A SOP Template for Supply Chain Management in Manufacturing provides a standardized framework to ensure consistent processes across procurement, production, and distribution. This template helps streamline operations, improve efficiency, and reduce errors by clearly defining roles, responsibilities, and workflows. Implementing a well-structured SOP supports better coordination between suppliers, manufacturers, and logistics teams.

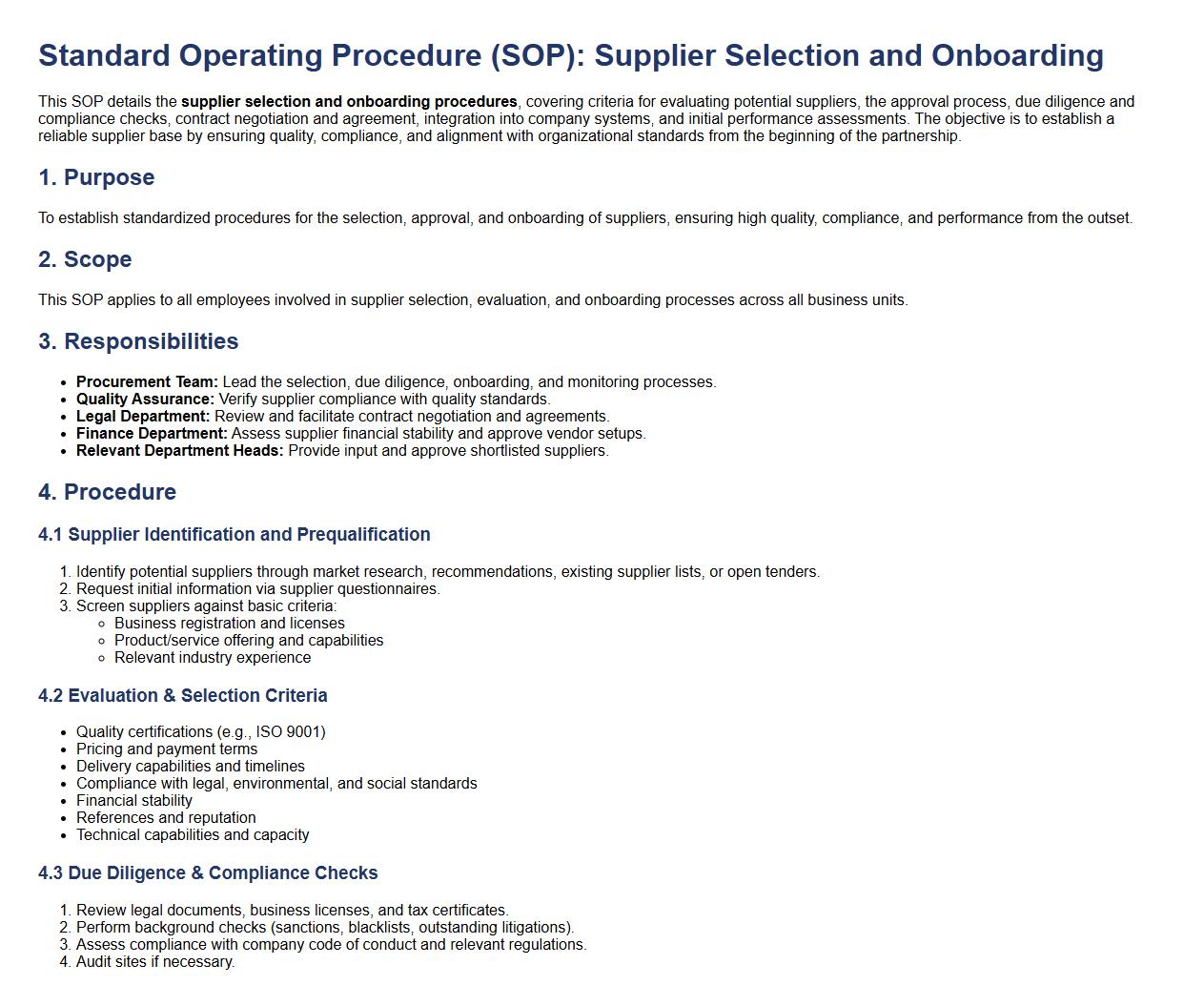

Supplier selection and onboarding procedures.

