A SOP Template for Production Line Setup in Manufacturing ensures standardized procedures are followed for efficient assembly line configuration. It outlines step-by-step instructions to optimize resource allocation, equipment installation, and worker assignments. This template helps minimize errors and downtime, boosting overall production quality and consistency.

Pre-setup safety checks and workspace preparation.

This SOP details the procedure for pre-setup safety checks and workspace preparation to ensure a safe and organized environment before commencing any work. It covers the inspection of tools and equipment, identification and removal of potential hazards, proper layout and cleanliness of the workspace, verification of safety gear availability, and confirmation of emergency protocols. The objective is to minimize risks, enhance worker safety, and promote efficient workflow from the outset of any project or task.

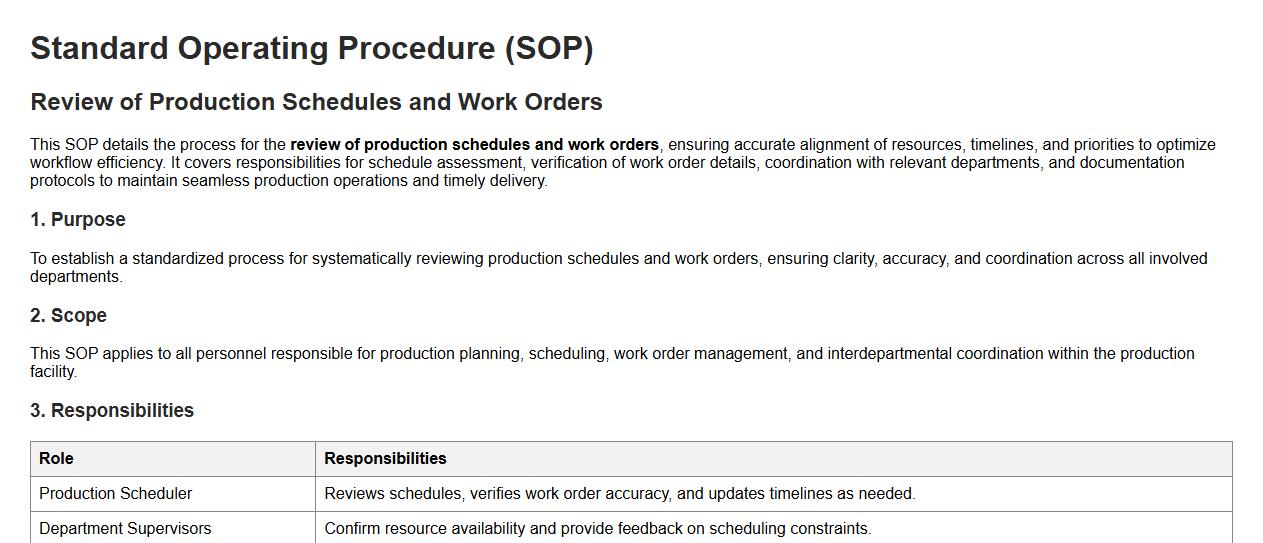

Review of production schedules and work orders.

This SOP details the process for the review of production schedules and work orders, ensuring accurate alignment of resources, timelines, and priorities to optimize workflow efficiency. It covers responsibilities for schedule assessment, verification of work order details, coordination with relevant departments, and documentation protocols to maintain seamless production operations and timely delivery.

Assembly and calibration of machinery and equipment.

This SOP details the assembly and calibration of machinery and equipment, covering step-by-step procedures for proper setup, alignment, and adjustment to ensure optimal performance. It includes guidelines for verifying component integrity, safe handling practices, use of calibration tools, and documentation of calibration results. The objective is to maintain machinery accuracy, enhance operational efficiency, and prevent equipment malfunctions through standardized assembly and precise calibration techniques.

Verification and installation of tooling and fixtures.

