A SOP Template for Manufacturing Quality Control ensures consistent procedures for maintaining product standards and regulatory compliance. It outlines detailed steps for inspection, testing, and documentation to minimize defects and improve process efficiency. Implementing this template helps streamline quality assurance workflows and enhances overall manufacturing reliability.

Raw material inspection and acceptance criteria.

This SOP defines the raw material inspection and acceptance criteria to ensure all incoming materials meet specified quality standards before use in production. It covers inspection procedures, documentation requirements, sampling methods, quality parameter checks, rejection criteria, and communication protocols with suppliers to maintain product integrity and compliance with regulatory guidelines.

Production line setup and pre-start checks.

This SOP details the production line setup and pre-start checks, covering equipment inspection, calibration, safety checks, material availability, and verification of operational parameters to ensure efficient and safe production. The procedure aims to minimize downtime, prevent equipment failure, and maintain product quality by systematically preparing the production line before starting full-scale operations.

In-process quality control checks and documentation.

This SOP details the procedures for in-process quality control checks and documentation, encompassing systematic monitoring of production processes, criteria for quality inspections, identification and correction of deviations, proper recording of inspection results, and maintaining accurate documentation to ensure product consistency and compliance with quality standards throughout the manufacturing cycle.

Standardized sampling and testing procedures.

This SOP establishes standardized sampling and testing procedures to ensure consistency, accuracy, and reliability in sample collection and analysis. It covers proper sample identification, handling, preservation, transport, and detailed testing methodologies to maintain data integrity and compliance with quality standards. The objective is to minimize variability and errors, enabling precise and repeatable results for informed decision-making and regulatory adherence.

Defect identification, segregation, and reporting protocol.

This SOP details the defect identification, segregation, and reporting protocol, covering the systematic process for detecting product defects, segregating non-conforming items from the production line, and accurately reporting defects to relevant departments. It ensures product quality by preventing defective products from reaching customers, facilitates timely corrective actions, and maintains comprehensive documentation for quality control and continuous improvement efforts.

Calibration and maintenance of inspection equipment.

This SOP details the calibration and maintenance of inspection equipment, covering procedures for regular calibration, routine maintenance schedules, equipment cleaning protocols, accuracy verification methods, documentation requirements, and troubleshooting common issues. The objective is to ensure that all inspection equipment functions correctly and provides reliable measurements, thereby maintaining quality control and compliance with industry standards.

Final product inspection and release procedure.

This SOP details the final product inspection and release procedure, including criteria for product quality assessment, inspection methods and tools, defect identification and classification, process for approval or rejection, documentation requirements, and steps for releasing the product for shipment. The objective is to ensure that all finished products meet established quality standards before they are distributed to customers, maintaining product integrity and customer satisfaction.

