A SOP Template for Production Line Changeover ensures a standardized process to minimize downtime and maintain product quality during equipment or product switches. It outlines detailed steps, responsible personnel, and required tools to streamline transitions efficiently. This template enhances consistency, safety, and operational effectiveness in manufacturing environments.

Pre-changeover equipment shutdown and isolation procedures.

This SOP details the pre-changeover equipment shutdown and isolation procedures to ensure safe and efficient transition between production runs. It covers step-by-step instructions for safely powering down equipment, isolating hazardous energy sources, verifying zero energy state, and securing machinery to prevent accidental startup. The procedure aims to protect personnel from injury, prevent equipment damage, and maintain compliance with safety regulations during changeover processes.

Removal and safe disposal of previous product materials.

This SOP details the process for the removal and safe disposal of previous product materials, including proper identification, handling, segregation, and transportation of residual substances. It emphasizes adherence to environmental regulations, workplace safety standards, and waste management protocols to prevent contamination, ensure worker safety, and promote sustainable disposal practices.

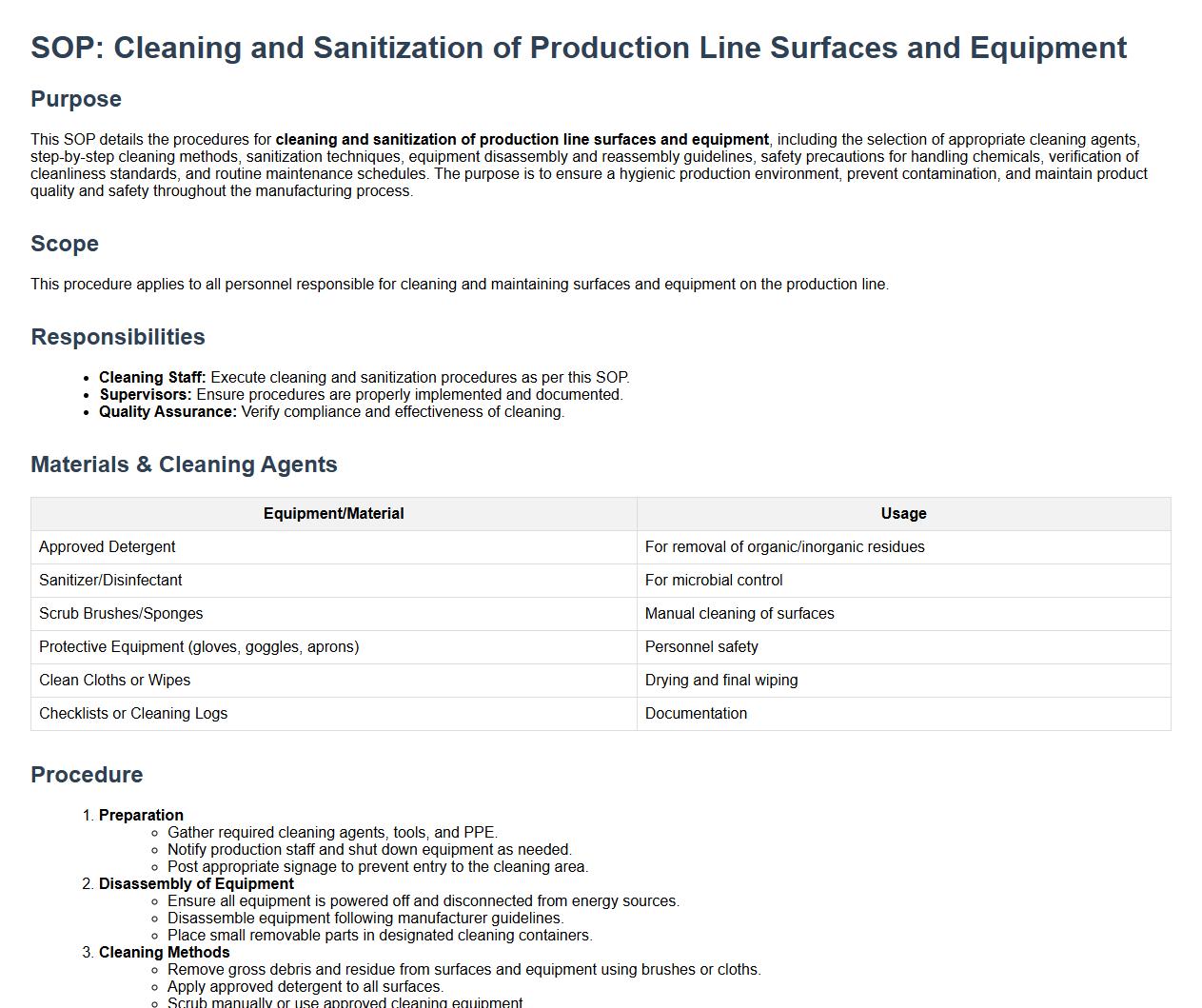

Cleaning and sanitization of production line surfaces and equipment.

