A SOP Template for Workstation Cleanliness in Manufacturing provides clear, standardized guidelines to ensure all workstations are maintained at optimal hygiene levels. This template outlines specific cleaning tasks, schedules, and responsible personnel to promote safety and efficiency on the production floor. Consistent use of this SOP minimizes contamination risks and supports compliance with industry regulations.

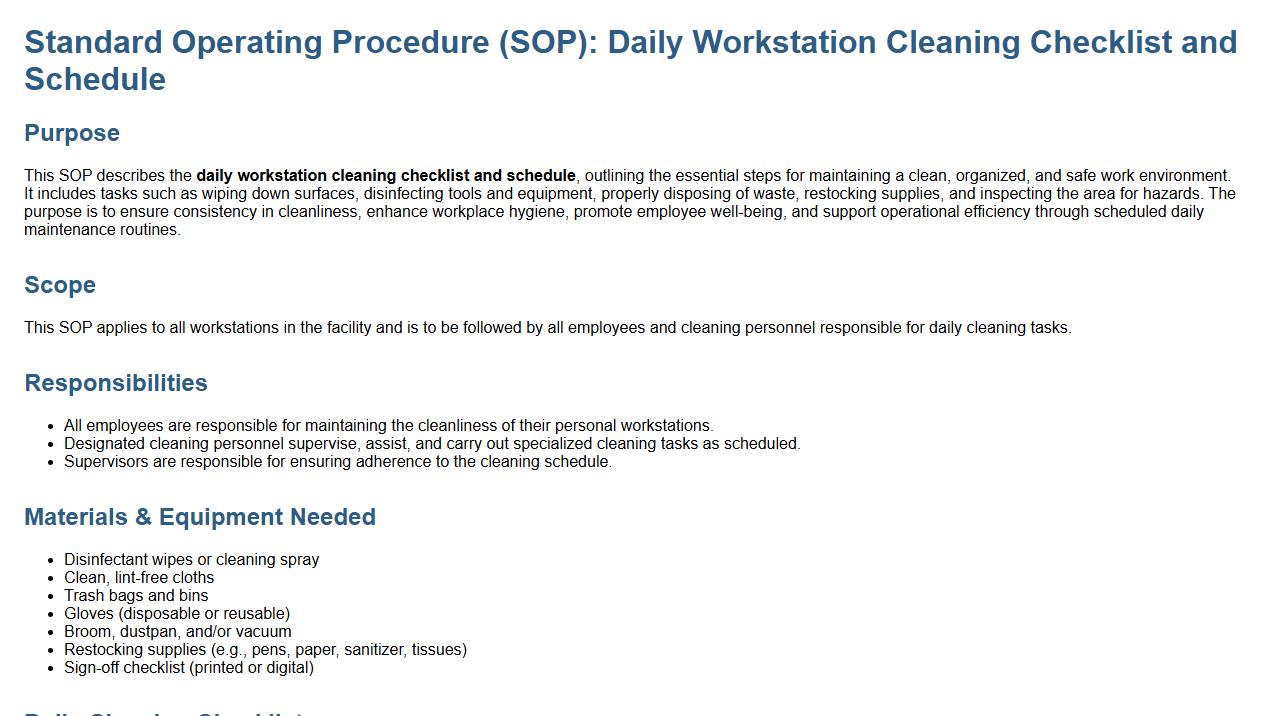

Daily workstation cleaning checklist and schedule.

This SOP describes the daily workstation cleaning checklist and schedule, outlining the essential steps for maintaining a clean, organized, and safe work environment. It includes tasks such as wiping down surfaces, disinfecting tools and equipment, properly disposing of waste, restocking supplies, and inspecting the area for hazards. The purpose is to ensure consistency in cleanliness, enhance workplace hygiene, promote employee well-being, and support operational efficiency through scheduled daily maintenance routines.

