A SOP Template for Hazardous Material Handling provides a standardized framework to ensure safe and compliant management of dangerous substances. It outlines clear procedures for storage, transportation, and disposal to minimize risks and protect workers and the environment. This template helps organizations maintain regulatory compliance and enhance workplace safety through consistent practices.

Hazardous material identification and classification.

This SOP focuses on hazardous material identification and classification, detailing the processes for accurately recognizing hazardous substances, categorizing them according to regulatory standards, understanding their physical and chemical properties, labeling requirements, and ensuring proper handling and storage. The goal is to minimize risks associated with hazardous materials, protect personnel and the environment, and comply with applicable safety regulations and guidelines.

Personal protective equipment (PPE) requirements and usage.

This SOP details the personal protective equipment (PPE) requirements and usage to ensure employee safety across various work environments. It covers the selection, proper wearing, maintenance, and replacement of PPE such as gloves, helmets, goggles, and respiratory protection. The objective is to minimize exposure to hazards that can cause injury or illness by enforcing consistent use of appropriate protective gear. Training and compliance monitoring are integral components to uphold workplace safety standards.

Safe storage procedures for hazardous materials.

This SOP details safe storage procedures for hazardous materials, including proper labeling and identification, selection of appropriate storage containers, segregation of incompatible substances, ventilation requirements, temperature and humidity controls, regular inspection and maintenance of storage areas, emergency spill response measures, and compliance with regulatory standards. The goal is to minimize risks associated with hazardous materials by ensuring secure and organized storage, protecting personnel, property, and the environment from potential hazards.

Material handling and transport protocols.

This SOP details material handling and transport protocols, encompassing safe lifting techniques, equipment usage guidelines, load securing methods, transportation route planning, hazard identification, personal protective equipment requirements, and emergency response procedures. The goal is to minimize risks of injury, damage to materials, and operational disruptions by promoting efficient and safe handling and transport practices within the workplace.

Spill prevention, containment, and cleanup procedures.

This SOP details spill prevention, containment, and cleanup procedures designed to minimize environmental impact and ensure workplace safety. It covers methods to prevent spills through proper storage and handling of hazardous materials, steps for immediate containment to limit spill spread, and systematic cleanup protocols to effectively remove contaminants. The procedure aims to protect personnel, maintain regulatory compliance, and reduce potential damage to property and ecosystems.

Emergency response and evacuation procedures.

This SOP details emergency response and evacuation procedures, focusing on immediate actions during emergencies, clear evacuation routes, roles and responsibilities of personnel, communication protocols, assembly points, and post-evacuation accountability. The objective is to ensure a swift, organized, and safe evacuation to minimize risks to life and property in various emergency scenarios such as fires, natural disasters, or hazardous material incidents.

Hazard communication and labeling standards.

This SOP details hazard communication and labeling standards to ensure clear identification and management of hazardous materials. It covers requirements for proper labeling of chemicals, safety data sheets (SDS) accessibility, employee training on hazard recognition, and communication protocols to maintain workplace safety and regulatory compliance. The goal is to reduce risks by providing accurate information about chemical hazards to all personnel.

Waste disposal and decontamination processes.

This SOP details the waste disposal and decontamination processes, covering proper segregation, handling, and disposal of waste materials, protocols for cleaning and decontaminating equipment and surfaces, safe management of hazardous substances, and compliance with environmental regulations. The goal is to minimize environmental impact, reduce contamination risks, and ensure a safe working environment through effective waste management and thorough decontamination practices.

