A SOP Template for Manufacturing Operations provides a standardized framework to document critical processes, ensuring consistency and quality across production activities. This template helps streamline workflows, reduce errors, and maintain compliance with industry regulations by clearly outlining step-by-step procedures. Using a well-designed SOP template enhances operational efficiency and supports continuous improvement in manufacturing environments.

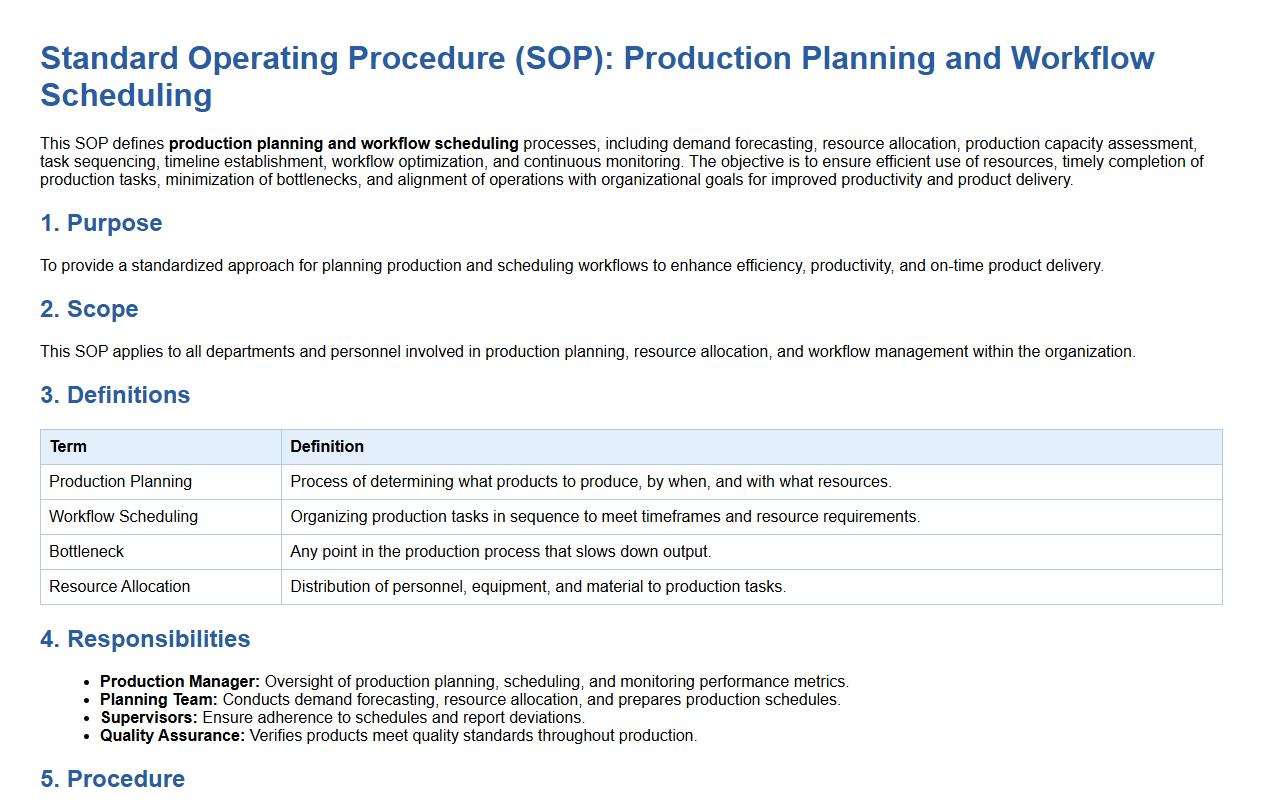

Production planning and workflow scheduling.

This SOP defines production planning and workflow scheduling processes, including demand forecasting, resource allocation, production capacity assessment, task sequencing, timeline establishment, workflow optimization, and continuous monitoring. The objective is to ensure efficient use of resources, timely completion of production tasks, minimization of bottlenecks, and alignment of operations with organizational goals for improved productivity and product delivery.

