A SOP Template for Manufacturing Production Planning provides a structured framework to streamline and standardize production workflows, ensuring efficiency and consistency. It outlines step-by-step procedures for scheduling, resource allocation, and quality control to optimize manufacturing output. This template helps reduce errors, improve communication, and maintain compliance with industry standards.

Production scheduling and workflow management.

This SOP details production scheduling and workflow management, encompassing planning, coordination, and optimization of production activities. It covers the development of production schedules, resource allocation, task prioritization, monitoring workflow progress, and adjusting plans to ensure efficient use of time and materials. The objective is to streamline operations, minimize downtime, enhance productivity, and meet delivery deadlines consistently through effective management of production processes.

Raw material and inventory control procedures.

This SOP details raw material and inventory control procedures, encompassing the systematic receipt, inspection, storage, and management of raw materials. It includes inventory tracking, stock rotation methods such as FIFO, quality assurance checks, and accurate documentation to ensure optimal inventory levels and minimize waste. The goal is to maintain efficient supply chain operations, prevent material shortages, and support production continuity through effective inventory control practices.

Quality assurance and product inspection protocols.

This SOP defines quality assurance and product inspection protocols, covering systematic procedures for monitoring product quality, conducting thorough inspections at various production stages, identifying and addressing defects, maintaining compliance with industry standards, and ensuring customer satisfaction through consistent product excellence. The goal is to establish reliable quality control measures that prevent defects and enhance overall product integrity.

Equipment setup, calibration, and maintenance routines.

This SOP details equipment setup, calibration, and maintenance routines, covering the proper procedures for installing and configuring equipment, performing regular calibration to ensure accuracy and reliability, and conducting routine maintenance to extend equipment lifespan and prevent failures. It aims to guarantee optimal performance, safety, and compliance with operational standards through standardized and systematic practices.

Workforce shift allocation and labor management.

This SOP details the procedures for workforce shift allocation and labor management, including the planning and scheduling of shifts, managing employee availability, monitoring labor productivity, ensuring compliance with labor laws, handling shift swaps and overtime, and maintaining accurate labor records. The goal is to optimize workforce efficiency, ensure fair and equitable shift distribution, and maintain a productive and compliant labor environment.

Standardized work instructions for each production process.

This SOP provides standardized work instructions for each production process, ensuring consistency, efficiency, and quality control in manufacturing operations. It covers detailed step-by-step procedures, equipment usage guidelines, safety protocols, and quality assurance checkpoints to maintain uniformity across all production stages. The goal is to optimize workflow, minimize errors, and facilitate training and compliance with industry standards.

Health, safety, and environmental compliance procedures.

This SOP defines the health, safety, and environmental compliance procedures necessary to maintain a safe workplace and minimize environmental impact. It includes identifying hazards, implementing control measures, ensuring regulatory compliance, conducting regular safety inspections and audits, providing employee training, managing waste disposal, and responding to incidents. The purpose is to promote a culture of safety, protect employee well-being, and ensure environmental sustainability in all operational activities.

