A SOP Template for Manufacturing Plant Maintenance provides a standardized framework to ensure consistent and efficient maintenance processes. This template helps streamline routine inspections, equipment servicing, and repairs to minimize downtime and enhance plant productivity. Clear guidelines within the template support safety compliance and reduce the risk of operational failures.

Preventive maintenance scheduling and planning.

This SOP details the processes involved in preventive maintenance scheduling and planning, including the systematic identification of maintenance tasks, development of maintenance schedules, allocation of resources, tracking of maintenance activities, and evaluation of equipment performance. Its goal is to minimize equipment downtime, extend asset lifespan, and ensure operational efficiency through timely and organized maintenance interventions.

Equipment inspection and condition monitoring procedures.

This SOP details equipment inspection and condition monitoring procedures, encompassing regular visual inspections, operational performance assessments, maintenance scheduling, fault detection methods, and record-keeping standards. The objective is to ensure all equipment remains in optimal working condition, prevent unexpected breakdowns, enhance safety, and extend the lifespan of machinery through systematic monitoring and timely interventions.

Corrective maintenance request and documentation process.

This SOP details the corrective maintenance request and documentation process, encompassing the identification of maintenance issues, submission of maintenance requests, prioritization and approval procedures, assignment of maintenance tasks, execution and monitoring of repairs, and thorough documentation of all maintenance activities. The objective is to ensure timely and efficient resolution of equipment and facility malfunctions, minimize downtime, and maintain accurate records for accountability and continuous improvement.

Spare parts inventory management and procurement.

This SOP details the procedures for spare parts inventory management and procurement, covering accurate inventory tracking, demand forecasting, supplier selection and evaluation, purchase order processing, receipt and inspection of parts, storage and organization, stock replenishment strategies, cost control measures, and reporting. The aim is to ensure the timely availability of critical spare parts, minimize downtime, optimize inventory levels, and maintain efficient procurement workflows to support operational continuity.

