A SOP Template for Manufacturing Incident Reporting standardizes the process of documenting and addressing incidents on the production floor to ensure safety and compliance. It outlines clear steps for reporting, investigation, and corrective actions, helping to minimize downtime and prevent recurrence. This template enhances accountability and maintains detailed records for regulatory audits and continuous improvement.

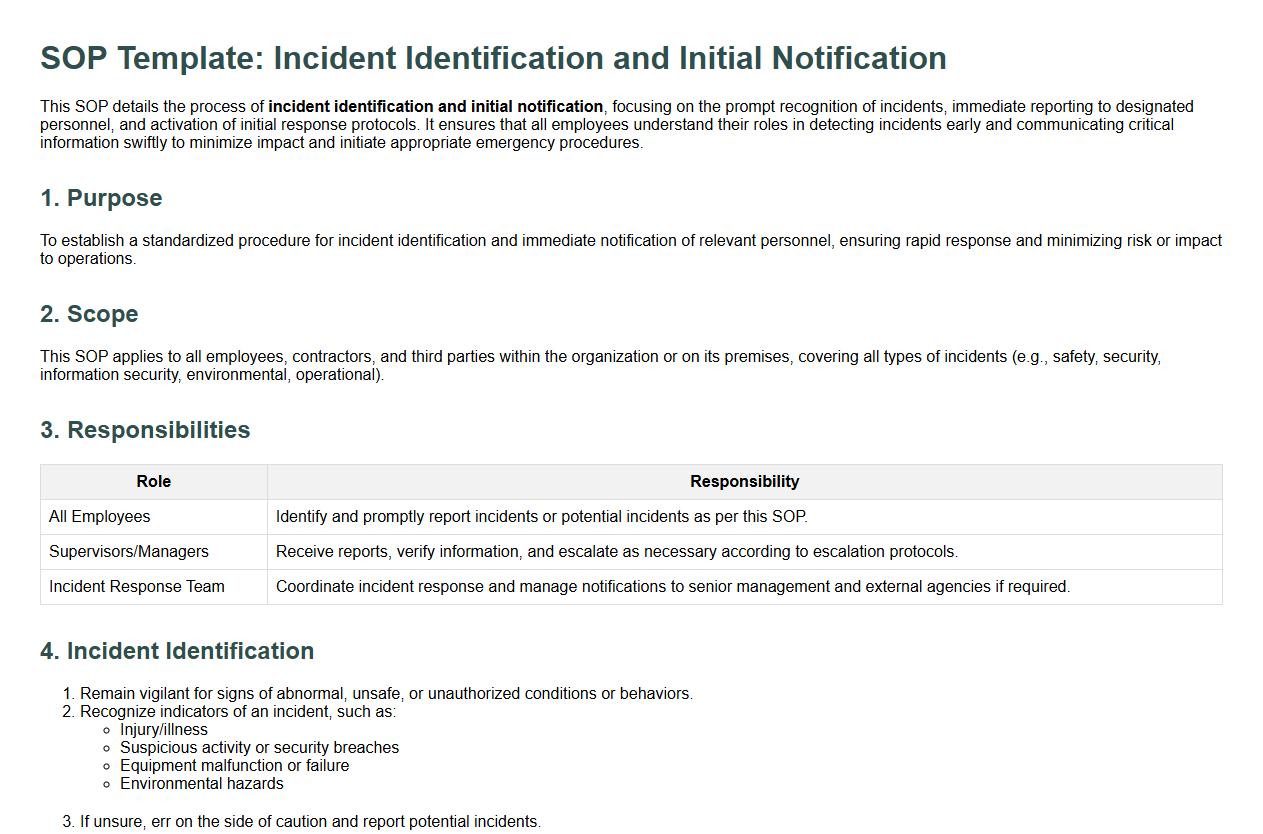

Incident Identification and Initial Notification.

This SOP details the process of incident identification and initial notification, focusing on the prompt recognition of incidents, immediate reporting to designated personnel, and activation of initial response protocols. It ensures that all employees understand their roles in detecting incidents early and communicating critical information swiftly to minimize impact and initiate appropriate emergency procedures.

