A SOP Template for Manufacturing Documentation Control ensures consistent and accurate handling of all manufacturing records. This template streamlines the process of creating, reviewing, and updating documentation to maintain compliance with industry standards. It enhances traceability and accountability throughout the production workflow.

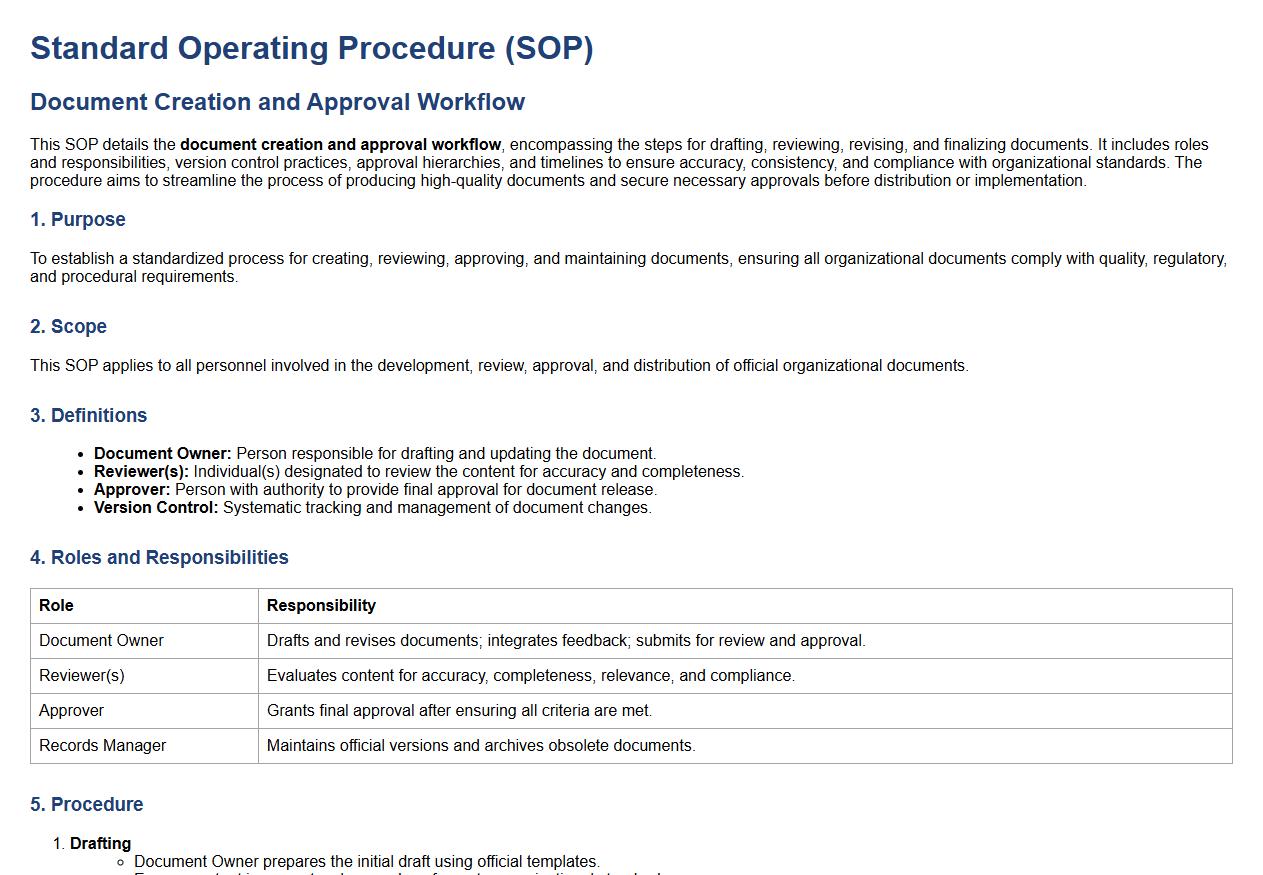

Document creation and approval workflow.

