A SOP Template for Documentation Control in Manufacturing ensures consistent management and organization of critical production records. This template outlines standardized procedures for document creation, revision, approval, and storage to maintain compliance and traceability. Implementing this SOP improves efficiency and reduces errors in manufacturing documentation workflows.

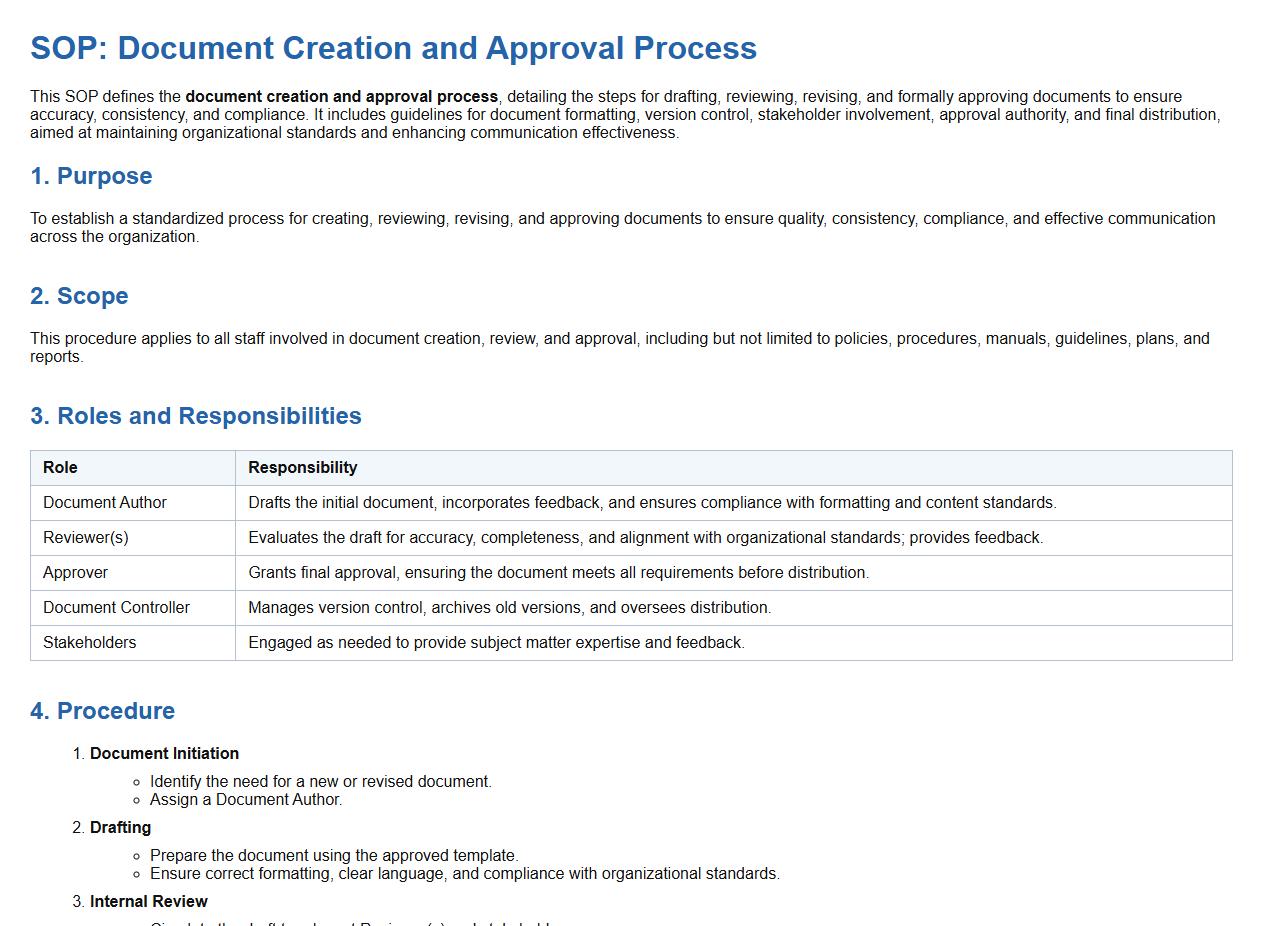

Document creation and approval process.

This SOP defines the document creation and approval process, detailing the steps for drafting, reviewing, revising, and formally approving documents to ensure accuracy, consistency, and compliance. It includes guidelines for document formatting, version control, stakeholder involvement, approval authority, and final distribution, aimed at maintaining organizational standards and enhancing communication effectiveness.