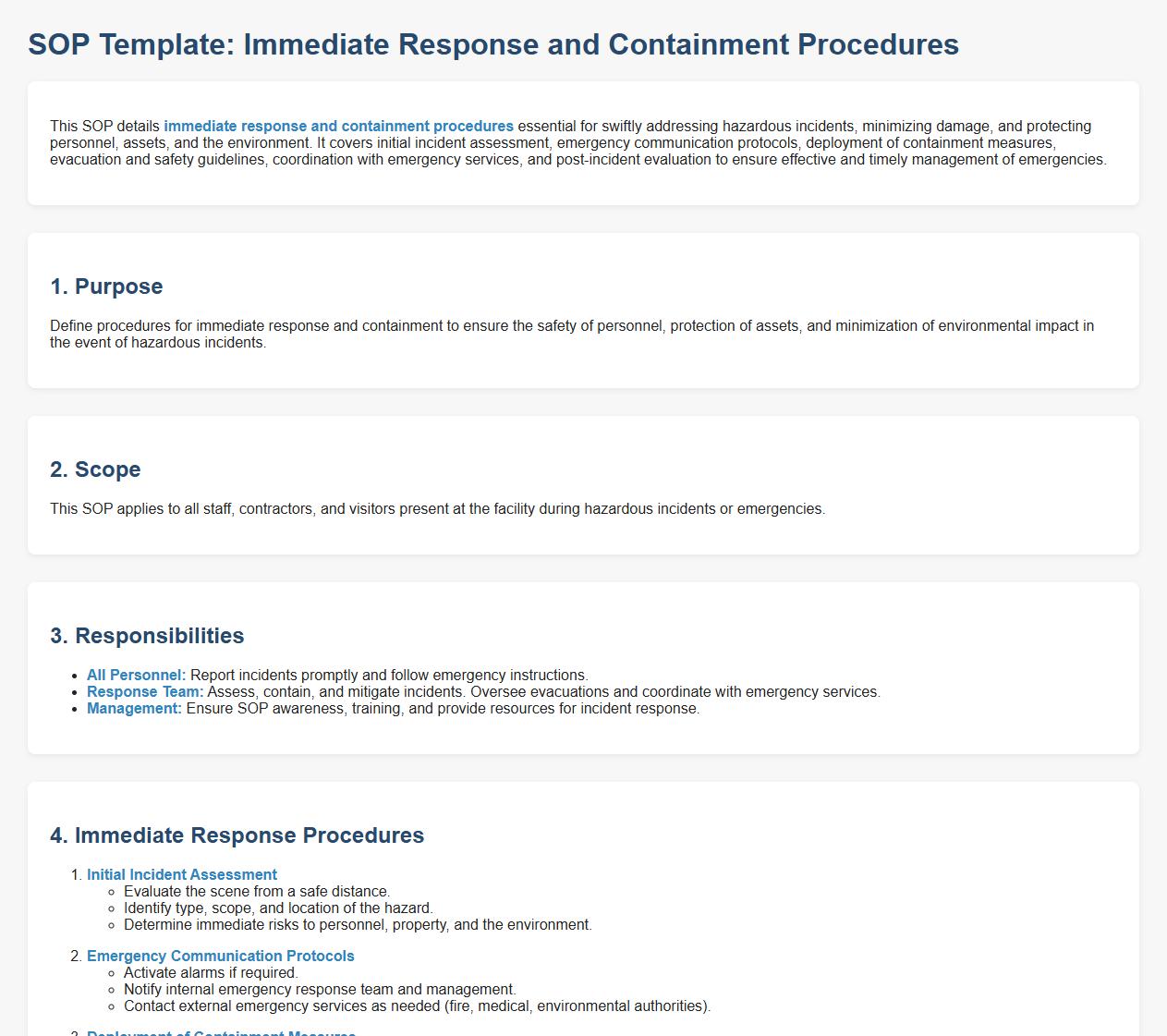

Immediate Response and Containment Procedures.

This SOP details immediate response and containment procedures essential for swiftly addressing hazardous incidents, minimizing damage, and protecting personnel, assets, and the environment. It covers initial incident assessment, emergency communication protocols, deployment of containment measures, evacuation and safety guidelines, coordination with emergency services, and post-incident evaluation to ensure effective and timely management of emergencies.

