A SOP Template for Raw Material Handling in Manufacturing ensures standardized procedures for receiving, inspecting, storing, and managing raw materials. It enhances efficiency, minimizes contamination risks, and maintains material quality throughout the production process. Following this template supports regulatory compliance and promotes workplace safety.

Raw material receiving and inspection procedures.

This SOP details the raw material receiving and inspection procedures to ensure the quality and compliance of incoming materials. It covers the verification of delivery documents, physical inspection of raw materials for damage or contamination, sampling protocols for quality testing, proper labeling and documentation, handling and storage requirements, and communication of any discrepancies or rejections to suppliers. The objective is to maintain high standards of raw material quality to support efficient production processes and product safety.

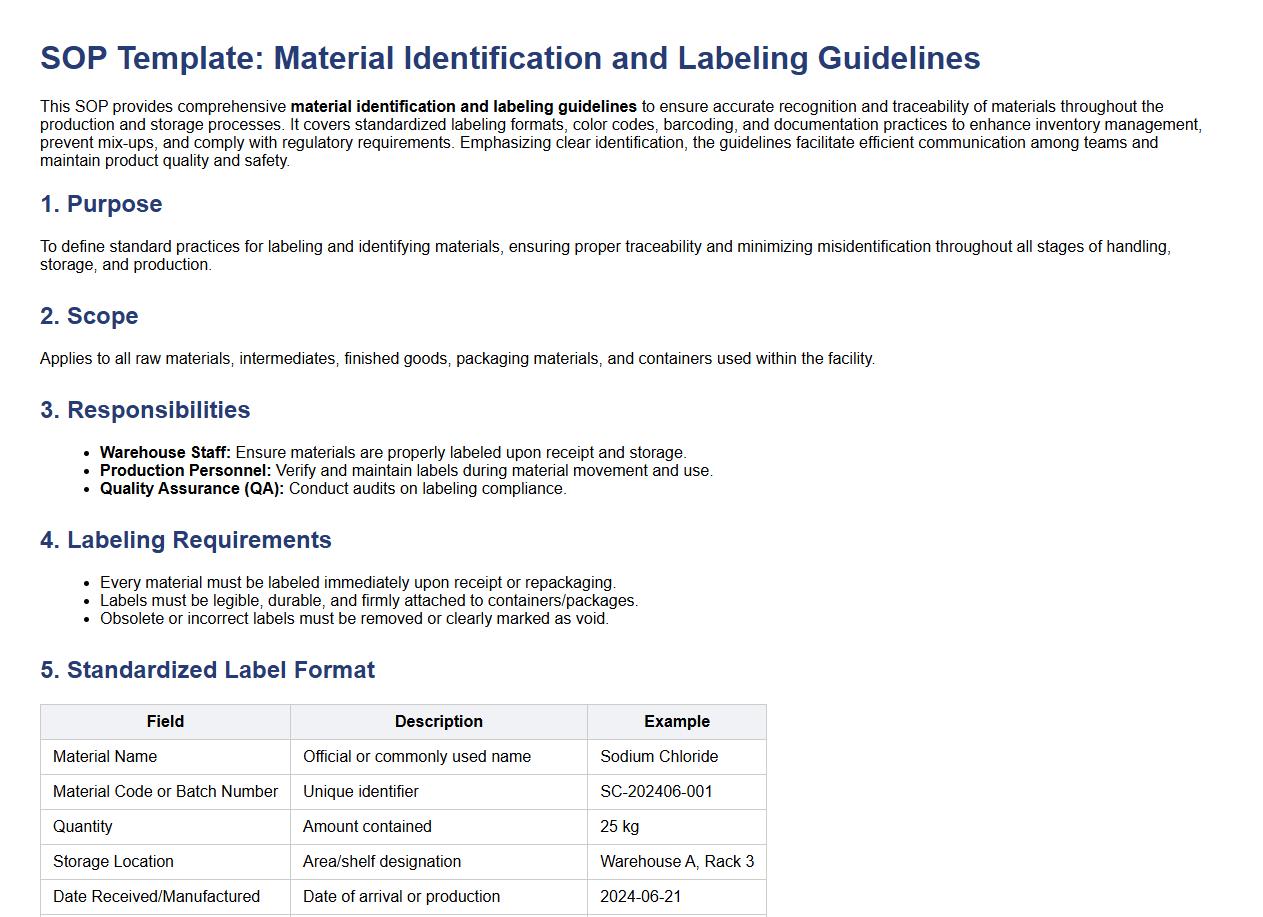

Material identification and labeling guidelines.