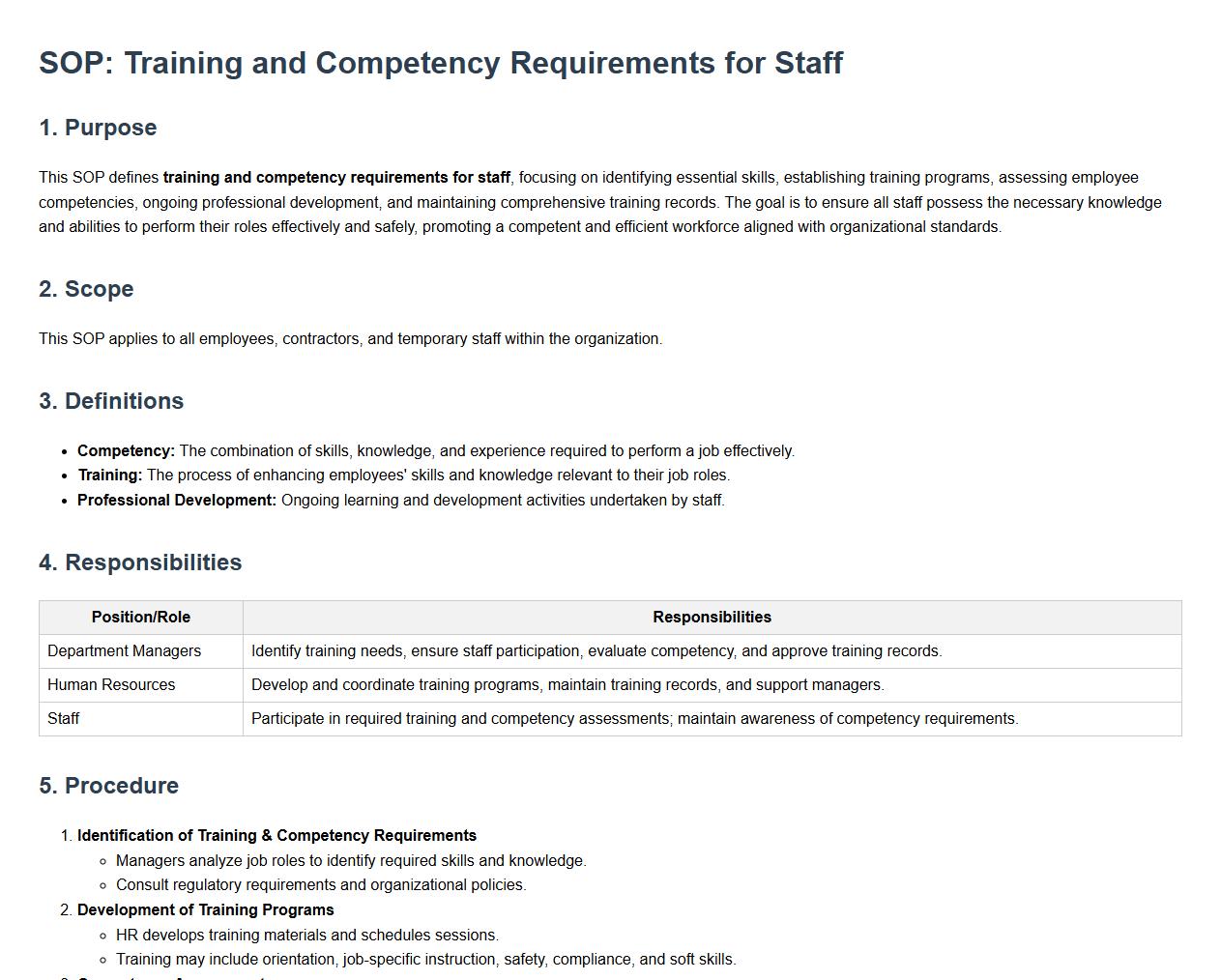

Training and competency requirements for staff.

This SOP defines training and competency requirements for staff, focusing on identifying essential skills, establishing training programs, assessing employee competencies, ongoing professional development, and maintaining comprehensive training records. The goal is to ensure all staff possess the necessary knowledge and abilities to perform their roles effectively and safely, promoting a competent and efficient workforce aligned with organizational standards.

