A SOP Template for Manufacturing Machine Operation provides a standardized framework to ensure consistent and safe use of machinery in production processes. This template includes detailed step-by-step instructions, safety protocols, and maintenance guidelines to enhance operational efficiency and minimize errors. Utilizing this template helps streamline training, improve compliance, and maintain high-quality output in manufacturing environments.

Machine start-up and shut-down procedures.

This SOP details machine start-up and shut-down procedures, including pre-operational checks, safety inspections, proper initialization steps, controlled start-up sequences, operational monitoring, safe shut-down practices, and post-operation maintenance. The goal is to ensure the safe and efficient handling of machinery to prevent accidents, equipment damage, and operational disruptions.

Pre-operation safety checks and PPE requirements.

This SOP details pre-operation safety checks and PPE requirements essential for ensuring a safe working environment. It outlines the necessary inspections to be conducted before starting any machinery or equipment, including verifying operational integrity, identifying hazards, and confirming safety features are functional. The procedure also specifies the mandatory personal protective equipment (PPE) to be worn, such as helmets, gloves, eye protection, and high-visibility clothing, to minimize risks and enhance worker safety during operations.

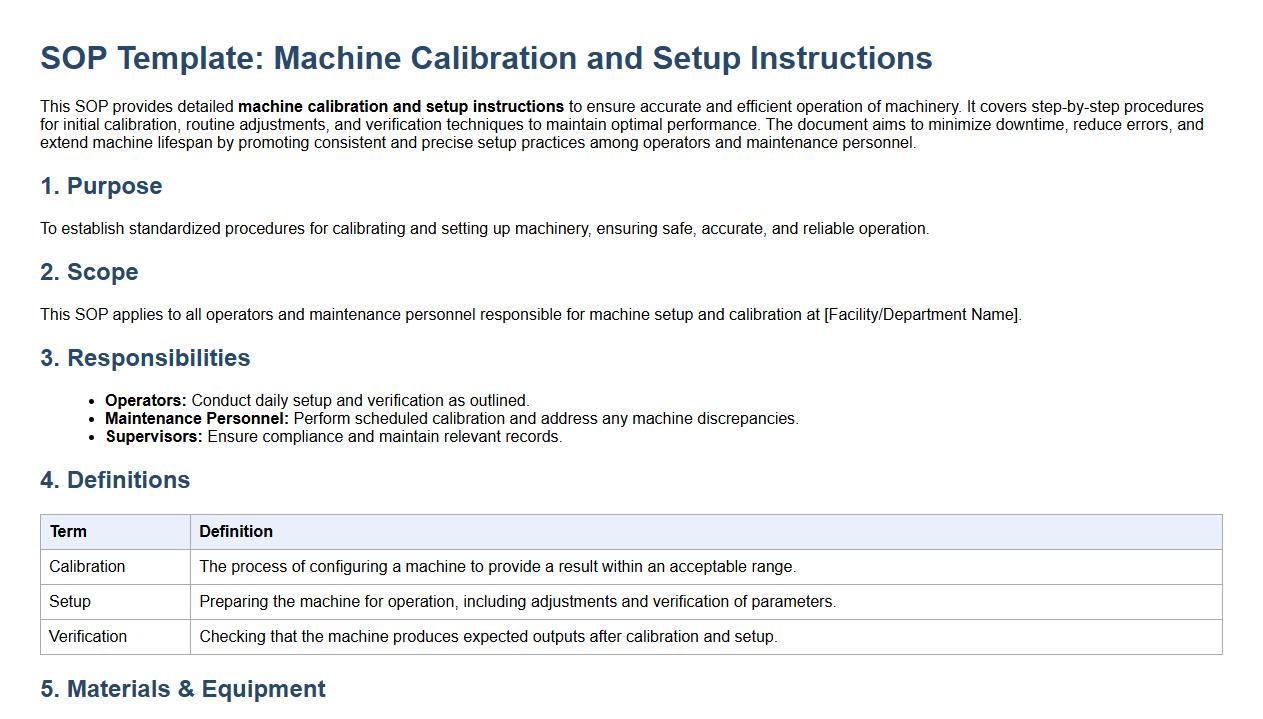

Machine calibration and setup instructions.