This SOP details the supplier selection and onboarding procedures, covering criteria for evaluating potential suppliers, the approval process, due diligence and compliance checks, contract negotiation and agreement, integration into company systems, and initial performance assessments. The objective is to establish a reliable supplier base by ensuring quality, compliance, and alignment with organizational standards from the beginning of the partnership.

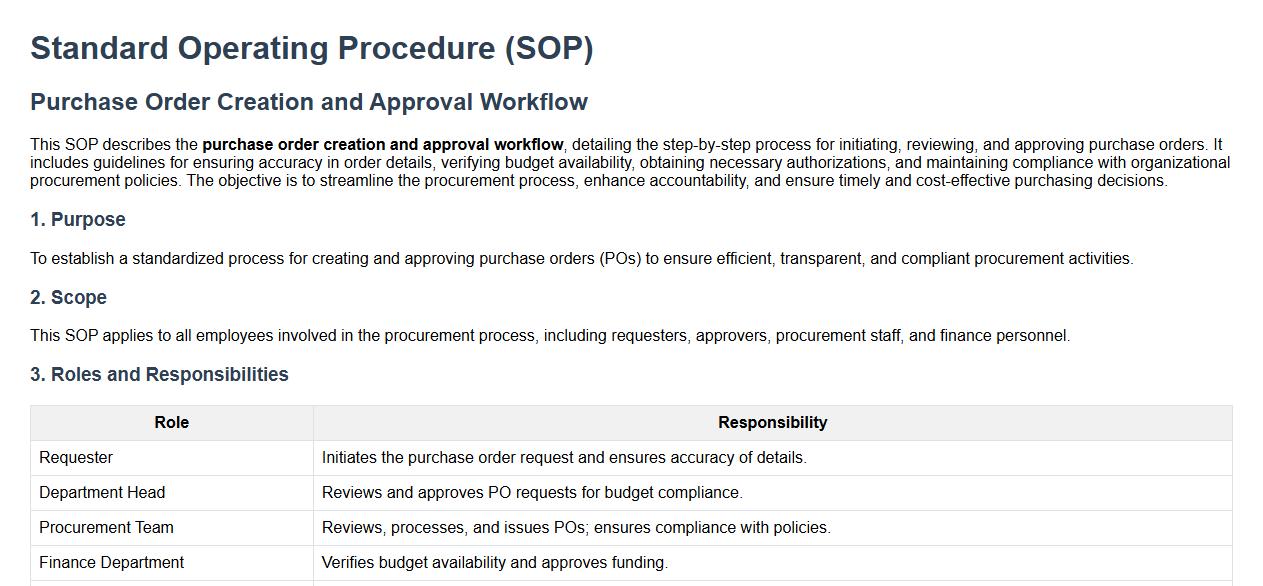

Purchase order creation and approval workflow.

This SOP describes the purchase order creation and approval workflow, detailing the step-by-step process for initiating, reviewing, and approving purchase orders. It includes guidelines for ensuring accuracy in order details, verifying budget availability, obtaining necessary authorizations, and maintaining compliance with organizational procurement policies. The objective is to streamline the procurement process, enhance accountability, and ensure timely and cost-effective purchasing decisions.

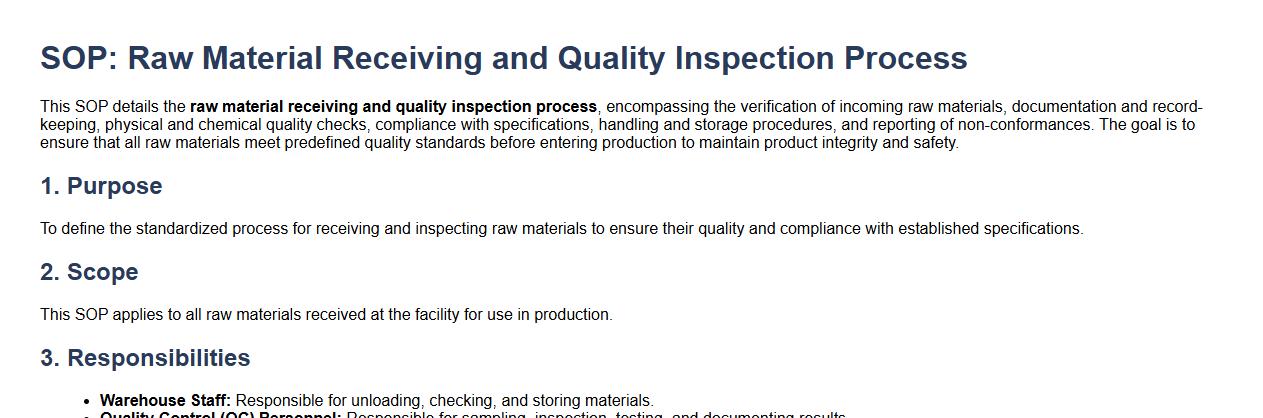

Raw material receiving and quality inspection process.

