A SOP Template for Manufacturing Assembly Line Operations ensures standardized procedures are followed, enhancing efficiency and consistency. It outlines step-by-step instructions, safety protocols, and quality control measures essential to maintaining smooth production flow. Clear documentation helps reduce errors, training time, and operational downtime on the assembly line.

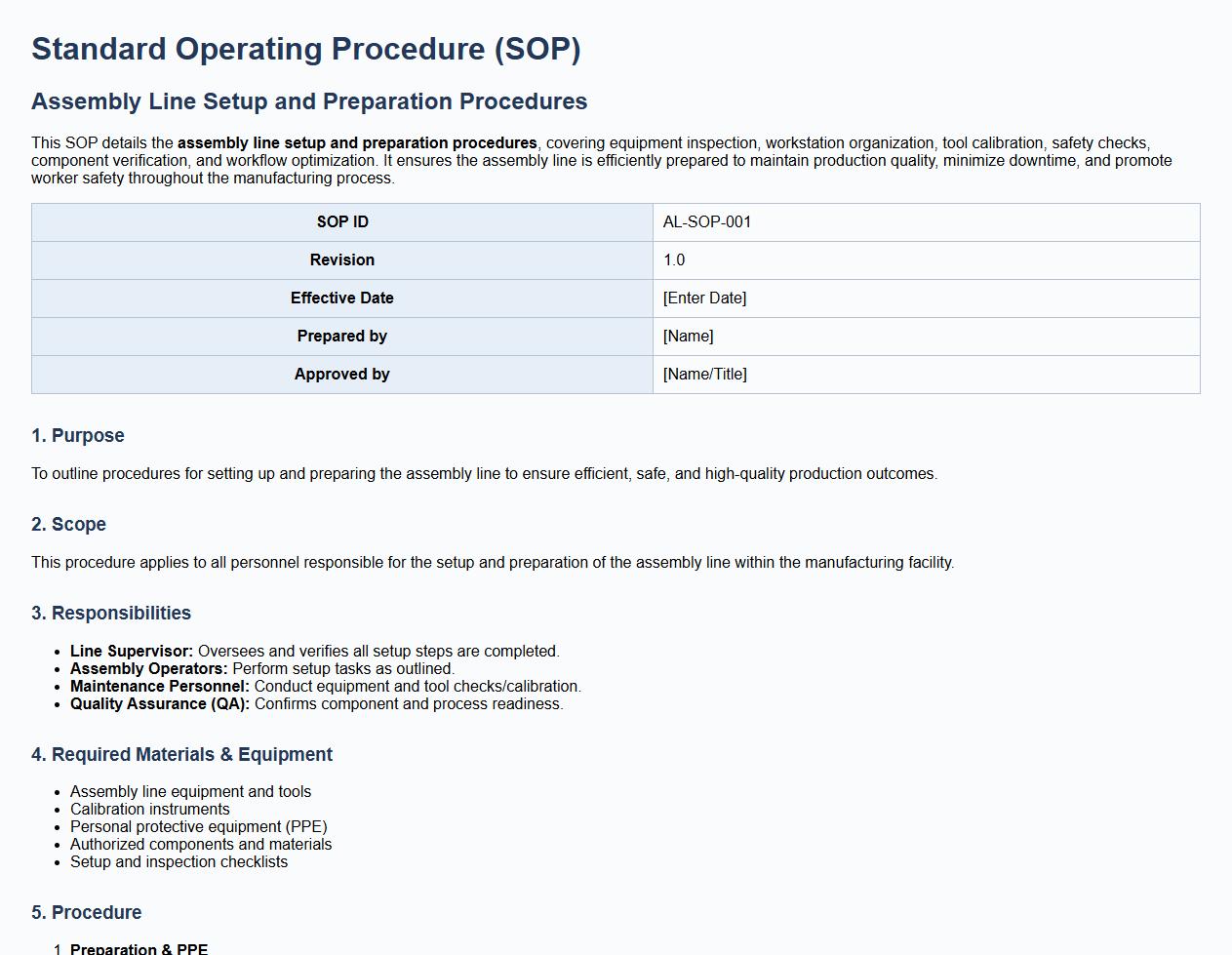

Assembly line setup and preparation procedures.