This SOP details the procedures for cleaning and sanitization of production line surfaces and equipment, including the selection of appropriate cleaning agents, step-by-step cleaning methods, sanitization techniques, equipment disassembly and reassembly guidelines, safety precautions for handling chemicals, verification of cleanliness standards, and routine maintenance schedules. The purpose is to ensure a hygienic production environment, prevent contamination, and maintain product quality and safety throughout the manufacturing process.

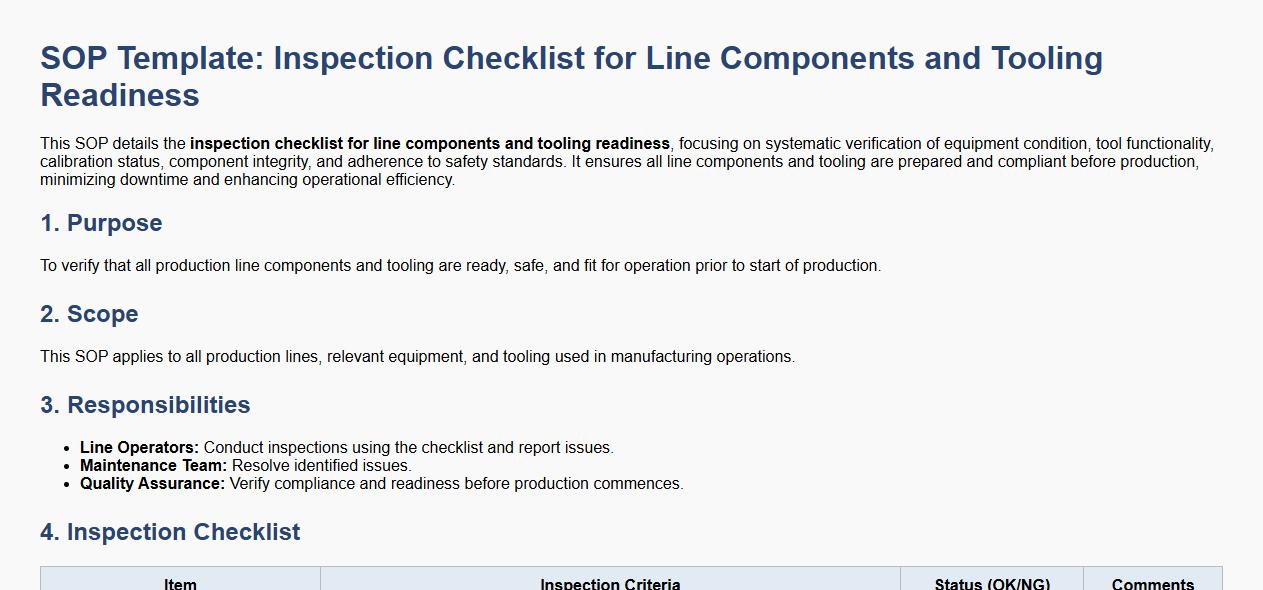

Inspection checklist for line components and tooling readiness.

This SOP details the inspection checklist for line components and tooling readiness, focusing on systematic verification of equipment condition, tool functionality, calibration status, component integrity, and adherence to safety standards. It ensures all line components and tooling are prepared and compliant before production, minimizing downtime and enhancing operational efficiency.