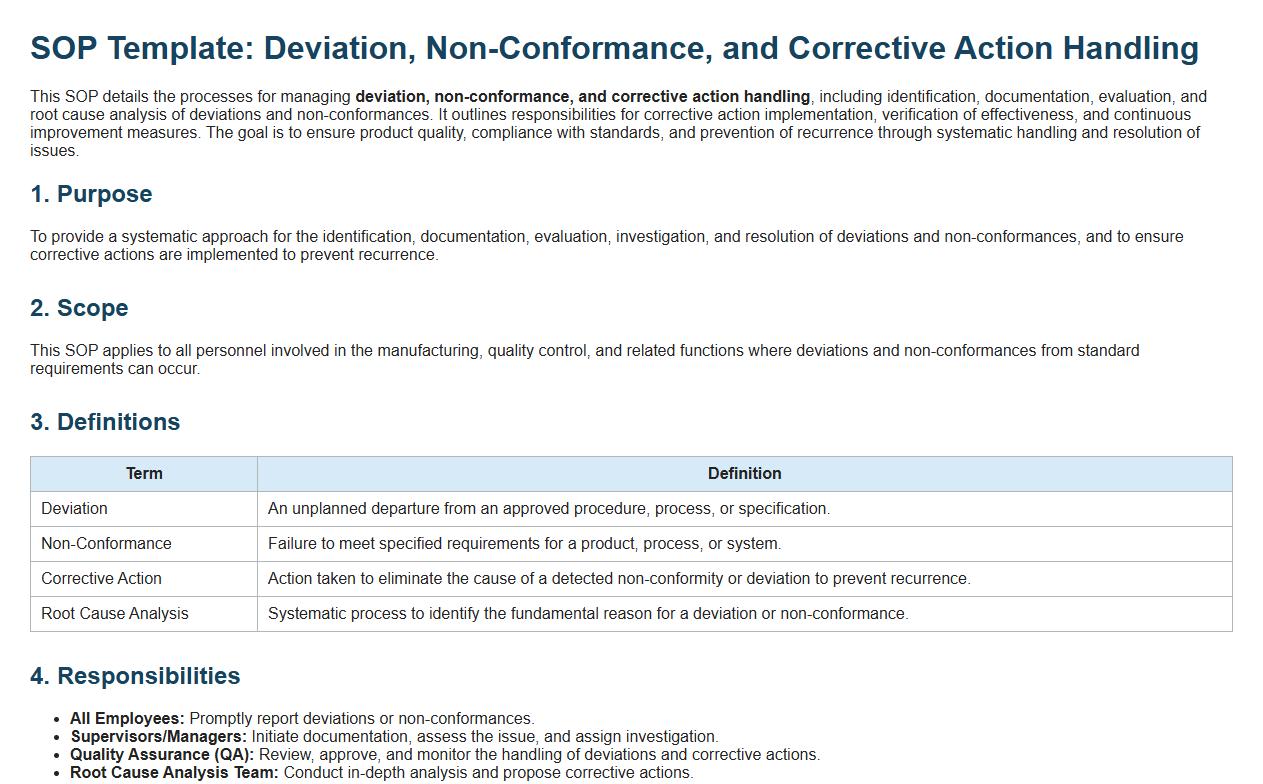

Deviation, non-conformance, and corrective action handling.

This SOP details the processes for managing deviation, non-conformance, and corrective action handling, including identification, documentation, evaluation, and root cause analysis of deviations and non-conformances. It outlines responsibilities for corrective action implementation, verification of effectiveness, and continuous improvement measures. The goal is to ensure product quality, compliance with standards, and prevention of recurrence through systematic handling and resolution of issues.

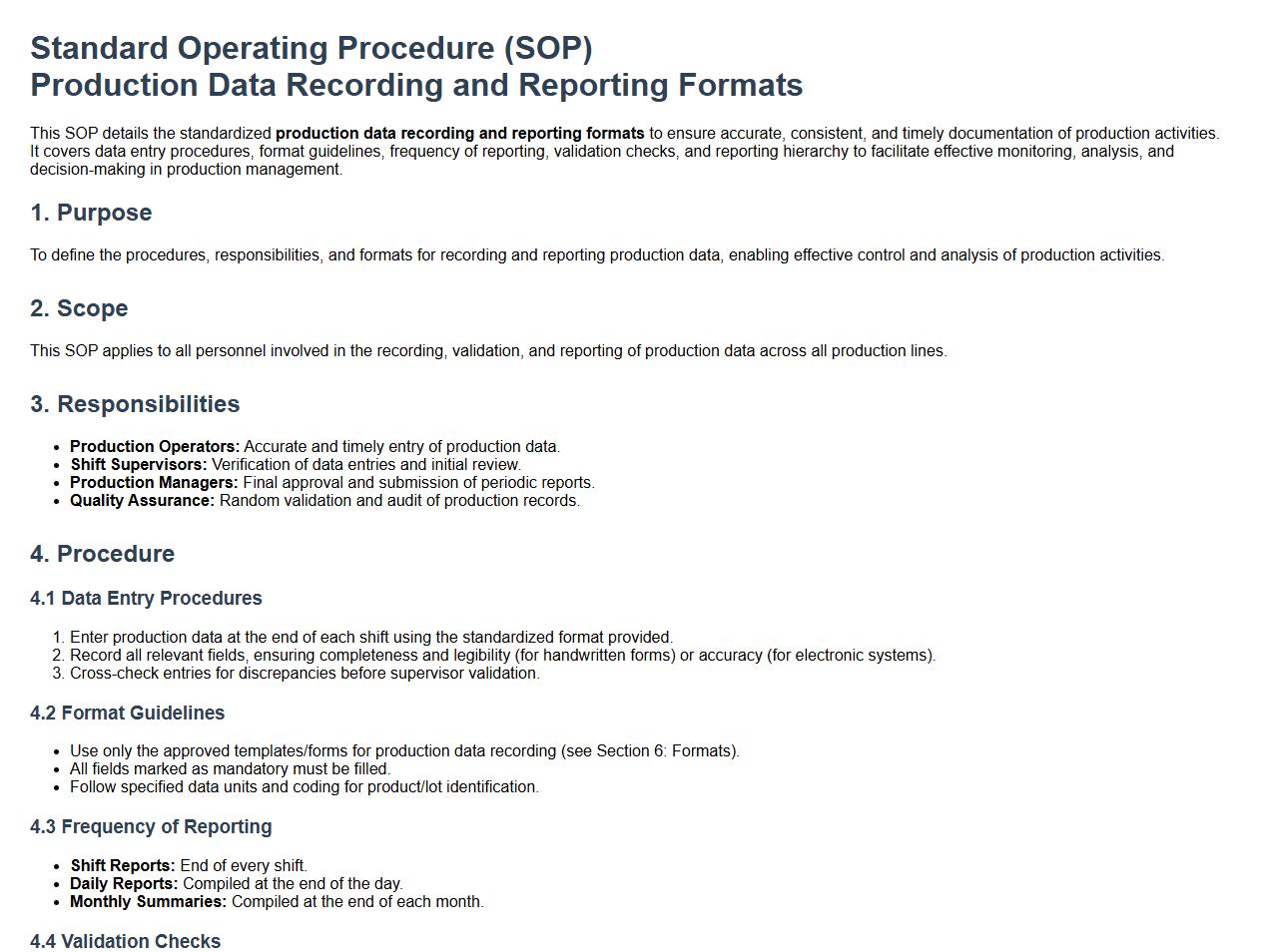

Production data recording and reporting formats.