This SOP details the document creation and approval workflow, encompassing the steps for drafting, reviewing, revising, and finalizing documents. It includes roles and responsibilities, version control practices, approval hierarchies, and timelines to ensure accuracy, consistency, and compliance with organizational standards. The procedure aims to streamline the process of producing high-quality documents and secure necessary approvals before distribution or implementation.

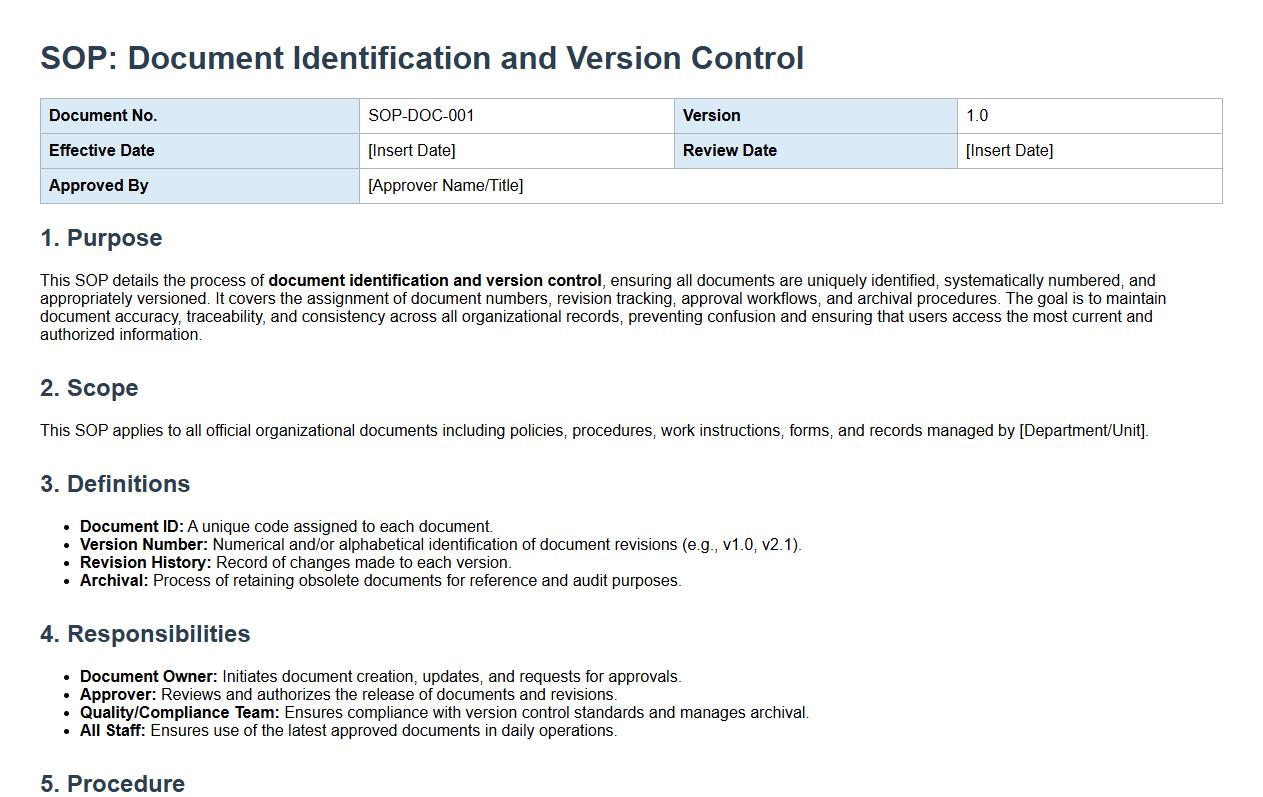

Document identification and version control.