This SOP details the raw material receiving and quality inspection process, encompassing the verification of incoming raw materials, documentation and record-keeping, physical and chemical quality checks, compliance with specifications, handling and storage procedures, and reporting of non-conformances. The goal is to ensure that all raw materials meet predefined quality standards before entering production to maintain product integrity and safety.

Inventory tracking and warehouse management guidelines.

This SOP details inventory tracking and warehouse management guidelines, encompassing accurate inventory recording, stock level monitoring, warehouse layout optimization, proper storage techniques, order verification, shipment handling, and regular audits. The goal is to ensure efficient inventory control, reduce discrepancies, enhance warehouse organization, and support smooth supply chain operations through standardized procedures.

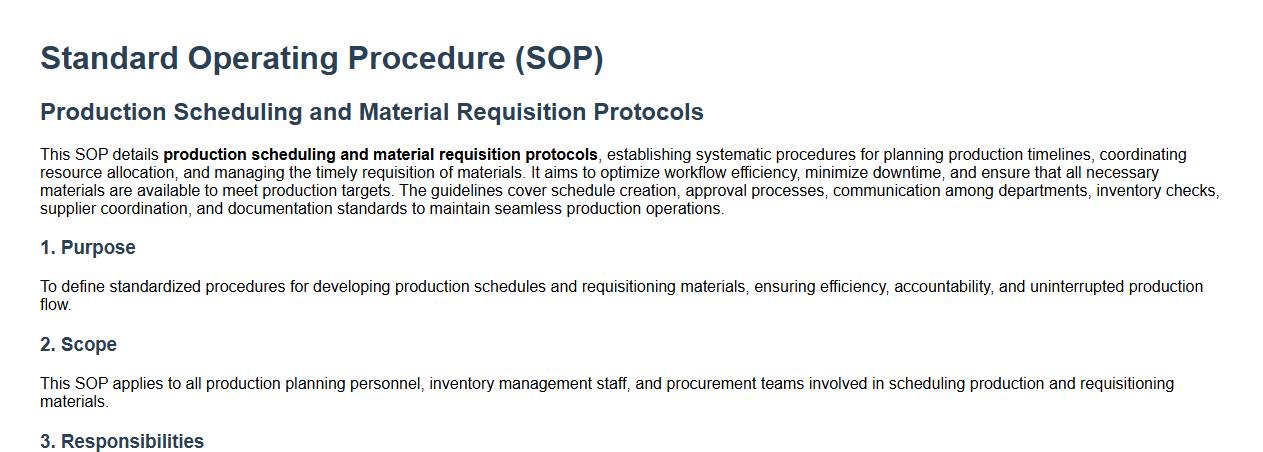

Production scheduling and material requisition protocols.

This SOP details production scheduling and material requisition protocols, establishing systematic procedures for planning production timelines, coordinating resource allocation, and managing the timely requisition of materials. It aims to optimize workflow efficiency, minimize downtime, and ensure that all necessary materials are available to meet production targets. The guidelines cover schedule creation, approval processes, communication among departments, inventory checks, supplier coordination, and documentation standards to maintain seamless production operations.

