A SOP Template for Safety Procedures in Manufacturing ensures consistent and clear guidelines to protect workers and maintain compliance with industry standards. It outlines specific steps for hazard identification, equipment use, and emergency response, reducing risks and promoting a safe working environment. Proper implementation of this template enhances operational efficiency while prioritizing employee well-being.

Hazard identification and risk assessment procedures.

This SOP details the hazard identification and risk assessment procedures, focusing on systematically recognizing potential hazards in the workplace, evaluating the associated risks, and implementing appropriate control measures. It includes steps for hazard identification, risk analysis, risk evaluation, and documentation to ensure a safe working environment and compliance with safety regulations.

Personal protective equipment (PPE) usage and maintenance guidelines.

This SOP provides comprehensive personal protective equipment (PPE) usage and maintenance guidelines, covering the selection, proper use, cleaning, inspection, and storage of PPE to ensure optimal protection for employees in various workplace environments. The procedures emphasize adherence to safety standards, regular maintenance schedules, and proper training to minimize exposure to hazards and maintain the effectiveness and longevity of all protective gear.

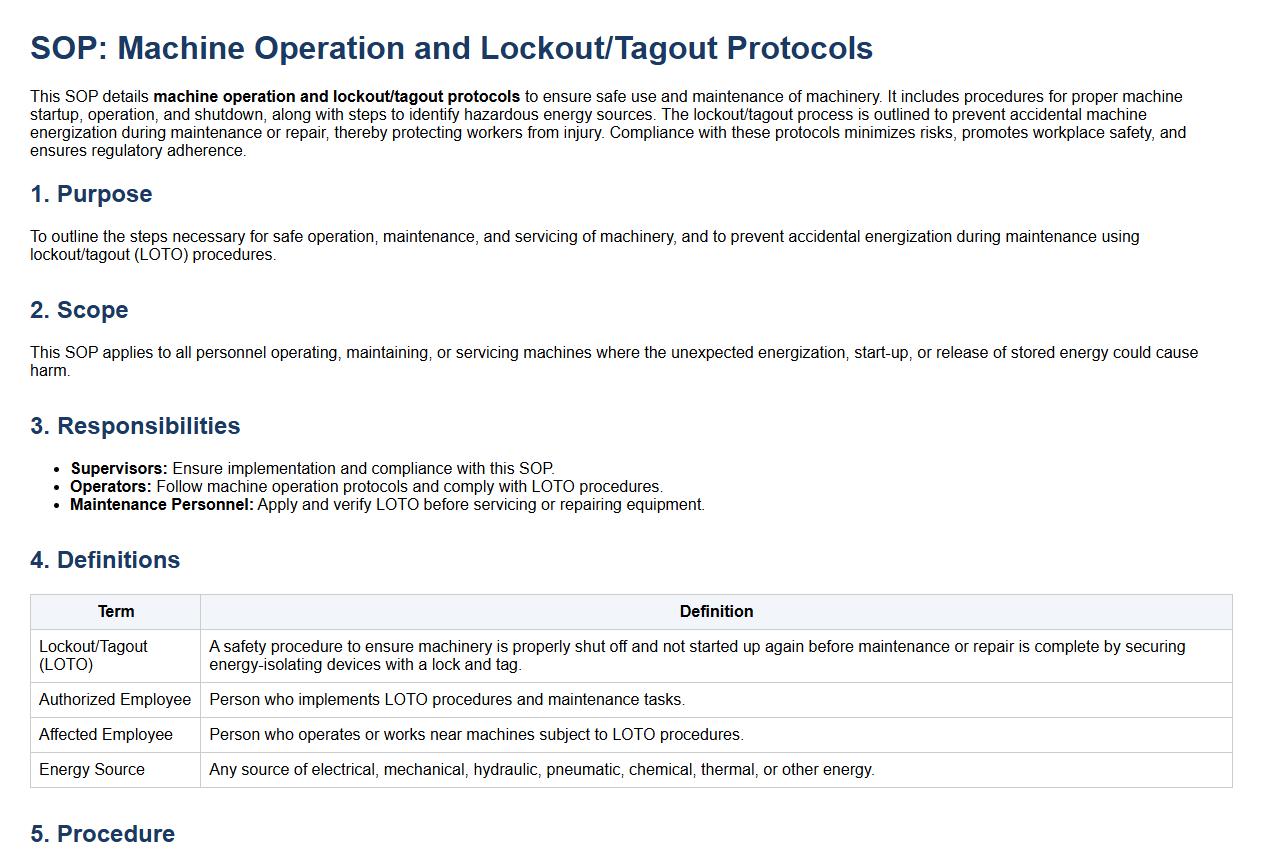

Machine operation and lockout/tagout protocols.

