A SOP Template for Packaging and Shipping ensures consistent and efficient handling of products from the packaging stage to delivery. This template outlines standardized procedures to maintain product quality, accuracy, and safety during transit. Implementing a well-structured SOP minimizes errors and enhances overall supply chain reliability.

Order verification and documentation procedures.

This SOP details the order verification and documentation procedures, encompassing the processes for confirming customer orders, validating order accuracy, updating inventory records, generating and maintaining order documentation, and ensuring compliance with company policies. The objective is to streamline order processing, minimize errors, and enhance customer satisfaction through systematic verification and thorough record-keeping.

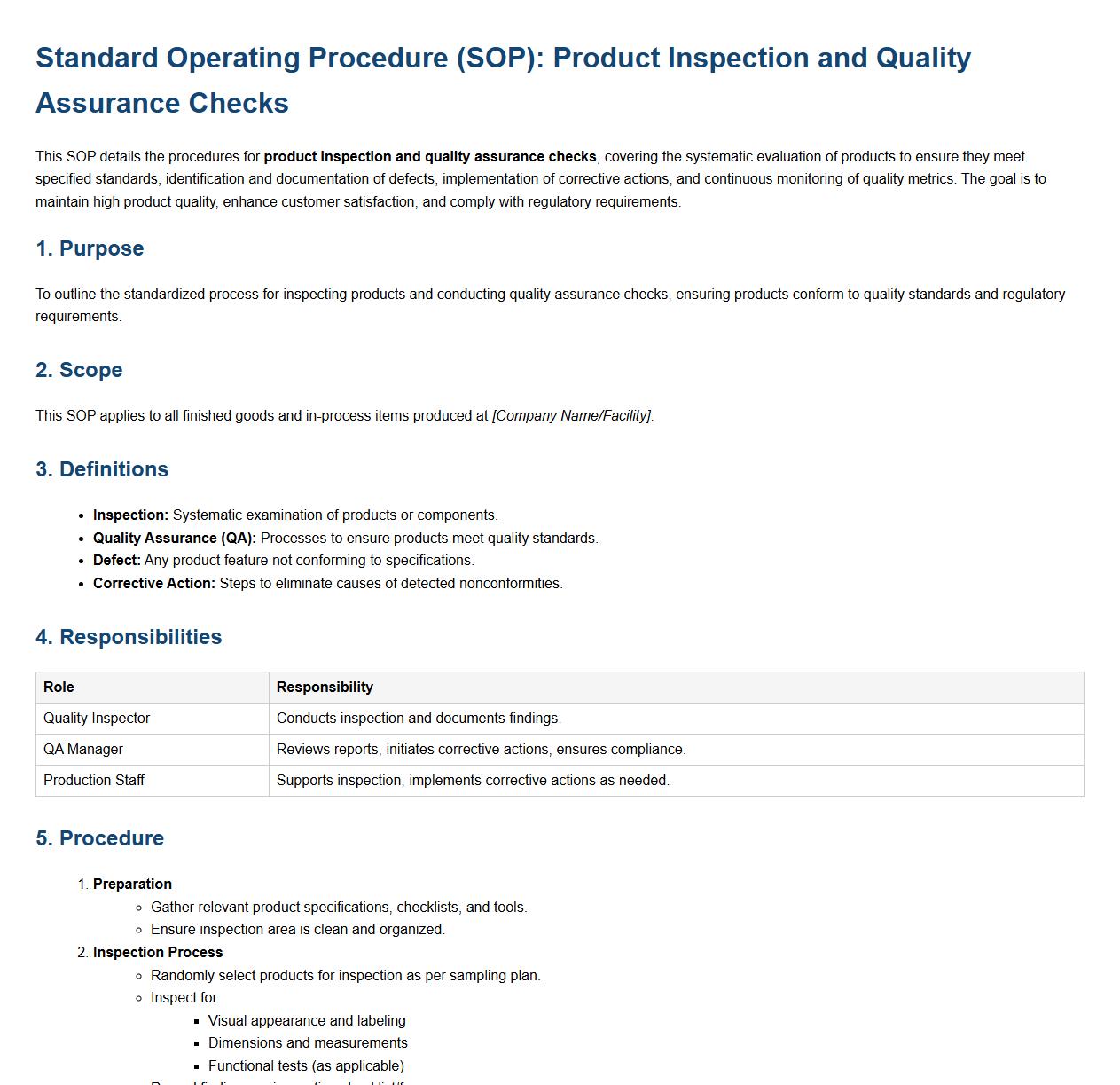

Product inspection and quality assurance checks.

This SOP details the procedures for product inspection and quality assurance checks, covering the systematic evaluation of products to ensure they meet specified standards, identification and documentation of defects, implementation of corrective actions, and continuous monitoring of quality metrics. The goal is to maintain high product quality, enhance customer satisfaction, and comply with regulatory requirements.

