A SOP Template for Product Recall in Manufacturing provides a structured framework to efficiently manage the withdrawal of defective products from the market. It outlines clear procedures for identifying, documenting, and communicating with stakeholders to minimize risks and ensure compliance with regulatory standards. This template helps maintain product safety and protect brand reputation through prompt and organized recall actions.

Product identification and traceability procedures.

This SOP details product identification and traceability procedures to ensure accurate tracking of products throughout the supply chain. It includes methods for labeling, recording batch or serial numbers, maintaining traceability records, and procedures for tracking product movement from production to delivery. The goal is to enhance product quality control, facilitate recalls if necessary, and comply with regulatory requirements for transparency and accountability.

Recall initiation and decision-making authority.

This SOP details the recall initiation and decision-making authority process, outlining the criteria for initiating a product recall, the roles and responsibilities of key personnel involved, and the authority required to approve recall actions. It ensures a structured and efficient approach to promptly identifying, assessing, and managing product recalls to protect consumer safety and maintain compliance with regulatory requirements.

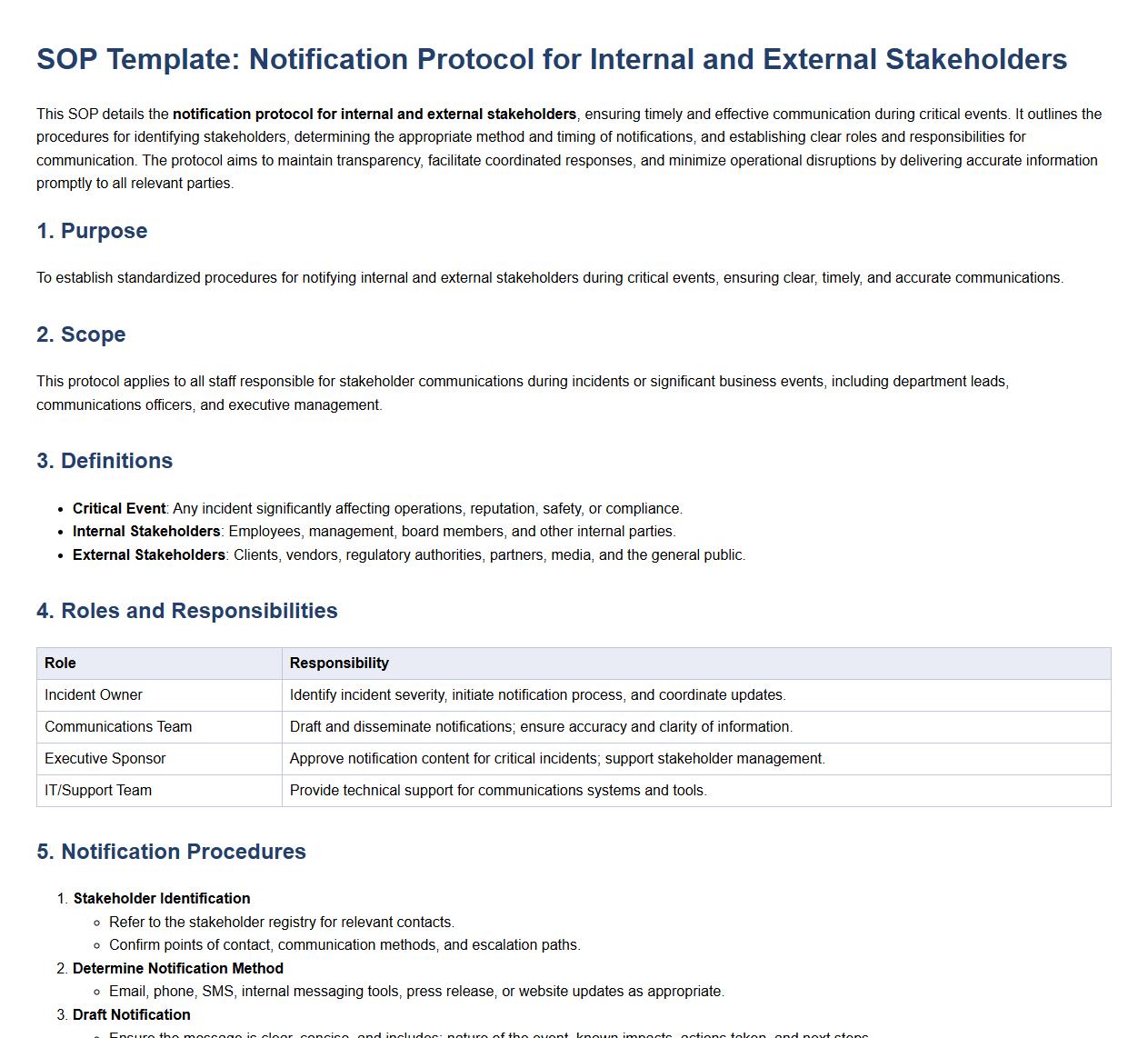

Notification protocol for internal and external stakeholders.