This SOP details the standardized production data recording and reporting formats to ensure accurate, consistent, and timely documentation of production activities. It covers data entry procedures, format guidelines, frequency of reporting, validation checks, and reporting hierarchy to facilitate effective monitoring, analysis, and decision-making in production management.

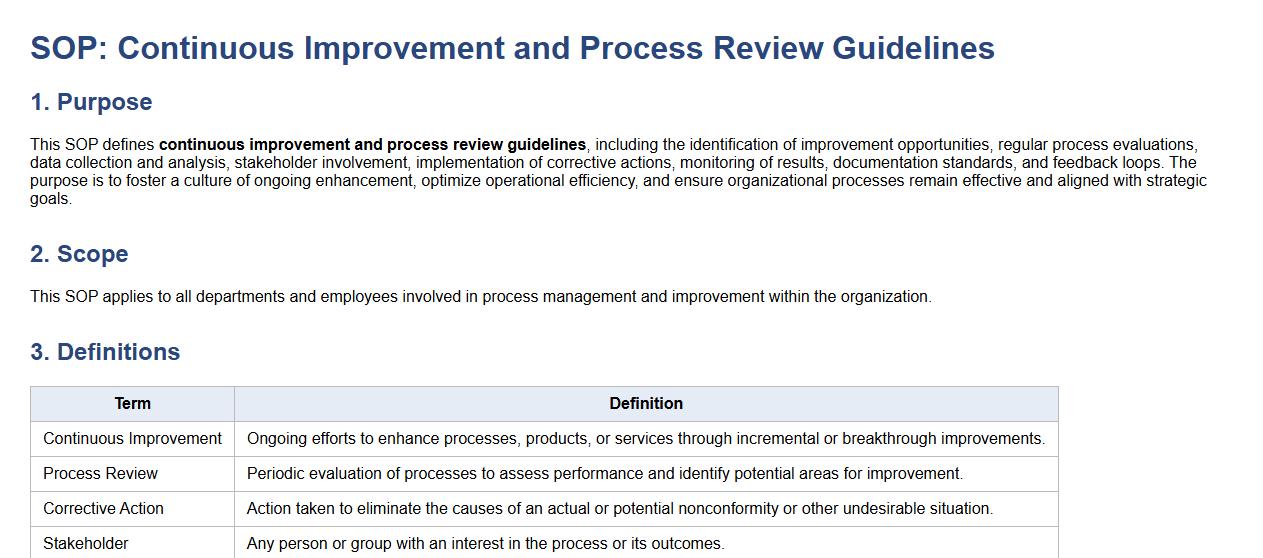

Continuous improvement and process review guidelines.

This SOP defines continuous improvement and process review guidelines, including the identification of improvement opportunities, regular process evaluations, data collection and analysis, stakeholder involvement, implementation of corrective actions, monitoring of results, documentation standards, and feedback loops. The purpose is to foster a culture of ongoing enhancement, optimize operational efficiency, and ensure organizational processes remain effective and aligned with strategic goals.

What are the key objectives outlined in the SOP for Manufacturing Production Planning?

The key objectives in the SOP for Manufacturing Production Planning include ensuring efficient use of resources, meeting production deadlines, and maintaining product quality. The SOP aims to optimize the production process by reducing waste and minimizing downtime. Additionally, it focuses on aligning production schedules with customer demands and inventory levels.

Which roles and departments are responsible for implementing the production planning procedures in the SOP?

The SOP assigns the production planning team, production managers, and the supply chain department as primary responsible parties for implementation. Quality assurance and procurement departments also play critical roles in supporting production planning activities. Collaboration between these departments ensures seamless execution and adherence to the SOP.

What standardized steps must be followed to develop and approve the production schedule according to the SOP?

The SOP mandates a structured process for developing the production schedule, starting with demand forecasting and resource assessment. After drafting, the schedule undergoes a review and validation phase involving key stakeholders. Final approval is granted by the production manager before execution.

How does the SOP address the management of material requirements and inventory control?

The SOP emphasizes accurate calculation of material requirements to prevent shortages or excess inventory. It integrates inventory control procedures that include regular stock audits and reorder level monitoring. These controls aim to ensure material availability aligns with production needs without overstocking.

What methods are described in the SOP for monitoring, reviewing, and updating the production plan?

The SOP outlines continuous monitoring through production reports and key performance indicators (KPIs). Regular review meetings are scheduled to assess plan accuracy and address any deviations. It also specifies a process for updating the production plan to incorporate changes in demand or resource availability.