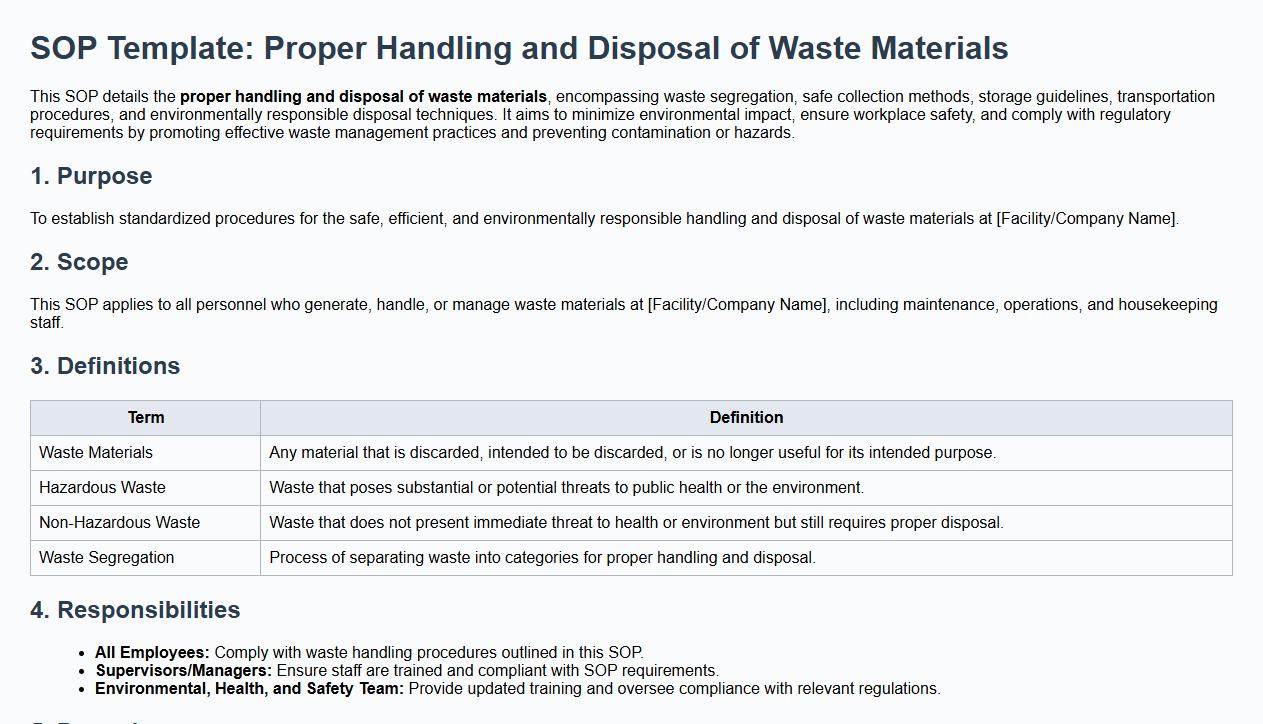

Proper handling and disposal of waste materials.

This SOP details the proper handling and disposal of waste materials, encompassing waste segregation, safe collection methods, storage guidelines, transportation procedures, and environmentally responsible disposal techniques. It aims to minimize environmental impact, ensure workplace safety, and comply with regulatory requirements by promoting effective waste management practices and preventing contamination or hazards.

Steps for sanitizing tools and equipment after each shift.

This SOP describes the steps for sanitizing tools and equipment after each shift, including initial cleaning to remove debris, application of appropriate disinfectants, proper drying techniques, and safe storage practices. The procedure ensures all tools and equipment are thoroughly sanitized to prevent contamination, maintain hygiene standards, and promote a safe working environment for all personnel.

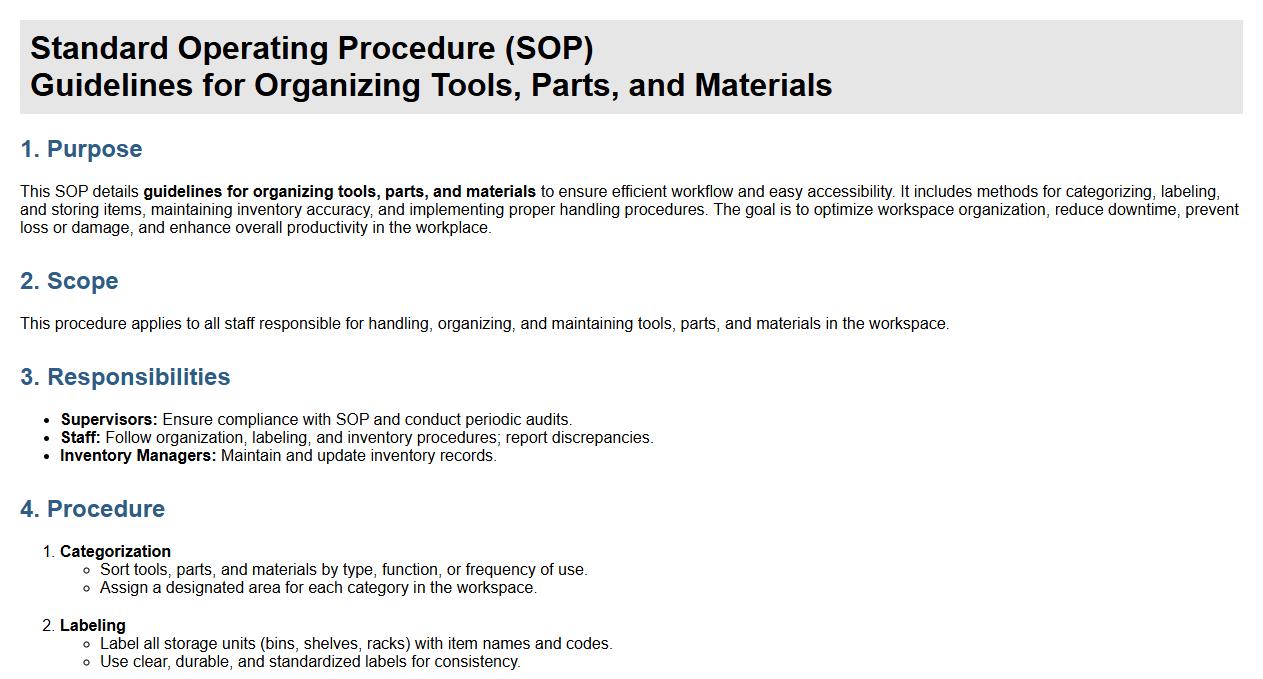

Guidelines for organizing tools, parts, and materials.