This SOP details the process of document identification and version control, ensuring all documents are uniquely identified, systematically numbered, and appropriately versioned. It covers the assignment of document numbers, revision tracking, approval workflows, and archival procedures. The goal is to maintain document accuracy, traceability, and consistency across all organizational records, preventing confusion and ensuring that users access the most current and authorized information.

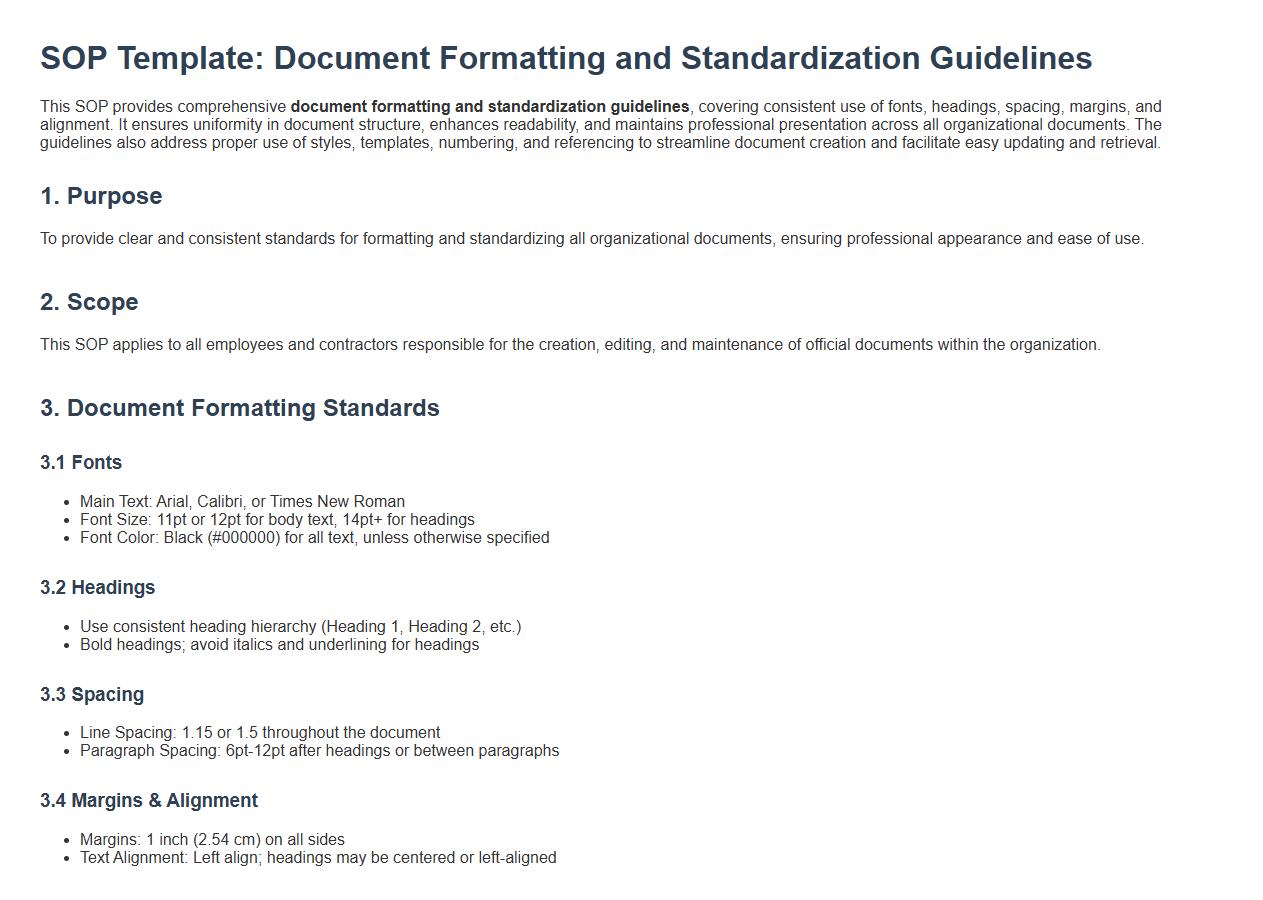

Document formatting and standardization guidelines.

