A SOP Template for Manufacturing Production Line Setup provides a clear and standardized procedure to ensure efficient and consistent assembly line operations. It outlines step-by-step instructions, safety protocols, and quality control measures essential for smooth production flow. This template helps minimize errors, reduce downtime, and maintain high productivity standards in manufacturing environments.

Production line equipment preparation and inspection.

This SOP details the procedures for production line equipment preparation and inspection, encompassing equipment setup, pre-operation checks, maintenance protocols, safety verification, and documentation requirements. The goal is to ensure efficient and safe production processes by preventing equipment malfunctions and minimizing downtime through systematic inspection and preparation.

Raw material verification and staging procedures.

This SOP defines the raw material verification and staging procedures, including receiving and inspecting raw materials, verifying material specifications and documentation, identifying and labeling approved materials, proper storage and staging techniques, and maintaining accurate records. The goal is to ensure that only quality-assured raw materials are used in production, minimizing errors and production delays while maintaining traceability and compliance with regulatory standards.

Assembly station configuration and alignment.

This SOP details the procedures for assembly station configuration and alignment, covering the setup of workstation components, tool calibration, equipment positioning, and alignment verification. The goal is to ensure optimal station performance, minimize assembly errors, and maintain consistent product quality through precise alignment and standardized configuration protocols.

Machine calibration and operational checks.

This SOP details the procedures for machine calibration and operational checks, including step-by-step instructions for calibrating equipment, verifying machine accuracy, performing routine inspections, identifying faults, and ensuring optimal performance. The goal is to maintain machinery reliability, enhance safety, and prevent operational downtime by following standardized calibration and checking protocols.