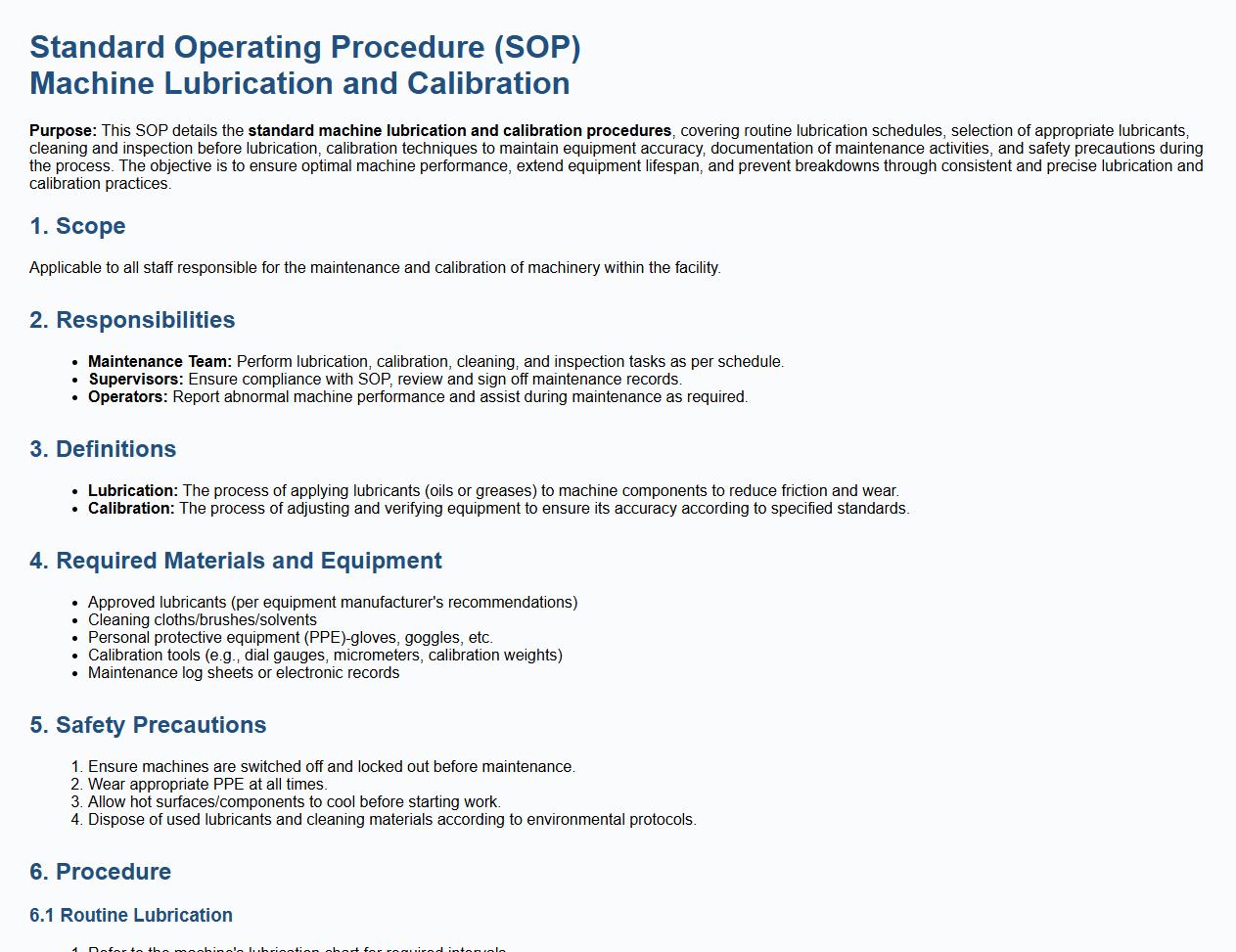

Standard machine lubrication and calibration procedures.

This SOP details the standard machine lubrication and calibration procedures, covering routine lubrication schedules, selection of appropriate lubricants, cleaning and inspection before lubrication, calibration techniques to maintain equipment accuracy, documentation of maintenance activities, and safety precautions during the process. The objective is to ensure optimal machine performance, extend equipment lifespan, and prevent breakdowns through consistent and precise lubrication and calibration practices.

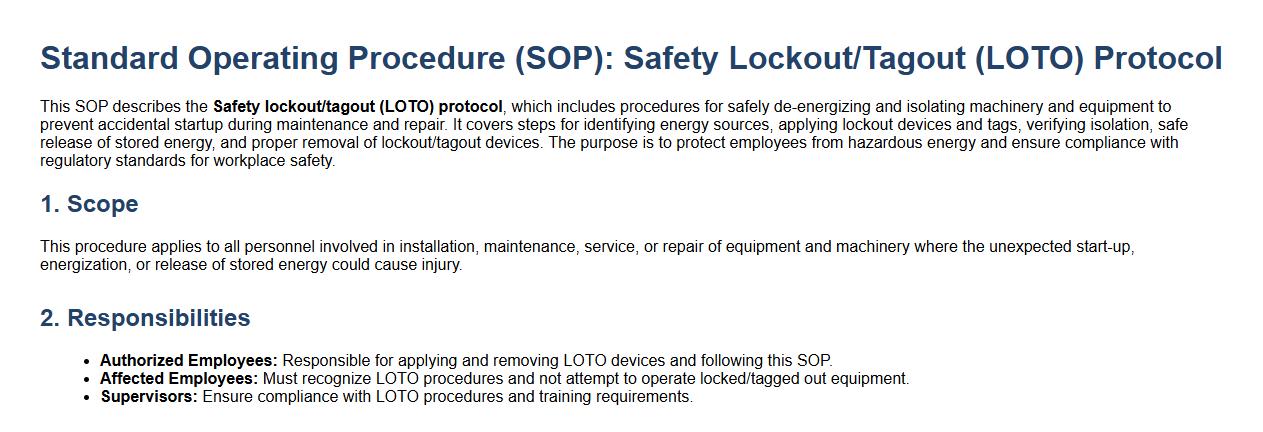

Safety lockout/tagout (LOTO) protocol.

