A SOP Template for Lean Manufacturing Implementation provides a structured framework to standardize processes and enhance efficiency by eliminating waste. It outlines essential steps, roles, and responsibilities to ensure consistent application of lean principles across production lines. This template serves as a vital tool to drive continuous improvement and maintain operational excellence in manufacturing environments.

Lean assessment and value stream mapping procedures.

This SOP details the lean assessment and value stream mapping procedures, including steps for identifying waste, analyzing current processes, mapping value streams, prioritizing improvement opportunities, and implementing lean principles to enhance operational efficiency. The goal is to streamline workflows, reduce inefficiencies, and maximize value delivery to customers through systematic assessment and continuous improvement.

Standardized work documentation and update protocols.

This SOP details the standardized work documentation and update protocols, covering the procedures for creating, maintaining, and regularly updating work instructions and documentation. It aims to ensure consistency, accuracy, and accessibility of all work-related documents by establishing clear guidelines for version control, review schedules, employee training on documentation standards, and communication of updates. This protocol supports operational efficiency, quality assurance, and compliance with organizational and regulatory requirements.

5S workplace organization and audit checklist.

This SOP details the implementation and maintenance of the 5S workplace organization methodology, including Sort, Set in order, Shine, Standardize, and Sustain. It provides a comprehensive audit checklist to assess the organization, cleanliness, and efficiency of the workspace, ensuring a safe, productive, and orderly environment. The purpose is to promote continuous improvement, enhance operational efficiency, reduce waste, and foster a culture of discipline and accountability in the workplace.

Daily production and process monitoring routines.

This SOP details the daily production and process monitoring routines, outlining systematic checks and documentation practices to ensure optimal operational efficiency, product quality, and adherence to safety standards. It covers routine inspection of equipment, verification of production parameters, real-time data recording, identification and resolution of deviations, and communication protocols for reporting anomalies. The objective is to maintain consistent production flow, minimize downtime, and uphold regulatory compliance through vigilant and proactive monitoring.