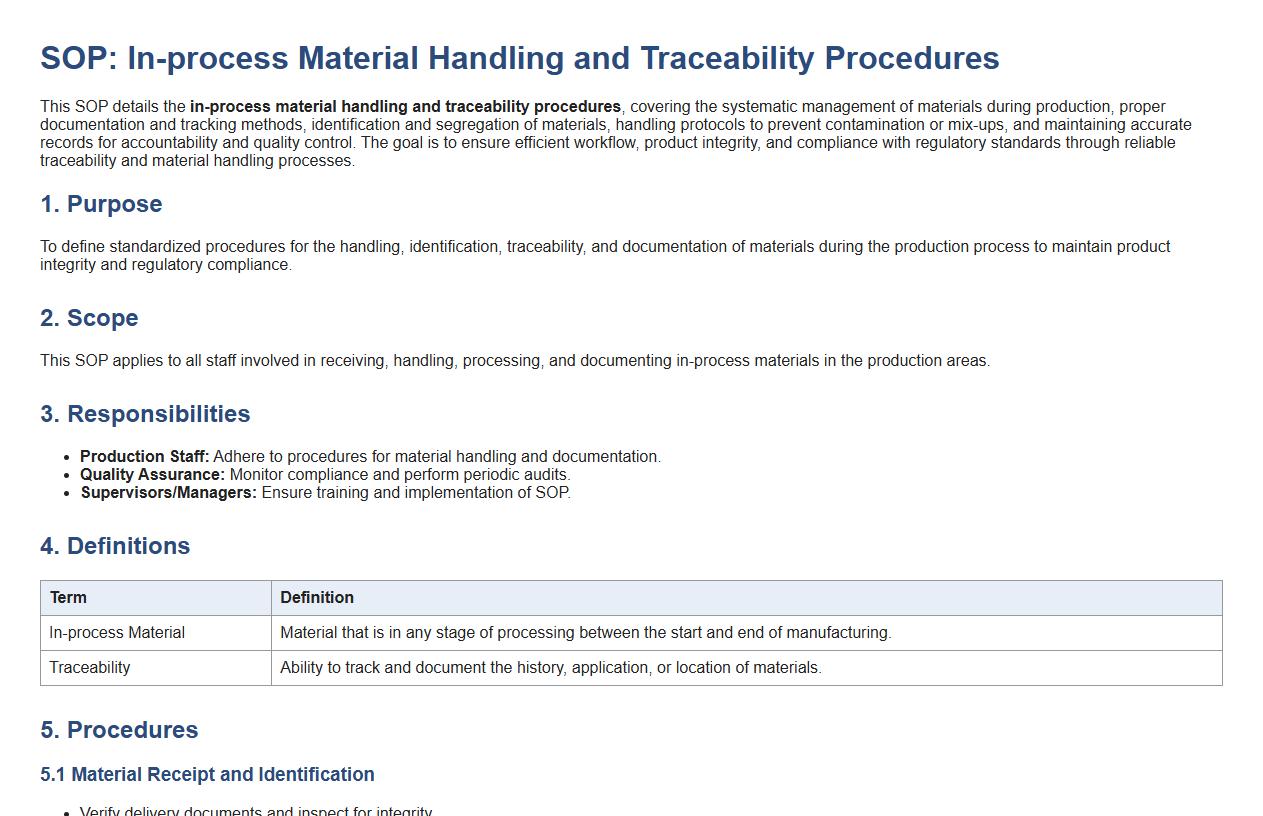

In-process material handling and traceability procedures.

This SOP details the in-process material handling and traceability procedures, covering the systematic management of materials during production, proper documentation and tracking methods, identification and segregation of materials, handling protocols to prevent contamination or mix-ups, and maintaining accurate records for accountability and quality control. The goal is to ensure efficient workflow, product integrity, and compliance with regulatory standards through reliable traceability and material handling processes.

