A SOP Template for Quality Assurance in Manufacturing provides a standardized framework to ensure consistent product quality and compliance with industry standards. It outlines detailed procedures for inspection, testing, and corrective actions to minimize defects and improve process efficiency. Implementing this template helps streamline quality control processes and maintain regulatory compliance across production cycles.

Product quality inspection procedures.

This SOP details the product quality inspection procedures, encompassing the steps for receiving and reviewing raw materials, in-process quality checks, final product evaluations, and documentation of inspection results. It ensures that all products meet specified quality standards, regulatory requirements, and customer expectations by implementing systematic inspection protocols and corrective actions for any identified non-conformities.

Raw material receiving and verification process.

This SOP details the raw material receiving and verification process, covering procedures for inspecting and accepting raw materials upon delivery. It includes verifying supplier documentation, checking material quality and quantity, recording discrepancies, and ensuring compliance with predefined standards. The goal is to maintain accurate inventory control, ensure raw materials meet quality requirements, and prevent production delays or quality issues due to defective or incorrect supplies.

In-process quality control checkpoints.

This SOP defines the procedures for in-process quality control checkpoints to ensure product consistency and compliance throughout manufacturing. It includes the identification of critical control points, sampling methods, inspection criteria, testing protocols, documentation processes, and corrective actions. The goal is to detect and address quality issues promptly during production, minimizing defects and ensuring final product standards are met.

Standardized equipment calibration protocols.

This SOP details the standardized equipment calibration protocols, covering the procedures for regular calibration, verification of accuracy, documentation requirements, calibration frequency, and responsibilities. The objective is to ensure all equipment is properly calibrated to maintain precision, reliability, and compliance with industry standards, ultimately enhancing quality control and operational efficiency.

Sampling and testing methodologies for finished goods.

This SOP details the sampling and testing methodologies for finished goods, outlining procedures for selecting representative samples, preparing samples for analysis, and conducting tests to ensure product quality and compliance with specifications. It includes guidelines for sampling frequency, equipment calibration, test methods validation, data recording, and interpretation of results to maintain consistent quality control and meet regulatory standards.

Deviation and non-conformance reporting guidelines.

This SOP establishes deviation and non-conformance reporting guidelines to ensure systematic identification, documentation, and resolution of any deviations from established procedures, standards, or specifications. It covers the process for reporting non-conformances, assessment and investigation, corrective and preventive actions, communication protocols, and continuous improvement measures to maintain product quality and compliance with regulatory requirements.

Corrective and preventive action (CAPA) procedures.

This SOP details Corrective and Preventive Action (CAPA) procedures, encompassing the identification, documentation, and investigation of non-conformities, root cause analysis, implementation of corrective actions, verification of their effectiveness, and the establishment of preventive measures to avoid recurrence. It aims to enhance process quality, ensure compliance with regulatory standards, and promote continuous improvement within the organization.

Document control and revision management.

This SOP establishes guidelines for document control and revision management, including document creation, approval, distribution, revision tracking, version control, access permissions, archival, and disposal procedures. Its purpose is to ensure all organizational documents are accurate, up-to-date, and accessible while maintaining the integrity and traceability of revisions for compliance and operational efficiency.