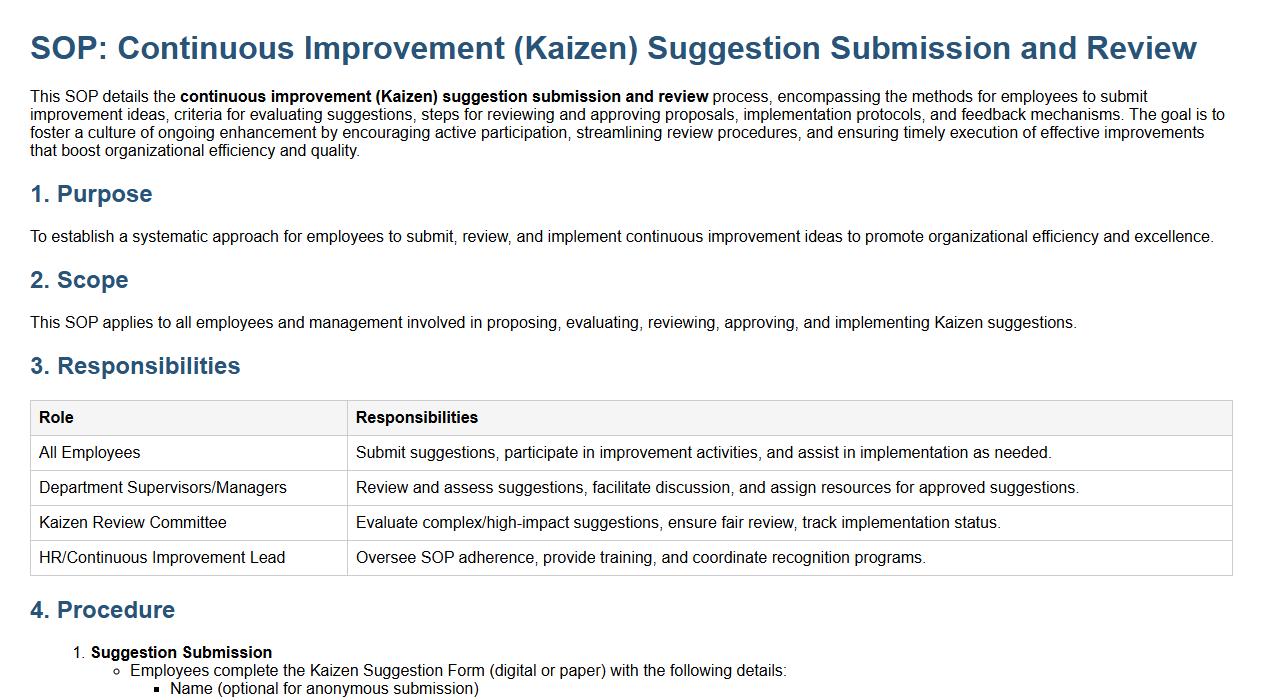

Continuous improvement (Kaizen) suggestion submission and review.

This SOP details the continuous improvement (Kaizen) suggestion submission and review process, encompassing the methods for employees to submit improvement ideas, criteria for evaluating suggestions, steps for reviewing and approving proposals, implementation protocols, and feedback mechanisms. The goal is to foster a culture of ongoing enhancement by encouraging active participation, streamlining review procedures, and ensuring timely execution of effective improvements that boost organizational efficiency and quality.