Packaging material selection and preparation.

This SOP details the process of packaging material selection and preparation, covering criteria for choosing appropriate packaging materials based on product type, durability, and environmental factors. It includes guidelines for inspecting, handling, and preparing materials to ensure optimal protection during storage and transportation. The objective is to maintain product integrity, comply with industry standards, and minimize waste through efficient packaging practices.

Standardized product packing techniques.

This SOP details standardized product packing techniques to ensure consistency, protection, and efficiency in packaging processes. It covers material selection, packing methods, labeling standards, quality checks, and handling procedures to maintain product integrity during storage and transportation. The objective is to optimize packaging operations, reduce damage, and enhance customer satisfaction through reliable and uniform packing practices.

Labeling and barcoding processes.

This SOP defines the labeling and barcoding processes to ensure accurate identification and tracking of products throughout the supply chain. It covers label creation standards, barcode generation, placement guidelines, quality control checks, and documentation requirements. The objective is to enhance inventory management, reduce errors, and facilitate efficient product traceability from production to delivery.

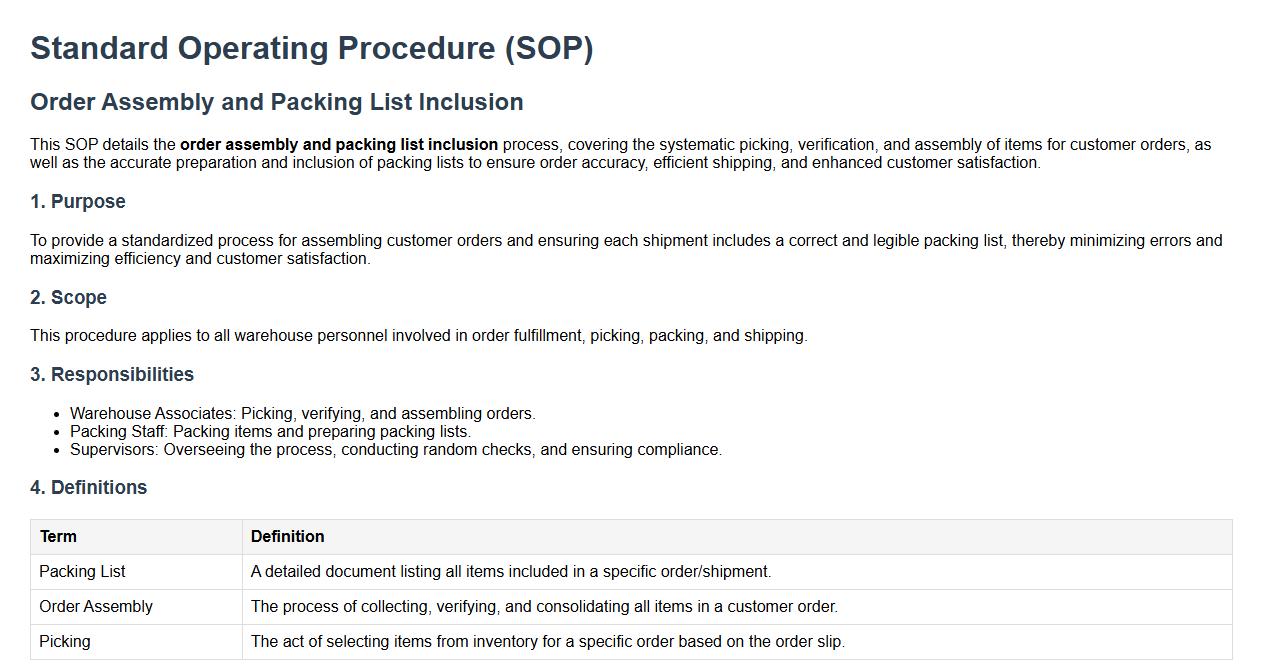

Order assembly and packing list inclusion.

This SOP details the order assembly and packing list inclusion process, covering the systematic picking, verification, and assembly of items for customer orders, as well as the accurate preparation and inclusion of packing lists to ensure order accuracy, efficient shipping, and enhanced customer satisfaction.

Handling special shipping instructions or fragile items.

This SOP details the procedures for handling special shipping instructions or fragile items, including receiving and reviewing shipping requirements, proper packaging techniques, labeling and documentation, communication with carriers, and monitoring during transit. The goal is to ensure the safe and secure delivery of sensitive or delicate goods while minimizing damage and meeting customer expectations through standardized handling and shipping protocols.

