A SOP Template for Production Scheduling standardizes the process of organizing and managing production timelines to enhance efficiency and reduce delays. It outlines clear steps for resource allocation, task prioritization, and timeline monitoring to ensure smooth workflow. This template serves as a valuable tool for maintaining consistency and improving communication across production teams.

Production forecast and demand analysis procedures.

This SOP details production forecast and demand analysis procedures, covering the systematic approach to predicting future product demand, analyzing market trends, assessing historical sales data, collaborating with sales and marketing teams, and utilizing forecasting tools and software. The objective is to enhance production planning accuracy, optimize inventory levels, reduce waste, and ensure timely fulfillment of customer orders by aligning manufacturing output with anticipated market needs.

Raw material inventory assessment and procurement planning.

This SOP defines the process for raw material inventory assessment and procurement planning, including regular inventory audits, demand forecasting, supplier evaluation, procurement scheduling, cost management, and risk mitigation strategies. The goal is to ensure optimal inventory levels, prevent stockouts, reduce excess holding costs, and maintain uninterrupted production flow through effective planning and timely procurement of raw materials.

Detailed master production schedule (MPS) creation steps.

This SOP details the master production schedule (MPS) creation steps, covering demand forecasting, capacity planning, resource allocation, production batch sizing, timeline establishment, inventory level coordination, and schedule validation. The objective is to develop an accurate and efficient MPS that aligns production activities with customer demand while optimizing resource utilization and minimizing lead times.

Daily and weekly production plan development.

This SOP details the process of daily and weekly production plan development, covering task scheduling, resource allocation, capacity assessment, and workflow coordination. It ensures efficient production management by aligning operational activities with demand forecasts, minimizing downtime, and optimizing labor and equipment utilization to meet production targets consistently.

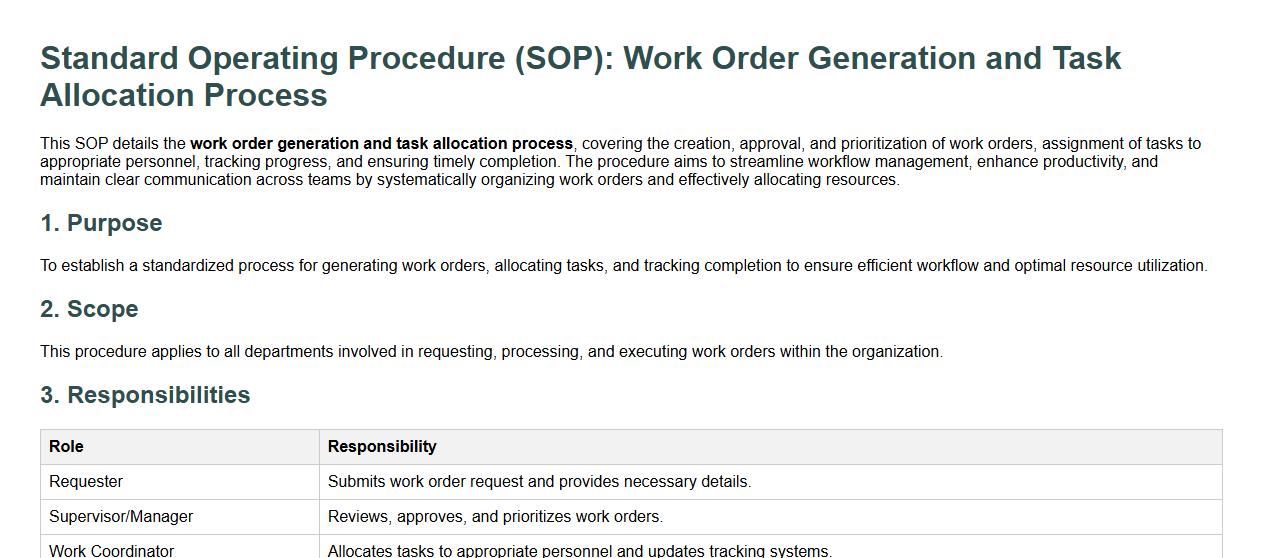

Work order generation and task allocation process.

This SOP details the work order generation and task allocation process, covering the creation, approval, and prioritization of work orders, assignment of tasks to appropriate personnel, tracking progress, and ensuring timely completion. The procedure aims to streamline workflow management, enhance productivity, and maintain clear communication across teams by systematically organizing work orders and effectively allocating resources.

