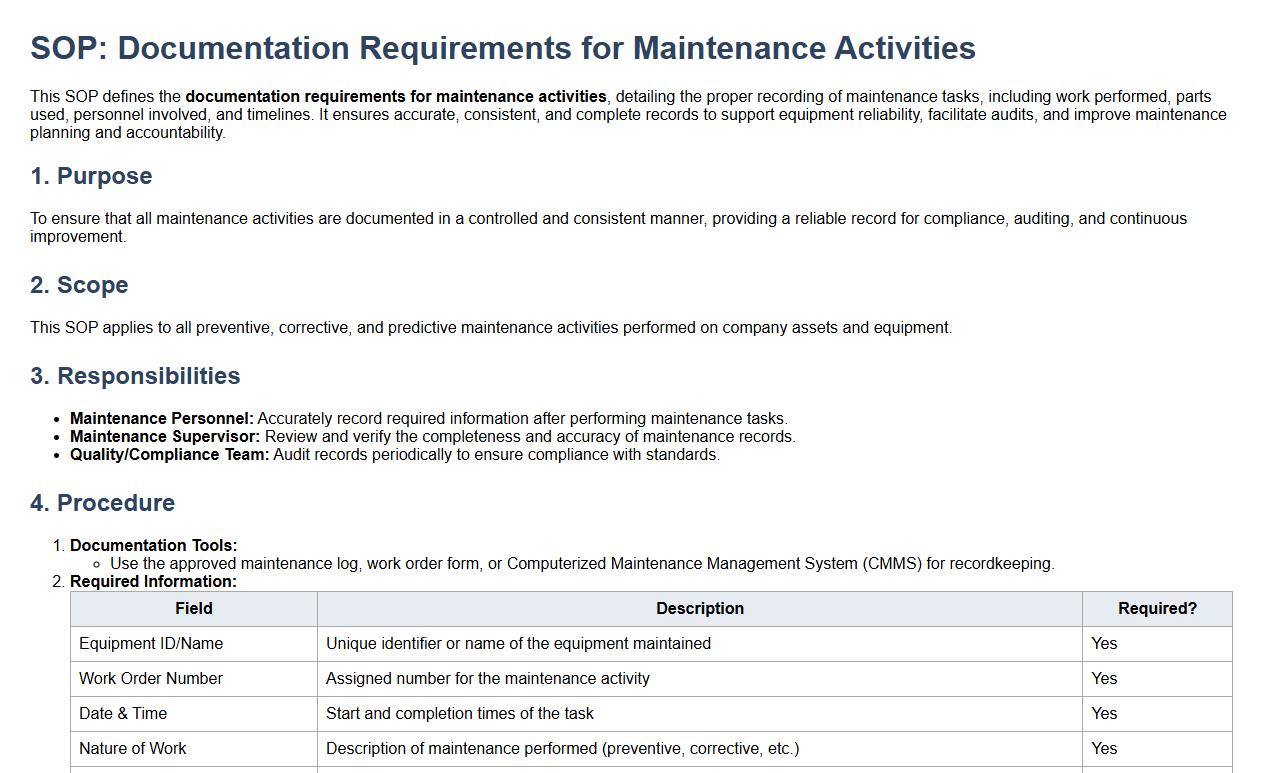

Documentation requirements for maintenance activities.

This SOP defines the documentation requirements for maintenance activities, detailing the proper recording of maintenance tasks, including work performed, parts used, personnel involved, and timelines. It ensures accurate, consistent, and complete records to support equipment reliability, facilitate audits, and improve maintenance planning and accountability.