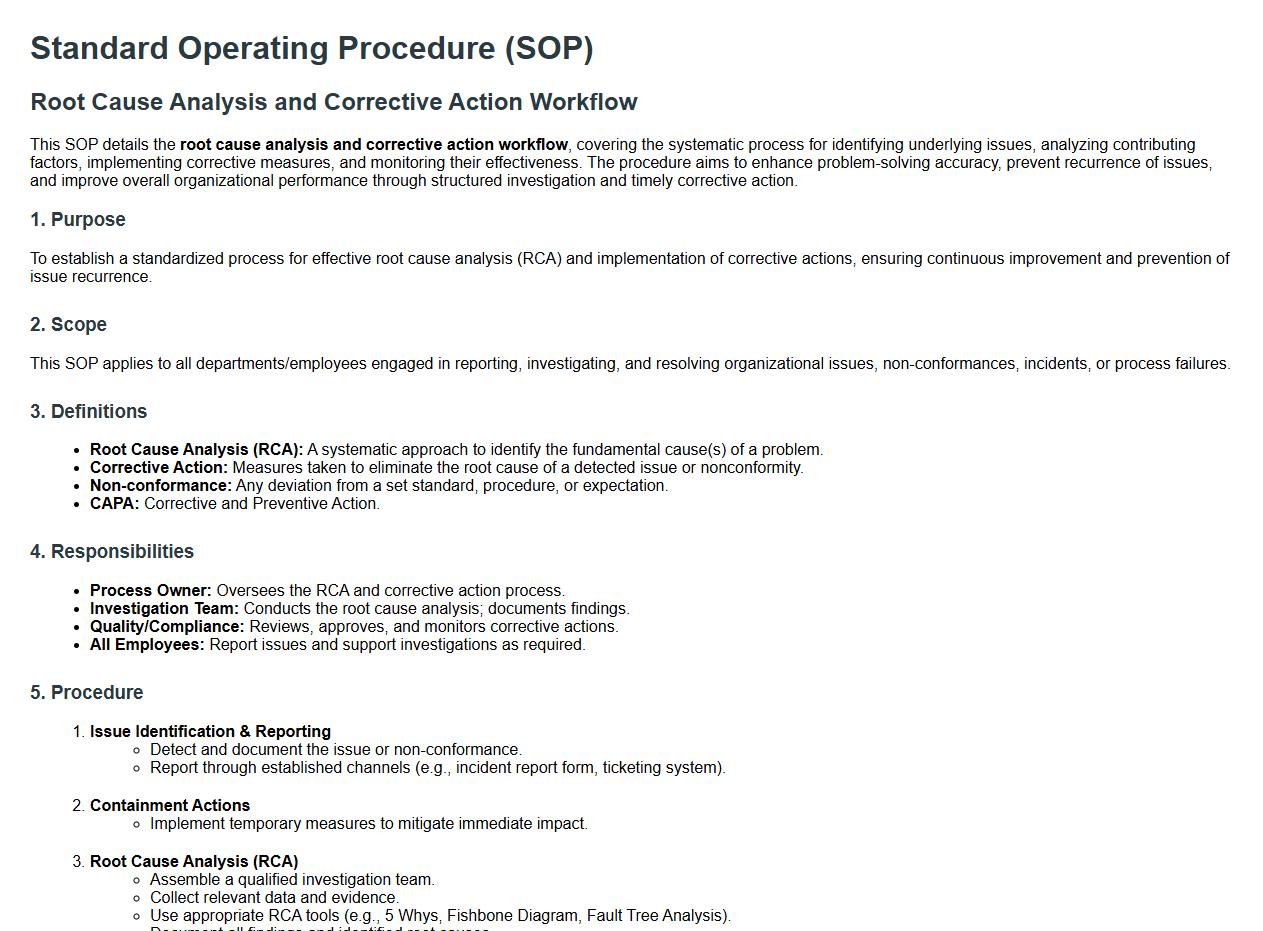

Root cause analysis and corrective action workflow.

This SOP details the root cause analysis and corrective action workflow, covering the systematic process for identifying underlying issues, analyzing contributing factors, implementing corrective measures, and monitoring their effectiveness. The procedure aims to enhance problem-solving accuracy, prevent recurrence of issues, and improve overall organizational performance through structured investigation and timely corrective action.