This SOP provides comprehensive document formatting and standardization guidelines, covering consistent use of fonts, headings, spacing, margins, and alignment. It ensures uniformity in document structure, enhances readability, and maintains professional presentation across all organizational documents. The guidelines also address proper use of styles, templates, numbering, and referencing to streamline document creation and facilitate easy updating and retrieval.

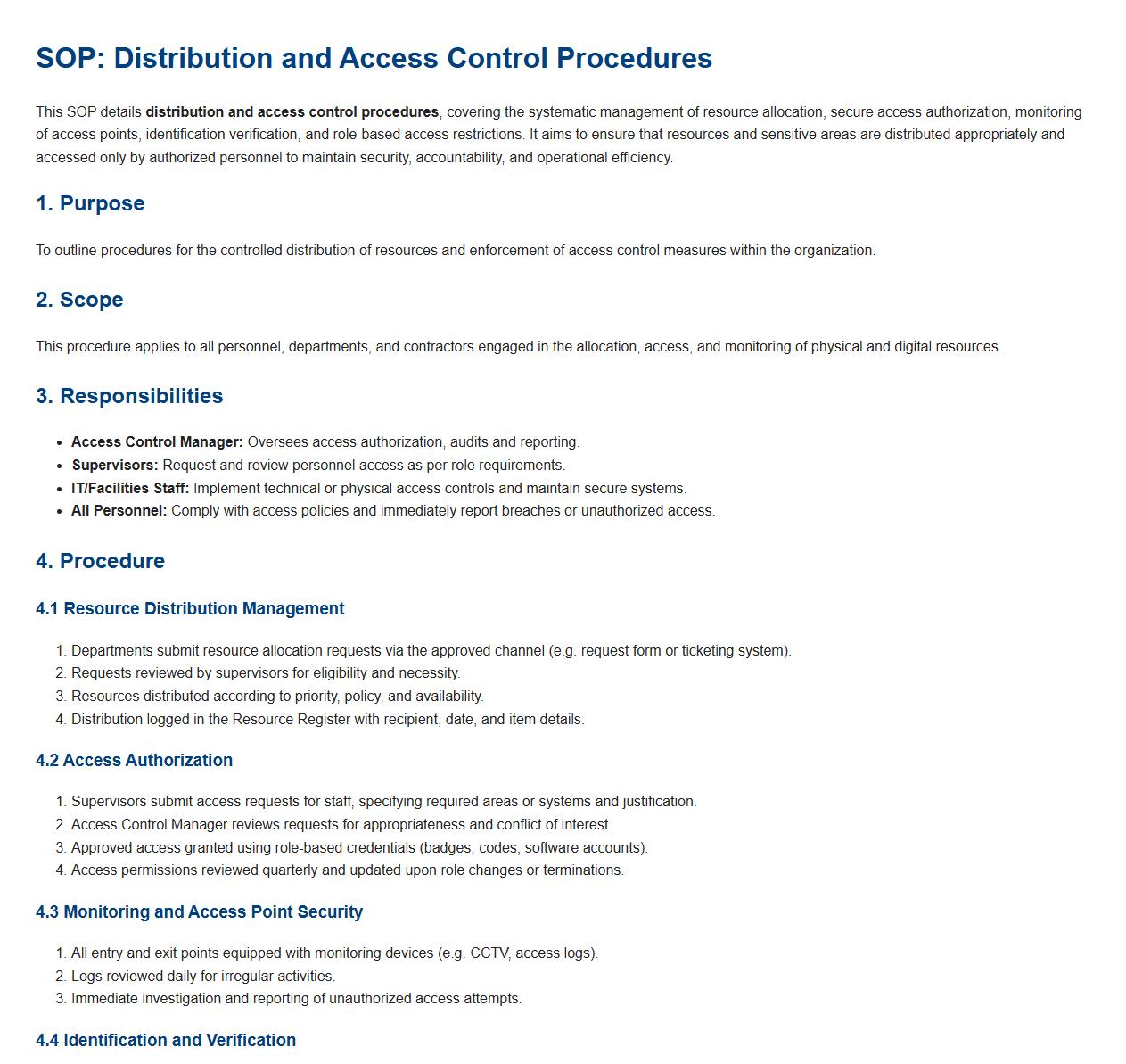

Distribution and access control procedures.

This SOP details distribution and access control procedures, covering the systematic management of resource allocation, secure access authorization, monitoring of access points, identification verification, and role-based access restrictions. It aims to ensure that resources and sensitive areas are distributed appropriately and accessed only by authorized personnel to maintain security, accountability, and operational efficiency.

Document revision and update protocols.

This SOP details the document revision and update protocols, including procedures for reviewing, approving, and implementing changes to organizational documents, maintaining version control, ensuring accuracy and compliance with relevant standards, communicating updates to stakeholders, and securely archiving previous versions. The objective is to guarantee that all documents remain current, reliable, and accessible to support effective operations and decision-making.

Obsolete document retrieval and archival processes.

This SOP details the obsolete document retrieval and archival processes, including the identification of outdated documents, secure retrieval methods, proper documentation of the retrieval process, criteria for document retention or disposal, systematic archival procedures, and compliance with regulatory and organizational standards. The goal is to ensure efficient management and preservation of obsolete documents while maintaining document integrity and facilitating easy access when required.