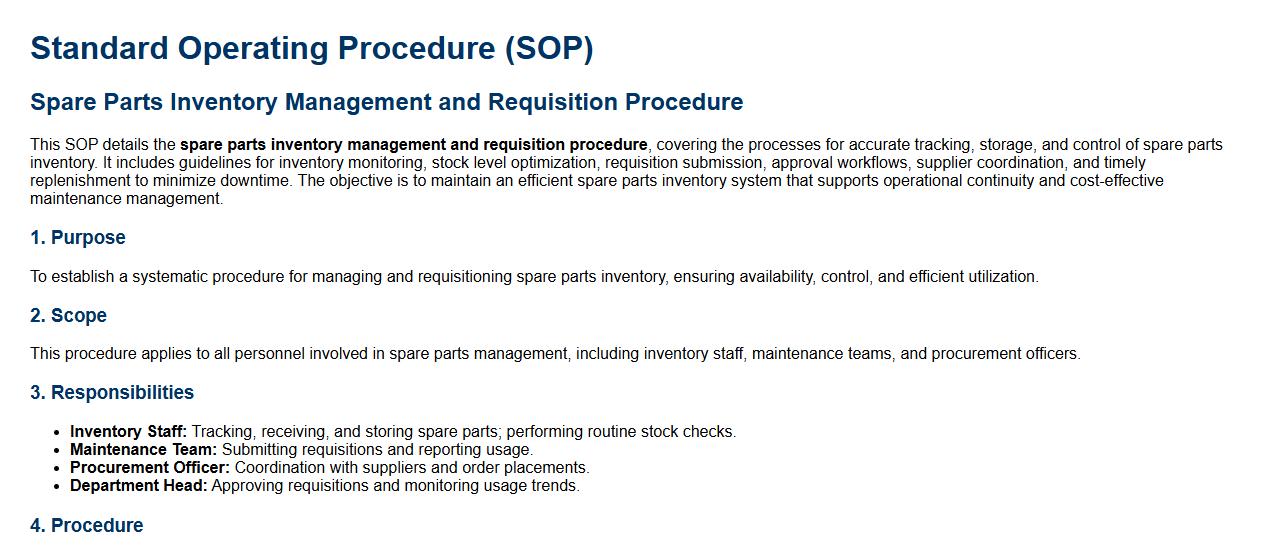

Spare parts inventory management and requisition procedure.

This SOP details the spare parts inventory management and requisition procedure, covering the processes for accurate tracking, storage, and control of spare parts inventory. It includes guidelines for inventory monitoring, stock level optimization, requisition submission, approval workflows, supplier coordination, and timely replenishment to minimize downtime. The objective is to maintain an efficient spare parts inventory system that supports operational continuity and cost-effective maintenance management.

