A SOP Template for Energy Management in Manufacturing provides a structured framework to systematically monitor, control, and optimize energy usage in production processes. It ensures consistent practices that improve energy efficiency, reduce waste, and lower operational costs. Implementing this template supports sustainability goals and compliance with industry standards.

Energy usage monitoring and benchmarking procedures.

This SOP details energy usage monitoring and benchmarking procedures, covering the systematic tracking of energy consumption, data collection methods, analysis techniques, performance comparison against industry standards, identification of energy-saving opportunities, and regular reporting. The goal is to optimize energy efficiency, reduce operational costs, and support sustainability initiatives by establishing consistent monitoring and benchmarking practices.

Operational guidelines for energy-efficient machinery usage.

This SOP details operational guidelines for energy-efficient machinery usage, focusing on optimizing machinery performance, reducing energy consumption, and minimizing environmental impact. It includes procedures for regular maintenance, proper machine calibration, energy-saving operational techniques, monitoring and recording energy use, and training personnel on efficient machinery practices. The objective is to enhance productivity while promoting sustainable and cost-effective energy management in machinery operations.

Standard schedule for equipment maintenance to optimize energy consumption.

This SOP establishes a standard schedule for equipment maintenance aimed at optimizing energy consumption by ensuring regular inspection, cleaning, lubrication, and timely repairs of machinery. The procedure includes defining maintenance intervals, documenting maintenance activities, and using data-driven insights to improve equipment efficiency, reduce downtime, and minimize energy waste. Adhering to this schedule supports sustainable energy use, extends equipment lifespan, and lowers operational costs.

Procedures for lighting and HVAC system management.

This SOP details the procedures for lighting and HVAC system management, encompassing system installation, regular maintenance schedules, energy efficiency optimization, troubleshooting common issues, safety protocols during repairs, and guidelines for system upgrades. The objective is to ensure optimal performance, energy conservation, and occupant comfort while maintaining system reliability and safety.

Protocol for implementing and maintaining energy-saving devices.

This SOP details the protocol for implementing and maintaining energy-saving devices, covering device selection criteria, installation procedures, regular maintenance schedules, monitoring and performance evaluation, energy consumption reporting, staff training on energy conservation, troubleshooting common issues, and continuous improvement strategies to ensure optimal energy efficiency and cost savings within the organization.

Procedures for shutting down idle equipment and machinery.

This SOP details the procedures for shutting down idle equipment and machinery to ensure safety, prevent damage, and conserve energy. It includes steps for properly powering off machinery, securing equipment against unauthorized use, conducting inspections for potential hazards, and documenting shutdown activities. Adhering to these procedures helps maintain operational efficiency and reduces risk of accidents during equipment inactivity.