Securing the Incident Area and Ensuring Safety.

This SOP describes procedures for securing the incident area and ensuring safety, including isolating the site, controlling access, identifying hazards, providing protective equipment, alerting emergency responders, and maintaining clear communication. The goal is to protect all personnel, prevent further incidents, and facilitate effective emergency response and investigation.

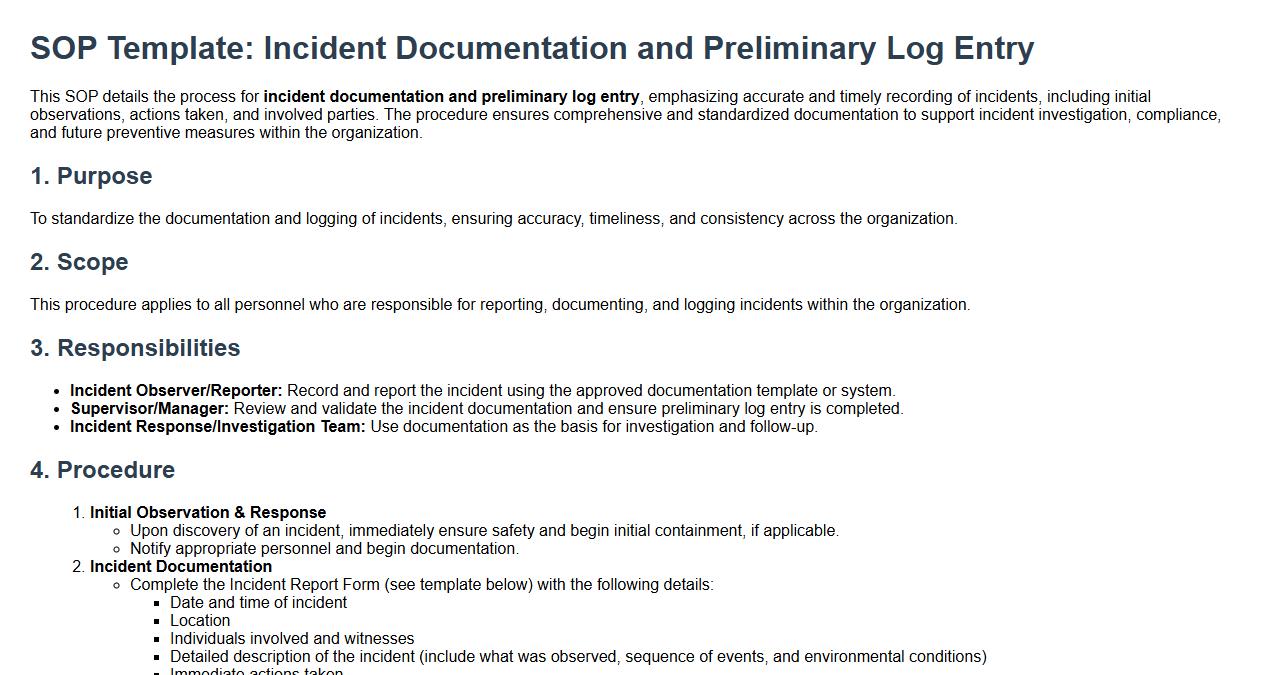

Incident Documentation and Preliminary Log Entry.

This SOP details the process for incident documentation and preliminary log entry, emphasizing accurate and timely recording of incidents, including initial observations, actions taken, and involved parties. The procedure ensures comprehensive and standardized documentation to support incident investigation, compliance, and future preventive measures within the organization.

Incident Reporting Form Completion and Submission.

This SOP details the process for incident reporting form completion and submission, ensuring that all workplace incidents are accurately documented and communicated promptly. It covers the steps for identifying incidents, filling out the required forms with precise information, verifying details for accuracy, and submitting reports to the appropriate authorities or departments in a timely manner. This procedure aims to facilitate effective incident tracking, promote safety improvements, and comply with regulatory requirements.