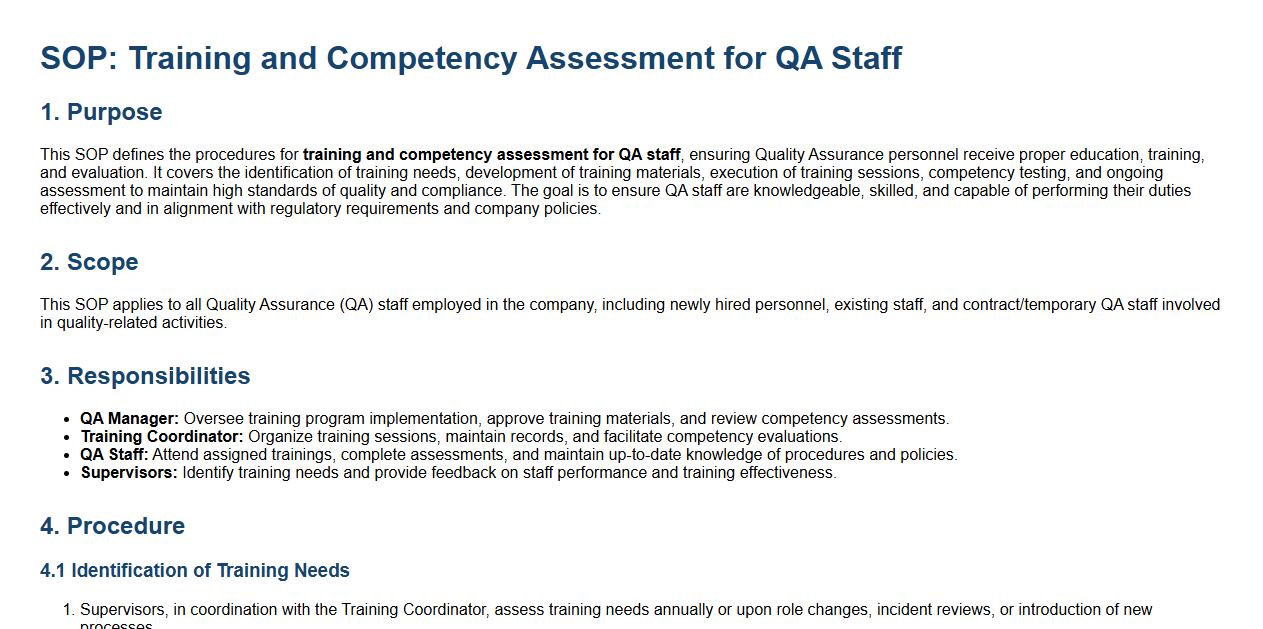

Training and competency assessment for QA staff.

This SOP defines the procedures for training and competency assessment for QA staff, ensuring Quality Assurance personnel receive proper education, training, and evaluation. It covers the identification of training needs, development of training materials, execution of training sessions, competency testing, and ongoing assessment to maintain high standards of quality and compliance. The goal is to ensure QA staff are knowledgeable, skilled, and capable of performing their duties effectively and in alignment with regulatory requirements and company policies.