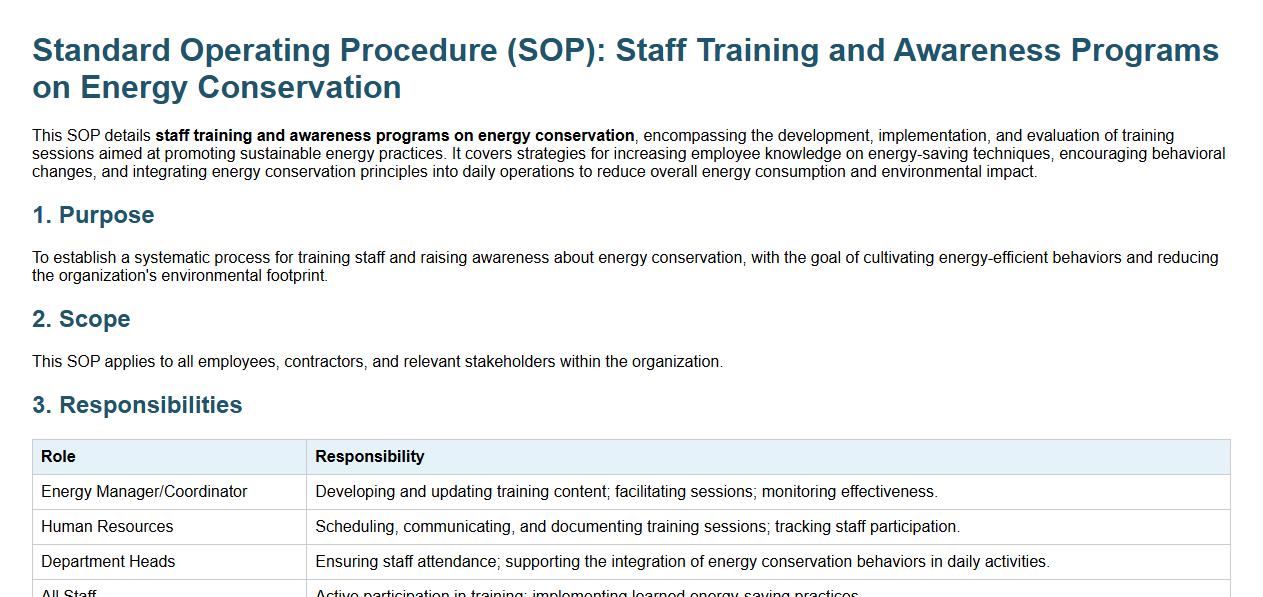

Staff training and awareness programs on energy conservation.

This SOP details staff training and awareness programs on energy conservation, encompassing the development, implementation, and evaluation of training sessions aimed at promoting sustainable energy practices. It covers strategies for increasing employee knowledge on energy-saving techniques, encouraging behavioral changes, and integrating energy conservation principles into daily operations to reduce overall energy consumption and environmental impact.

Guidelines for energy audits and inspection routines.

This SOP provides comprehensive guidelines for energy audits and inspection routines, detailing systematic procedures to assess energy consumption, identify inefficiencies, and recommend improvements. It covers planning and scheduling audits, data collection methods, inspection checklist development, analysis of findings, reporting standards, and follow-up actions to enhance energy efficiency and reduce operational costs.

Reporting and documentation of energy consumption data.

This SOP details the procedures for reporting and documentation of energy consumption data, including systematic data collection, accurate recording methods, regular monitoring, verification processes, and timely reporting formats. The aim is to ensure comprehensive tracking of energy usage for effective analysis, regulatory compliance, and strategic energy management.