This SOP provides detailed machine calibration and setup instructions to ensure accurate and efficient operation of machinery. It covers step-by-step procedures for initial calibration, routine adjustments, and verification techniques to maintain optimal performance. The document aims to minimize downtime, reduce errors, and extend machine lifespan by promoting consistent and precise setup practices among operators and maintenance personnel.

Raw material loading and handling guidelines.

This SOP provides comprehensive raw material loading and handling guidelines, encompassing safe loading procedures, proper lifting techniques, equipment usage protocols, material storage requirements, and hazard identification. The objective is to minimize material damage, prevent workplace injuries, and ensure efficient and safe handling of raw materials throughout the supply chain process.

Standardized machine operating procedures step-by-step.

This SOP details standardized machine operating procedures in a step-by-step format, ensuring consistent and safe use of machinery. It covers machine setup, operational guidelines, safety checks, routine maintenance, troubleshooting, shutdown processes, and proper documentation. The goal is to maximize equipment efficiency, minimize downtime, and protect operators by adhering to uniform standards across all operations.

In-process quality control checks and documentation.

This SOP details the procedures for in-process quality control checks and documentation, encompassing the systematic monitoring of product quality during manufacturing, verification of critical parameters, identification and correction of deviations, and accurate recording of inspection results. Its purpose is to ensure consistent product quality, compliance with regulatory standards, and traceability throughout the production process.

Troubleshooting common machine faults and errors.

This SOP provides a comprehensive guide for troubleshooting common machine faults and errors, covering the identification of typical machine issues, diagnostic procedures, step-by-step troubleshooting techniques, preventive maintenance tips, and safety precautions. The objective is to ensure efficient machine operation, minimize downtime, and promote a safe working environment by equipping personnel with the knowledge and tools necessary to quickly resolve machine malfunctions.