This SOP details the notification protocol for internal and external stakeholders, ensuring timely and effective communication during critical events. It outlines the procedures for identifying stakeholders, determining the appropriate method and timing of notifications, and establishing clear roles and responsibilities for communication. The protocol aims to maintain transparency, facilitate coordinated responses, and minimize operational disruptions by delivering accurate information promptly to all relevant parties.

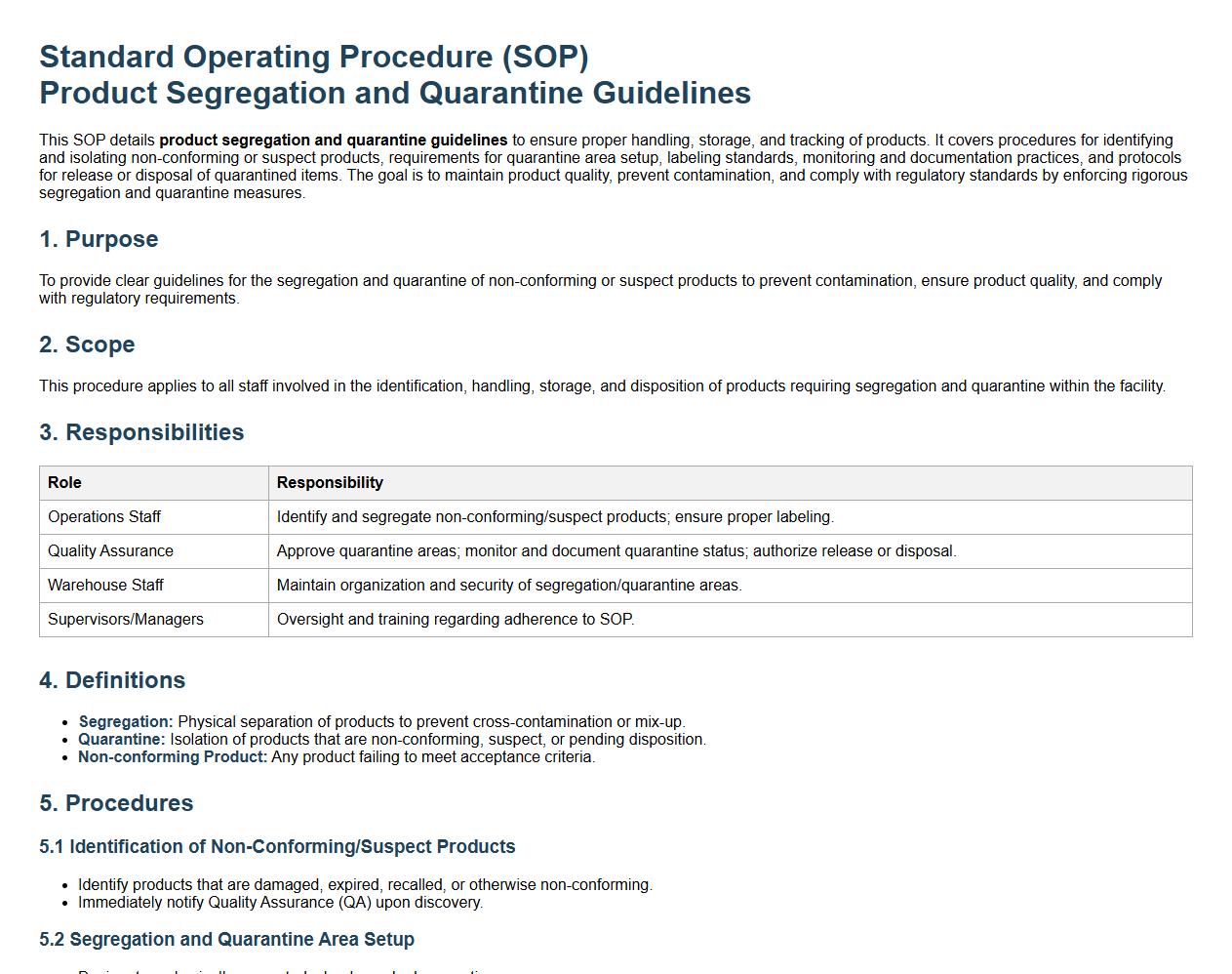

Product segregation and quarantine guidelines.