This SOP details the assembly line setup and preparation procedures, covering equipment inspection, workstation organization, tool calibration, safety checks, component verification, and workflow optimization. It ensures the assembly line is efficiently prepared to maintain production quality, minimize downtime, and promote worker safety throughout the manufacturing process.

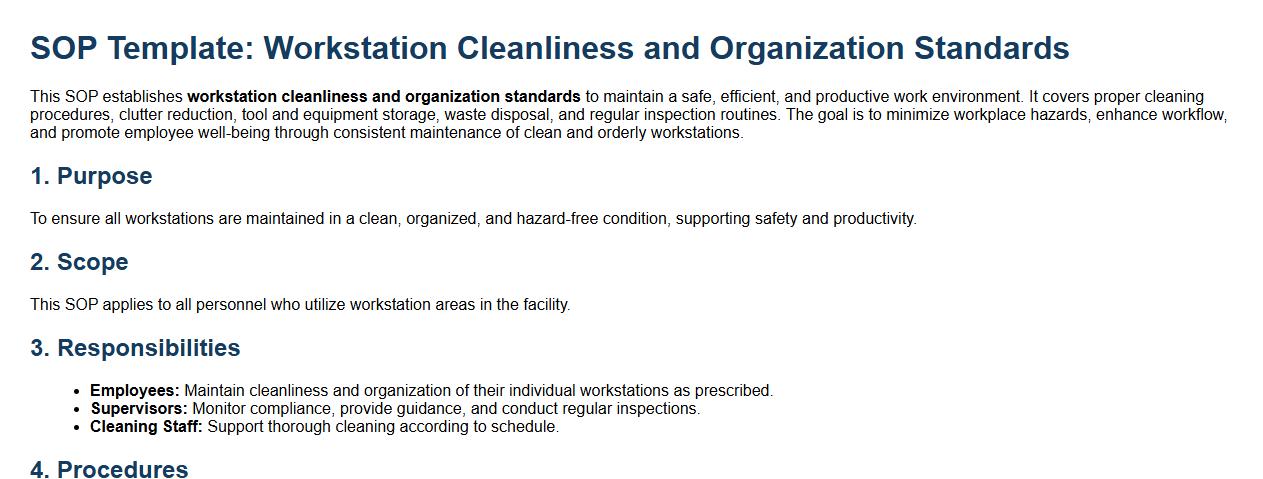

Workstation cleanliness and organization standards.

This SOP establishes workstation cleanliness and organization standards to maintain a safe, efficient, and productive work environment. It covers proper cleaning procedures, clutter reduction, tool and equipment storage, waste disposal, and regular inspection routines. The goal is to minimize workplace hazards, enhance workflow, and promote employee well-being through consistent maintenance of clean and orderly workstations.