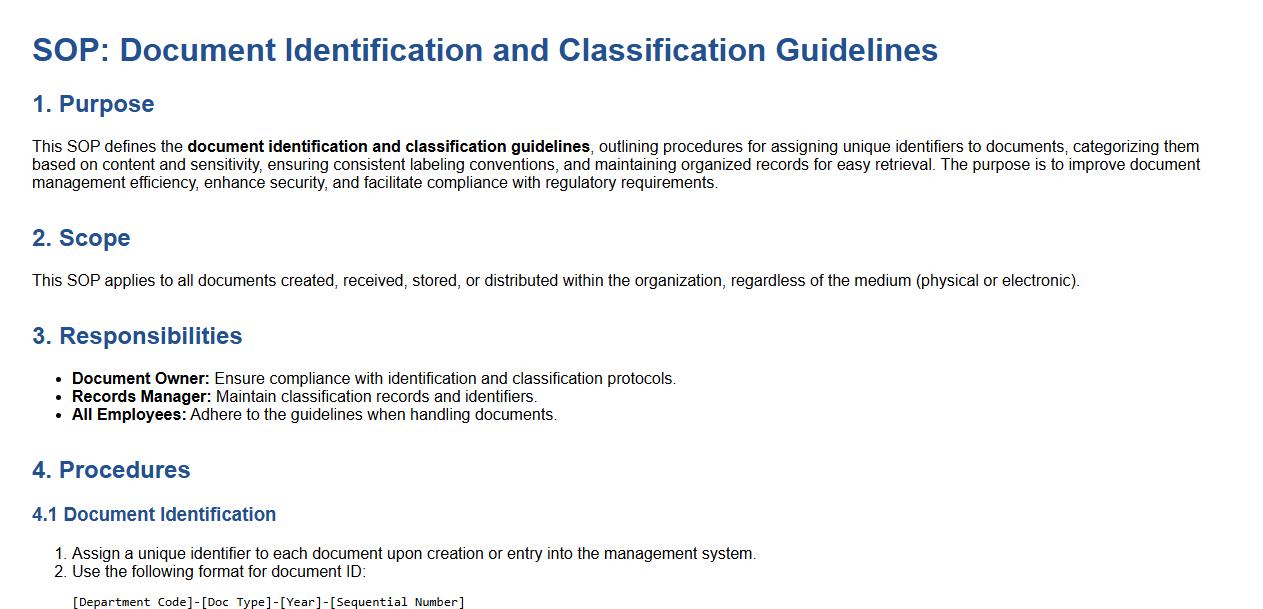

Document identification and classification guidelines.

This SOP defines the document identification and classification guidelines, outlining procedures for assigning unique identifiers to documents, categorizing them based on content and sensitivity, ensuring consistent labeling conventions, and maintaining organized records for easy retrieval. The purpose is to improve document management efficiency, enhance security, and facilitate compliance with regulatory requirements.