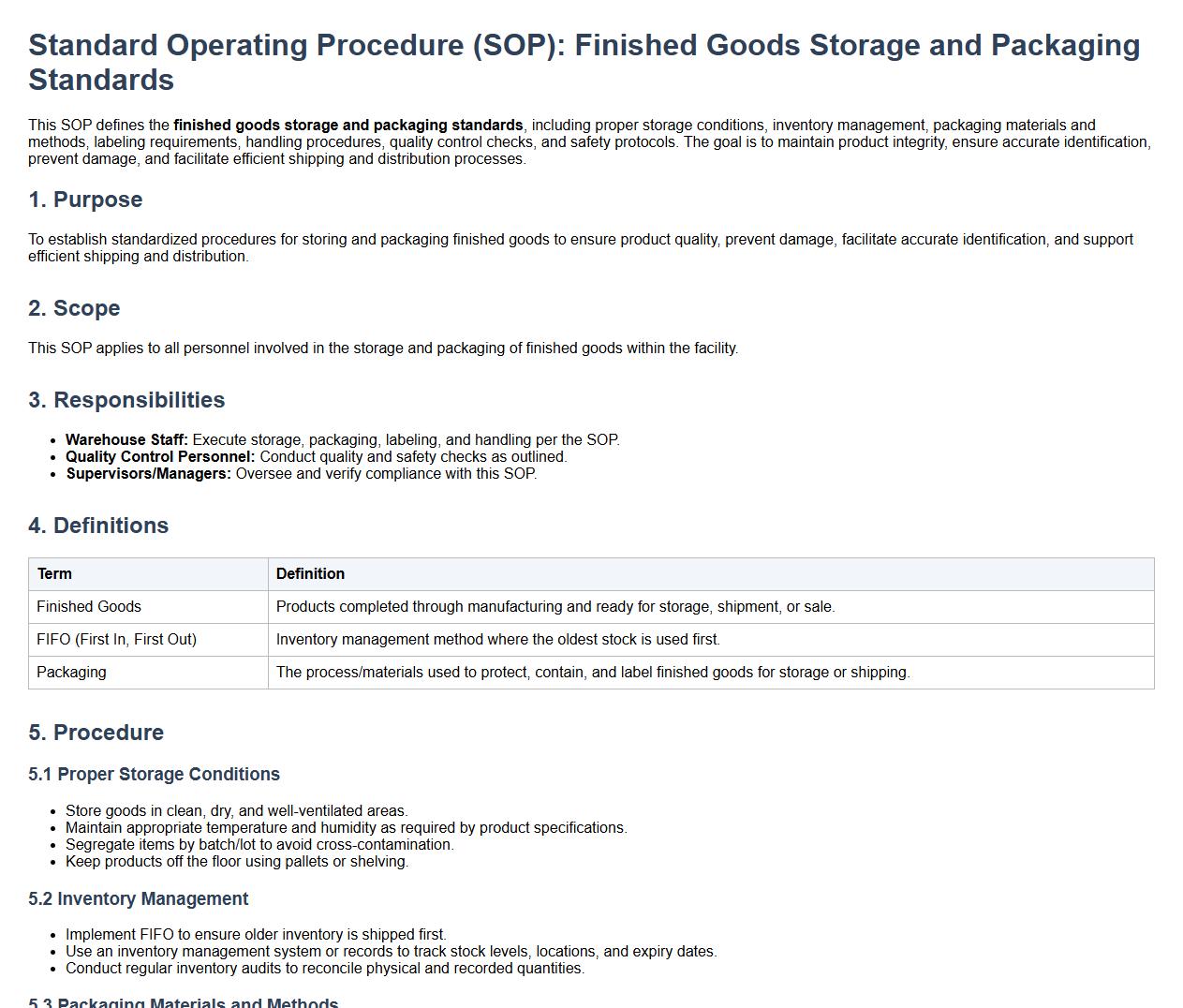

Finished goods storage and packaging standards.

This SOP defines the finished goods storage and packaging standards, including proper storage conditions, inventory management, packaging materials and methods, labeling requirements, handling procedures, quality control checks, and safety protocols. The goal is to maintain product integrity, ensure accurate identification, prevent damage, and facilitate efficient shipping and distribution processes.