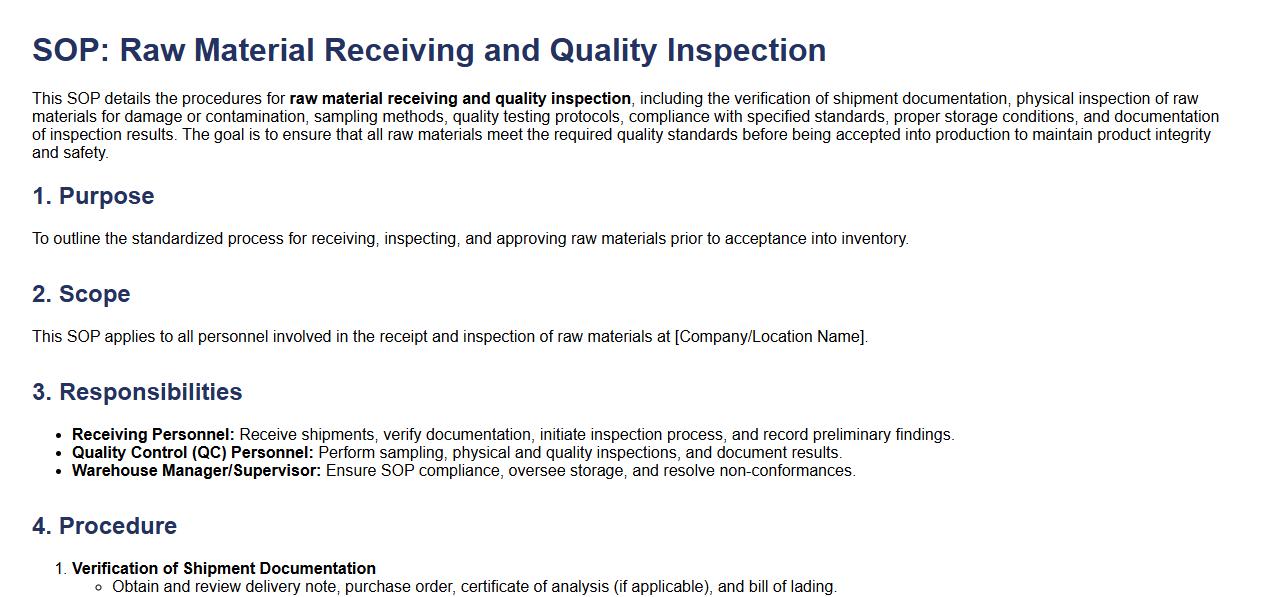

Raw material receiving and quality inspection.

This SOP details the procedures for raw material receiving and quality inspection, including the verification of shipment documentation, physical inspection of raw materials for damage or contamination, sampling methods, quality testing protocols, compliance with specified standards, proper storage conditions, and documentation of inspection results. The goal is to ensure that all raw materials meet the required quality standards before being accepted into production to maintain product integrity and safety.