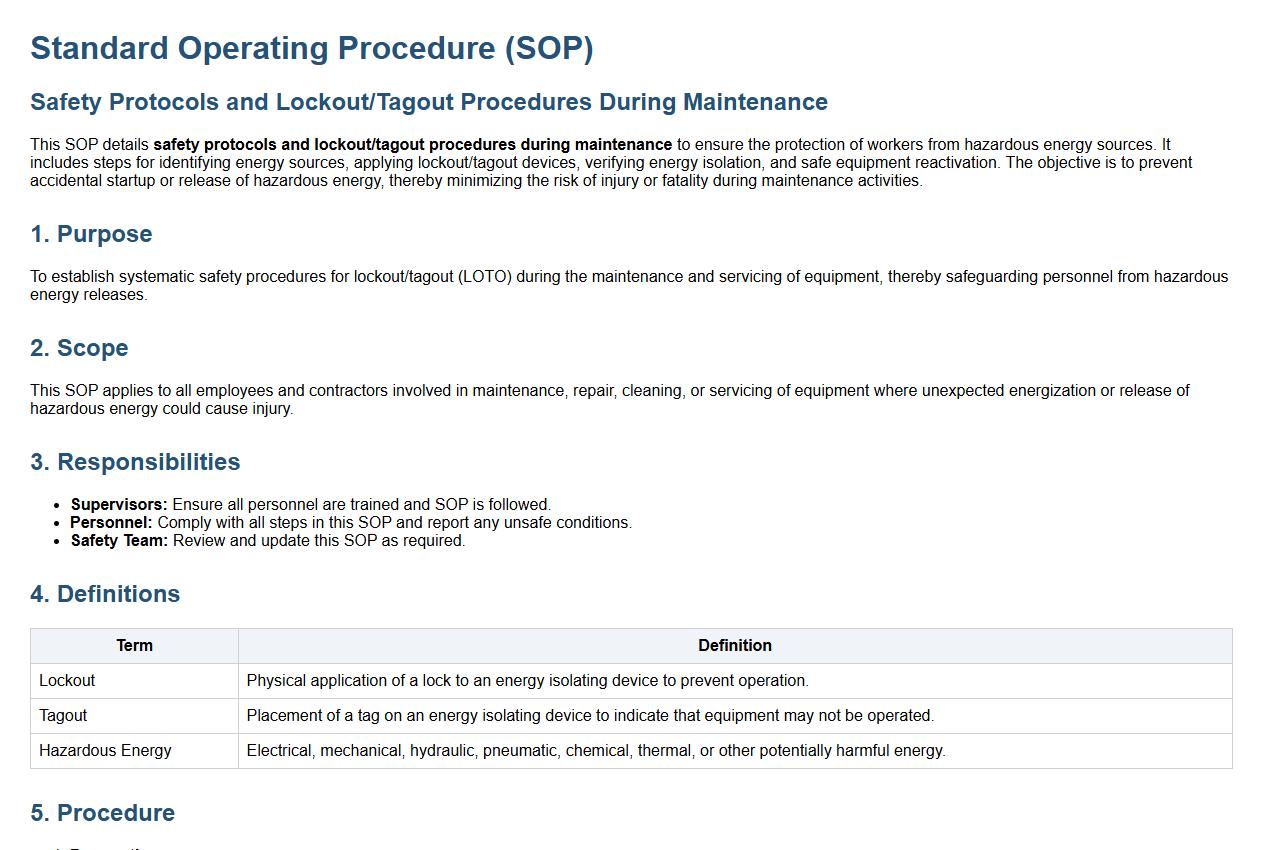

Safety protocols and lockout/tagout procedures during maintenance.

This SOP details safety protocols and lockout/tagout procedures during maintenance to ensure the protection of workers from hazardous energy sources. It includes steps for identifying energy sources, applying lockout/tagout devices, verifying energy isolation, and safe equipment reactivation. The objective is to prevent accidental startup or release of hazardous energy, thereby minimizing the risk of injury or fatality during maintenance activities.