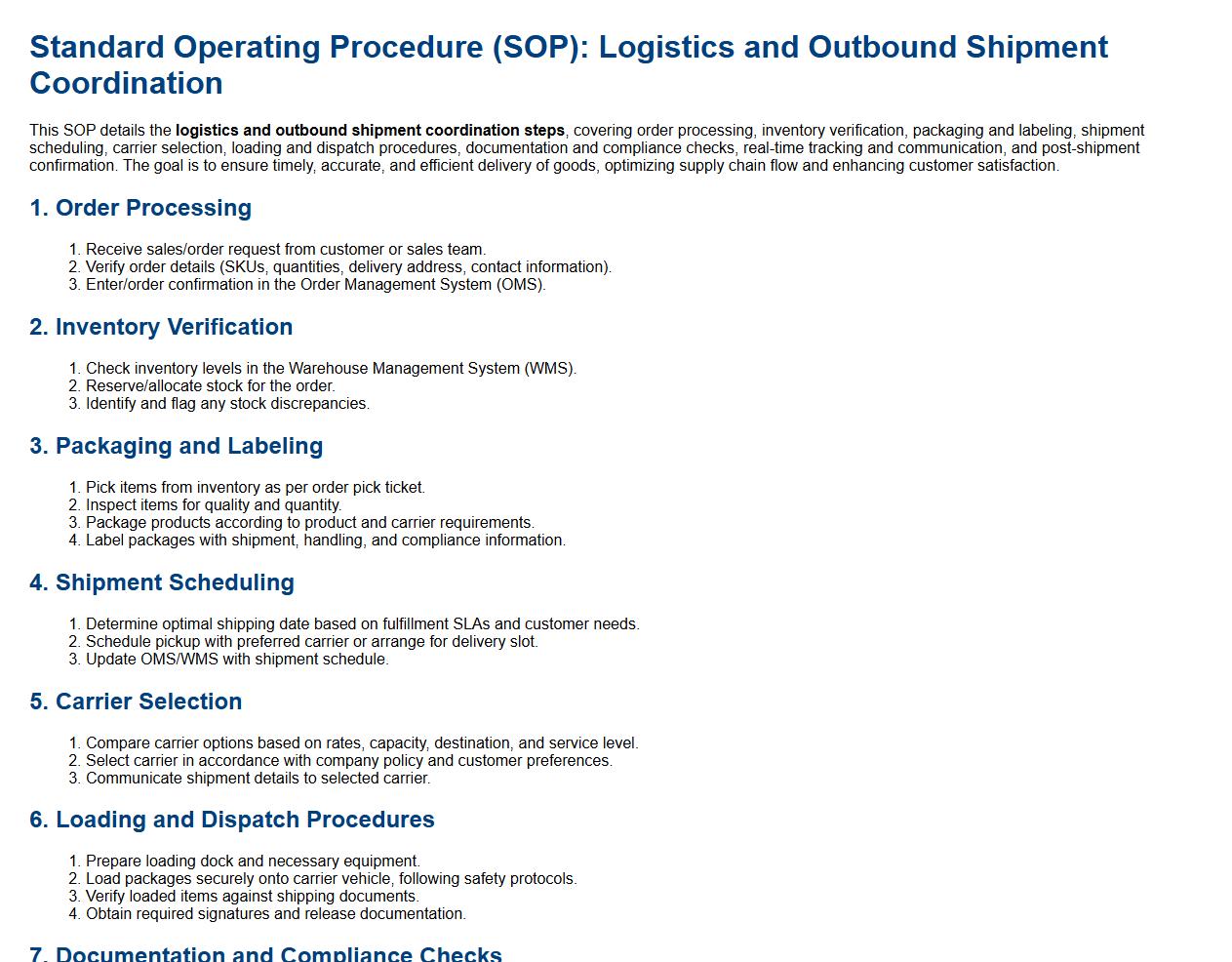

Logistics and outbound shipment coordination steps.

This SOP details the logistics and outbound shipment coordination steps, covering order processing, inventory verification, packaging and labeling, shipment scheduling, carrier selection, loading and dispatch procedures, documentation and compliance checks, real-time tracking and communication, and post-shipment confirmation. The goal is to ensure timely, accurate, and efficient delivery of goods, optimizing supply chain flow and enhancing customer satisfaction.