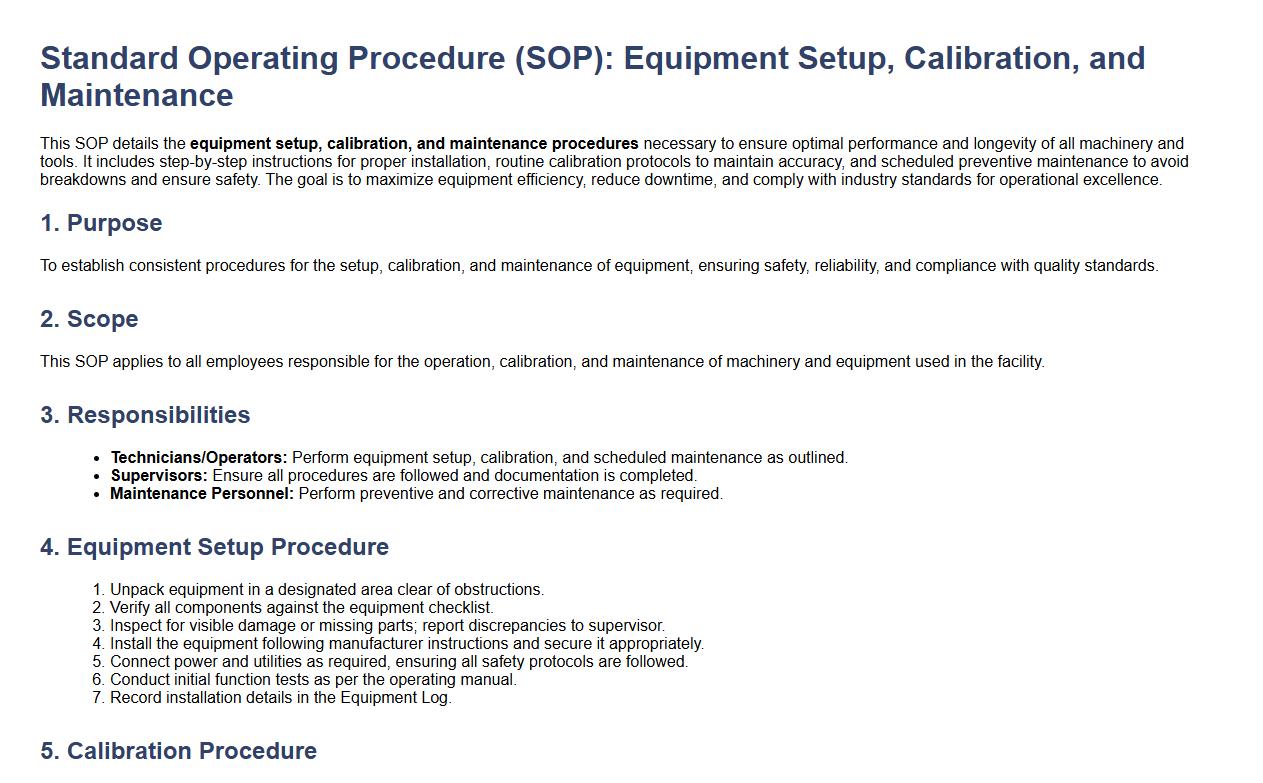

Equipment setup, calibration, and maintenance procedures.

This SOP details the equipment setup, calibration, and maintenance procedures necessary to ensure optimal performance and longevity of all machinery and tools. It includes step-by-step instructions for proper installation, routine calibration protocols to maintain accuracy, and scheduled preventive maintenance to avoid breakdowns and ensure safety. The goal is to maximize equipment efficiency, reduce downtime, and comply with industry standards for operational excellence.

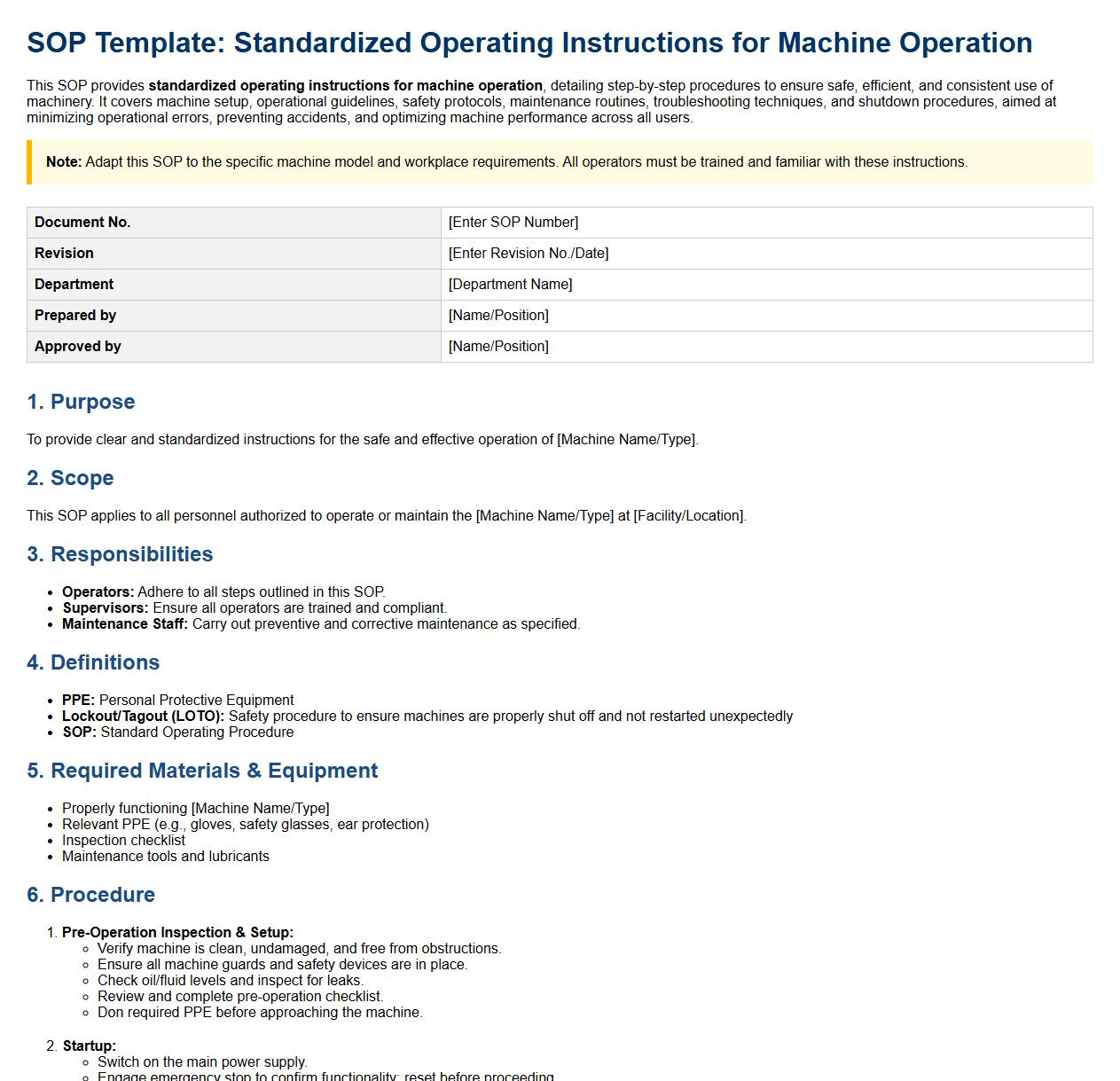

Standardized operating instructions for machine operation.