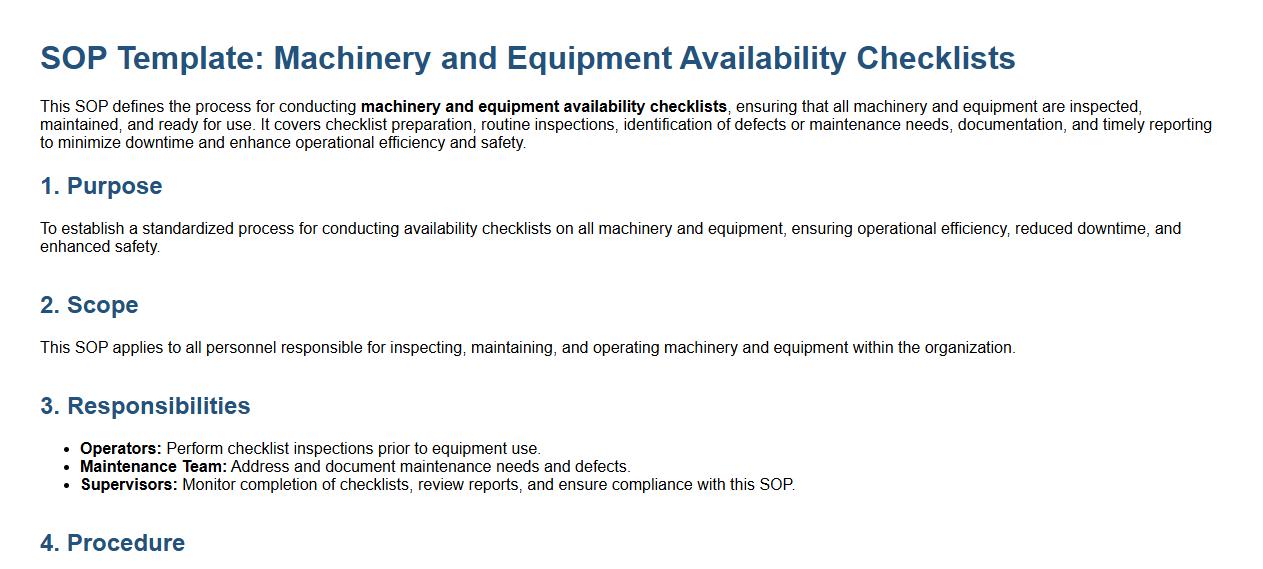

Machinery and equipment availability checklists.

This SOP defines the process for conducting machinery and equipment availability checklists, ensuring that all machinery and equipment are inspected, maintained, and ready for use. It covers checklist preparation, routine inspections, identification of defects or maintenance needs, documentation, and timely reporting to minimize downtime and enhance operational efficiency and safety.