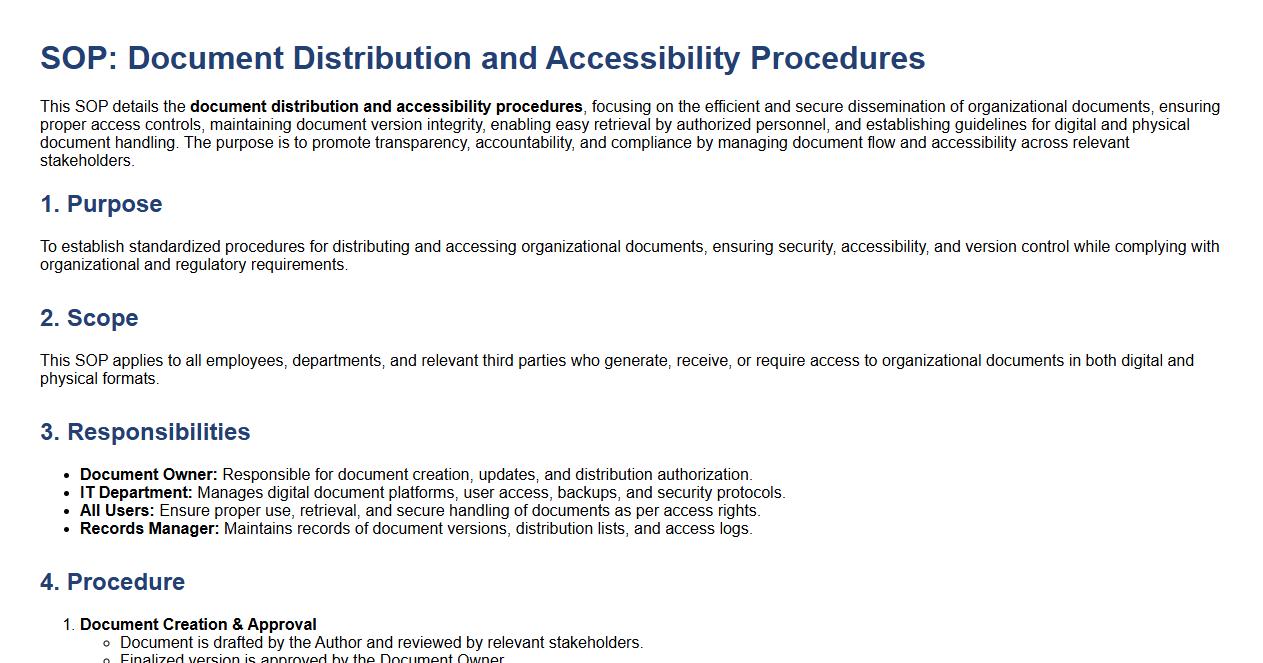

Document distribution and accessibility procedures.

This SOP details the document distribution and accessibility procedures, focusing on the efficient and secure dissemination of organizational documents, ensuring proper access controls, maintaining document version integrity, enabling easy retrieval by authorized personnel, and establishing guidelines for digital and physical document handling. The purpose is to promote transparency, accountability, and compliance by managing document flow and accessibility across relevant stakeholders.

Version control and document revision tracking.

This SOP details version control and document revision tracking processes, including establishing version numbering systems, documenting changes and updates, assigning revision responsibilities, maintaining revision history logs, ensuring document accessibility and security, and standardizing review and approval workflows. The goal is to maintain accurate, organized, and up-to-date documentation to support quality management and compliance requirements.

Document retention and archiving requirements.

This SOP defines the document retention and archiving requirements, including the classification of documents, retention periods, storage methods, access controls, and disposal procedures. The objective is to ensure that all organizational records are systematically preserved, accessible when needed, and securely destroyed in compliance with regulatory standards and company policies.

Obsolete document withdrawal and destruction steps.

This SOP details the obsolete document withdrawal and destruction steps, including identifying outdated documents, securing withdrawal approval, removing documents from active use, and implementing secure destruction methods. The procedure ensures confidentiality, compliance with regulatory requirements, and prevents the use of outdated information, maintaining document integrity and organizational efficiency.

Confidentiality and security of controlled documents.

This SOP establishes the protocols for maintaining the confidentiality and security of controlled documents, including proper document classification, access control, storage, distribution, and disposal. It aims to protect sensitive information from unauthorized access, ensure document integrity, and support compliance with regulatory and organizational requirements.

Periodic review and audit of documentation.

This SOP details the process for the periodic review and audit of documentation, including scheduling regular reviews, assessing document accuracy and compliance, updating outdated information, ensuring proper version control, identifying gaps or inconsistencies, and maintaining audit trails. The objective is to guarantee that all organizational documents remain current, accurate, and aligned with regulatory requirements and internal standards, thus supporting effective management and operational excellence.