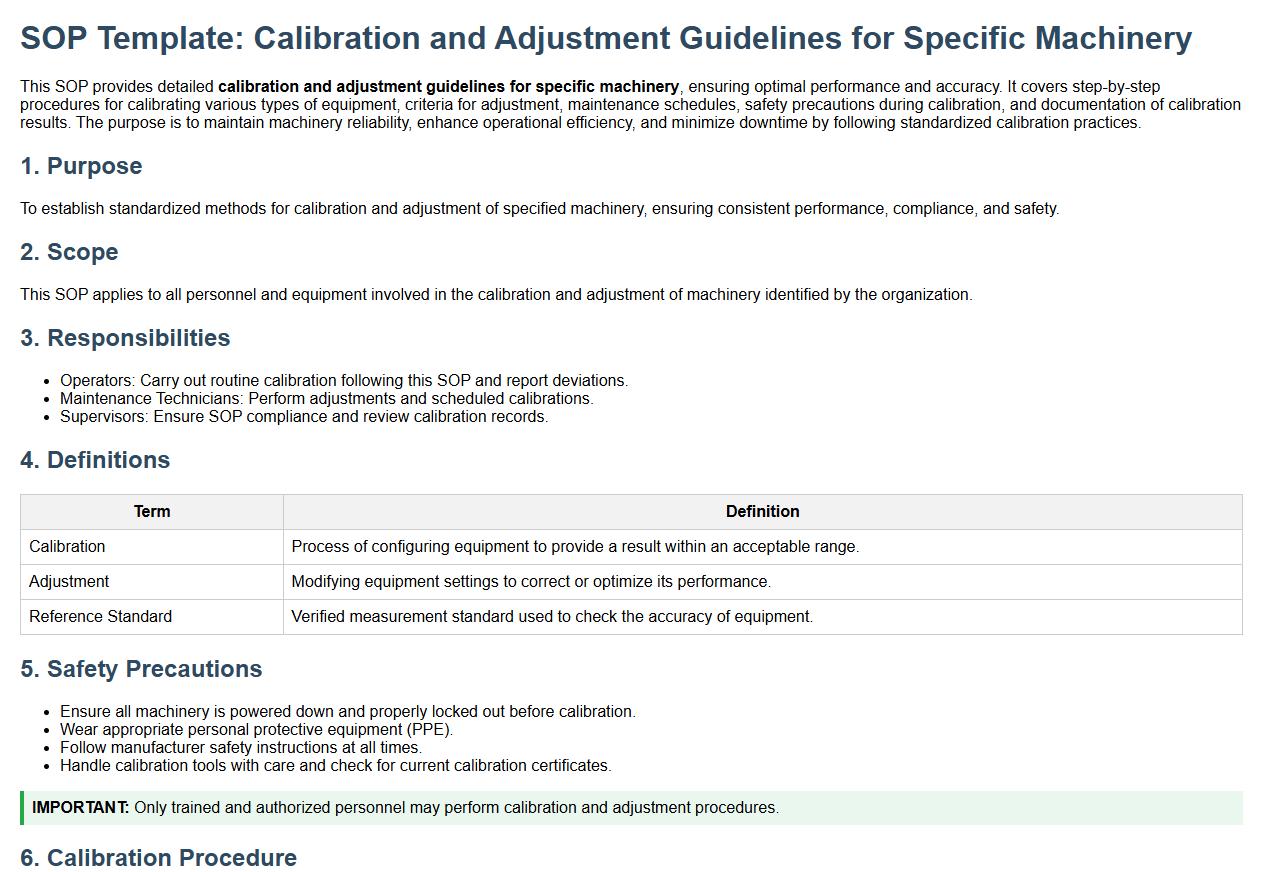

Calibration and adjustment guidelines for specific machinery.

This SOP provides detailed calibration and adjustment guidelines for specific machinery, ensuring optimal performance and accuracy. It covers step-by-step procedures for calibrating various types of equipment, criteria for adjustment, maintenance schedules, safety precautions during calibration, and documentation of calibration results. The purpose is to maintain machinery reliability, enhance operational efficiency, and minimize downtime by following standardized calibration practices.

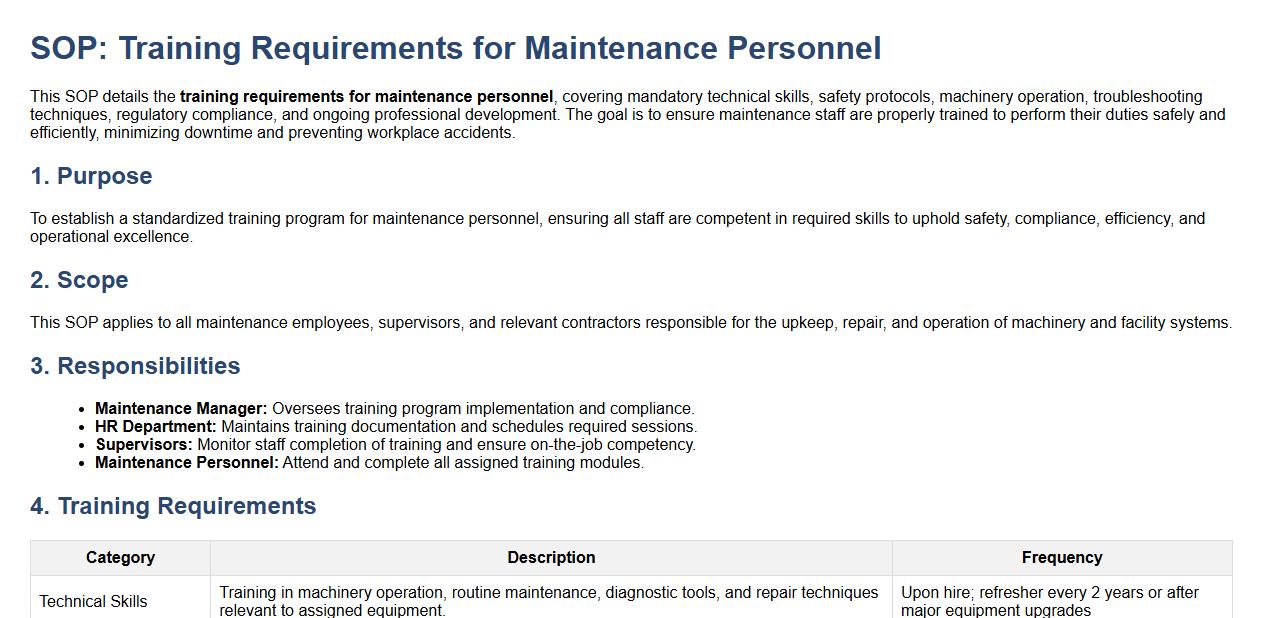

Training requirements for maintenance personnel.

This SOP details the training requirements for maintenance personnel, covering mandatory technical skills, safety protocols, machinery operation, troubleshooting techniques, regulatory compliance, and ongoing professional development. The goal is to ensure maintenance staff are properly trained to perform their duties safely and efficiently, minimizing downtime and preventing workplace accidents.