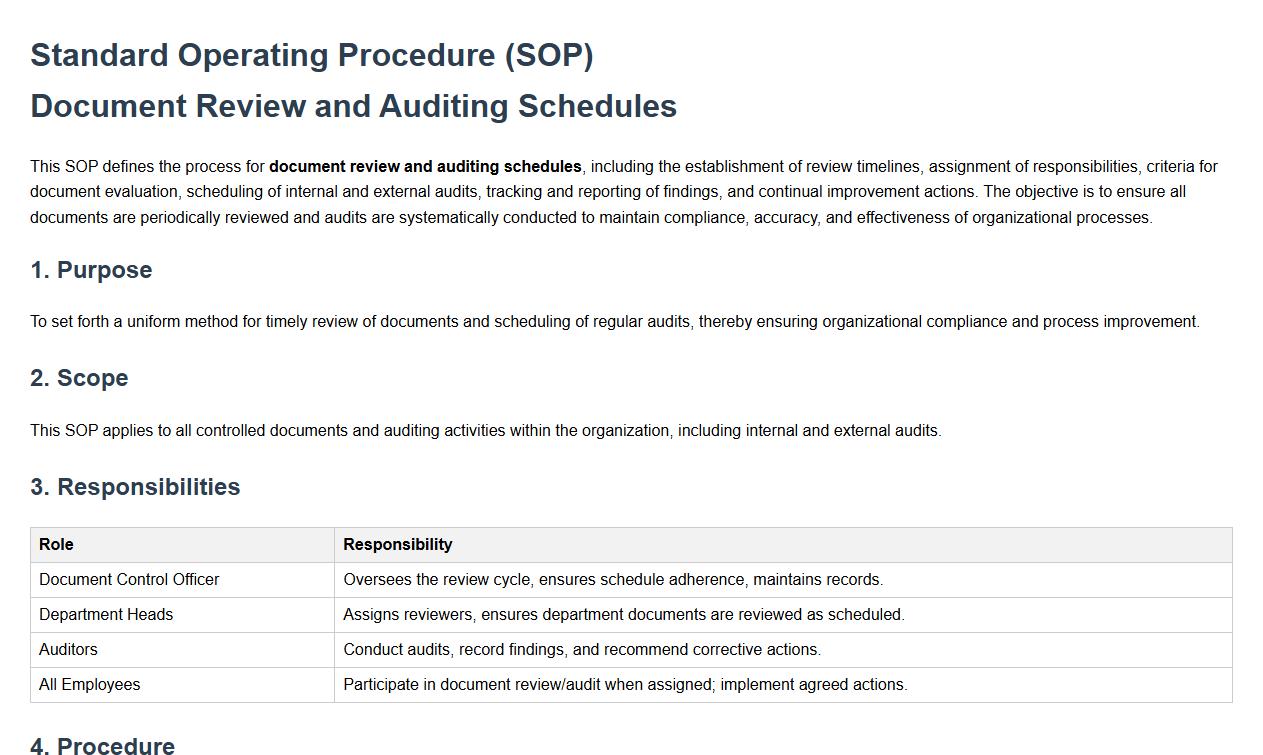

Document review and auditing schedules.

This SOP defines the process for document review and auditing schedules, including the establishment of review timelines, assignment of responsibilities, criteria for document evaluation, scheduling of internal and external audits, tracking and reporting of findings, and continual improvement actions. The objective is to ensure all documents are periodically reviewed and audits are systematically conducted to maintain compliance, accuracy, and effectiveness of organizational processes.