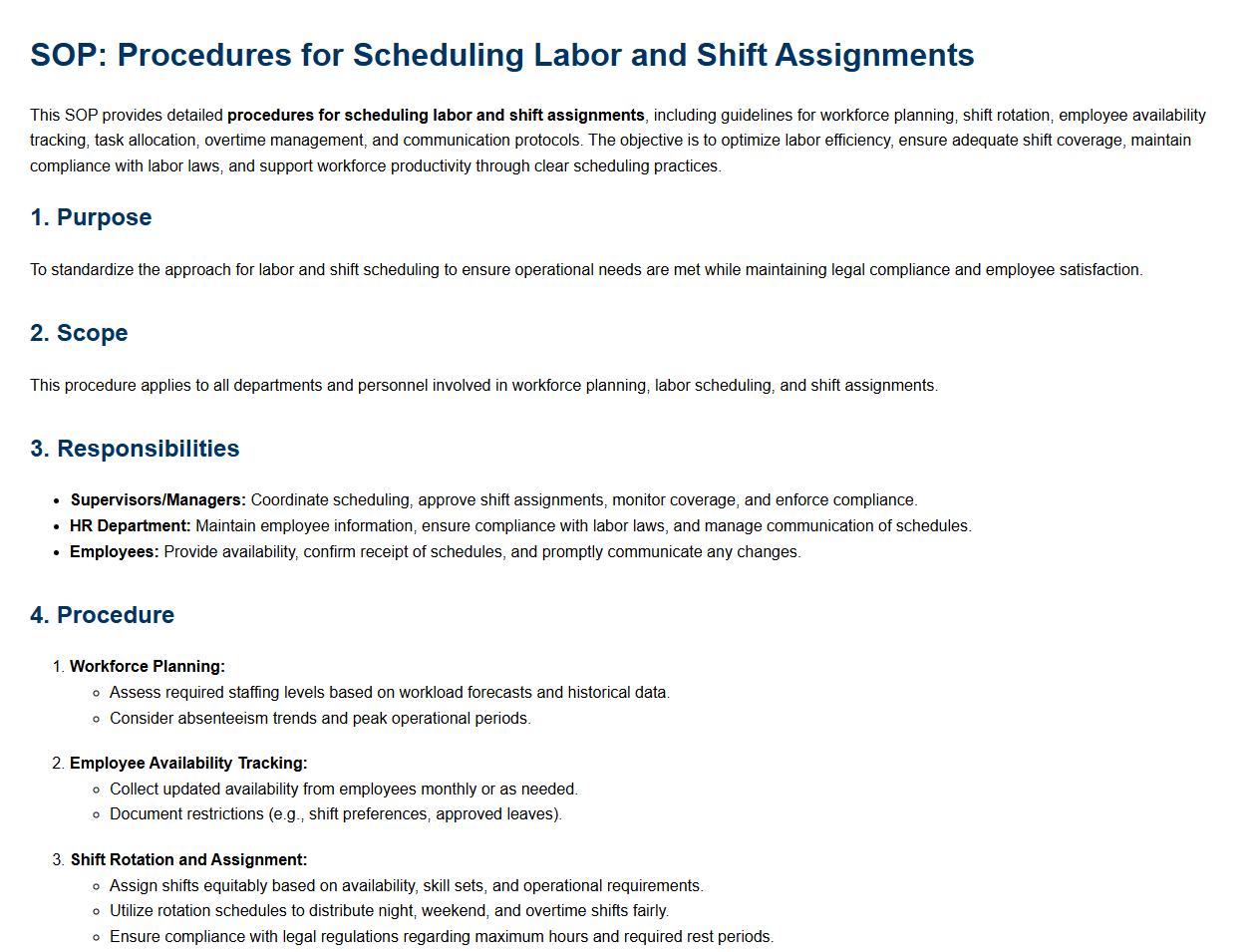

Procedures for scheduling labor and shift assignments.

This SOP provides detailed procedures for scheduling labor and shift assignments, including guidelines for workforce planning, shift rotation, employee availability tracking, task allocation, overtime management, and communication protocols. The objective is to optimize labor efficiency, ensure adequate shift coverage, maintain compliance with labor laws, and support workforce productivity through clear scheduling practices.

Process for tracking progress and adjusting schedules.

This SOP details the process for tracking progress and adjusting schedules, including setting milestones, monitoring task completion, identifying delays or bottlenecks, updating timelines, reallocating resources, and communicating changes to relevant stakeholders to ensure project objectives are met efficiently and on time.