This SOP provides comprehensive material identification and labeling guidelines to ensure accurate recognition and traceability of materials throughout the production and storage processes. It covers standardized labeling formats, color codes, barcoding, and documentation practices to enhance inventory management, prevent mix-ups, and comply with regulatory requirements. Emphasizing clear identification, the guidelines facilitate efficient communication among teams and maintain product quality and safety.

Material storage and segregation protocols.

This SOP details material storage and segregation protocols, focusing on the proper organization, handling, and separation of various materials to prevent contamination, damage, and safety hazards. It includes guidelines for labeling, storage conditions, inventory management, and segregation based on material type, compatibility, and regulatory requirements. The objective is to maintain material integrity, ensure workplace safety, and optimize storage efficiency.

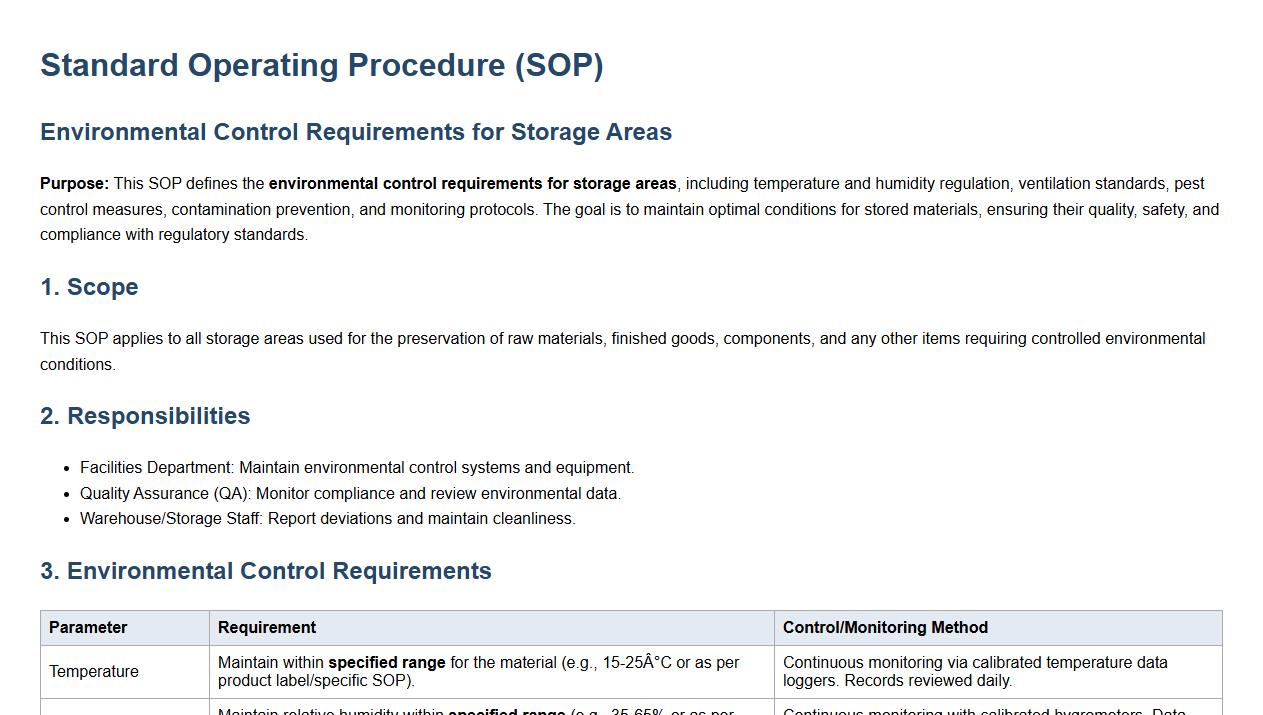

Environmental control requirements for storage areas.