This SOP details machine operation and lockout/tagout protocols to ensure safe use and maintenance of machinery. It includes procedures for proper machine startup, operation, and shutdown, along with steps to identify hazardous energy sources. The lockout/tagout process is outlined to prevent accidental machine energization during maintenance or repair, thereby protecting workers from injury. Compliance with these protocols minimizes risks, promotes workplace safety, and ensures regulatory adherence.

Chemical handling, storage, and spill response.

This SOP details chemical handling, storage, and spill response procedures to ensure safe management of hazardous substances. It includes guidelines for proper labeling, secure storage, personal protective equipment usage, safe handling practices, spill prevention strategies, immediate spill containment and cleanup methods, disposal protocols, and emergency response actions to minimize health risks and environmental impact.

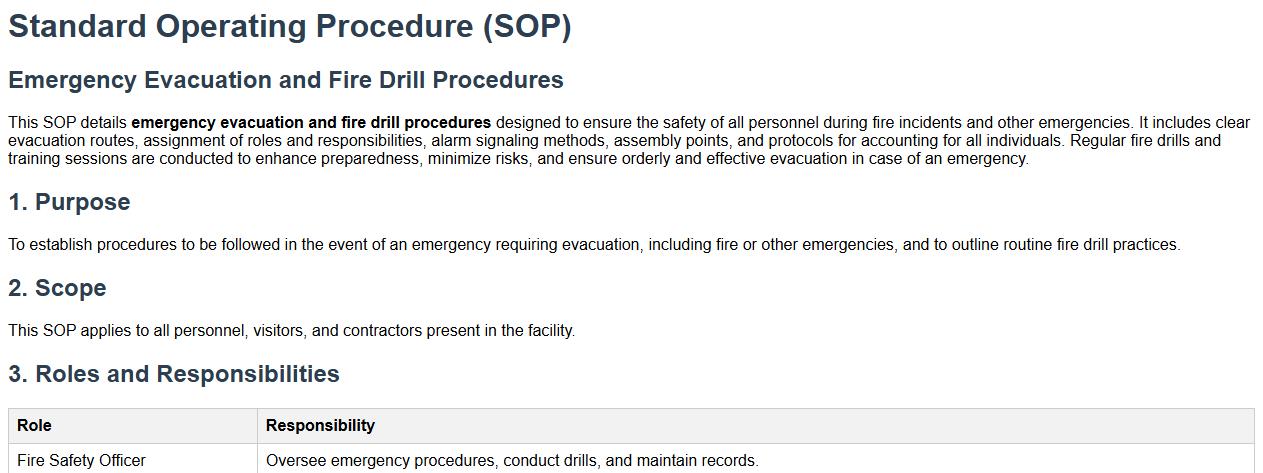

Emergency evacuation and fire drill procedures.

This SOP details emergency evacuation and fire drill procedures designed to ensure the safety of all personnel during fire incidents and other emergencies. It includes clear evacuation routes, assignment of roles and responsibilities, alarm signaling methods, assembly points, and protocols for accounting for all individuals. Regular fire drills and training sessions are conducted to enhance preparedness, minimize risks, and ensure orderly and effective evacuation in case of an emergency.

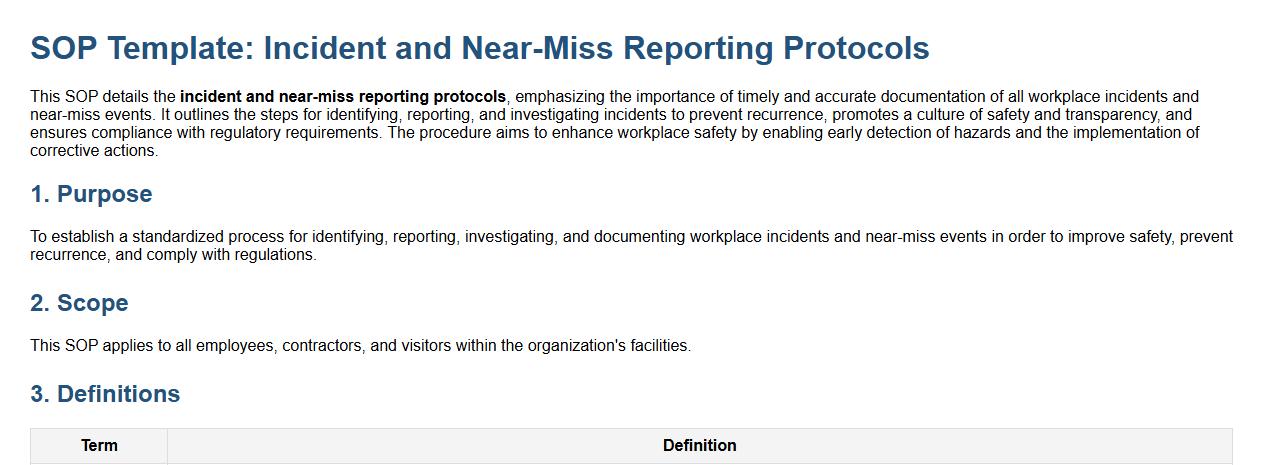

Incident and near-miss reporting protocols.

