A SOP Template for Workplace Hygiene in Manufacturing ensures consistent cleaning and sanitation practices to maintain a safe and healthy environment. It outlines specific procedures, responsibilities, and frequency of hygiene tasks to prevent contamination and promote employee well-being. Implementing this template helps manufacturers comply with regulatory standards and improve overall production quality.

Workstation cleaning and sanitation procedures.

This SOP details workstation cleaning and sanitation procedures, including the steps for daily cleaning, proper use of cleaning agents, sanitizing surfaces and equipment, waste disposal protocols, and maintaining hygiene standards. The goal is to ensure a clean and safe work environment that prevents contamination, promotes employee health, and complies with regulatory requirements.

Personal hygiene requirements for employees.

This SOP establishes the personal hygiene requirements for employees to maintain a clean and healthy workplace environment. It covers guidelines on proper handwashing techniques, use of protective clothing, grooming standards, and protocols for reporting illness. The objective is to prevent contamination, reduce the spread of germs, and promote overall employee well-being and safety within the organization.

Hand washing and sanitization guidelines.

This SOP details hand washing and sanitization guidelines essential for maintaining hygiene and preventing the spread of infections. It covers proper hand washing techniques, recommended duration, use of soap and water, appropriate hand sanitizers, and critical times for hand hygiene, such as before eating and after contact with contaminants. These guidelines aim to promote health and safety in workplaces, healthcare settings, and public areas by reducing the transmission of germs and ensuring effective personal hygiene practices.

Use and maintenance of personal protective equipment (PPE).

This SOP details the proper use and maintenance of personal protective equipment (PPE), covering the selection, correct usage, cleaning, inspection, storage, and replacement of PPE. It aims to ensure the safety and health of all personnel by minimizing exposure to workplace hazards through effective PPE practices and adherence to safety standards.

Scheduled cleaning and disinfection of common areas.

This SOP details the procedures for scheduled cleaning and disinfection of common areas, including the identification of high-touch surfaces, selection of appropriate cleaning agents and disinfectants, frequency of cleaning tasks, proper use of personal protective equipment (PPE), waste disposal protocols, and documentation of cleaning activities. The goal is to maintain a hygienic environment, reduce the risk of infection transmission, and ensure the health and safety of all occupants in shared spaces.

Waste management and disposal protocols.

This SOP details the waste management and disposal protocols, covering waste segregation, collection, storage, transportation, treatment, and final disposal. It emphasizes compliance with environmental regulations, minimizing environmental impact, and promoting recycling and waste reduction practices. The procedures ensure safe handling of hazardous and non-hazardous waste, staff training requirements, and monitoring to maintain a clean and sustainable operational environment.

Guidelines for handling raw materials and finished products.

This SOP establishes comprehensive guidelines for handling raw materials and finished products to ensure quality, safety, and efficiency throughout the production process. It covers receiving, inspection, storage, handling, and transportation protocols to prevent contamination, damage, and loss. The purpose is to maintain product integrity, comply with regulatory standards, and optimize operational workflows from raw material intake to final product dispatch.

Pest control measures and documentation.

This SOP defines pest control measures and documentation procedures, including identification of pest types, selection and application of appropriate pest control methods, safety protocols for handling pesticides, monitoring and evaluation of pest control effectiveness, regular inspection schedules, and accurate documentation of all pest control activities. The objective is to maintain a pest-free environment while ensuring compliance with health and safety regulations and minimizing environmental impact.