This SOP defines the environmental control requirements for storage areas, including temperature and humidity regulation, ventilation standards, pest control measures, contamination prevention, and monitoring protocols. The goal is to maintain optimal conditions for stored materials, ensuring their quality, safety, and compliance with regulatory standards.

Raw material traceability and documentation process.

This SOP defines the raw material traceability and documentation process, detailing procedures for tracking raw materials from receipt through production to ensure product quality and compliance. It covers methods for recording material origin, batch numbers, storage conditions, and handling instructions, as well as maintaining accurate and accessible documentation to support audits, quality control, and regulatory requirements.

Material handling equipment usage and cleaning procedures.

This SOP details the material handling equipment usage and cleaning procedures, covering the proper operation, maintenance, and cleaning of forklifts, pallet jacks, conveyors, and other handling tools. It aims to ensure safe and efficient equipment handling, prevent contamination, reduce wear and tear, and maintain a clean and safe work environment. Regular inspections, cleaning schedules, and operator training are emphasized to maximize equipment longevity and workplace safety.

Procedure for sampling and quality testing of materials.

This SOP details the procedure for sampling and quality testing of materials, encompassing the selection of appropriate sampling methods, sample collection techniques, sample preservation and labeling, quality testing protocols, data recording and analysis, and reporting of results. The objective is to ensure that materials meet specified quality standards through systematic sampling and accurate testing, thereby maintaining product integrity and compliance with regulatory requirements.