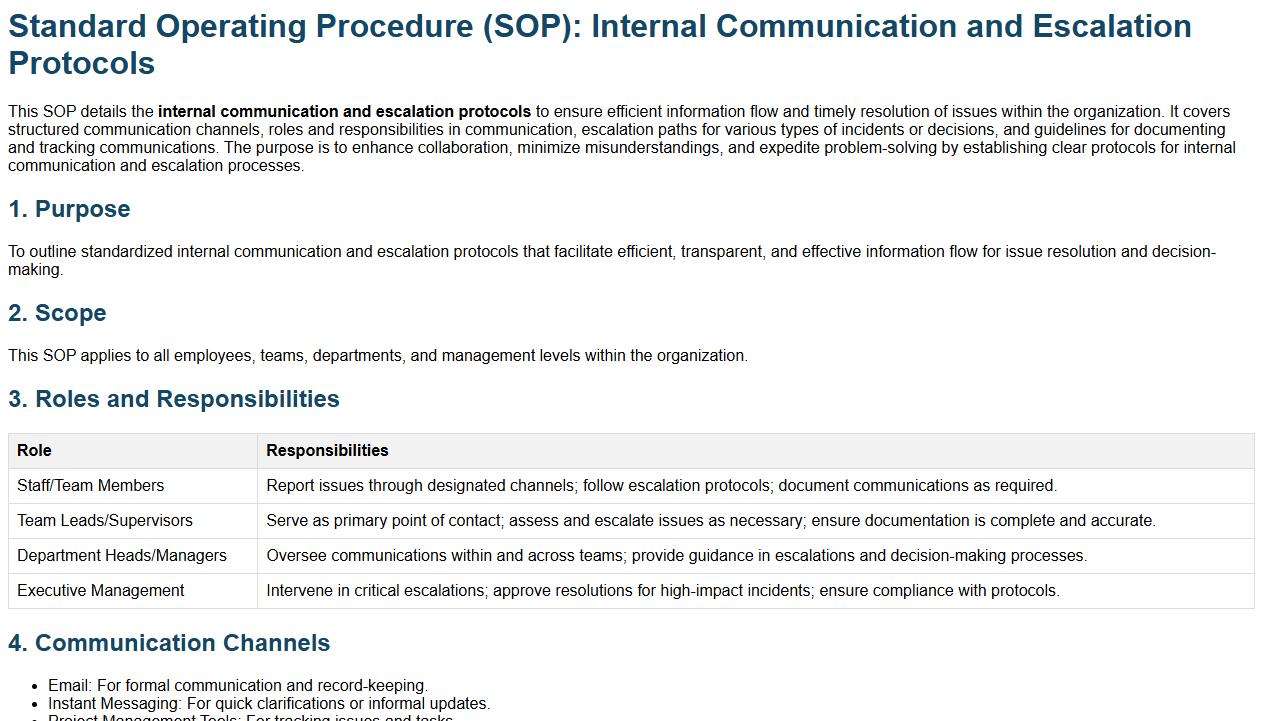

Internal Communication and Escalation Protocols.

This SOP details the internal communication and escalation protocols to ensure efficient information flow and timely resolution of issues within the organization. It covers structured communication channels, roles and responsibilities in communication, escalation paths for various types of incidents or decisions, and guidelines for documenting and tracking communications. The purpose is to enhance collaboration, minimize misunderstandings, and expedite problem-solving by establishing clear protocols for internal communication and escalation processes.