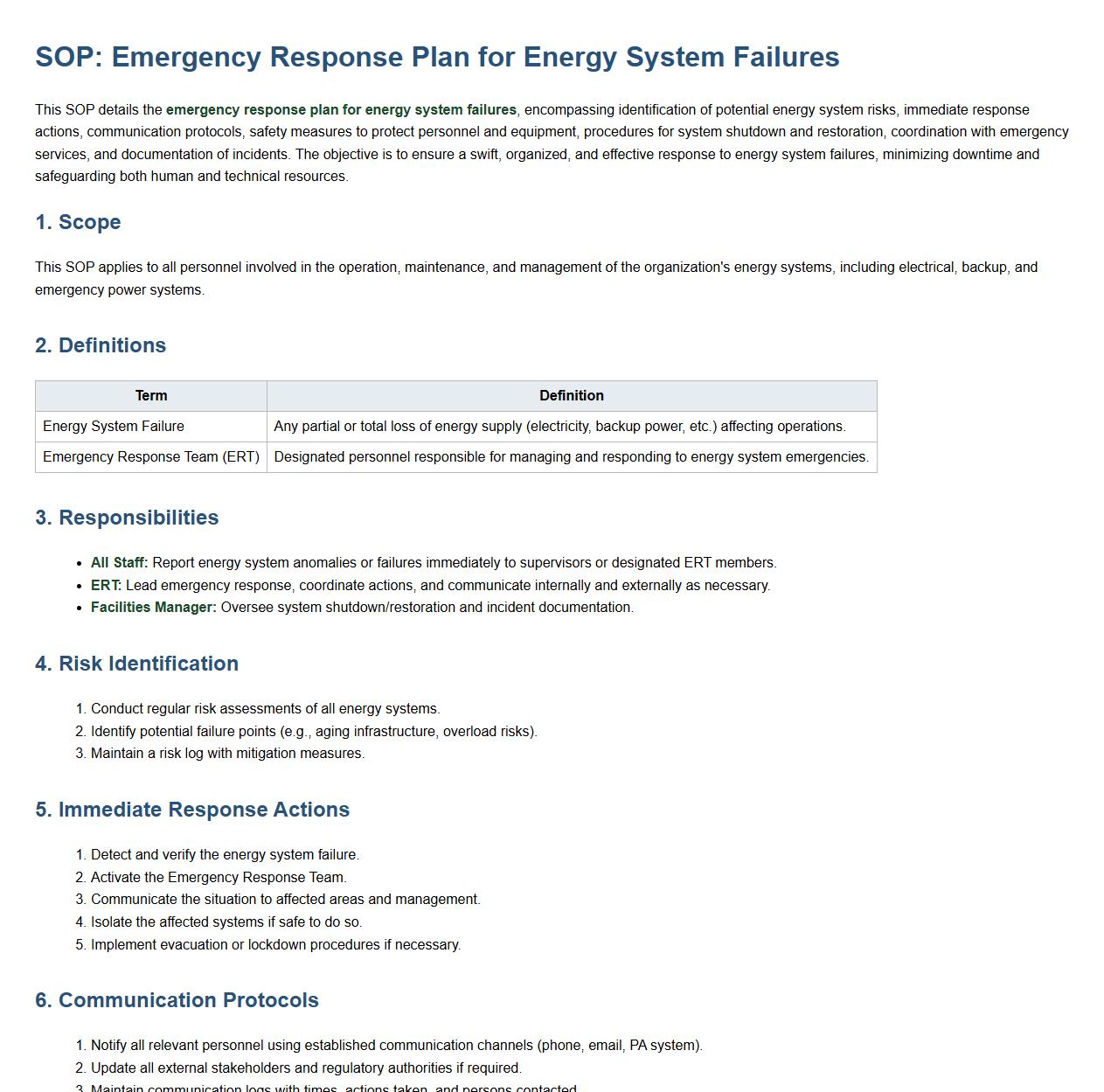

Emergency response plan for energy system failures.

This SOP details the emergency response plan for energy system failures, encompassing identification of potential energy system risks, immediate response actions, communication protocols, safety measures to protect personnel and equipment, procedures for system shutdown and restoration, coordination with emergency services, and documentation of incidents. The objective is to ensure a swift, organized, and effective response to energy system failures, minimizing downtime and safeguarding both human and technical resources.

What are the main objectives of the SOP for Energy Management in Manufacturing?

The main objectives of the SOP for Energy Management aim to reduce energy consumption through efficient practices. It focuses on minimizing environmental impact while enhancing cost savings in manufacturing operations. The SOP also ensures compliance with energy regulations and promotes sustainable production.

Which roles and responsibilities are defined for implementing energy-saving procedures?

Specific roles and responsibilities include energy managers overseeing implementation and employees adhering to energy-saving protocols. Management commits to providing resources and training for energy efficiency initiatives. Clear accountability is established to ensure active participation across all organizational levels.

What monitoring and reporting mechanisms are specified for tracking energy consumption?

The SOP outlines the use of energy monitoring systems such as meters and software to record consumption data. Regular reporting schedules ensure timely analysis and identification of inefficiencies. This data-driven approach supports informed decision-making to optimize energy use continuously.

Which operational controls are detailed for optimizing equipment and process energy use?

Operational controls include standard procedures for equipment maintenance, process adjustments, and scheduling to reduce energy waste. Energy-efficient technologies and automation are recommended to enhance performance. Controls are designed to align with production demands while minimizing unnecessary consumption.

What steps are included for continuous improvement in energy performance according to the SOP?

The SOP mandates regular energy audits and reviews to identify improvement opportunities. Training programs and feedback mechanisms encourage ongoing employee engagement. Continuous improvement cycles ensure energy strategies evolve with technological advances and operational changes.