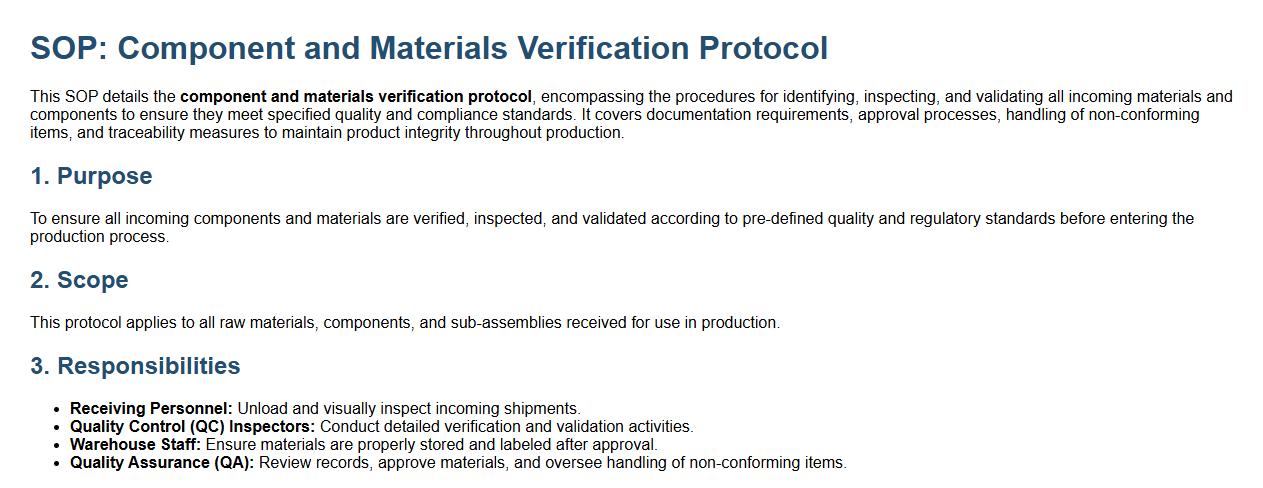

Component and materials verification protocol.

This SOP details the component and materials verification protocol, encompassing the procedures for identifying, inspecting, and validating all incoming materials and components to ensure they meet specified quality and compliance standards. It covers documentation requirements, approval processes, handling of non-conforming items, and traceability measures to maintain product integrity throughout production.