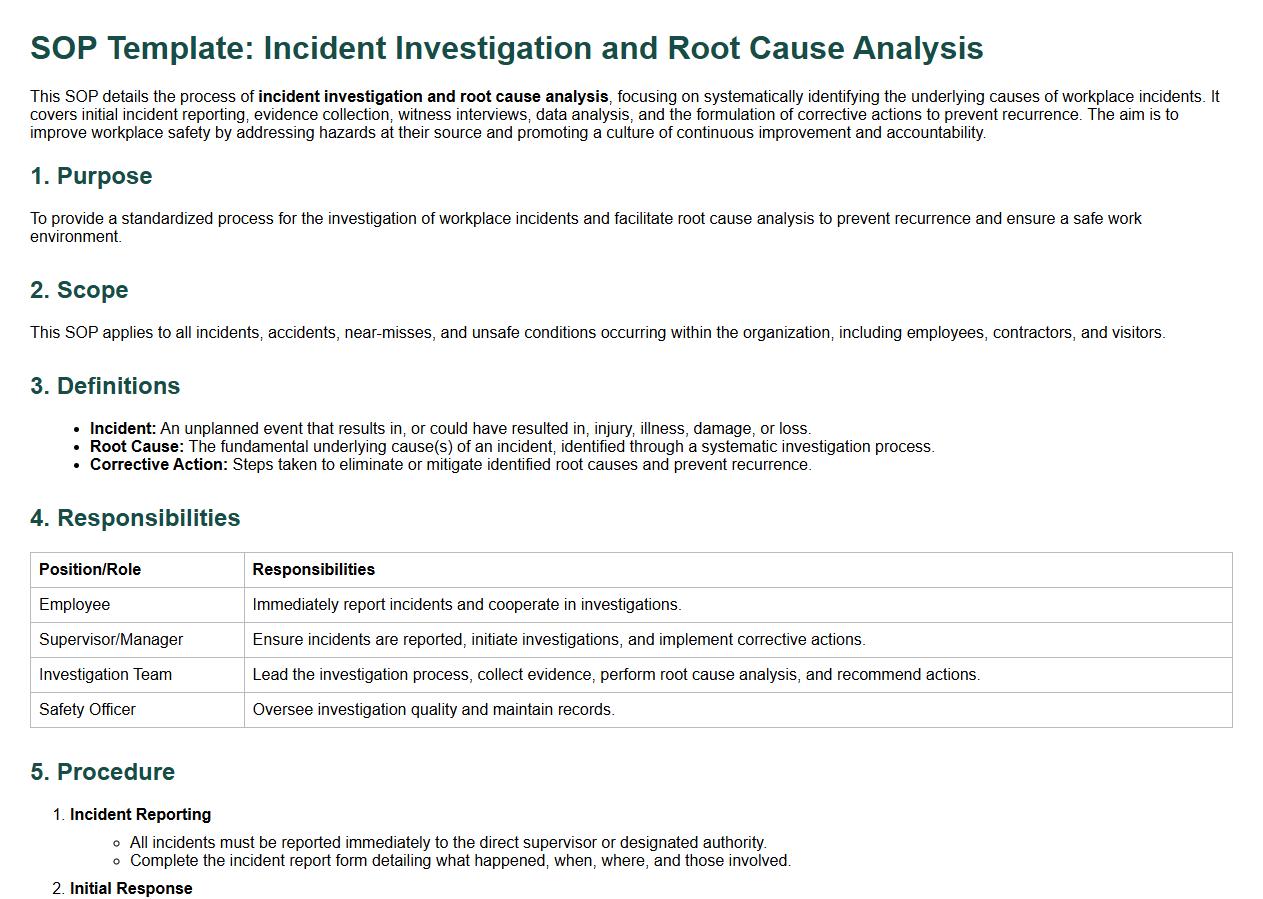

Incident Investigation and Root Cause Analysis.

This SOP details the process of incident investigation and root cause analysis, focusing on systematically identifying the underlying causes of workplace incidents. It covers initial incident reporting, evidence collection, witness interviews, data analysis, and the formulation of corrective actions to prevent recurrence. The aim is to improve workplace safety by addressing hazards at their source and promoting a culture of continuous improvement and accountability.

Corrective and Preventive Action Implementation.

This SOP details the process for Corrective and Preventive Action Implementation, including identification of non-conformities, root cause analysis, development of corrective actions, verification of effectiveness, documentation procedures, and continuous improvement strategies. The purpose is to ensure systematic resolution of issues, prevent recurrence, and enhance overall quality and compliance within the organization.