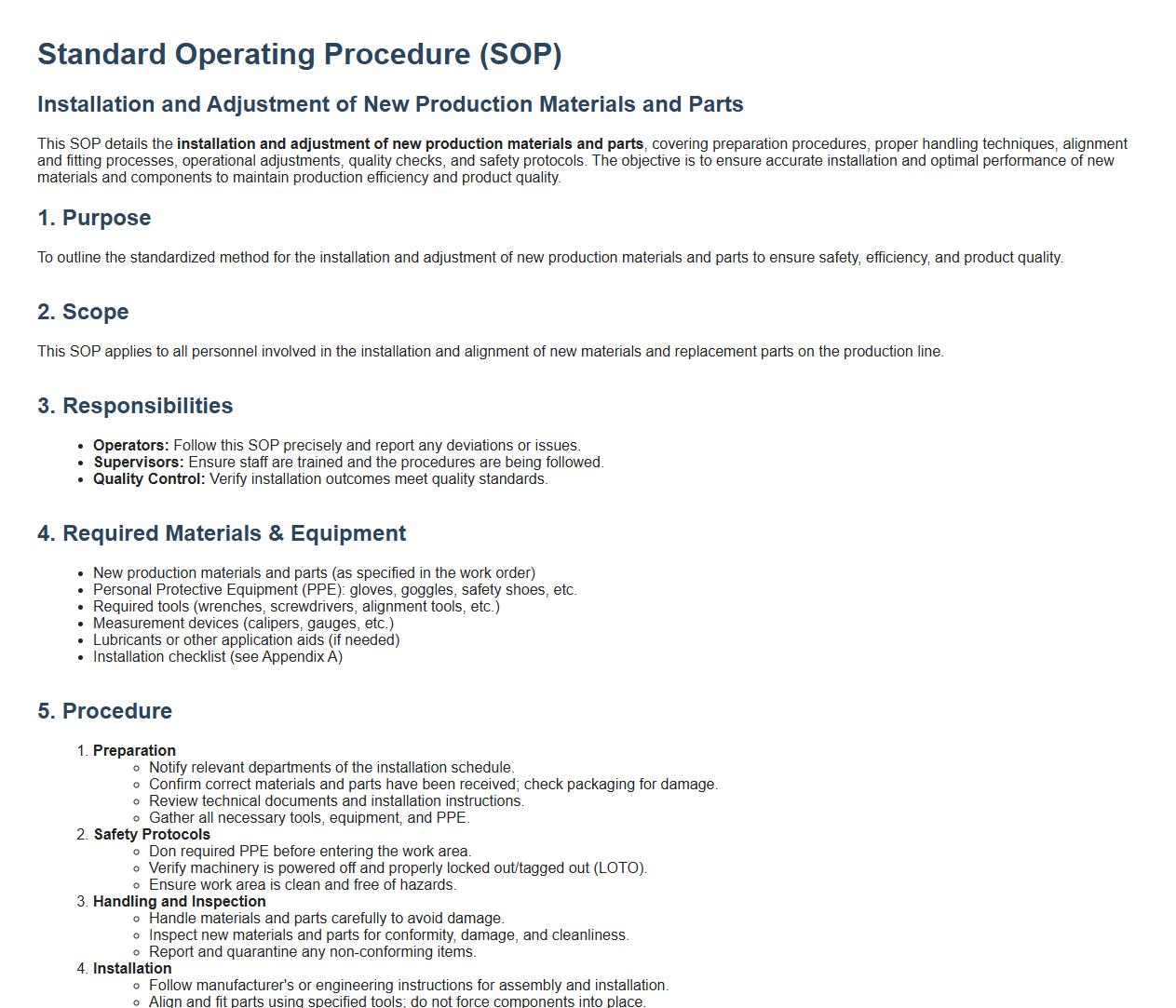

Installation and adjustment of new production materials and parts.

This SOP details the installation and adjustment of new production materials and parts, covering preparation procedures, proper handling techniques, alignment and fitting processes, operational adjustments, quality checks, and safety protocols. The objective is to ensure accurate installation and optimal performance of new materials and components to maintain production efficiency and product quality.