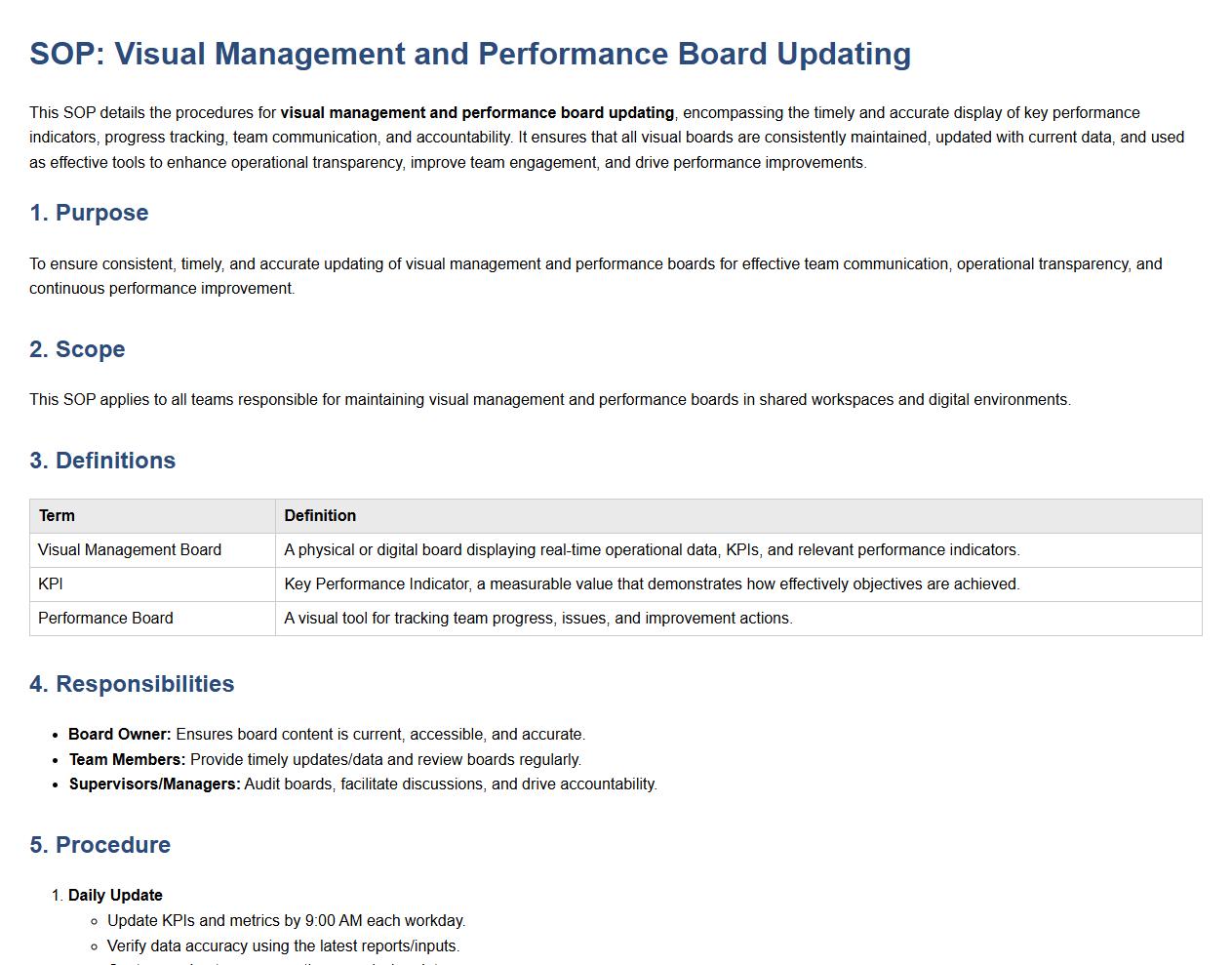

Visual management and performance board updating.

This SOP details the procedures for visual management and performance board updating, encompassing the timely and accurate display of key performance indicators, progress tracking, team communication, and accountability. It ensures that all visual boards are consistently maintained, updated with current data, and used as effective tools to enhance operational transparency, improve team engagement, and drive performance improvements.

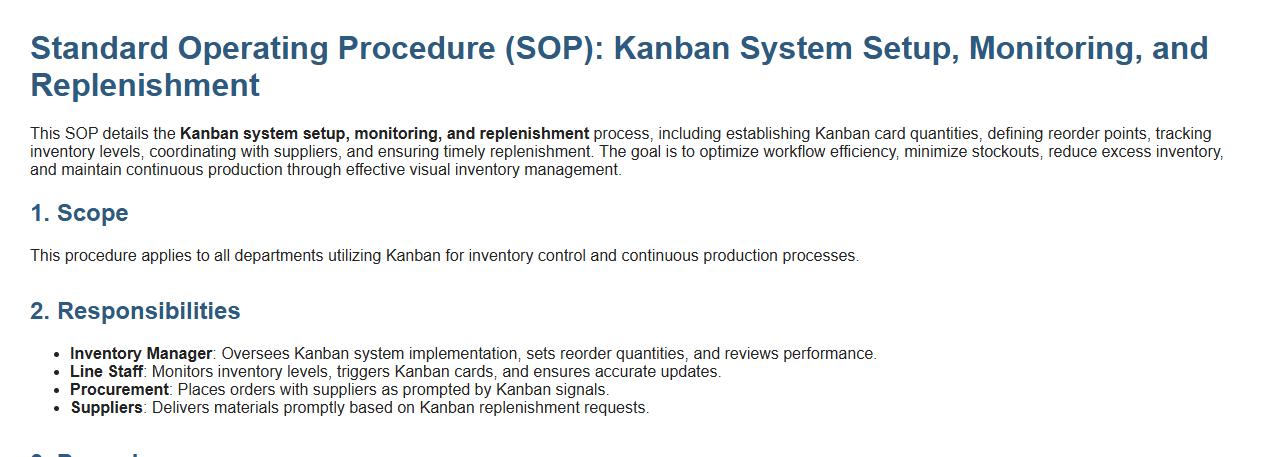

Kanban system setup, monitoring, and replenishment.

This SOP details the Kanban system setup, monitoring, and replenishment process, including establishing Kanban card quantities, defining reorder points, tracking inventory levels, coordinating with suppliers, and ensuring timely replenishment. The goal is to optimize workflow efficiency, minimize stockouts, reduce excess inventory, and maintain continuous production through effective visual inventory management.