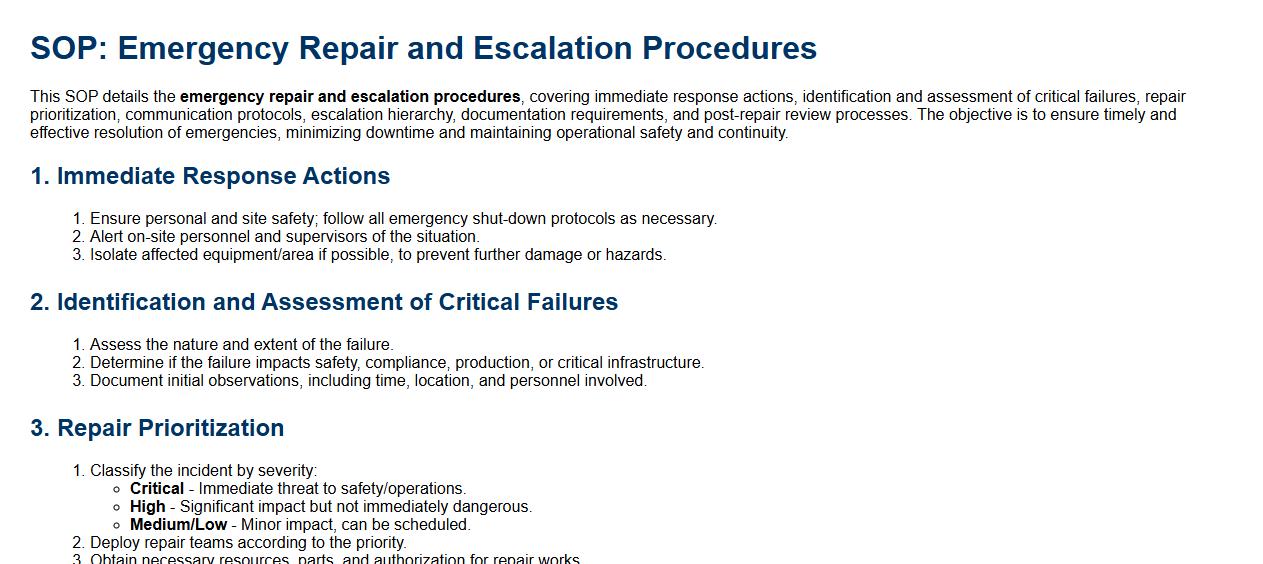

Emergency repair and escalation procedures.

This SOP details the emergency repair and escalation procedures, covering immediate response actions, identification and assessment of critical failures, repair prioritization, communication protocols, escalation hierarchy, documentation requirements, and post-repair review processes. The objective is to ensure timely and effective resolution of emergencies, minimizing downtime and maintaining operational safety and continuity.

What is the primary objective of the SOP for Equipment Maintenance in Manufacturing?

The primary objective of the SOP for Equipment Maintenance is to ensure the consistent and effective upkeep of manufacturing equipment. This process minimizes downtime and maximizes equipment lifespan through standardized maintenance practices. Additionally, it aims to improve operational efficiency and product quality by preventing unexpected equipment failures.

Which personnel are responsible for executing and documenting equipment maintenance tasks?

Qualified maintenance technicians and engineers are typically responsible for executing equipment maintenance tasks. Supervisors oversee the process to ensure adherence to SOP guidelines. Documentation of all maintenance activities is completed by the assigned personnel to maintain accurate records of equipment conditions and interventions.

What specific procedures are outlined for routine, preventive, and corrective maintenance?

The SOP details routine maintenance procedures, such as inspections and cleaning, to keep equipment functioning optimally. Preventive maintenance includes scheduled servicing and parts replacement to avoid breakdowns. Corrective maintenance procedures address repair actions required after detecting faults or failures during operation.

How are maintenance schedules and equipment status tracked and updated in the SOP?

The SOP requires the use of a maintenance schedule system to plan and track all maintenance activities. Equipment status is regularly updated in logs or digital management systems to reflect current operational conditions. This ensures timely interventions and provides transparency for audit and review purposes.

What safety and compliance requirements are specified for maintenance activities in the SOP?

The SOP emphasizes adherence to safety protocols such as lockout/tagout procedures and use of personal protective equipment. Compliance with industry standards and regulations ensures safe working conditions and legal adherence. Additionally, risk assessments and hazard identifications are integral parts of maintenance planning.