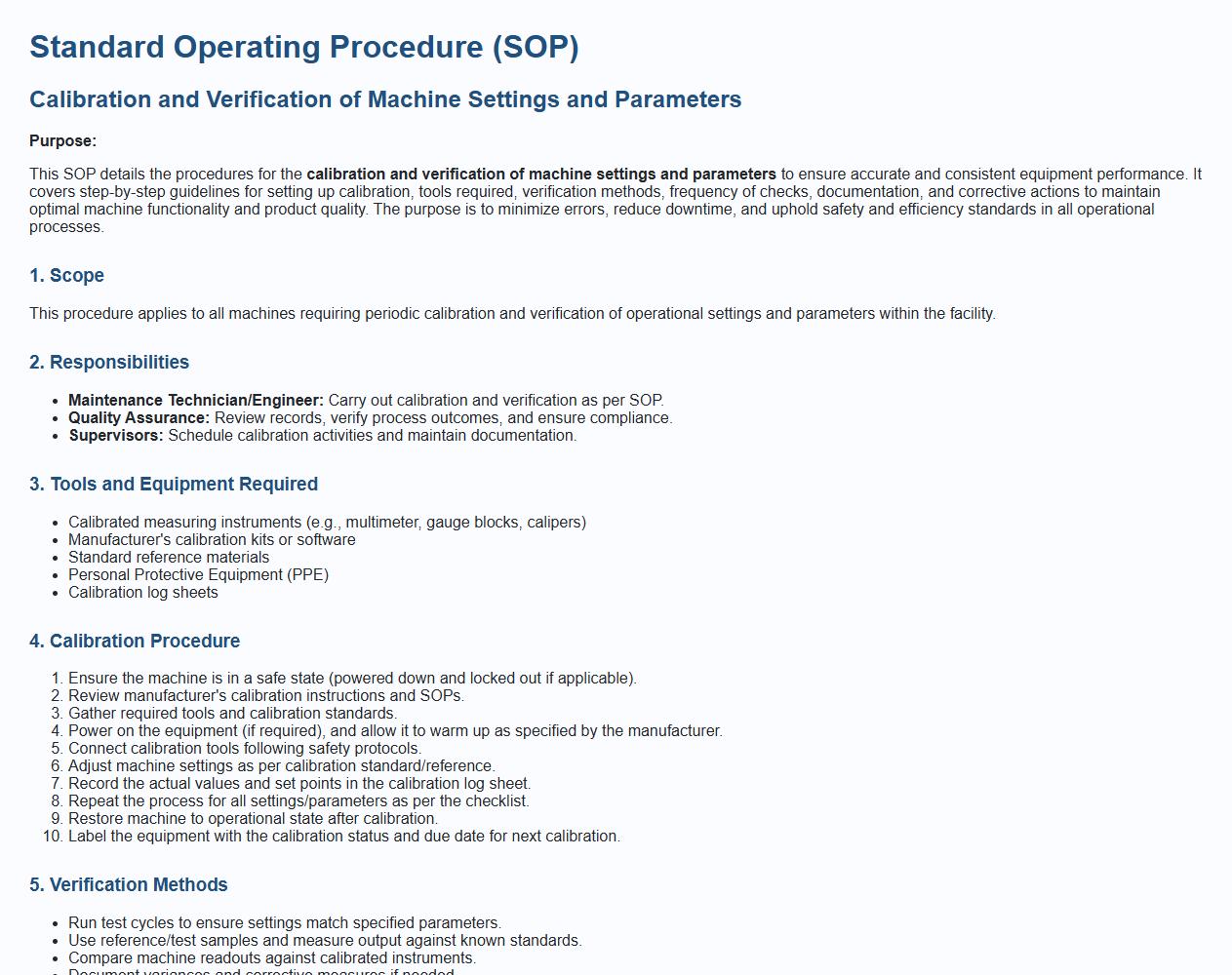

Calibration and verification of machine settings and parameters.

This SOP details the procedures for the calibration and verification of machine settings and parameters to ensure accurate and consistent equipment performance. It covers step-by-step guidelines for setting up calibration, tools required, verification methods, frequency of checks, documentation, and corrective actions to maintain optimal machine functionality and product quality. The purpose is to minimize errors, reduce downtime, and uphold safety and efficiency standards in all operational processes.