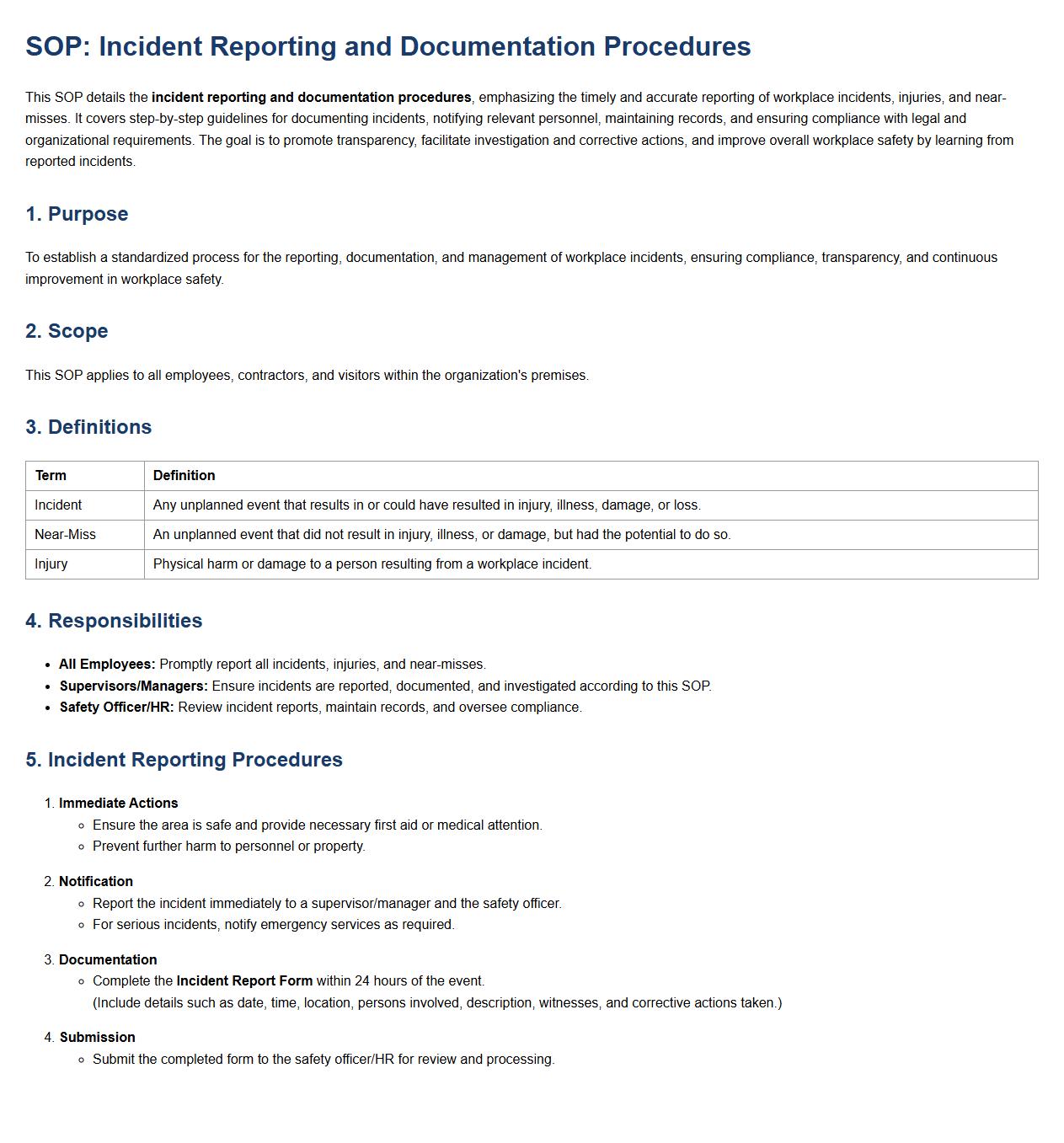

Incident reporting and documentation procedures.

This SOP details the incident reporting and documentation procedures, emphasizing the timely and accurate reporting of workplace incidents, injuries, and near-misses. It covers step-by-step guidelines for documenting incidents, notifying relevant personnel, maintaining records, and ensuring compliance with legal and organizational requirements. The goal is to promote transparency, facilitate investigation and corrective actions, and improve overall workplace safety by learning from reported incidents.

What are the key personal protective equipment (PPE) requirements specified in the SOP for handling hazardous materials?

The SOP emphasizes the use of appropriate protective gloves to prevent skin exposure to hazardous chemicals. It mandates wearing chemical-resistant aprons and eye protection such as safety goggles or face shields to safeguard against splashes. Additionally, respiratory protection devices are required when working with airborne hazardous substances to ensure safe breathing conditions.

How does the SOP define emergency response procedures for hazardous material spills or exposures?

The SOP outlines immediate notification of designated emergency personnel upon a spill or exposure incident. It prioritizes containment of the spill using absorbent materials and proper ventilation to minimize hazards. Furthermore, it instructs on prompt medical evaluation and decontamination for affected individuals to reduce health risks.

What labeling and storage protocols for hazardous materials are mandated in the SOP?

The SOP requires that all hazardous materials be labeled clearly with chemical identity, hazard warnings, and handling instructions. It enforces storage in designated, well-ventilated areas separated according to compatibility to prevent dangerous reactions. Regular inspections and inventory management ensure labels remain visible and containers are intact.

Which decontamination steps are outlined in the SOP for personnel and equipment after handling hazardous substances?

The SOP specifies thorough washing of exposed skin with soap and water immediately after handling hazardous materials. It mandates proper cleaning and neutralization of equipment using approved decontamination agents to eliminate residue. Finally, disposal of contaminated cleaning materials must follow hazardous waste protocols to avoid secondary contamination.

How does the SOP specify procedures for the safe transportation and disposal of hazardous materials?

The SOP requires using certified containers that are leak-proof and properly sealed for transporting hazardous materials to prevent spills. It mandates adherence to regulatory guidelines for labeling and documentation during transport to ensure safety and compliance. Disposal must be conducted by licensed waste handlers using approved methods to minimize environmental impact.