This SOP describes the Safety lockout/tagout (LOTO) protocol, which includes procedures for safely de-energizing and isolating machinery and equipment to prevent accidental startup during maintenance and repair. It covers steps for identifying energy sources, applying lockout devices and tags, verifying isolation, safe release of stored energy, and proper removal of lockout/tagout devices. The purpose is to protect employees from hazardous energy and ensure compliance with regulatory standards for workplace safety.

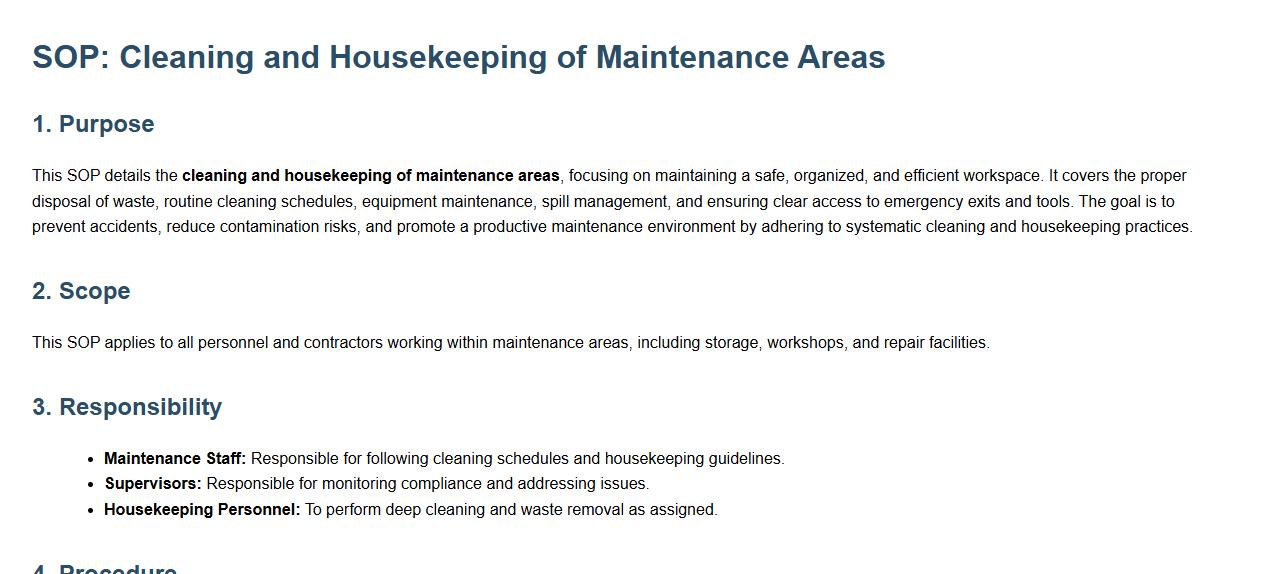

Cleaning and housekeeping of maintenance areas.

This SOP details the cleaning and housekeeping of maintenance areas, focusing on maintaining a safe, organized, and efficient workspace. It covers the proper disposal of waste, routine cleaning schedules, equipment maintenance, spill management, and ensuring clear access to emergency exits and tools. The goal is to prevent accidents, reduce contamination risks, and promote a productive maintenance environment by adhering to systematic cleaning and housekeeping practices.