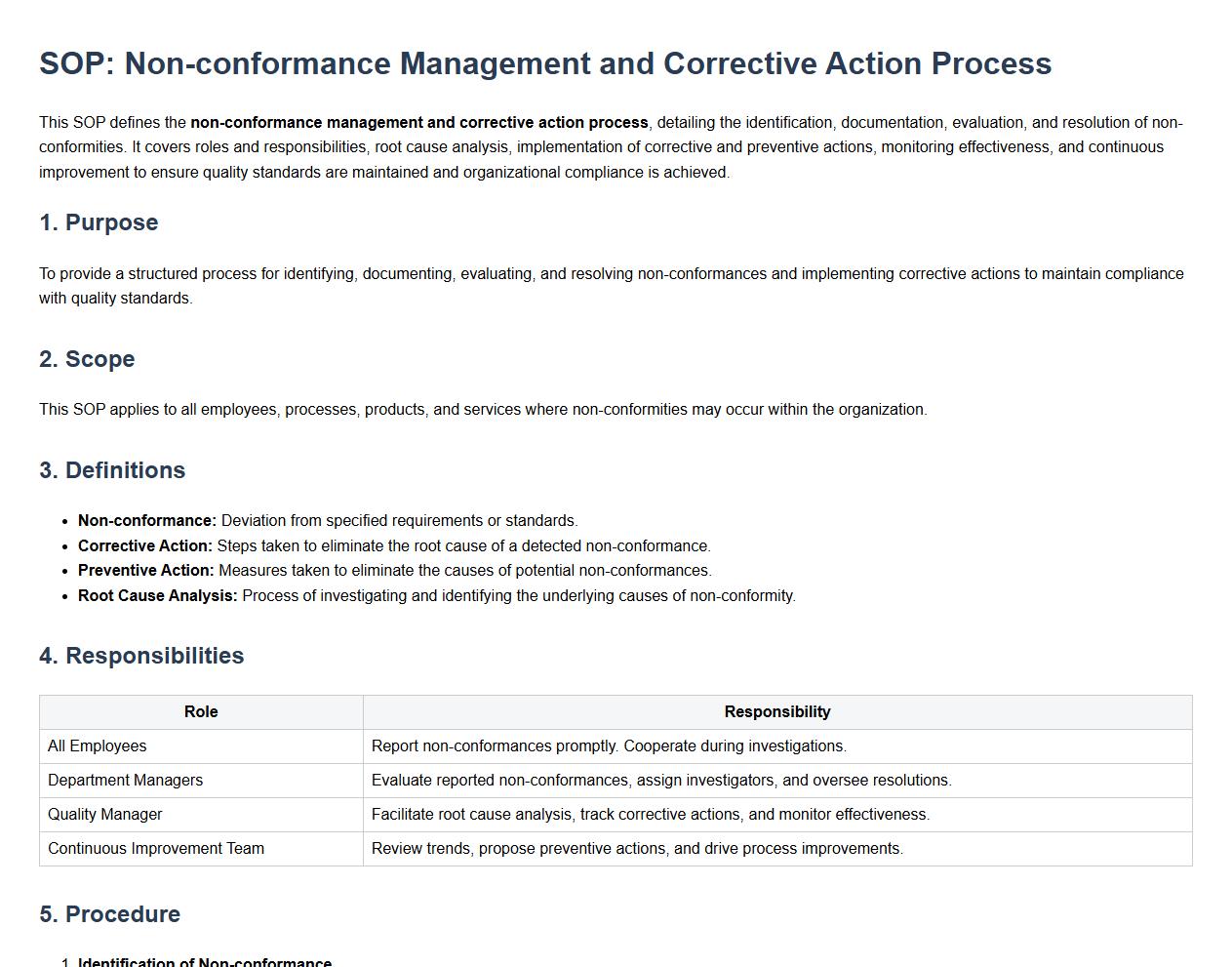

Non-conformance management and corrective action process.

This SOP defines the non-conformance management and corrective action process, detailing the identification, documentation, evaluation, and resolution of non-conformities. It covers roles and responsibilities, root cause analysis, implementation of corrective and preventive actions, monitoring effectiveness, and continuous improvement to ensure quality standards are maintained and organizational compliance is achieved.

Traceability and batch record-keeping requirements.

This SOP defines the traceability and batch record-keeping requirements essential for maintaining accurate and comprehensive documentation of product batches. It covers procedures for recording batch numbers, tracking raw materials and components, documenting production processes, and ensuring compliance with regulatory standards. The purpose is to facilitate product recalls, quality control, and accountability through systematic and transparent record-keeping practices.

Quality control staff training and competency assessment.

This SOP details the procedures for quality control staff training and competency assessment, covering the identification of training needs, development and delivery of training programs, evaluation of staff skills, competency testing, ongoing performance monitoring, and documentation of training records. The objective is to ensure that quality control personnel are adequately trained and competent to perform their duties effectively, maintaining high standards of product quality and regulatory compliance.

What is the primary objective of the SOP for Manufacturing Quality Control?

The primary objective of the SOP for Manufacturing Quality Control is to ensure consistent product quality through standardized procedures. It aims to minimize defects and maintain compliance with regulatory requirements. Ultimately, the SOP supports the delivery of safe and effective products to customers.

Which critical steps ensure compliance within the manufacturing quality control process as outlined in the SOP?

Critical steps in the SOP include inspection and testing at key production stages to detect faults early. Proper calibration of equipment and adherence to defined sampling plans are essential for accurate results. Documentation of all procedures guarantees traceability and facilitates audit readiness.

What documentation and records must be maintained according to the SOP requirements?

The SOP mandates maintaining detailed test results, inspection logs, and calibration records to verify quality control activities. Batch records and deviation reports must also be documented to track production history. These records are crucial for compliance and continuous improvement efforts.

Who is responsible for monitoring and verifying adherence to the SOP in manufacturing quality control?

The quality control team is primarily responsible for monitoring adherence to the SOP during manufacturing. Supervisors ensure proper implementation, while quality assurance personnel perform periodic audits. This layered oversight guarantees consistent compliance and process integrity.

What corrective actions are specified in the SOP if a quality deviation is detected?

The SOP requires immediate investigation and root cause analysis upon detection of a quality deviation. Corrective actions include adjustment of process parameters and retraining of personnel where necessary. All actions must be documented and verified to prevent recurrence.