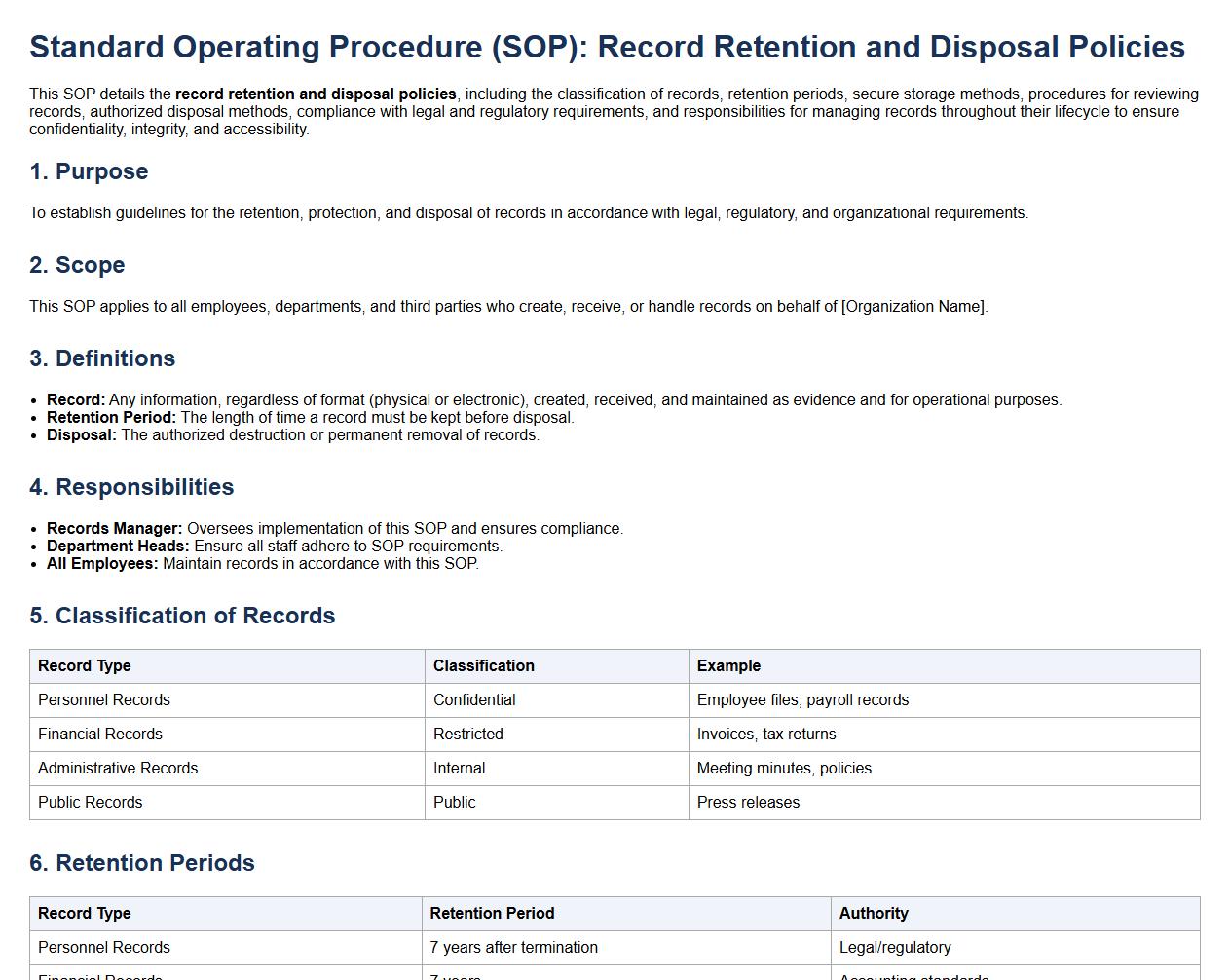

Record retention and disposal policies.

This SOP details the record retention and disposal policies, including the classification of records, retention periods, secure storage methods, procedures for reviewing records, authorized disposal methods, compliance with legal and regulatory requirements, and responsibilities for managing records throughout their lifecycle to ensure confidentiality, integrity, and accessibility.

Change request and deviation management.

This SOP defines the change request and deviation management process, encompassing the identification, documentation, assessment, approval, implementation, and monitoring of changes and deviations in projects or operations. It aims to ensure systematic control, risk assessment, and communication of changes to maintain product quality, compliance, and operational efficiency while minimizing potential negative impacts.

Employee training and acknowledgment tracking.

This SOP details the process for employee training and acknowledgment tracking, including the scheduling and delivery of training sessions, documentation of employee participation, methods for assessing understanding, and procedures for obtaining and recording employee acknowledgments. The goal is to ensure all employees are properly trained, that their knowledge is verified, and that there is a clear record of compliance with training requirements for organizational accountability and regulatory purposes.

Key Steps in Creation, Review, and Approval of Manufacturing Documents