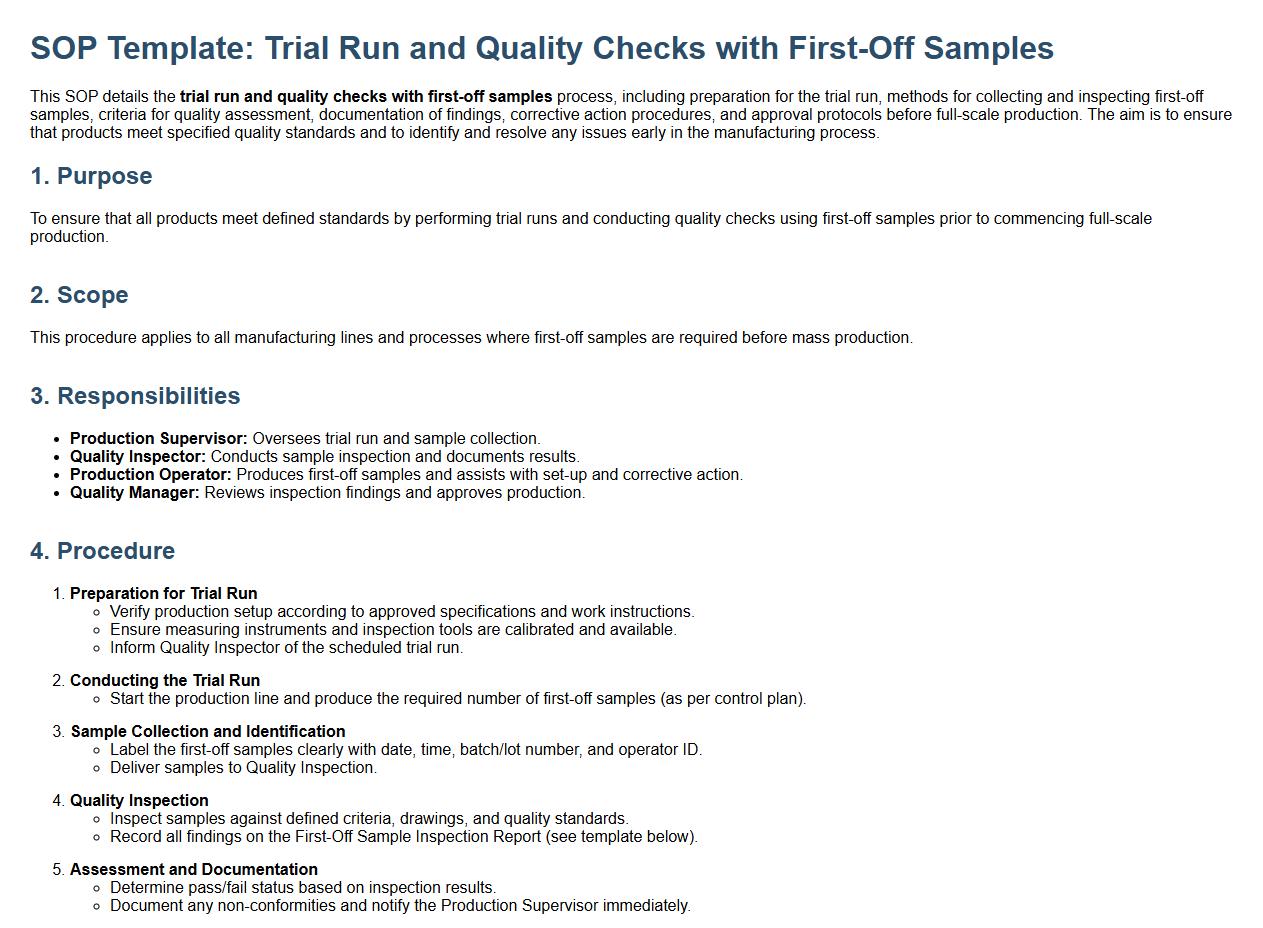

Trial run and quality checks with first-off samples.

This SOP details the trial run and quality checks with first-off samples process, including preparation for the trial run, methods for collecting and inspecting first-off samples, criteria for quality assessment, documentation of findings, corrective action procedures, and approval protocols before full-scale production. The aim is to ensure that products meet specified quality standards and to identify and resolve any issues early in the manufacturing process.