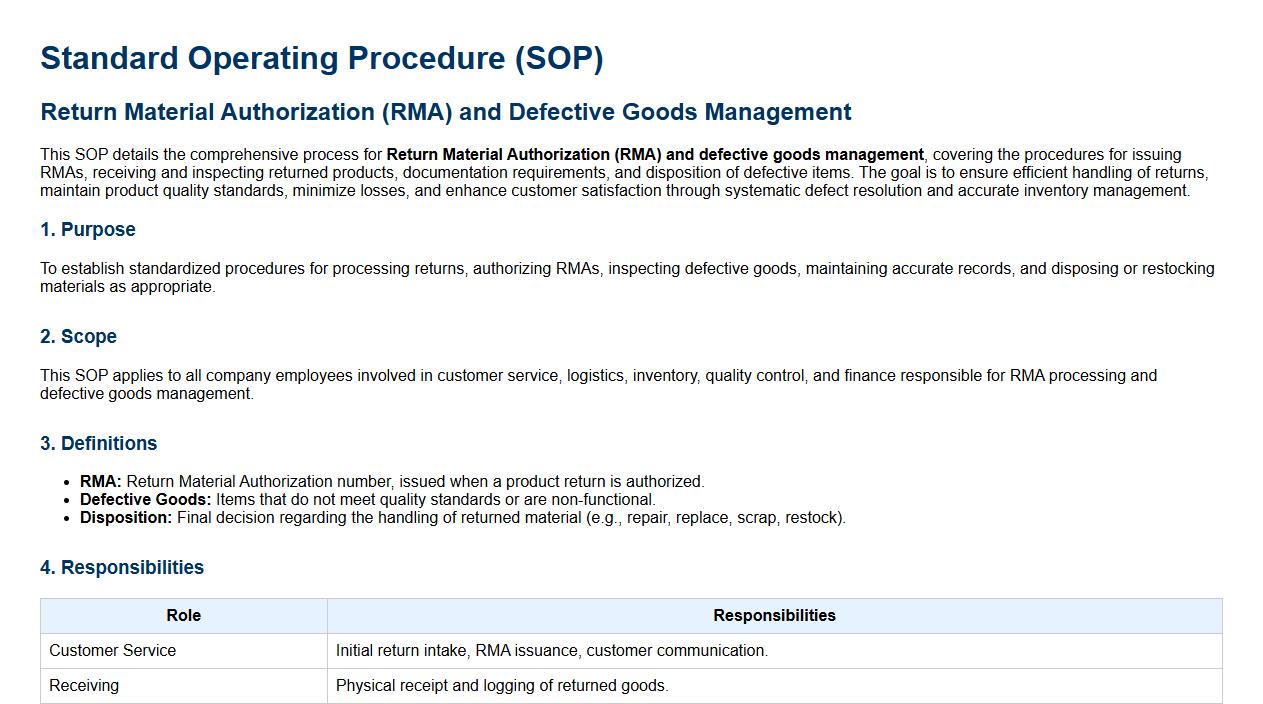

Return material authorization (RMA) and defective goods management.

This SOP details the comprehensive process for Return Material Authorization (RMA) and defective goods management, covering the procedures for issuing RMAs, receiving and inspecting returned products, documentation requirements, and disposition of defective items. The goal is to ensure efficient handling of returns, maintain product quality standards, minimize losses, and enhance customer satisfaction through systematic defect resolution and accurate inventory management.

Supply chain risk assessment and contingency planning.

This SOP details the process for supply chain risk assessment and contingency planning, covering the identification of potential supply chain risks, evaluation of their impact and likelihood, development of risk mitigation strategies, establishment of contingency plans, and continuous monitoring and review. Its purpose is to minimize disruptions, ensure operational continuity, and maintain the reliability and resilience of the supply chain in the face of uncertainties and unforeseen events.

What procedures are outlined for inventory tracking and control in the SOP?

The SOP specifies the use of real-time inventory tracking systems to ensure accurate stock levels. It mandates regular physical inventory audits to reconcile discrepancies and maintain data integrity. Additionally, it outlines clear guidelines for handling stock replenishment and minimizing wastage through efficient control mechanisms.

How does the SOP define roles and responsibilities within the supply chain process?

The SOP clearly assigns specific roles and responsibilities to each member of the supply chain team to ensure accountability. It emphasizes collaborative communication between procurement, warehouse, and logistics departments. Furthermore, it highlights the importance of defining decision-making authority to streamline processes and prevent delays.

What are the standard steps for supplier selection and evaluation as per the SOP?

The SOP outlines a structured process involving supplier qualification, performance assessment, and compliance checks. It requires evaluation based on quality, cost, delivery reliability, and service standards. Regular reviews and audits are mandated to maintain strong supplier relationships and ensure ongoing suitability.

How are discrepancies in material receipt and quality addressed according to the SOP?

The SOP mandates immediate notification and documentation of any discrepancies identified during material receipt inspection. It requires segregation of non-conforming materials and initiation of a corrective action process with the supplier. Additionally, it enforces rigorous root cause analysis to prevent recurrence and maintain quality standards.

What protocols for order fulfillment and delivery scheduling are established in the SOP?

The SOP establishes detailed order tracking and confirmation procedures to optimize fulfillment accuracy and timeliness. It prioritizes scheduling based on customer demand and inventory availability, ensuring efficient delivery. Clear communication channels are defined to coordinate between sales, warehouse, and logistics teams for seamless order execution.