The SOP mandates a structured process starting with drafting the document by authorized personnel. Next, the document undergoes a thorough review by subject matter experts to ensure accuracy and compliance. Finally, formal approval is granted by designated authorities before implementation.

Procedures for Version Control and Document Revision Tracking

The SOP defines strict version control procedures that require each document revision to be uniquely identified. All changes must be logged and tracked in a revision history to maintain transparency. This ensures that users always access the most current and approved version of manufacturing documents.

Measures for Secure Storage and Restricted Access

To protect sensitive manufacturing documents, the SOP recommends implementing secure storage solutions such as locked cabinets or encrypted digital systems. Access is limited to authorized personnel only, enforced through robust access control mechanisms. Regular audits are conducted to ensure compliance with security protocols.

Process for Distribution and Retrieval of Controlled Documents

The SOP outlines a controlled distribution process where documents are shared only with relevant stakeholders. It specifies retrieval procedures to ensure documents are returned or accounted for after use. This minimizes the risk of unauthorized dissemination or loss of critical manufacturing information.

Retention Period and Disposal Procedures for Obsolete Documents

The SOP defines clear retention periods aligned with regulatory requirements for all manufacturing documents. Upon reaching the end of their lifecycle, documents deemed obsolete undergo a secure disposal process to prevent misuse. Documentation of disposal activities is maintained to ensure traceability and compliance.