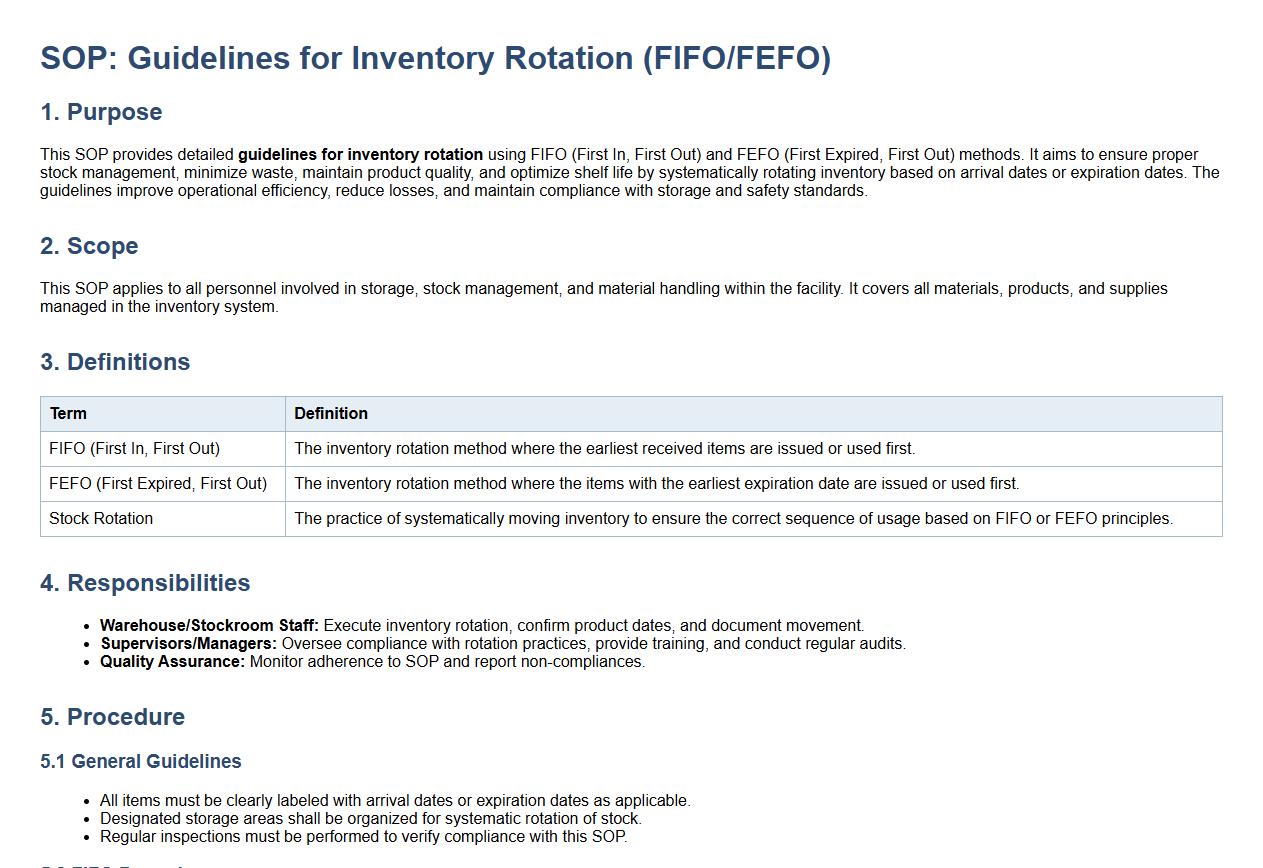

Guidelines for inventory rotation (FIFO/FEFO).

This SOP provides detailed guidelines for inventory rotation using FIFO (First In, First Out) and FEFO (First Expired, First Out) methods. It includes procedures to ensure proper stock management, minimize waste, maintain product quality, and optimize shelf life by systematically rotating inventory based on arrival dates or expiration dates. The guidelines aim to improve operational efficiency, reduce losses, and maintain compliance with storage and safety standards.

Non-conforming material identification and quarantine steps.

This SOP details the non-conforming material identification and quarantine steps, outlining procedures for detecting, labeling, and isolating materials that do not meet specified quality standards. It includes criteria for identifying non-conformities, assigning proper quarantine status, documenting findings, and preventing the use or shipment of defective materials. The purpose is to ensure product quality by effectively managing and controlling non-conforming materials until appropriate corrective actions are taken.

Raw material issue and transfer procedures to production.

This SOP details the raw material issue and transfer procedures to production, covering the accurate identification, documentation, and handling of raw materials from storage to the production floor. It ensures proper allocation, tracking, and timely delivery of materials to support uninterrupted manufacturing processes, emphasizing quality control, accountability, and compliance with inventory management standards to optimize production efficiency and minimize waste.

Critical Steps in Receiving and Verifying Raw Materials

The Standard Operating Procedure (SOP) mandates thorough inspection upon receipt to ensure raw materials meet quality standards. Verification involves checking supplier documentation, batch numbers, and compliance with predefined specifications. This step guarantees that only materials conforming to requirements proceed to production.

Ensuring Traceability and Documentation of Raw Material Batches

The SOP requires detailed recording of batch numbers, supplier information, and reception dates for all raw materials. This information is logged into a centralized system enhancing traceability throughout the manufacturing process. Proper documentation supports quality audits and recall procedures if necessary.

Specified Storage Conditions for Different Raw Materials

Storage protocols within the SOP specify temperature, humidity, and segregation needs tailored to each raw material type. These conditions preserve material integrity and prevent degradation or contamination. Adherence to these standards ensures consistent product quality and safety.

Addressing Contamination or Cross-Contamination Risks

The SOP outlines strict handling procedures to minimize the risk of contamination or cross-contact between different raw materials. This includes using dedicated equipment, cleaning protocols, and personnel hygiene requirements. Effective control of these risks is vital for maintaining product purity and compliance.

Procedures for Handling Non-Conforming or Rejected Raw Materials

The SOP establishes clear guidelines for identifying and isolating non-conforming materials to prevent their inadvertent use. Rejected batches are documented, quarantined, and either returned to the supplier or disposed of according to regulatory standards. This process safeguards the manufacturing workflow from quality breaches.