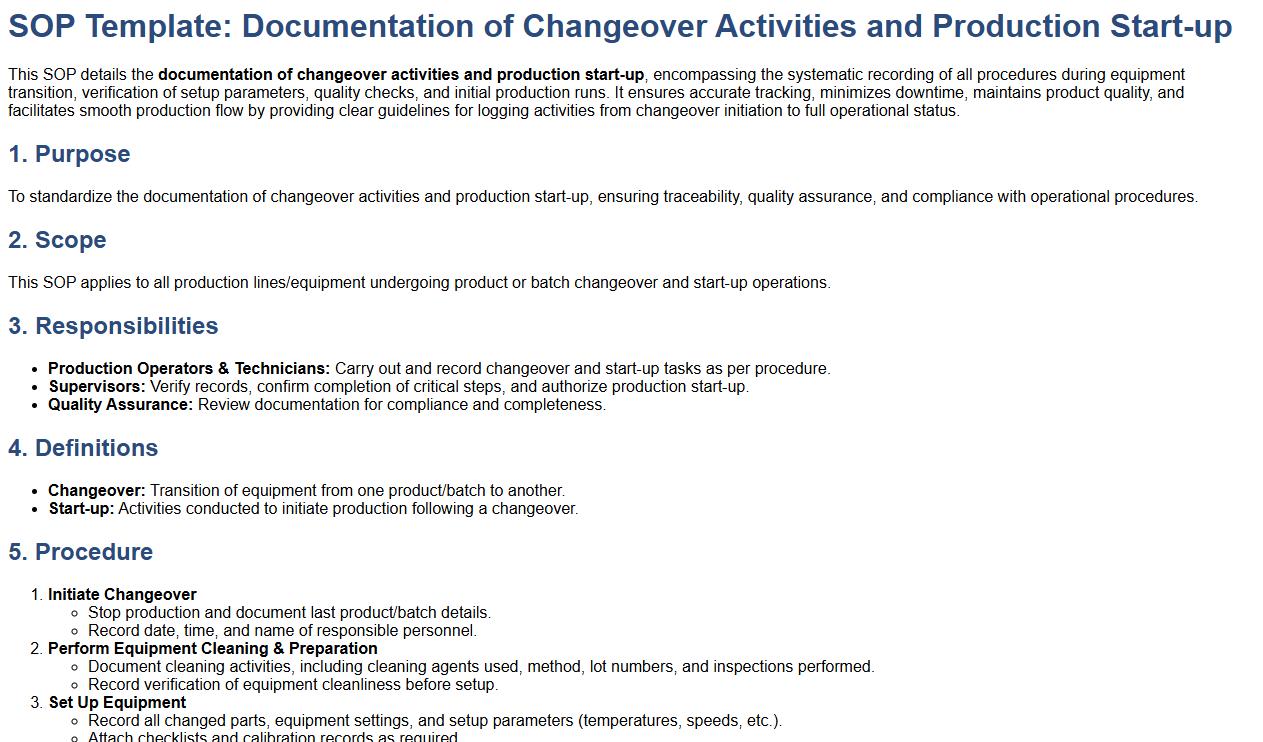

Documentation of changeover activities and production start-up.

This SOP details the documentation of changeover activities and production start-up, encompassing the systematic recording of all procedures during equipment transition, verification of setup parameters, quality checks, and initial production runs. It ensures accurate tracking, minimizes downtime, maintains product quality, and facilitates smooth production flow by providing clear guidelines for logging activities from changeover initiation to full operational status.