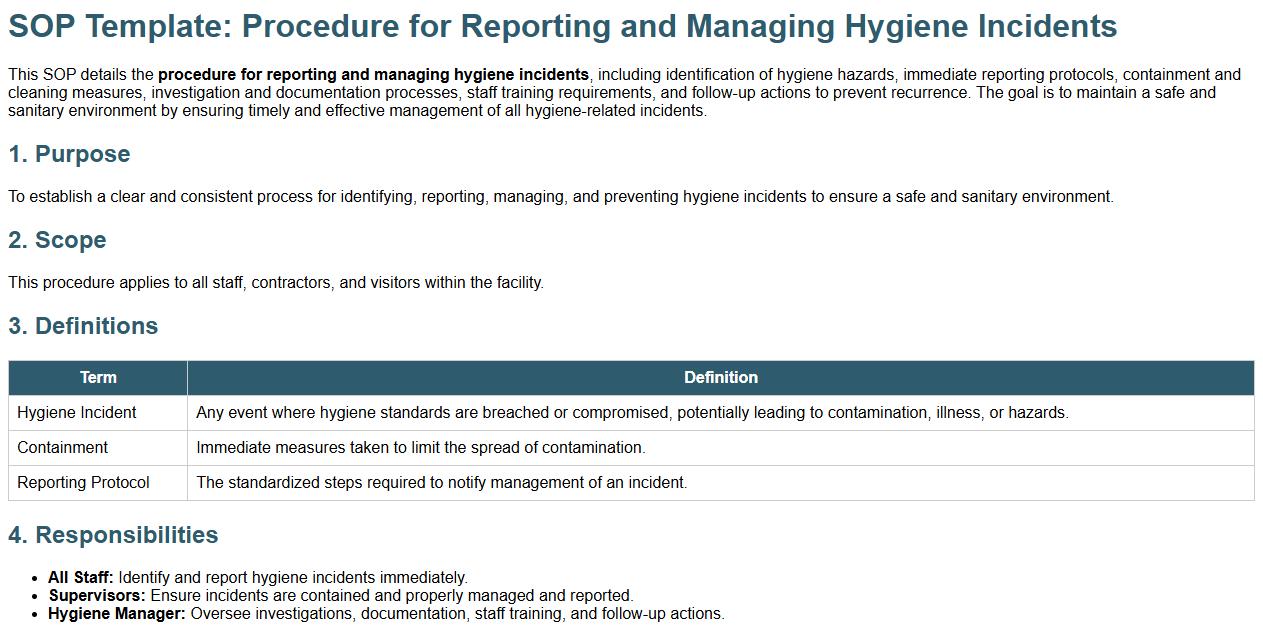

Procedure for reporting and managing hygiene incidents.

This SOP details the procedure for reporting and managing hygiene incidents, including identification of hygiene hazards, immediate reporting protocols, containment and cleaning measures, investigation and documentation processes, staff training requirements, and follow-up actions to prevent recurrence. The goal is to maintain a safe and sanitary environment by ensuring timely and effective management of all hygiene-related incidents.