This SOP details guidelines for organizing tools, parts, and materials to ensure efficient workflow and easy accessibility. It includes methods for categorizing, labeling, and storing items, maintaining inventory accuracy, and implementing proper handling procedures. The goal is to optimize workspace organization, reduce downtime, prevent loss or damage, and enhance overall productivity in the workplace.

Inspection protocol for workstation cleanliness before shift start.

This SOP details the inspection protocol for workstation cleanliness before shift start, outlining the steps to ensure all work areas are thoroughly cleaned and organized prior to beginning daily operations. It covers visual inspections, verification of cleaning schedules, identification and removal of hazards, proper disposal of waste, and maintaining hygiene standards to promote a safe and efficient working environment. Adherence to this protocol helps prevent contamination, enhances productivity, and supports overall workplace safety and quality control.

Documentation process for cleaning activities and issues found.

This SOP details the documentation process for cleaning activities and issues found, including recording cleaning schedules, specifying cleaning methods and materials used, documenting any discrepancies or issues encountered during cleaning, reporting unresolved problems to the relevant department, maintaining logs for compliance and quality control, and ensuring timely updates to cleaning records. The goal is to maintain accurate and comprehensive records to support cleanliness standards and facilitate effective issue resolution.

Instructions for safe use and storage of cleaning chemicals.

This SOP provides comprehensive instructions for safe use and storage of cleaning chemicals, including proper handling techniques, personal protective equipment requirements, appropriate labeling and storage conditions, procedures for dilution and application, ventilation guidelines, emergency response steps for spills and exposure, and disposal methods. The goal is to minimize health risks, prevent chemical accidents, and ensure a safe working environment.

Procedures for reporting spills or contamination incidents.

This SOP details the procedures for reporting spills or contamination incidents, including immediate identification and containment, notification protocols to relevant authorities, documentation and recording of the incident, assessment of environmental and health impacts, cleanup procedures, and preventive measures to avoid recurrence. The goal is to ensure prompt and effective response to minimize harm to people, property, and the environment.

Responsibilities assignment for cleaning tasks among staff.

This SOP details the responsibilities assignment for cleaning tasks among staff, ensuring clear delegation, accountability, and efficient completion of cleaning duties. It establishes guidelines for task distribution based on roles, schedules regular cleaning routines, and promotes a hygienic and orderly work environment. The procedure fosters teamwork and maintains cleanliness standards critical for safety and operational efficiency.

Compliance with safety and health regulations during cleaning.

This SOP establishes guidelines for compliance with safety and health regulations during cleaning activities, emphasizing proper use of personal protective equipment, safe handling and storage of cleaning chemicals, adherence to ventilation requirements, and protocols to prevent slip, trip, and fall hazards. The goal is to maintain a safe environment for cleaning personnel while ensuring adherence to all relevant occupational safety and health standards.

What are the primary objectives outlined in the SOP for maintaining workstation cleanliness in manufacturing?

The primary objectives of the SOP for workstation cleanliness focus on ensuring a safe and efficient manufacturing environment. It aims to prevent contamination and maintain product quality by enforcing strict cleanliness standards. Additionally, the SOP emphasizes minimizing equipment downtime and hazards caused by unclean workstations.

Which personnel are responsible for implementing and monitoring workstation cleanliness as per the SOP?

The SOP assigns responsibility to production operators and cleaning staff for implementing workstation cleanliness protocols. Supervisors are tasked with monitoring and verifying adherence to these standards regularly. Quality assurance teams also participate in audits to ensure compliance with the SOP.

What specific cleaning procedures and frequencies are mandated in the workstation cleanliness SOP?

The SOP mandates detailed cleaning procedures including wiping surfaces, sanitizing tools, and disposing of waste appropriately. Cleaning must be performed at the start, during breaks, and at the end of each shift to maintain ongoing cleanliness. Periodic deep cleaning is also required to address hard-to-reach areas and equipment.

What equipment and cleaning agents are approved for use according to the SOP for workstation cleanliness?

The SOP specifies use of approved equipment such as microfiber cloths, brushes, and vacuum cleaners designed for industrial settings. Cleaning agents must be non-toxic and effective against contaminants without damaging machinery. Only those chemicals listed in the SOP's approved product list are authorized for use.

How does the SOP define the documentation and recordkeeping requirements for cleanliness checks?

The SOP requires strict documentation of all cleanliness inspections to ensure traceability and accountability. Checklists and cleaning logs must be completed and retained for specified periods as per regulatory guidelines. Electronic records are preferred to facilitate easy retrieval and audit readiness.