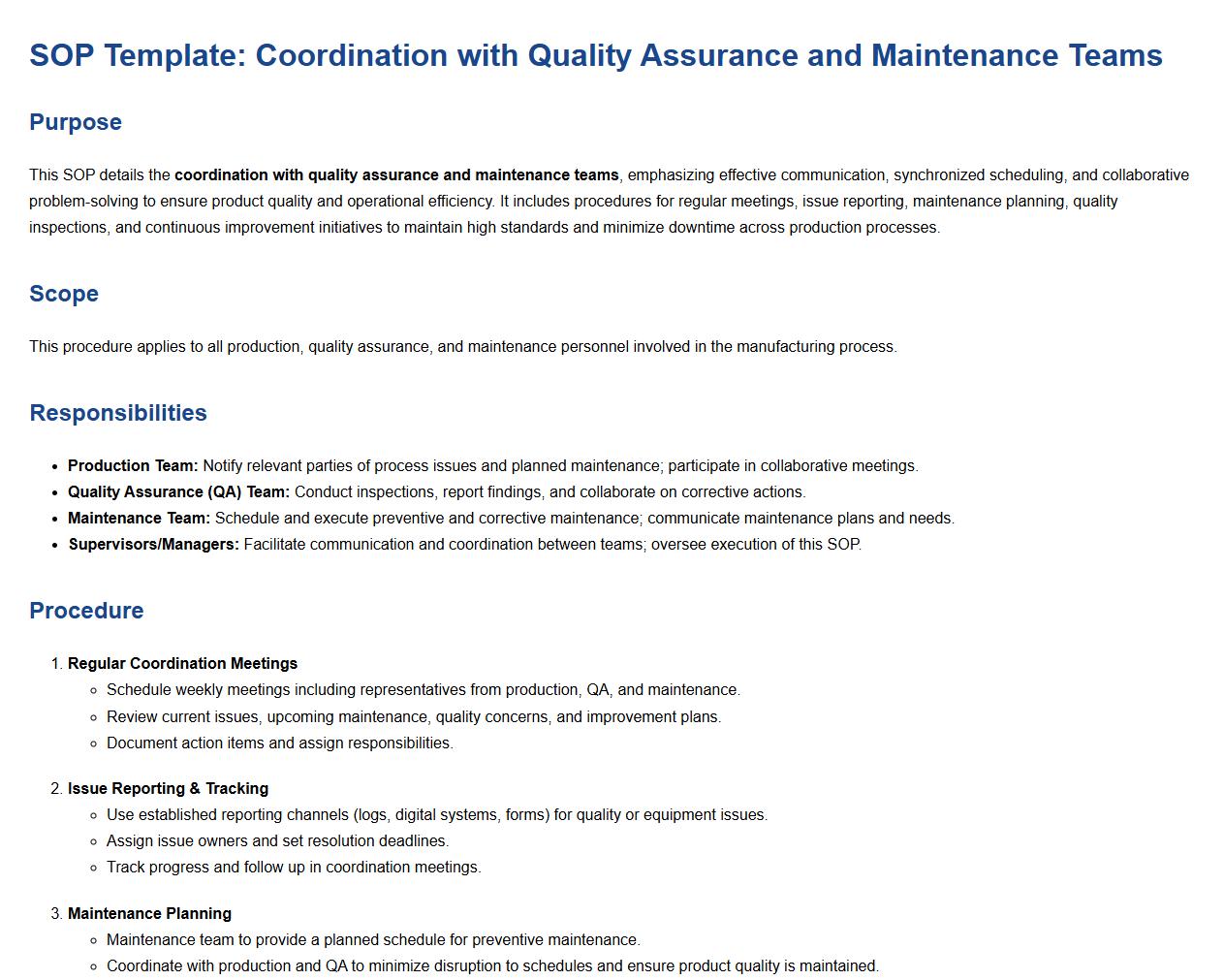

Coordination with quality assurance and maintenance teams.

This SOP details the coordination with quality assurance and maintenance teams, emphasizing effective communication, synchronized scheduling, and collaborative problem-solving to ensure product quality and operational efficiency. It includes procedures for regular meetings, issue reporting, maintenance planning, quality inspections, and continuous improvement initiatives to maintain high standards and minimize downtime across production processes.

Documentation, reporting, and communication protocols.

This SOP details the documentation, reporting, and communication protocols essential for maintaining accurate records, ensuring timely and clear communication, and facilitating effective reporting processes. It covers procedures for documenting incidents, reporting to relevant stakeholders, utilizing communication tools, maintaining confidentiality, and ensuring compliance with organizational and regulatory requirements to enhance transparency and accountability.

Criteria for Prioritizing Production Orders in SOP

The SOP for Production Scheduling uses order urgency as a primary criterion to prioritize production orders. It also considers inventory levels and customer delivery deadlines to ensure timely fulfillment. Additionally, factors such as production capacity and resource availability are evaluated to optimize the schedule.

Process for Handling Changes or Disruptions in the Production Schedule

The SOP defines a structured protocol for managing changes or disruptions to maintain workflow continuity. It mandates immediate assessment of the impact followed by swift communication to all stakeholders. Contingency plans and rescheduling procedures are employed to minimize delays and maintain efficiency.

Roles and Responsibilities in Production Scheduling Activities

The SOP outlines the production planner as the key role responsible for schedule creation and adjustments. It assigns operators and supervisors to monitor execution and report issues promptly. Additionally, management oversees compliance and resource allocation to support the scheduling objectives.

Documentation and Communication Protocols for Schedule Changes

The SOP requires all schedule changes to be documented in a centralized system for transparency and traceability. Communication protocols include notifying relevant teams through formal channels such as emails or meetings. These steps ensure alignment across departments and prevent misinformation.

Resource Allocation and Constraint Management During Scheduling

The SOP emphasizes resource allocation based on availability and production priorities to optimize workflows. Constraint management involves identifying bottlenecks and adjusting schedules to mitigate their impact. Continuous monitoring and updates to the schedule support effective resource utilization.