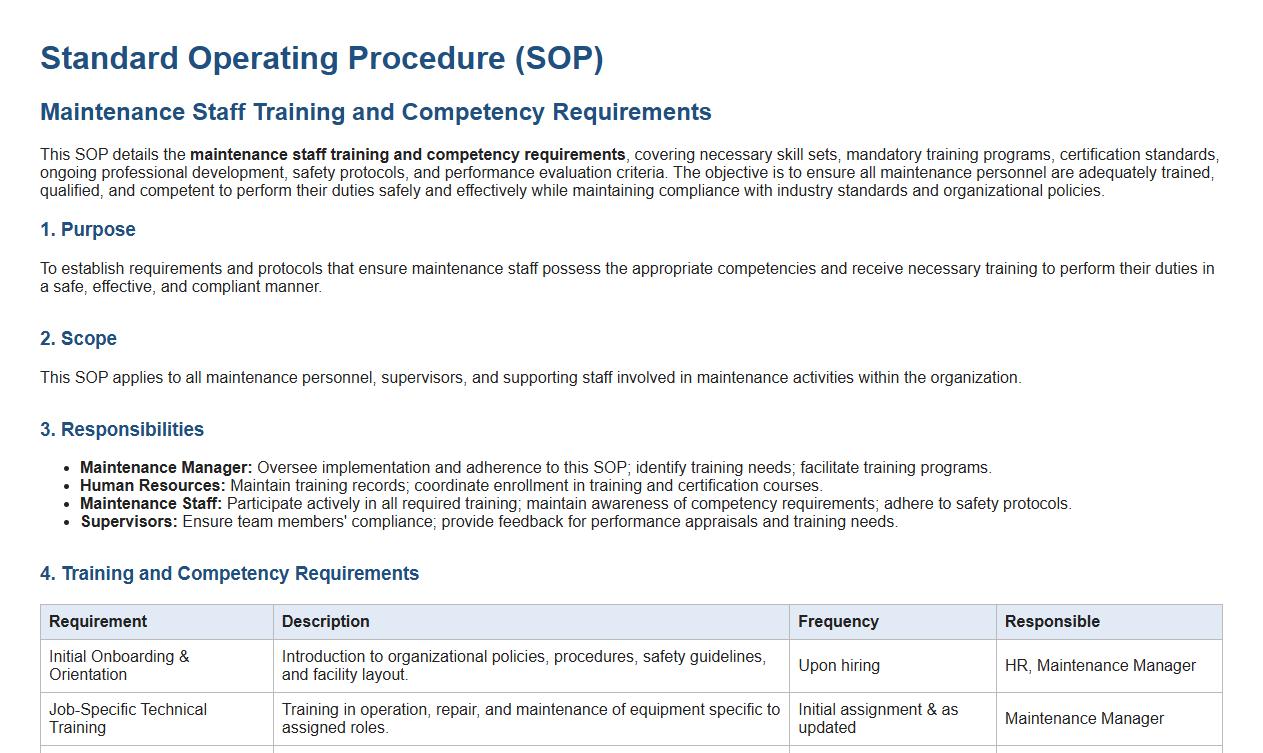

Maintenance staff training and competency requirements.

This SOP details the maintenance staff training and competency requirements, covering necessary skill sets, mandatory training programs, certification standards, ongoing professional development, safety protocols, and performance evaluation criteria. The objective is to ensure all maintenance personnel are adequately trained, qualified, and competent to perform their duties safely and effectively while maintaining compliance with industry standards and organizational policies.

Breakdown troubleshooting and escalation guidelines.

This SOP details breakdown troubleshooting and escalation guidelines to ensure timely identification, diagnosis, and resolution of equipment or system failures. It includes steps for immediate troubleshooting, criteria for escalating issues to higher levels of support, communication protocols, and documentation requirements to minimize downtime and maintain operational efficiency.