This SOP provides standardized operating instructions for machine operation, detailing step-by-step procedures to ensure safe, efficient, and consistent use of machinery. It covers machine setup, operational guidelines, safety protocols, maintenance routines, troubleshooting techniques, and shutdown procedures, aimed at minimizing operational errors, preventing accidents, and optimizing machine performance across all users.

In-process quality control and defect management.

This SOP details the procedures for in-process quality control and defect management, encompassing continuous monitoring of production processes, identification and documentation of defects, corrective action implementation, and prevention of recurrence. The objective is to maintain high product quality standards, minimize defects, enhance process efficiency, and ensure customer satisfaction through systematic defect detection and resolution during production.

Safety protocols and emergency response procedures.

This SOP details safety protocols and emergency response procedures designed to protect employees and minimize risks in the workplace. It covers hazard identification, risk assessment, preventive measures, emergency communication plans, evacuation routes, first aid response, and incident reporting. The goal is to ensure a safe working environment by effectively managing potential emergencies and safeguarding all personnel through comprehensive preparation and swift action.

Inventory tracking and material handling.

This SOP details inventory tracking and material handling procedures, covering accurate inventory documentation, stock monitoring, material storage protocols, safe handling practices, equipment usage, and regular audits. The objective is to maintain optimal inventory levels, ensure efficient material flow, reduce loss or damage, and promote workplace safety through standardized and systematic processes.

Finished goods packaging and labeling requirements.

This SOP defines the finished goods packaging and labeling requirements to ensure that all products are securely packaged and accurately labeled before distribution. It covers packaging materials, methods, quality standards, labeling information such as product details, batch numbers, expiry dates, and compliance with regulatory guidelines. The objective is to maintain product integrity, ensure traceability, and provide clear information to customers, thereby supporting effective inventory management and regulatory compliance.

Waste management and disposal processes.

This SOP details waste management and disposal processes, covering waste segregation, collection, storage, transportation, treatment, and final disposal methods. The procedures ensure compliance with environmental regulations, promote sustainability through recycling and reduction, and minimize health and safety risks associated with waste handling. Proper documentation and monitoring are included to maintain effective waste control and environmental protection.

Document control and continuous improvement reporting.

This SOP details the processes for document control and continuous improvement reporting, encompassing the creation, revision, approval, distribution, and archiving of documents. It ensures all documentation is accurate, up-to-date, and accessible to authorized personnel. The procedure also includes mechanisms for identifying areas of improvement, tracking performance metrics, reporting findings, and implementing corrective actions. The goal is to maintain document integrity while fostering a culture of ongoing enhancement and operational excellence.

What are the critical control points identified in the SOP for Manufacturing Operations?

The SOP identifies critical control points as stages in the manufacturing process where potential hazards can occur and must be strictly monitored. These points include raw material inspection, in-process sampling, and final product testing. Effective management at these control points ensures product safety and process reliability.

How does the SOP define and ensure compliance with safety regulations during manufacturing processes?

The SOP defines safety regulations by incorporating legal standards and industry best practices to prevent workplace hazards. Compliance is ensured through regular training, strict use of personal protective equipment (PPE), and routine safety audits. These measures maintain a safe manufacturing environment and minimize accident risks.

What standard procedures are outlined for equipment cleaning and maintenance in the manufacturing SOP?

The SOP outlines detailed cleaning and maintenance schedules, including frequency, methods, and approved cleaning agents to prevent contamination. Equipment must be inspected before and after use to verify proper functioning. This ensures consistent operational efficiency and product quality.

How does the SOP address deviation handling and documentation during manufacturing operations?

The SOP mandates immediate reporting and thorough documentation of any deviations from standard procedures to track non-conformances. It includes defined corrective and preventive action protocols to resolve issues promptly. This systematic approach ensures continuous process improvement and compliance.

Which quality assurance measures are mandated in the SOP to maintain product consistency and integrity?

The SOP mandates quality assurance measures such as in-process monitoring, batch record reviews, and final product inspections. It emphasizes strict adherence to validated procedures and proper documentation to maintain product consistency. These controls safeguard the integrity and reliability of the manufactured goods.