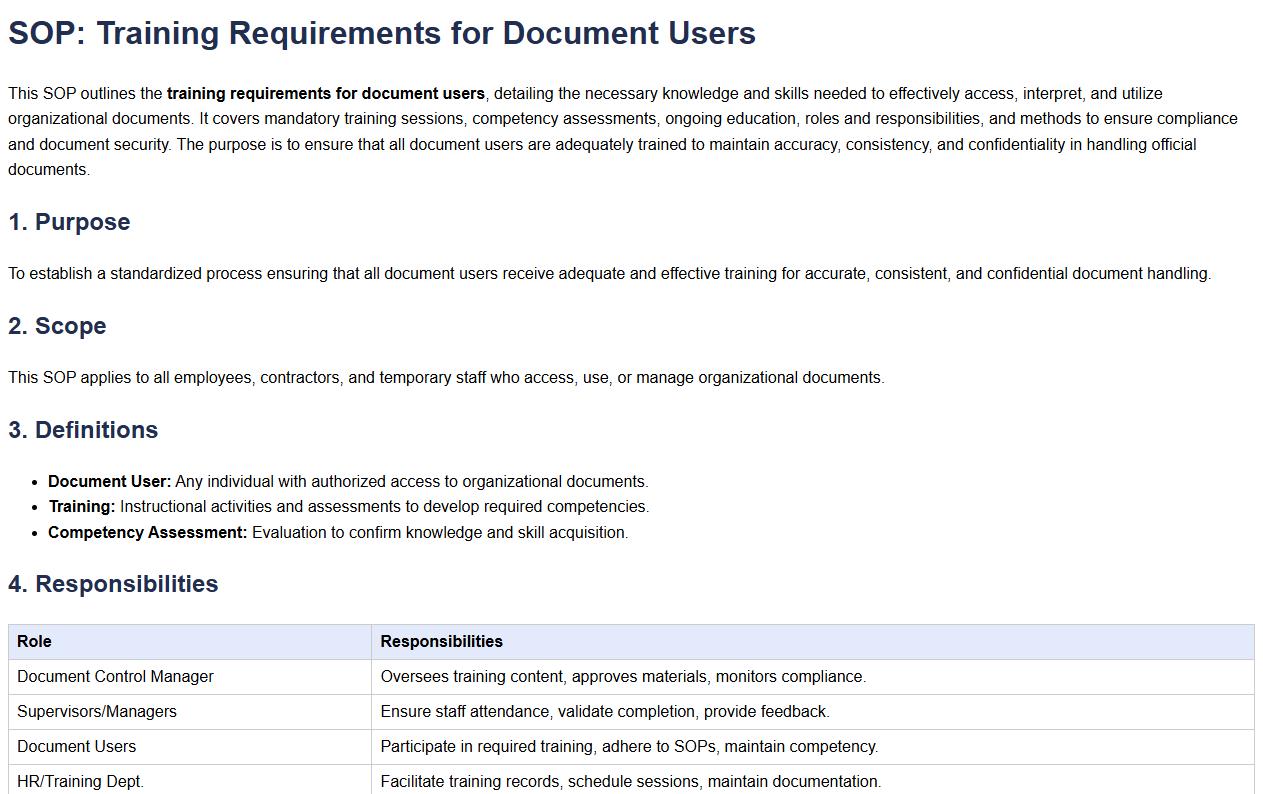

Training requirements for document users.

This SOP outlines the training requirements for document users, detailing the necessary knowledge and skills needed to effectively access, interpret, and utilize organizational documents. It covers mandatory training sessions, competency assessments, ongoing education, roles and responsibilities, and methods to ensure compliance and document security. The purpose is to ensure that all document users are adequately trained to maintain accuracy, consistency, and confidentiality in handling official documents.

Non-conformance handling and corrective action procedures.

This SOP describes the processes for non-conformance handling and corrective action procedures, including identification, documentation, analysis, and resolution of non-conformances. It aims to ensure timely corrective actions, prevent recurrence, and maintain compliance with quality standards by involving relevant personnel and continuous monitoring of effectiveness.

What procedures must be followed for the creation and approval of new manufacturing documents according to the SOP?

The SOP mandates the initiation of new manufacturing documents through a formal drafting process involving technical experts. Each document must undergo a thorough review and approval by authorized personnel to ensure compliance and accuracy. The final approved document is then signed off and registered in the official document control system for traceability.

How does the SOP define roles and responsibilities for document revision and version control?

The SOP assigns specific roles for document revision to designated individuals who are responsible for making updates and ensuring accuracy. Version control is strictly managed by document control personnel who track changes and maintain a version history. This systematic approach prevents unauthorized edits and guarantees that only current, approved documents are in use.

What are the requirements for secure storage and accessibility of controlled documents as per the SOP?

The SOP requires all controlled documents to be stored in secure, access-controlled environments to protect against unauthorized access or loss. Accessibility must be convenient for authorized staff to enable efficient use while maintaining strict control measures. Backup procedures are also mandated to ensure document preservation in case of system failures.

How does the SOP outline the process for document distribution and retrieval in the manufacturing facility?

Document distribution is handled through a centralized system that ensures only the latest approved versions are disseminated to relevant departments. Retrieval protocols include logging of document requests and usage to maintain an audit trail. This controlled distribution process supports operational integrity and compliance with regulatory standards.

What steps are specified in the SOP for the periodic review and obsolescence of outdated documentation?

The SOP requires scheduled periodic reviews to verify the ongoing relevance and accuracy of manufacturing documents. Documents deemed outdated or obsolete must be formally withdrawn and replaced with updated versions, following an established approval process. Proper documentation of these changes ensures continuous improvement and compliance with quality standards.