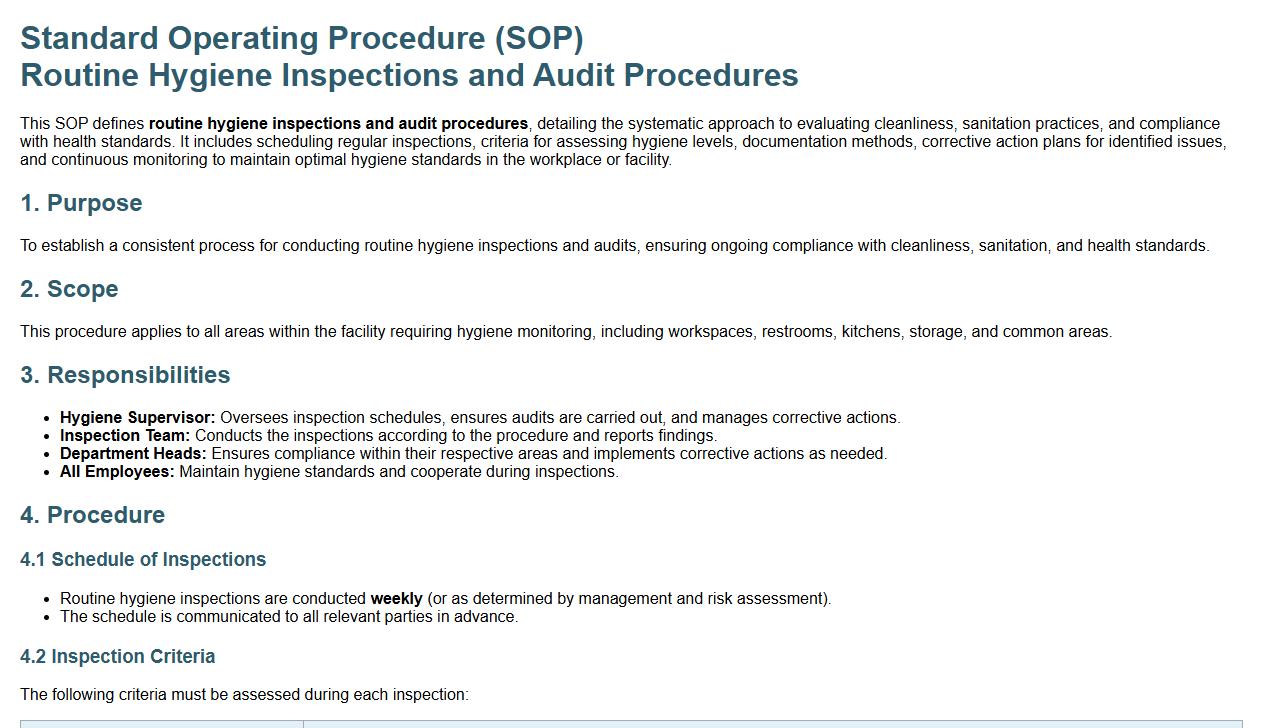

Routine hygiene inspections and audit procedures.

This SOP defines routine hygiene inspections and audit procedures, detailing the systematic approach to evaluating cleanliness, sanitation practices, and compliance with health standards. It includes scheduling regular inspections, criteria for assessing hygiene levels, documentation methods, corrective action plans for identified issues, and continuous monitoring to maintain optimal hygiene standards in the workplace or facility.

What are the essential personal hygiene practices required by the SOP for employees in the manufacturing area?

The SOP mandates that employees maintain proper hand hygiene by washing hands before starting work, after breaks, and when switching tasks. Employees must also wear clean uniforms and use appropriate protective gear, including hairnets and gloves, to prevent contamination. Personal grooming standards such as trimmed nails and no jewelry are emphasized to uphold strict hygiene levels.

How does the SOP address the cleaning and sanitation frequency for production equipment and work surfaces?

The SOP requires regular cleaning and sanitation of all production equipment and work surfaces to prevent cross-contamination. Cleaning schedules are typically defined as before, during, and after production shifts, ensuring consistent maintenance of hygiene. The use of approved sanitizers and monitoring of cleaning efficacy are integral parts of the frequency protocol.

What procedures does the SOP specify for the storage and handling of cleaning chemicals in the workplace?

The SOP outlines strict guidelines for the safe storage and handling of cleaning chemicals to avoid hazards and contamination. Chemicals must be stored in designated, labeled areas away from production zones and accessible only to trained personnel. Proper dilution, usage instructions, and disposal methods are clearly documented to ensure compliance and safety.

How are waste disposal and management responsibilities outlined in the SOP for maintaining workplace hygiene?

The SOP establishes clear waste disposal and management protocols to maintain cleanliness and reduce contamination risks. Employees are instructed to segregate waste according to type, use designated containers, and ensure timely removal from production areas. Responsibilities for monitoring and documenting waste handling practices are assigned to specific roles to maintain accountability.

What are the documented procedures for reporting and managing hygiene-related incidents in the manufacturing facility?

The SOP mandates immediate reporting and management of any hygiene-related incidents to minimize impact on product safety. Incidents must be logged, investigated, and corrective actions implemented promptly to prevent recurrence. Communication channels are clearly defined to ensure all relevant personnel are informed and appropriate measures are taken swiftly.