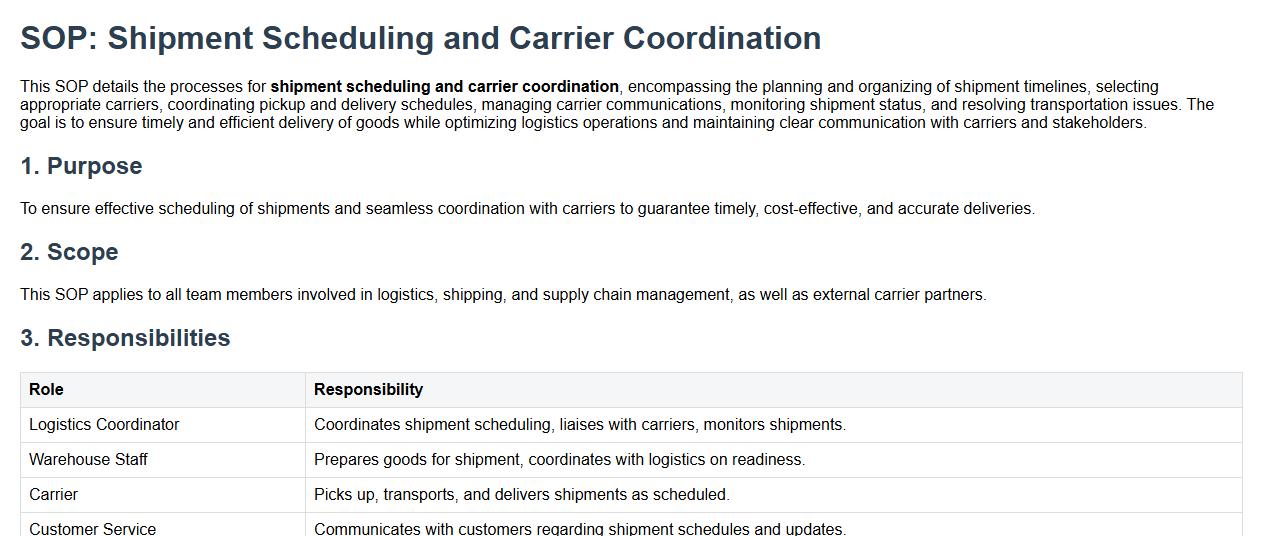

Shipment scheduling and carrier coordination.

This SOP details the processes for shipment scheduling and carrier coordination, encompassing the planning and organizing of shipment timelines, selecting appropriate carriers, coordinating pickup and delivery schedules, managing carrier communications, monitoring shipment status, and resolving transportation issues. The goal is to ensure timely and efficient delivery of goods while optimizing logistics operations and maintaining clear communication with carriers and stakeholders.

Final pre-shipment inspection and approval.

This SOP details the process for final pre-shipment inspection and approval, including thorough product quality checks, verification against order specifications, packaging integrity assessment, compliance with regulatory standards, documentation review, and final authorization for shipment. The objective is to ensure that all products meet the required quality and safety criteria before dispatch, minimizing risks of defects and customer dissatisfaction.

Package handover, tracking, and record maintenance.

This SOP details the procedures for package handover, tracking, and record maintenance, covering the systematic transfer of packages between personnel, accurate tracking through designated tools or software, and diligent record-keeping to ensure accountability and traceability. The aim is to streamline the logistics process, reduce errors, and maintain comprehensive documentation for audit and reporting purposes.

What are the mandatory labeling requirements specified in the SOP for packaging and shipping?

The SOP mandates that all packages must include a clear and accurate label identifying the product name, batch number, and expiration date. Labels must be resistant to environmental factors such as moisture and abrasion to maintain readability throughout transit. Additionally, special handling instructions must be prominently displayed to ensure proper care during shipping and delivery.

Which packaging materials are approved according to the SOP for different product categories?

The SOP specifies that approved packaging materials vary based on product sensitivity and category, including tamper-evident seals for pharmaceuticals. Fragile items require cushioned materials such as foam or bubble wrap, while temperature-sensitive products must be packaged with insulated containers. Only materials that comply with regulatory and safety standards are permitted for use in packaging.

What steps must be followed to verify product integrity before shipment as per the SOP?

Before shipment, the SOP requires a thorough inspection to confirm the product's physical condition and completeness, ensuring there are no defects or discrepancies. Documentation such as quality checklists and verification reports must be completed and signed off by authorized personnel. Any inconsistencies or damages must be reported and addressed prior to dispatch.

What documentation needs to accompany each shipment under the SOP guidelines?

Each shipment must include comprehensive documentation such as packing lists, certificates of analysis, and shipping manifests as outlined in the SOP. These documents ensure traceability and compliance with regulatory requirements throughout the supply chain. In addition, any special permits or import/export certificates must be included when applicable.

What are the SOP-defined procedures for addressing damaged or compromised packages during shipping?

The SOP mandates immediate reporting and documentation of any damaged or compromised packages upon receipt or discovery during transit. A detailed damage report must be prepared, and the incident communicated to the logistics team for investigation and corrective action. Replacement or re-shipment procedures are then initiated in accordance with quality assurance standards.