This SOP details the incident and near-miss reporting protocols, emphasizing the importance of timely and accurate documentation of all workplace incidents and near-miss events. It outlines the steps for identifying, reporting, and investigating incidents to prevent recurrence, promotes a culture of safety and transparency, and ensures compliance with regulatory requirements. The procedure aims to enhance workplace safety by enabling early detection of hazards and the implementation of corrective actions.

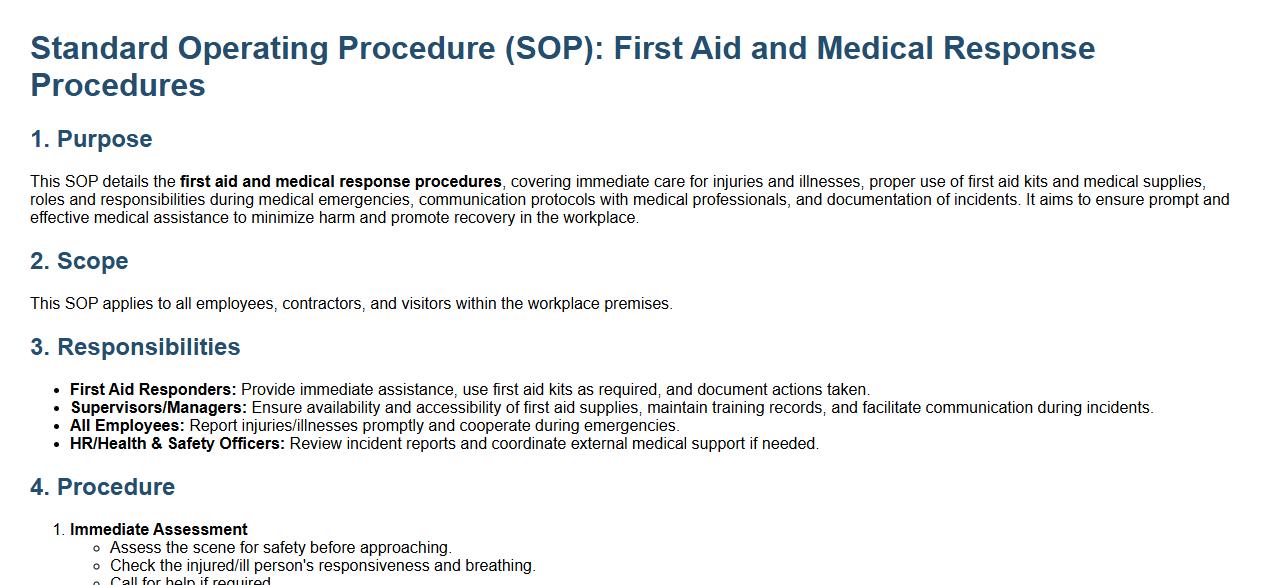

First aid and medical response procedures.

This SOP details the first aid and medical response procedures, covering immediate care for injuries and illnesses, proper use of first aid kits and medical supplies, roles and responsibilities during medical emergencies, communication protocols with medical professionals, and documentation of incidents. It aims to ensure prompt and effective medical assistance to minimize harm and promote recovery in the workplace.