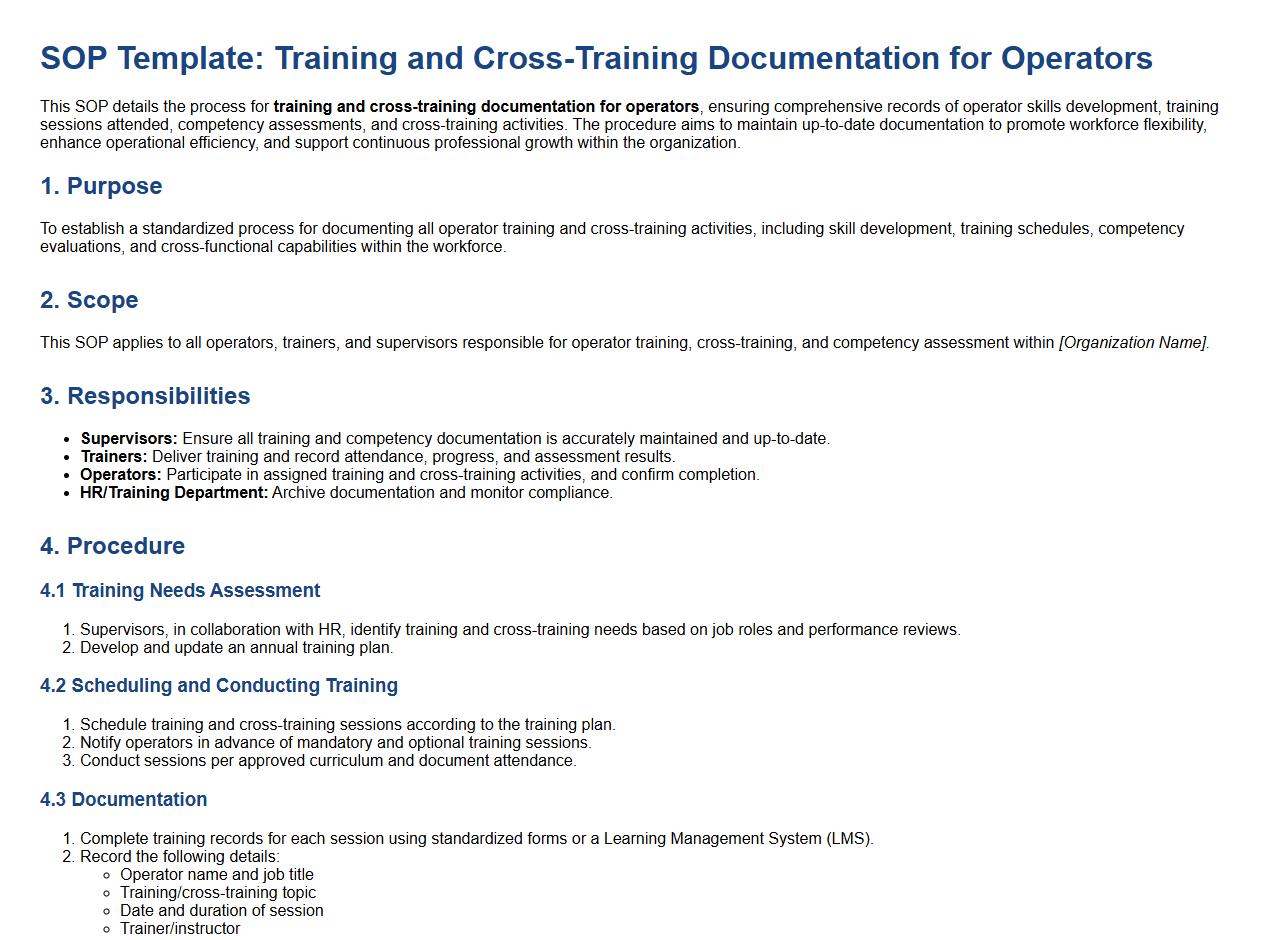

Training and cross-training documentation for operators.

This SOP details the process for training and cross-training documentation for operators, ensuring comprehensive records of operator skills development, training sessions attended, competency assessments, and cross-training activities. The procedure aims to maintain up-to-date documentation to promote workforce flexibility, enhance operational efficiency, and support continuous professional growth within the organization.