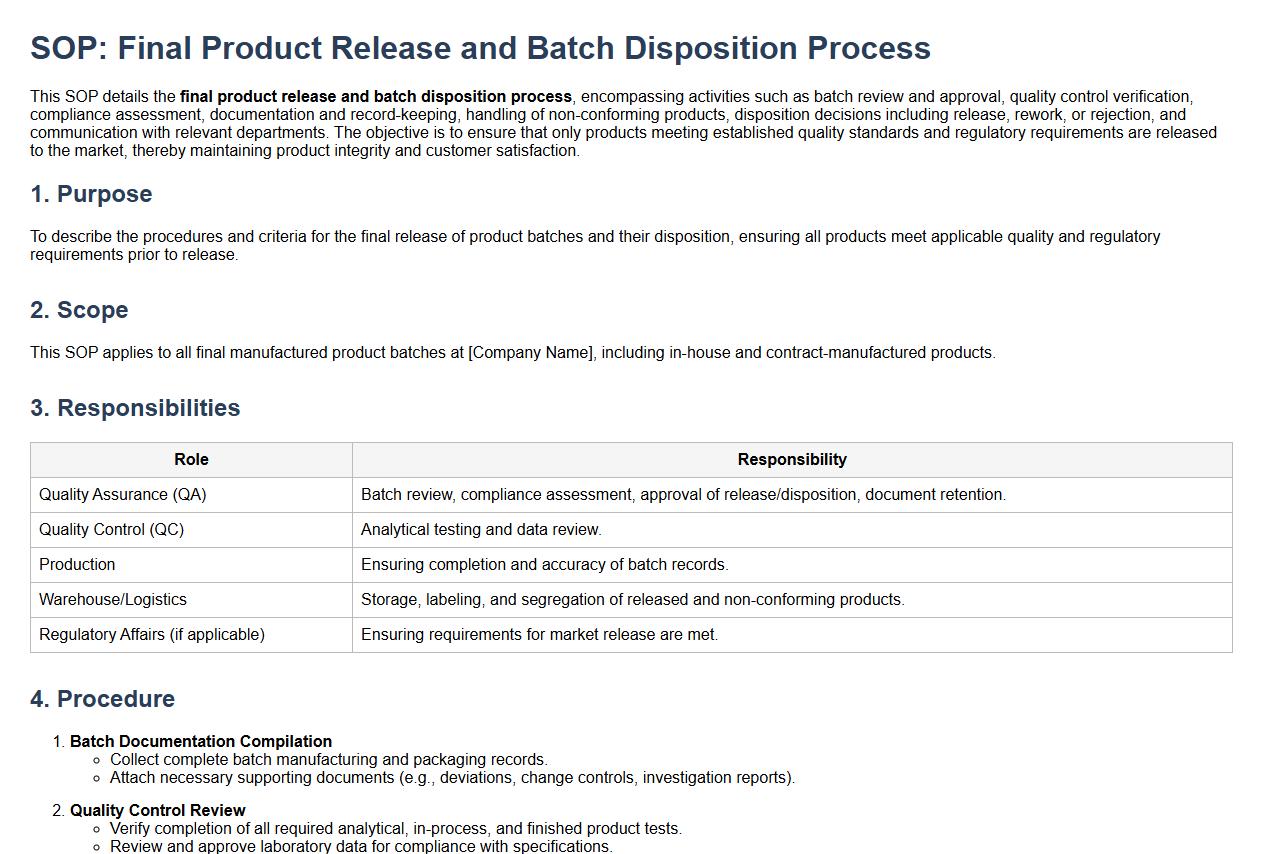

Final product release and batch disposition process.

This SOP details the final product release and batch disposition process, encompassing activities such as batch review and approval, quality control verification, compliance assessment, documentation and record-keeping, handling of non-conforming products, disposition decisions including release, rework, or rejection, and communication with relevant departments. The objective is to ensure that only products meeting established quality standards and regulatory requirements are released to the market, thereby maintaining product integrity and customer satisfaction.

What are the key objectives of the SOP for Quality Assurance in Manufacturing?

The key objectives of the SOP for Quality Assurance in Manufacturing focus on ensuring product consistency and meeting customer requirements. It aims to minimize defects and enhance overall production efficiency through systematic quality control. The SOP establishes clear criteria to maintain compliance with industry standards and regulatory guidelines.

Which critical control points are identified and monitored in this SOP?

The SOP identifies critical control points such as raw material inspection, in-process testing, and final product verification. These points are closely monitored to prevent defects and ensure product safety throughout the manufacturing process. Monitoring at these stages allows early detection and correction of potential quality issues.

How does the SOP define roles and responsibilities for quality assurance personnel?

The SOP clearly delineates roles and responsibilities for quality assurance personnel, including inspectors, supervisors, and quality managers. It assigns accountability for conducting inspections, documenting findings, and implementing corrective actions. This structured approach ensures efficient execution of quality tasks and continuous improvement.

What is the documented procedure for reporting and handling non-conformances?

The SOP outlines a documented procedure for promptly reporting non-conformances through standardized forms and communication channels. It requires thorough investigation to identify root causes and implementation of corrective and preventive actions. Proper documentation ensures traceability and compliance with quality management systems.

Which methods are specified in the SOP for verifying product compliance and quality standards?

The SOP specifies various methods for verifying product compliance, including visual inspections, dimensional measurements, and functional testing. It also incorporates statistical quality control techniques to analyze production data for consistency. These methods collectively ensure products meet predefined quality standards before release.