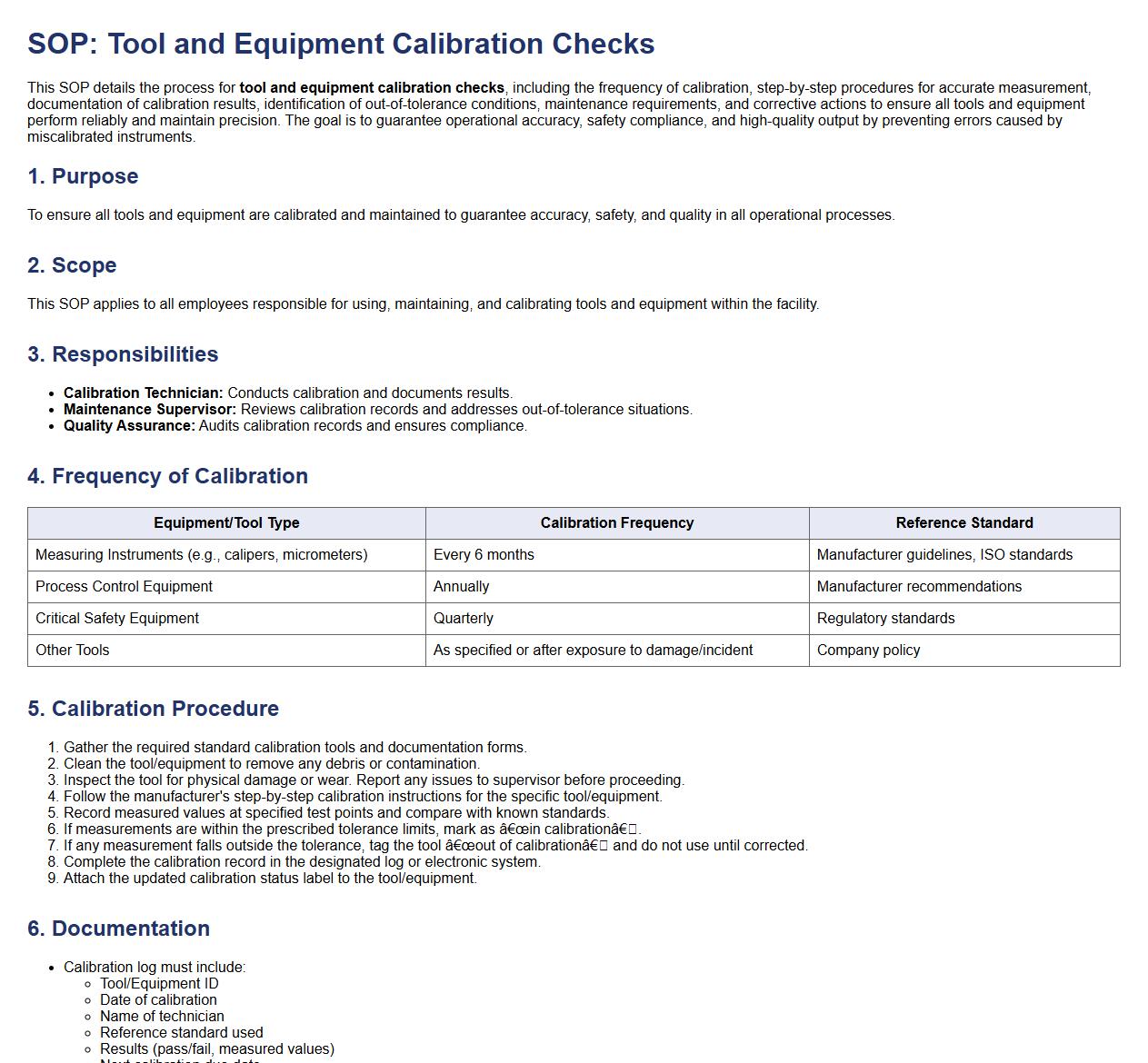

Tool and equipment calibration checks.

This SOP details the process for tool and equipment calibration checks, including the frequency of calibration, step-by-step procedures for accurate measurement, documentation of calibration results, identification of out-of-tolerance conditions, maintenance requirements, and corrective actions to ensure all tools and equipment perform reliably and maintain precision. The goal is to guarantee operational accuracy, safety compliance, and high-quality output by preventing errors caused by miscalibrated instruments.

Step-by-step assembly process instructions.

This SOP provides detailed step-by-step assembly process instructions to ensure accurate and efficient construction of products, outlining each phase from initial preparation to final quality checks, minimizing errors, and maintaining consistent production standards.

In-line quality control and defect identification.

This SOP details the procedures for in-line quality control and defect identification to ensure product consistency and minimize defects during the manufacturing process. It covers real-time inspection methods, defect detection criteria, corrective action protocols, operator responsibilities, and documentation requirements to maintain high-quality standards and improve overall production efficiency.

Worker safety practices and PPE requirements.

This SOP defines worker safety practices and PPE requirements, emphasizing the importance of personal protective equipment, proper usage protocols, hazard identification, risk assessment, and maintaining a safe work environment. It aims to minimize workplace injuries and health risks by ensuring all employees are equipped with appropriate PPE and trained in its correct use and maintenance.

Batch tracking and traceability documentation.

This SOP details the batch tracking and traceability documentation process, covering the systematic recording of batch information, product identification, and tracking from production to distribution. It includes procedures for maintaining accurate records, ensuring compliance with regulatory requirements, enabling efficient recall management, and supporting quality control and supply chain transparency. The aim is to enhance product safety, accountability, and customer confidence through precise traceability throughout the product lifecycle.

Equipment shutdown and end-of-shift procedures.

This SOP details the equipment shutdown and end-of-shift procedures to ensure all machinery and tools are properly turned off, cleaned, and secured at the end of each work period. It includes steps for safely powering down equipment, performing necessary maintenance checks, documenting any issues or malfunctions, and preparing the workspace for the next shift. These procedures help maintain equipment longevity, ensure worker safety, and facilitate smooth operational transitions between shifts.