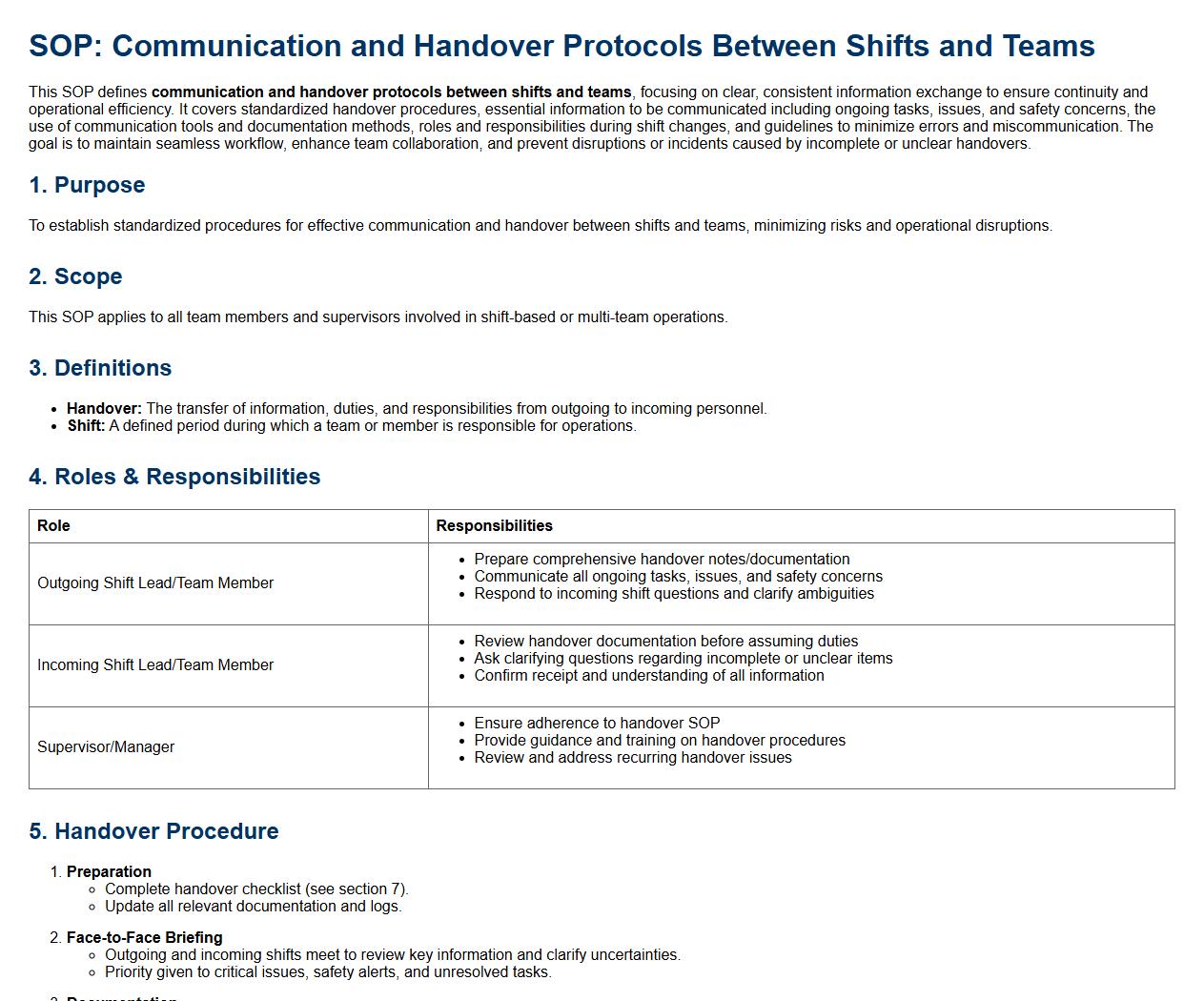

Communication and handover protocols between shifts and teams.

This SOP defines communication and handover protocols between shifts and teams, focusing on clear, consistent information exchange to ensure continuity and operational efficiency. It covers standardized handover procedures, essential information to be communicated including ongoing tasks, issues, and safety concerns, the use of communication tools and documentation methods, roles and responsibilities during shift changes, and guidelines to minimize errors and miscommunication. The goal is to maintain seamless workflow, enhance team collaboration, and prevent disruptions or incidents caused by incomplete or unclear handovers.