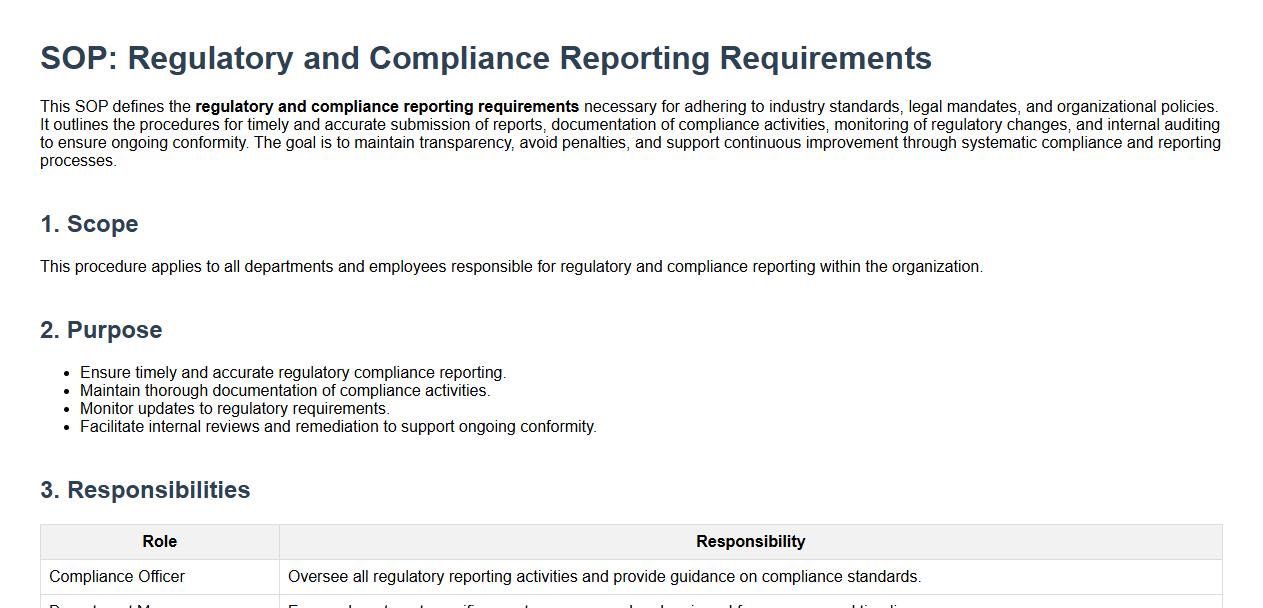

Regulatory and Compliance Reporting Requirements.

This SOP defines the regulatory and compliance reporting requirements necessary for adhering to industry standards, legal mandates, and organizational policies. It outlines the procedures for timely and accurate submission of reports, documentation of compliance activities, monitoring of regulatory changes, and internal auditing to ensure ongoing conformity. The goal is to maintain transparency, avoid penalties, and support continuous improvement through systematic compliance and reporting processes.