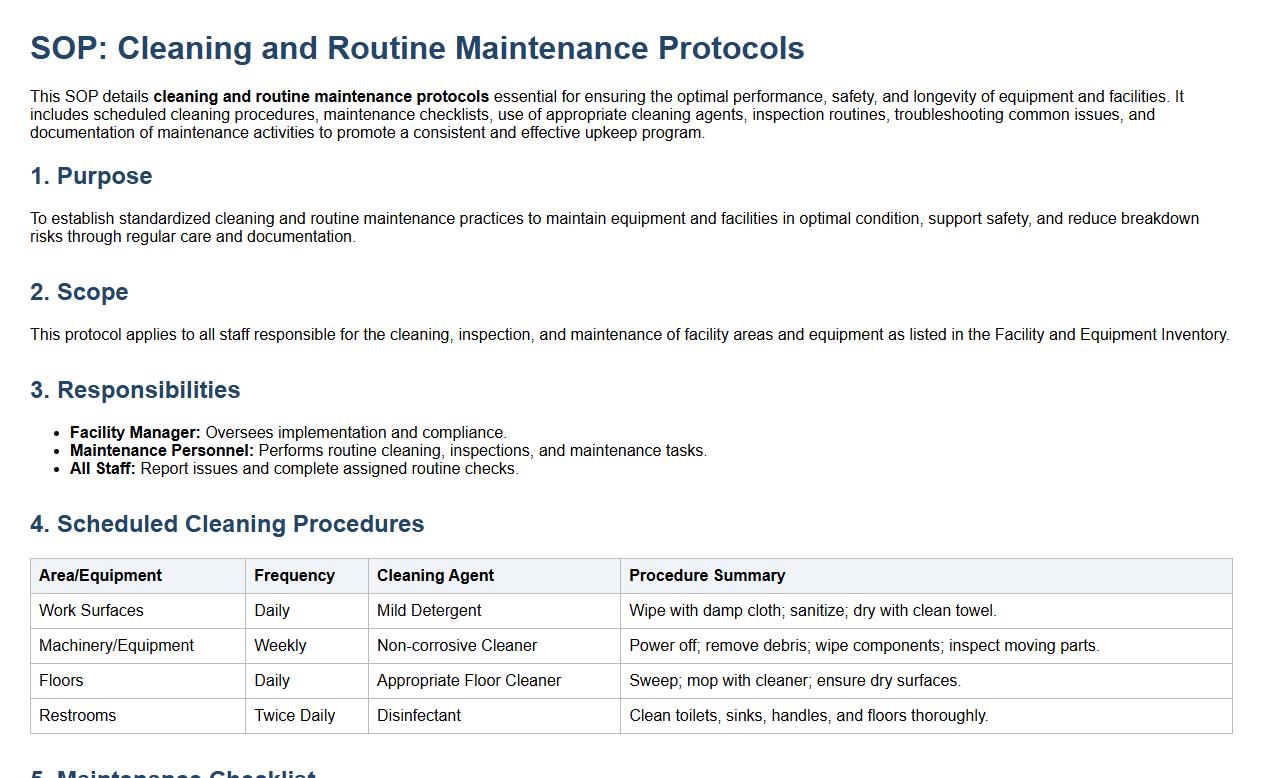

Cleaning and routine maintenance protocols.

This SOP details cleaning and routine maintenance protocols essential for ensuring the optimal performance, safety, and longevity of equipment and facilities. It includes scheduled cleaning procedures, maintenance checklists, use of appropriate cleaning agents, inspection routines, troubleshooting common issues, and documentation of maintenance activities to promote a consistent and effective upkeep program.

Emergency stop and incident reporting procedures.

This SOP defines the emergency stop and incident reporting procedures to ensure immediate response during emergencies and systematic documentation of incidents. It includes guidelines for activating emergency stop mechanisms on equipment, notifying appropriate personnel, securing the area, and providing first aid if needed. The procedure also covers accurate and timely reporting of all incidents to maintain safety standards, facilitate investigations, and implement corrective actions to prevent recurrence.

End-of-shift machine inspection and handover process.

This SOP defines the end-of-shift machine inspection and handover process, which includes detailed procedures for inspecting machinery to ensure proper functionality, identifying and reporting any defects or maintenance needs, cleaning and securing equipment, and effectively communicating machine status to the incoming shift. The goal is to maintain operational efficiency, enhance safety, and ensure seamless transition between shifts by providing clear documentation and accountability.

What are the key safety procedures outlined in the SOP for operating the manufacturing machine?

The SOP emphasizes hazard identification and risk assessment before starting the machine. It mandates following strict lockout/tagout procedures to ensure operator safety during maintenance. Operators must also adhere to clear guidelines on machine guarding and emergency stop protocols.

Which steps must be followed before, during, and after machine operation as per the SOP?

Before operation, the SOP requires a thorough machine inspection and verification of all safety devices. During operation, continuous monitoring and adherence to operating parameters are essential to maintain safe performance. After operation, the machine must be properly shut down, cleaned, and inspected to ensure readiness for the next cycle.

What specific personal protective equipment (PPE) is required by the SOP for this machine operation?

The SOP specifies mandatory use of safety gloves, protective eyewear, and hearing protection to prevent injuries. Depending on the machine and material handled, flame-resistant clothing and respiratory masks may be required. Proper PPE ensures both compliance and enhanced operator safety in the production environment.

How does the SOP address the handling of machine malfunctions or emergencies?

The SOP requires immediate cessation of machine operation upon detecting any abnormal condition or malfunction. Operators must follow established emergency stop procedures and notify maintenance personnel promptly. Detailed steps for safe troubleshooting and escalation protocols are clearly outlined to prevent accidents.

What documentation and recordkeeping requirements are specified in the SOP for each machine operation cycle?

The SOP mandates logging all machine operation parameters, inspection results, and maintenance activities in a formal record system. Any incidents or deviations must be documented with corrective actions taken noted. Accurate recordkeeping ensures traceability and supports continuous process improvement efforts.