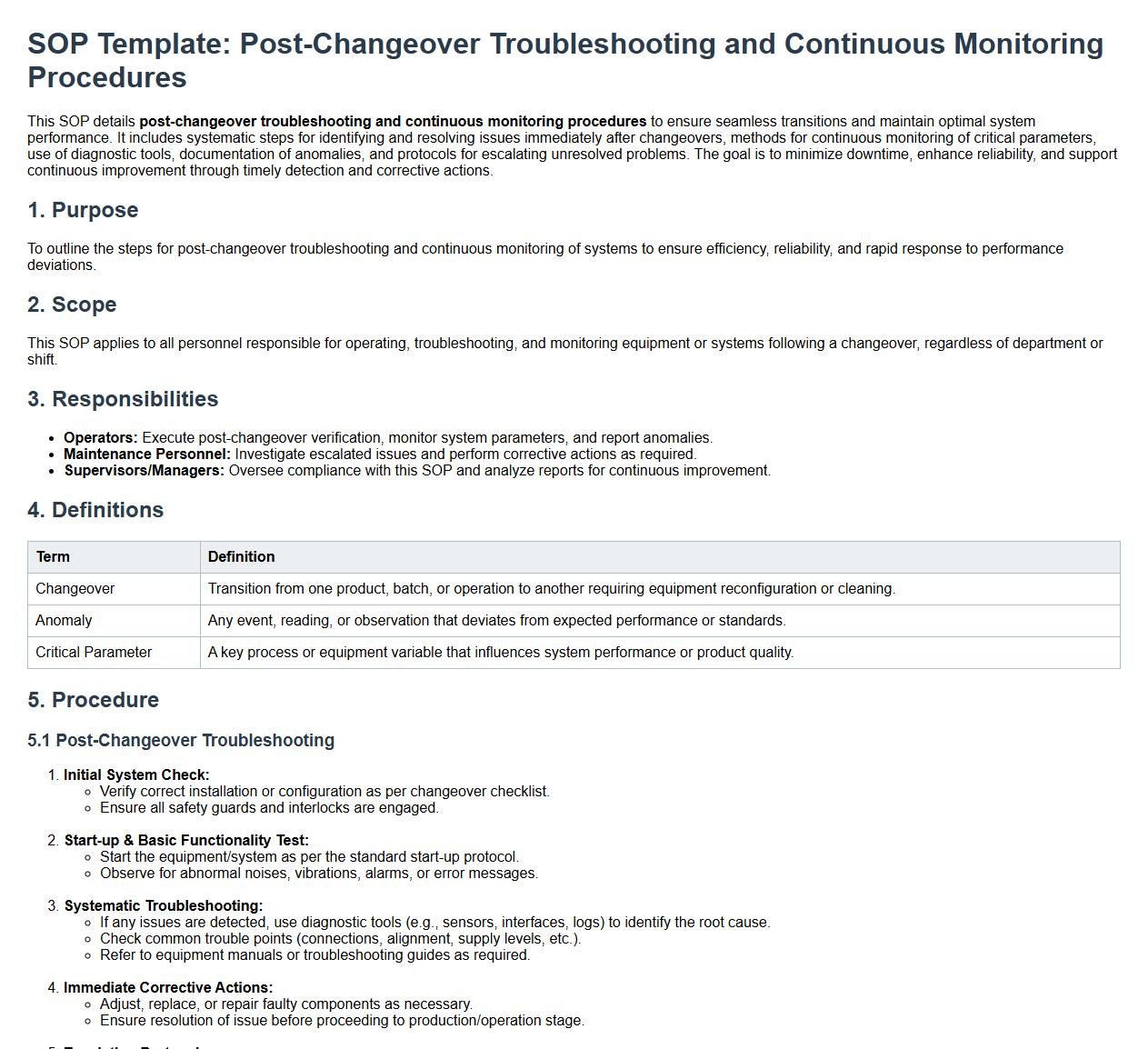

Post-changeover troubleshooting and continuous monitoring procedures.

This SOP details post-changeover troubleshooting and continuous monitoring procedures to ensure seamless transitions and maintain optimal system performance. It includes systematic steps for identifying and resolving issues immediately after changeovers, methods for continuous monitoring of critical parameters, use of diagnostic tools, documentation of anomalies, and protocols for escalating unresolved problems. The goal is to minimize downtime, enhance reliability, and support continuous improvement through timely detection and corrective actions.

Key Steps for Initiating a Production Line Changeover

The SOP outlines a series of structured steps to initiate a production line changeover effectively. These steps include shutting down the current line, preparing new materials, and calibrating the equipment. Following these instructions ensures minimal downtime and smooth transition between production batches.

Personnel Responsible for Verifying Production Line Readiness

The SOP specifies that production supervisors and quality control personnel are responsible for verifying the line's readiness before and after the changeover. Their roles involve inspecting equipment setup, material availability, and ensuring compliance with procedures. This verification process guarantees the line is fully operational and ready for production.

Safety and Quality Checks Mandated During Changeover

The SOP mandates comprehensive safety and quality checks throughout the changeover to prevent accidents and ensure product standards. Safety checks include verifying machine guards and emergency stops, while quality checks focus on product specifications and contamination control. These steps are critical to maintain safe working conditions and product integrity.

Equipment Cleaning and Material Handling in the Changeover Procedure

The SOP emphasizes thorough equipment cleaning to avoid cross-contamination during the changeover process. It also details proper material handling practices, including storage, labeling, and transfer protocols. Adhering to these guidelines ensures clean and organized production environments.

Documentation Requirements for Recording Production Line Changeover

The SOP requires detailed documentation for each changeover, including start and end times, personnel involved, and any issues encountered. These records are maintained to provide traceability and support continuous improvement efforts. Accurate documentation helps in tracking performance and ensuring compliance.