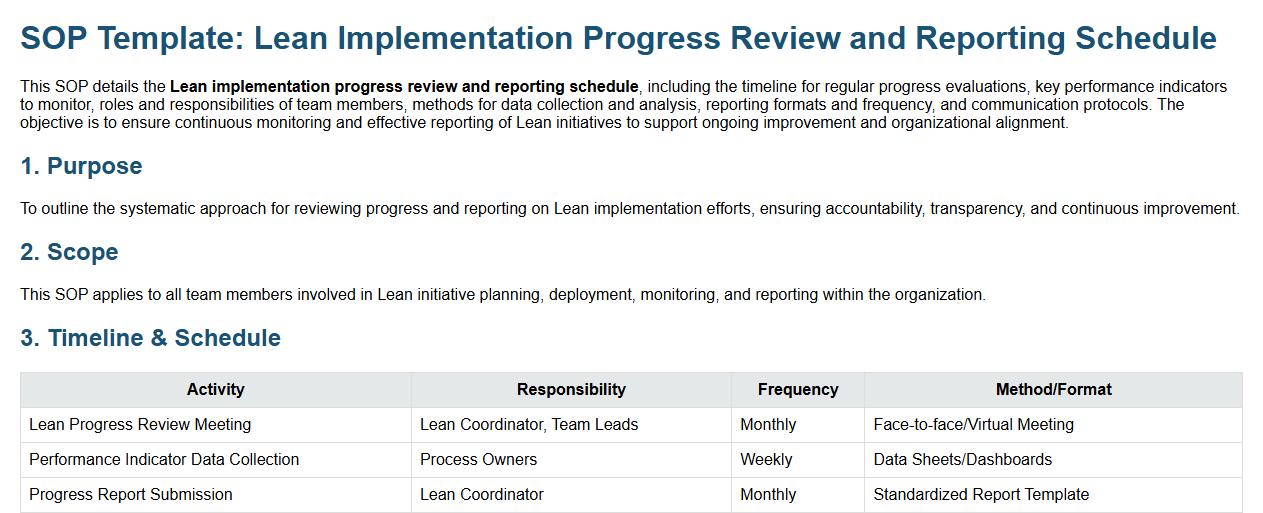

Lean implementation progress review and reporting schedule.

This SOP details the Lean implementation progress review and reporting schedule, including the timeline for regular progress evaluations, key performance indicators to monitor, roles and responsibilities of team members, methods for data collection and analysis, reporting formats and frequency, and communication protocols. The objective is to ensure continuous monitoring and effective reporting of Lean initiatives to support ongoing improvement and organizational alignment.

What are the primary objectives outlined in the SOP for Lean Manufacturing Implementation?

The SOP for Lean Manufacturing Implementation emphasizes eliminating waste to enhance operational efficiency. It aims to improve product quality by streamlining processes and reducing defects. Additionally, the SOP seeks to foster a culture of continuous improvement and employee engagement.

Which roles and responsibilities are specified in the SOP for successful Lean Manufacturing execution?

The SOP clearly defines the roles of Lean Champions responsible for driving the implementation and overseeing progress. Operators are tasked with adhering to standardized processes and reporting inefficiencies. Managers must support resource allocation and facilitate continuous training programs.

What standardized processes and workflows must be followed according to the Lean Manufacturing SOP?

The SOP mandates following standardized work instructions to ensure consistency and minimize variation. It promotes the use of visual management systems to track workflow and issue resolution. Regular process audits and checklists are required to maintain compliance and identify areas for improvement.

Which lean tools and techniques are mandated by the SOP for waste reduction and process improvement?

The SOP requires the implementation of 5S methodology to organize the workplace systematically. It promotes the use of Value Stream Mapping to identify and eliminate process bottlenecks. Additionally, techniques like Kaizen events and root cause analysis are prescribed for continuous problem-solving.

How does the SOP define performance measurement and continuous improvement criteria for Lean Manufacturing?

The SOP establishes key performance indicators (KPIs) focused on efficiency, quality, and waste reduction to measure success. It outlines regular review cycles to assess progress and adjust strategies accordingly. Continuous improvement is driven by employee feedback and data-driven decision-making processes.