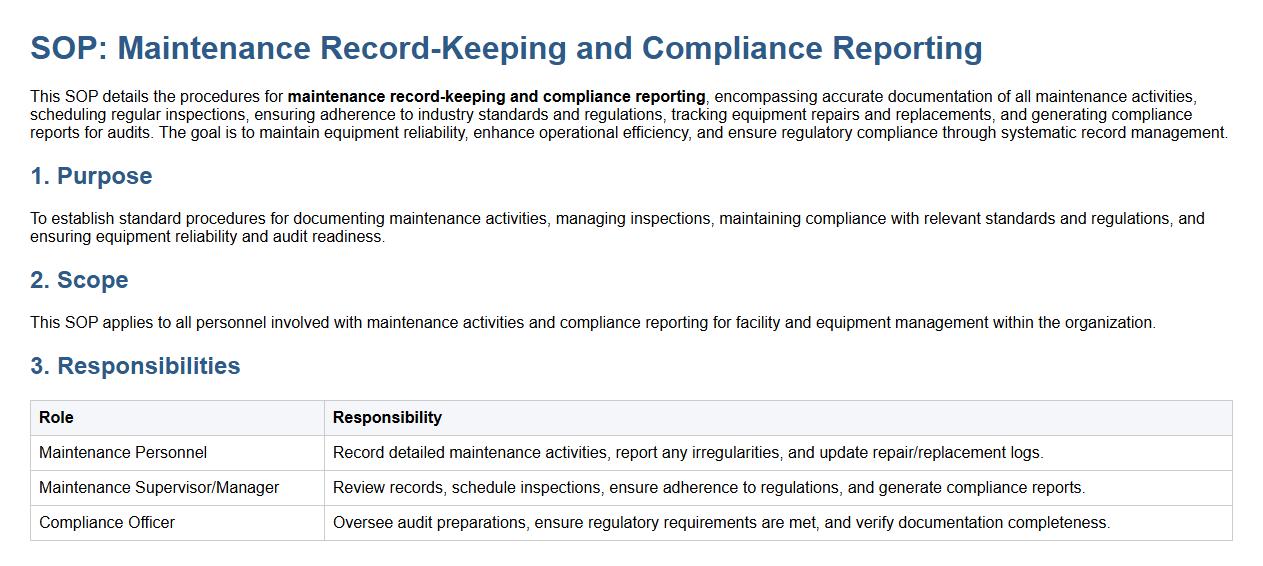

Maintenance record-keeping and compliance reporting.

This SOP details the procedures for maintenance record-keeping and compliance reporting, encompassing accurate documentation of all maintenance activities, scheduling regular inspections, ensuring adherence to industry standards and regulations, tracking equipment repairs and replacements, and generating compliance reports for audits. The goal is to maintain equipment reliability, enhance operational efficiency, and ensure regulatory compliance through systematic record management.

What is the primary objective of the SOP for Manufacturing Plant Maintenance?

The primary objective of the SOP for Manufacturing Plant Maintenance is to ensure the reliable and efficient operation of all equipment within the plant. It aims to minimize downtime and extend the lifespan of machinery through systematic maintenance practices. Additionally, the SOP provides a structured approach to maintaining quality and safety standards.

Which personnel roles and responsibilities are defined within the maintenance SOP?

The SOP clearly defines roles such as Maintenance Technicians, Supervisors, and Equipment Operators. Each role is assigned specific responsibilities, including performing inspections, reporting issues, and executing repair tasks. This structured definition ensures accountability and smooth coordination within the maintenance team.

What are the standard procedures for scheduling and documenting preventive maintenance tasks?

The SOP outlines a routine schedule for conducting preventive maintenance based on equipment usage and manufacturer's recommendations. It mandates the use of standardized checklists and digital logs to document all maintenance activities. Proper scheduling and record-keeping help in forecasting maintenance needs and avoiding unexpected equipment failures.

How does the SOP address safety and compliance measures during maintenance activities?

The SOP emphasizes strict adherence to safety protocols such as lockout/tagout procedures to prevent accidents. It ensures compliance with regulatory standards by mandating consistent use of personal protective equipment (PPE) and proper training. These measures safeguard personnel and promote a hazard-free work environment.

What steps are outlined in the SOP for handling equipment breakdowns and emergency repairs?

In case of equipment breakdowns, the SOP requires immediate notification to maintenance supervisors and activation of an emergency response plan. It also details prioritizing repairs based on the impact on production and safety. Documentation of the breakdown and repair process is mandatory to facilitate analysis and prevent recurrence.