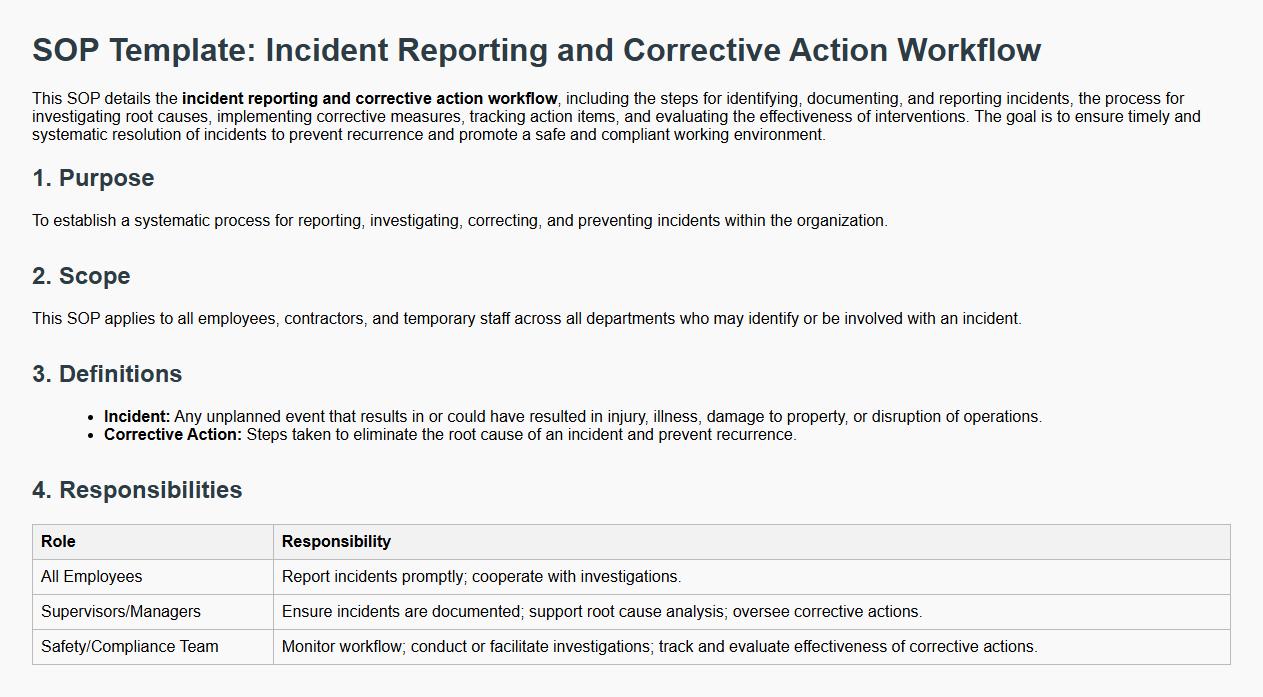

Incident reporting and corrective action workflow.

This SOP details the incident reporting and corrective action workflow, including the steps for identifying, documenting, and reporting incidents, the process for investigating root causes, implementing corrective measures, tracking action items, and evaluating the effectiveness of interventions. The goal is to ensure timely and systematic resolution of incidents to prevent recurrence and promote a safe and compliant working environment.

What are the critical steps outlined in the SOP for ensuring product quality during assembly?

The SOP emphasizes quality control checkpoints at various stages of the assembly process to detect defects early. It mandates standardized procedures for component inspection before assembly begins to uphold product standards. Additionally, it requires continuous monitoring and documented verification to maintain consistent product quality throughout production.

Which safety protocols must every operator follow according to the SOP?

Operators are required to wear personal protective equipment (PPE) at all times to minimize injury risks. The SOP enforces adherence to strict lockout/tagout procedures when handling machinery to prevent accidents. It also mandates regular safety briefings and emergency drills to ensure readiness in case of hazards.

How does the SOP specify handling equipment malfunctions or breakdowns on the assembly line?

Upon detecting a malfunction, operators must immediately stop the equipment and notify the maintenance team as per SOP guidelines. The SOP outlines clear steps for troubleshooting and logging the issue to facilitate timely repairs. It also requires a detailed post-repair inspection before resuming production to guarantee operational safety.

What documentation or record-keeping procedures are required by the SOP during production?

The SOP mandates maintaining comprehensive logs of all assembly activities, including inspections, deviations, and corrective actions. It requires real-time data entry into standardized forms or digital systems to ensure traceability. Proper documentation supports quality audits and compliance with regulatory standards throughout the production cycle.

How does the SOP address training and competency requirements for assembly line personnel?

The SOP stipulates that all personnel must complete mandatory training programs relevant to their specific assembly tasks before starting work. It stresses ongoing competency assessments to verify skill retention and address knowledge gaps. Regular refresher courses and certifications are required to maintain high performance and safety standards on the assembly line.