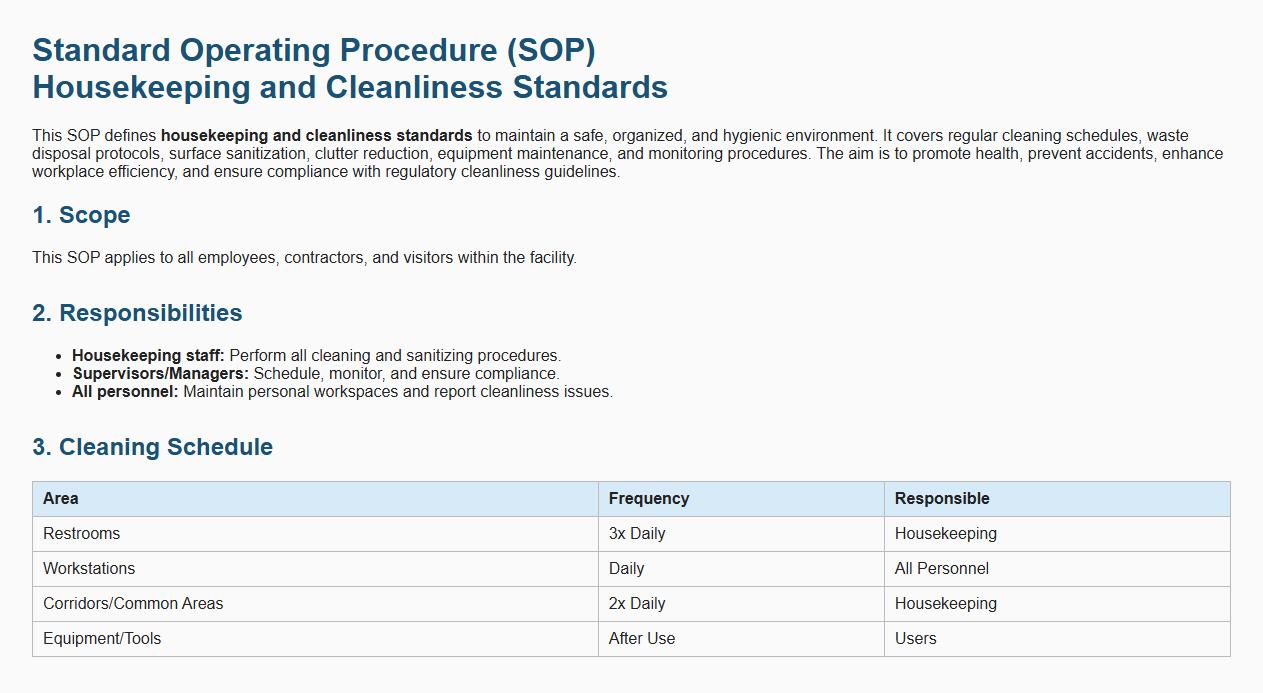

Housekeeping and cleanliness standards.

This SOP defines housekeeping and cleanliness standards to maintain a safe, organized, and hygienic environment. It covers regular cleaning schedules, waste disposal protocols, surface sanitization, clutter reduction, equipment maintenance, and monitoring procedures. The aim is to promote health, prevent accidents, enhance workplace efficiency, and ensure compliance with regulatory cleanliness guidelines.

Visitor and contractor safety orientation.

This SOP provides a comprehensive visitor and contractor safety orientation to ensure all individuals entering the site are informed of safety protocols, potential hazards, emergency procedures, and site-specific rules. It aims to promote a safe working environment by clearly communicating expectations, required personal protective equipment, access restrictions, and reporting procedures, thereby minimizing risks and enhancing overall workplace safety.

Periodic safety audits and inspection procedures.

This SOP details the periodic safety audits and inspection procedures, including scheduling regular safety audits, conducting comprehensive workplace inspections, identifying hazards and non-compliance issues, documenting findings, recommending corrective actions, and ensuring continuous improvement in safety standards. The objective is to maintain a safe working environment by systematically assessing and addressing potential risks and compliance with regulatory requirements.

What are the key personal protective equipment (PPE) requirements specified in this SOP for manufacturing areas?

The SOP mandates the use of protective gloves, safety goggles, and steel-toed boots in all manufacturing zones. Personnel must wear flame-resistant clothing when working near high-temperature equipment. Additionally, hearing protection is required in areas with noise levels exceeding 85 decibels.

Which emergency response steps must be followed in case of equipment malfunction, according to the SOP?

Immediately cease operation and activate the emergency stop button to prevent further damage. Notify the supervisor and the maintenance team to assess and resolve the malfunction. Evacuate the area if there is a risk of fire or chemical spill, following the designated emergency exit routes.

How does the SOP outline procedures for handling and storing hazardous materials safely?

All hazardous materials must be stored in clearly labeled, ventilated containment cabinets designed for chemical storage. Use appropriate PPE when handling these materials to avoid exposure and contamination risks. The SOP requires maintaining a detailed inventory and Safety Data Sheets (SDS) accessible near storage areas.

What are the mandatory lockout/tagout steps to prevent accidental machine start-up described in the SOP?

The SOP requires isolating the machine from its power source and applying a lockout device to secure it in the 'off' position. A visible tag describing the maintenance work and the responsible personnel must be attached. Only the individual who applied the lock and tag is authorized to remove them after the task is completed.

What routine safety checks and documentation are required by the SOP before commencing manufacturing operations?

Perform a comprehensive inspection of machinery, verifying all guards and safety devices are in place and functional. Record all findings and approvals in the daily safety checklist before starting production. Any identified issues must be reported and resolved prior to operation to ensure workplace safety.