This SOP details the verification and installation of tooling and fixtures, encompassing the procedures for inspecting, validating, and installing tooling equipment and fixtures to ensure proper fit, function, and compliance with quality standards. It includes guidelines for pre-installation checks, alignment and calibration, secure mounting, and documentation of verification results. The objective is to maintain accuracy, safety, and efficiency in manufacturing processes by ensuring all tooling and fixtures are correctly installed and functioning as intended.

Raw material inspection and staging procedures.

This SOP details the raw material inspection and staging procedures, encompassing the systematic evaluation of incoming raw materials for quality and compliance, verification against purchase orders and specifications, identification and segregation of non-conforming materials, proper labeling and documentation, and organized staging in designated areas to facilitate efficient production flow. The objective is to ensure that only approved raw materials enter the manufacturing process, thereby maintaining product quality and operational efficiency.

Machine startup and initial test run protocols.

This SOP details machine startup and initial test run protocols, covering pre-startup inspections, safety checks, equipment calibration, controlled startup procedures, monitoring during the initial test run, troubleshooting common issues, and documentation of test results. The objective is to ensure machines operate safely and efficiently from the outset, minimizing risks and preventing operational failures.

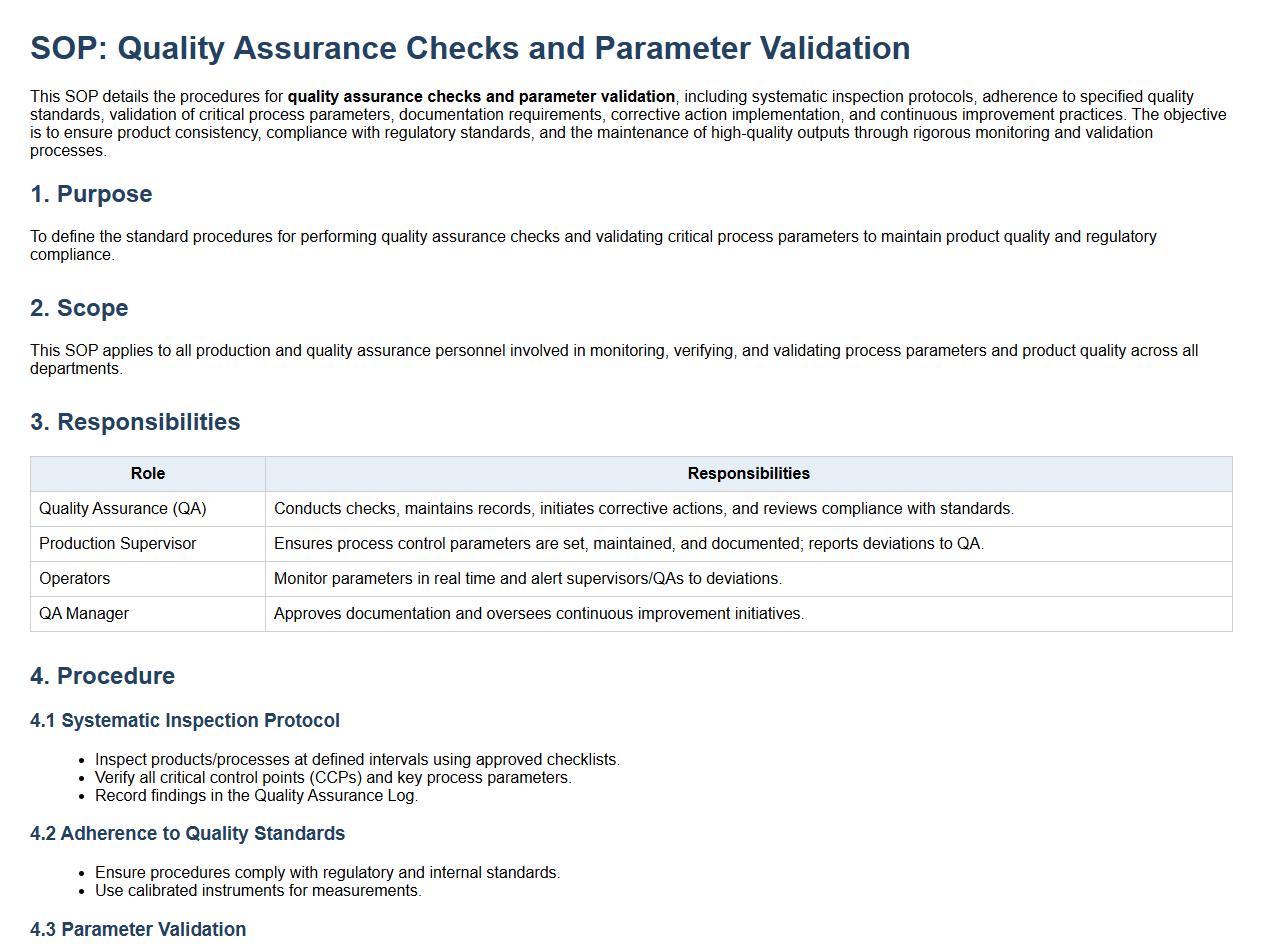

Quality assurance checks and parameter validation.

This SOP details the procedures for quality assurance checks and parameter validation, including systematic inspection protocols, adherence to specified quality standards, validation of critical process parameters, documentation requirements, corrective action implementation, and continuous improvement practices. The objective is to ensure product consistency, compliance with regulatory standards, and the maintenance of high-quality outputs through rigorous monitoring and validation processes.

Documentation of setup parameters and adjustments.

This SOP details the process for documentation of setup parameters and adjustments, including recording initial machine settings, monitoring and logging parameter changes, ensuring accuracy and consistency in documentation, and maintaining records for quality control and troubleshooting purposes. The goal is to provide a clear, standardized method for capturing setup information to facilitate efficient operations and traceability.

Communication of setup completion to production team.