This SOP details product segregation and quarantine guidelines to ensure proper handling, storage, and tracking of products. It covers procedures for identifying and isolating non-conforming or suspect products, requirements for quarantine area setup, labeling standards, monitoring and documentation practices, and protocols for release or disposal of quarantined items. The goal is to maintain product quality, prevent contamination, and comply with regulatory standards by enforcing rigorous segregation and quarantine measures.

Recall communication template for customers and regulators.

This SOP provides a standardized recall communication template designed for effectively notifying customers and regulators about product recalls. It ensures clarity, compliance with regulatory requirements, timely dissemination of essential information, and maintains transparency to protect public safety and uphold the company's reputation during recall incidents.

Corrective action and root cause analysis process.

This SOP defines the corrective action and root cause analysis process, detailing procedures for identifying, analyzing, and addressing non-conformities or issues within operations. It includes steps for problem identification, root cause investigation, implementation of corrective actions, verification of effectiveness, documentation, and continuous improvement to prevent recurrence and enhance overall organizational performance.

Documentation and record-keeping requirements for recalls.

This SOP details the documentation and record-keeping requirements for recalls, encompassing the systematic recording of recall initiation, tracking of affected products, communication logs with stakeholders, verification of product retrieval, and final disposition documentation. The purpose is to maintain accurate and comprehensive records to ensure traceability, regulatory compliance, and effective management of recall processes.

Procedure for product retrieval, transport, and disposal.

This SOP details the procedure for product retrieval, transport, and disposal, encompassing the identification and collection of products designated for retrieval, secure and compliant transportation methods, and environmentally responsible disposal practices. It ensures safe handling, minimizes risks during transit, and adheres to regulatory requirements to maintain product integrity and safeguard the environment.

Post-recall assessment and verification steps.

This SOP details the post-recall assessment and verification steps, focusing on the systematic evaluation of recalled products, verification of corrective actions, documentation of compliance, and communication with relevant stakeholders to ensure product safety and regulatory adherence. The purpose is to effectively confirm the resolution of recall issues and prevent recurrence, safeguarding consumer trust and organizational integrity.

Continuous improvement and recall prevention measures.

This SOP details the implementation of continuous improvement and recall prevention measures, focusing on systematic monitoring, evaluation, and enhancement of product quality and safety processes. It covers strategies for identifying potential risks, establishing corrective actions, fostering a culture of quality awareness, and maintaining compliance with regulatory standards to prevent product recalls and ensure customer satisfaction.

Key Steps Outlined in the SOP for Initiating a Product Recall in Manufacturing

The SOP mandates immediate identification and containment of the affected product batches as the initial step in the recall process. Following this, a formal notification must be issued to all stakeholders, including distributors and regulatory authorities. The procedure emphasizes a swift and organized approach to minimize risk and ensure consumer safety.

Who is Responsible for Decision-Making and Communication During the Recall Process According to the SOP?

The SOP designates the Recall Management Team, typically led by the Quality Assurance Manager, as the authority for decision-making during a recall. This team is tasked with coordinating all communication efforts, both internal and external. They ensure that information is accurate, timely, and compliant with regulatory requirements.

What Documentation and Records Must Be Maintained During a Product Recall as Specified in the SOP?

According to the SOP, detailed records of all recalled products, including batch numbers and distribution channels, must be meticulously maintained. Additionally, communication logs and corrective action reports are critical for traceability. Maintaining comprehensive documentation supports regulatory audits and continuous improvement.

How Does the SOP Define the Criteria for Classifying the Severity and Type of Product Recalls?

The SOP classifies recalls based on the potential health risk posed, categorizing them into Class I, II, or III recalls. A Class I recall involves products that could cause serious health consequences or death. This classification guides the urgency and scope of the recall actions required.

What Post-Recall Review and Corrective Actions Are Mandated by the SOP for Ongoing Process Improvement?

Post-recall, the SOP requires a thorough review to identify root causes and assess the recall's effectiveness. Corrective actions must be implemented to prevent recurrence, including process adjustments and employee training. This continuous improvement approach helps enhance product safety and quality standards.