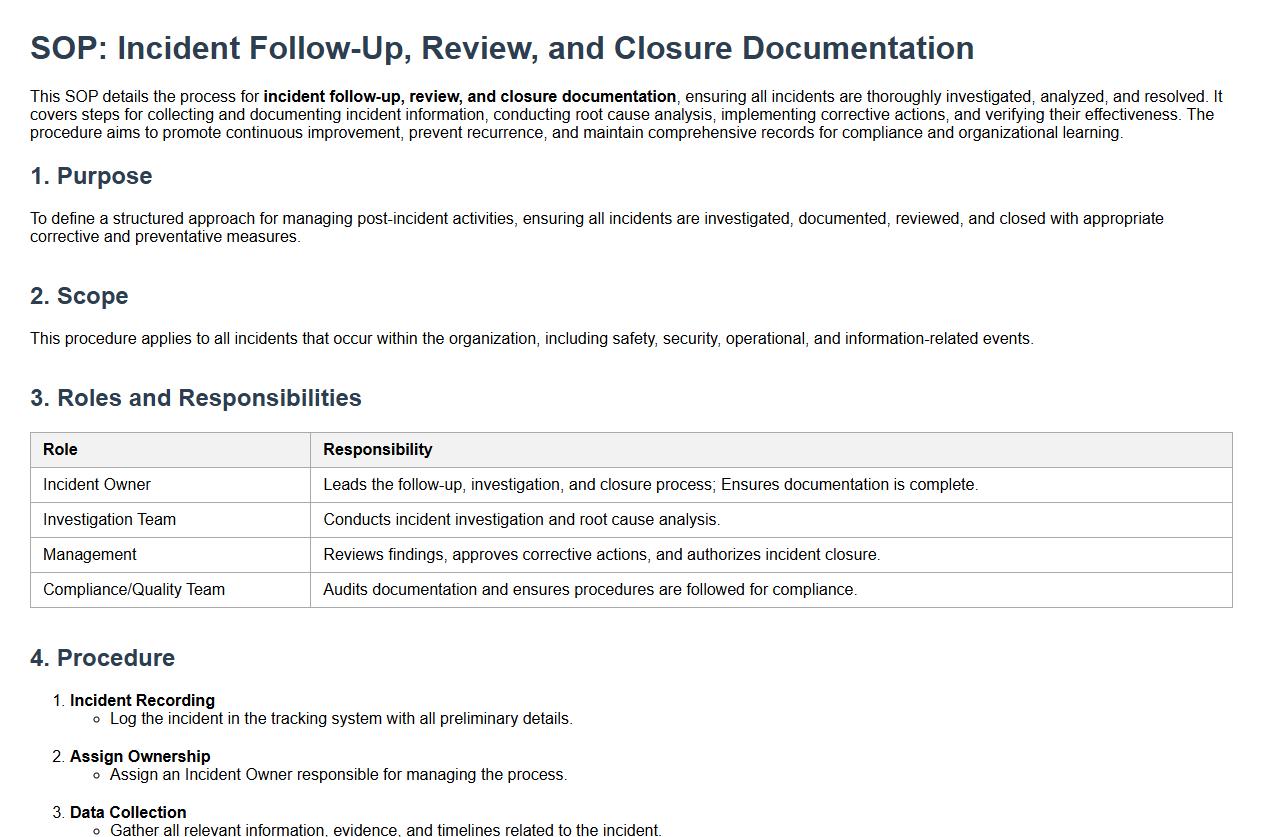

Incident Follow-Up, Review, and Closure Documentation.

This SOP details the process for incident follow-up, review, and closure documentation, ensuring all incidents are thoroughly investigated, analyzed, and resolved. It covers steps for collecting and documenting incident information, conducting root cause analysis, implementing corrective actions, and verifying their effectiveness. The procedure aims to promote continuous improvement, prevent recurrence, and maintain comprehensive records for compliance and organizational learning.

What is the primary objective of the Manufacturing Incident Reporting SOP?

The primary objective of the Manufacturing Incident Reporting SOP is to ensure consistent and timely identification, documentation, and communication of any incidents occurring within the manufacturing process. This SOP aims to minimize risks by facilitating effective corrective actions and continuous improvement. Ultimately, it enhances workplace safety and product quality by maintaining a systematic reporting structure.

Which incidents must be reported according to the SOP criteria?

According to the SOP criteria, all incidents that impact employee safety, product quality, or equipment functionality must be reported immediately. This includes accidents, near misses, equipment failures, and any deviations from standard operating procedures. Reporting these incidents is critical for initiating prompt corrective measures and preventing recurrence.

Who is responsible for initiating the incident reporting process as defined in the SOP?

The responsibility for initiating the incident reporting process lies primarily with the employee or personnel who witnesses or first identifies the incident. Supervisors are also tasked with ensuring that the incident is formally reported and logged according to SOP requirements. This shared responsibility ensures accountability and efficient incident management.

What are the required steps for documenting an incident under the SOP?

Documenting an incident under the SOP requires accurately recording the incident details, including the type of incident, time, location, and individuals involved. A thorough investigation and root cause analysis must be conducted to understand the contributing factors. Finally, the documentation must be reviewed and signed off by the appropriate supervisory or quality assurance personnel.

What timeline does the SOP mandate for submitting and escalating incident reports?

The SOP mandates that incident reports must be submitted within 24 hours of the incident occurrence to ensure prompt response. Escalation protocols require that significant or critical incidents be communicated immediately to higher management and relevant departments. Timely submission and escalation help mitigate risks and initiate corrective actions effectively.