This SOP details the communication of setup completion to the production team, ensuring timely and accurate notification once equipment or system setup is finalized. It covers the standardized process for confirming setup status, the designated communication channels, responsible personnel for delivering the update, and verification steps to confirm the production team has received and acknowledged the information. The goal is to facilitate smooth transitions between setup and production phases, minimizing downtime and enhancing operational efficiency.

Handover and sign-off procedures between setup and operations staff.

This SOP details the handover and sign-off procedures between setup and operations staff, ensuring a smooth transition and clear communication. It covers the responsibility transfer process, documentation requirements, checklist verification, issue identification and resolution, and final approval protocols. The goal is to maintain operational continuity, prevent errors, and promote accountability during shift changes and task completions.

What are the critical steps outlined in the SOP for initializing a new production line setup?

The SOP emphasizes the initial assessment of the production area to ensure all resources are adequately prepared. It requires detailed configuration of machinery according to product specifications to guarantee smooth operations. Finally, staff training and shift assignments must be completed to align team readiness with operational goals.

Which safety precautions must be verified according to the SOP before commencing production operations?

Before production starts, the SOP mandates verification of all safety protocols including emergency shut-off mechanisms and protective equipment. It also requires ensuring clear access to emergency exits and the presence of functional fire suppression systems. Regular safety drills are emphasized to keep the team vigilant and compliant.

How does the SOP specify the sequence for machine calibration and equipment checks?

The SOP outlines a strict sequence beginning with machine calibration to manufacturer specifications to maintain accuracy. Following calibration, comprehensive equipment checks must be performed to detect any faults or wear. Documentation of each calibration and check is essential for traceability and quality assurance.

What are the documentation and reporting requirements during each stage of the production line setup?

The SOP requires detailed documentation of every setup stage, including configuration changes and inspection results. This documentation must be recorded in standardized forms and logged into a centralized database. Additionally, progress reports should be submitted to supervisors for real-time monitoring and accountability.

Who is responsible for conducting final inspections and sign-off as defined in the SOP?

The SOP assigns the final inspection and sign-off responsibility to the Quality Assurance Manager or designated senior supervisor. This individual verifies that all setup criteria are met and production readiness is confirmed. Their approval is mandatory before the production line can commence full-scale operations.