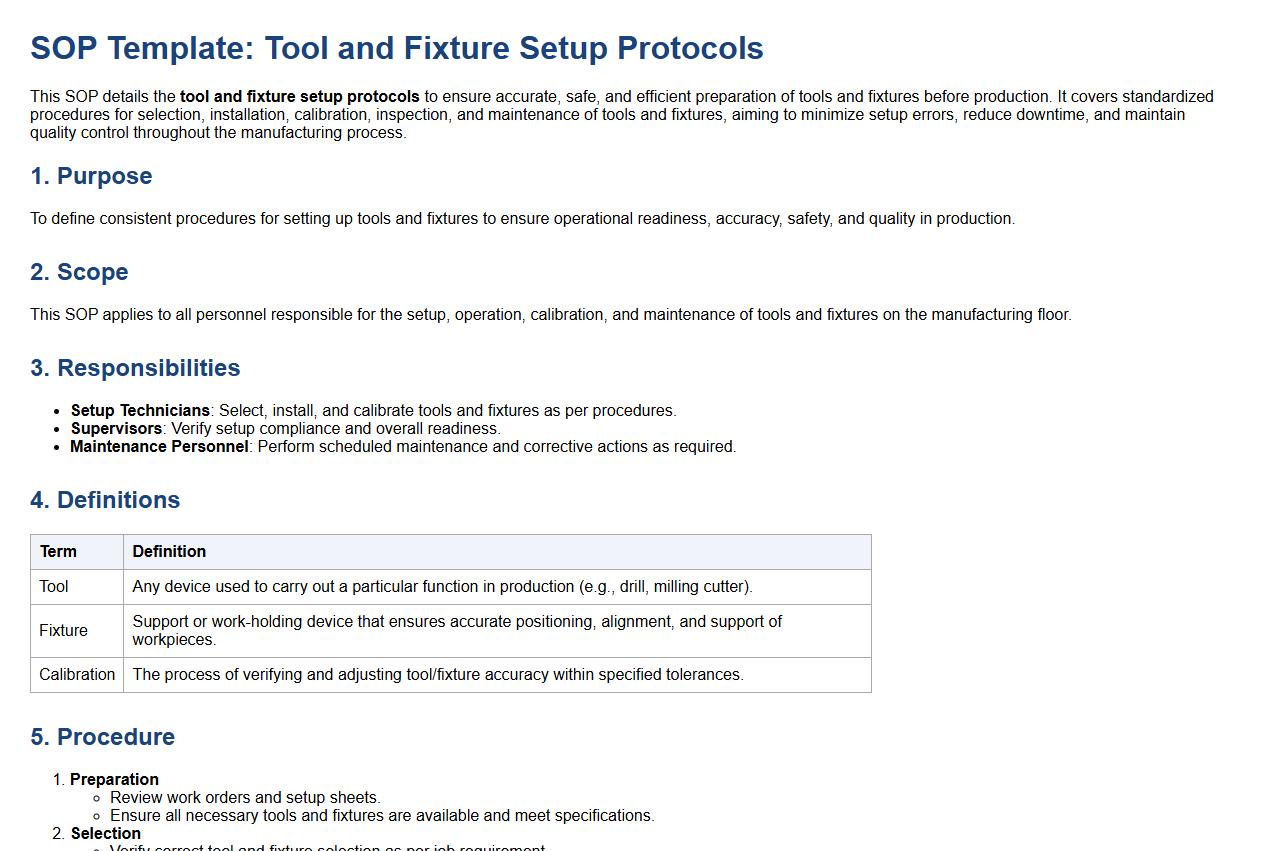

Tool and fixture setup protocols.

This SOP details the tool and fixture setup protocols to ensure accurate, safe, and efficient preparation of tools and fixtures before production. It covers standardized procedures for selection, installation, calibration, inspection, and maintenance of tools and fixtures, aiming to minimize setup errors, reduce downtime, and maintain quality control throughout the manufacturing process.

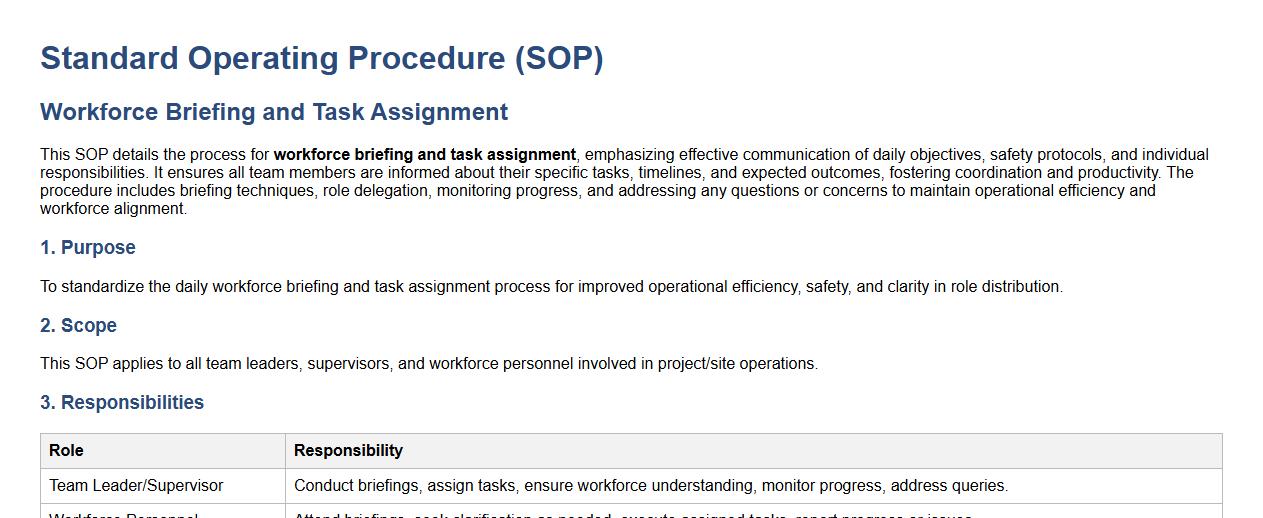

Workforce briefing and task assignment.

This SOP details the process for workforce briefing and task assignment, emphasizing effective communication of daily objectives, safety protocols, and individual responsibilities. It ensures all team members are informed about their specific tasks, timelines, and expected outcomes, fostering coordination and productivity. The procedure includes briefing techniques, role delegation, monitoring progress, and addressing any questions or concerns to maintain operational efficiency and workforce alignment.

Personal protective equipment (PPE) issuance and use.

This SOP details the procedures for personal protective equipment (PPE) issuance and use, including the selection, distribution, proper usage, maintenance, and replacement of PPE. It aims to ensure that all employees are equipped with the necessary protective gear to minimize exposure to workplace hazards, enhance safety compliance, and promote a culture of health and safety in the workplace.

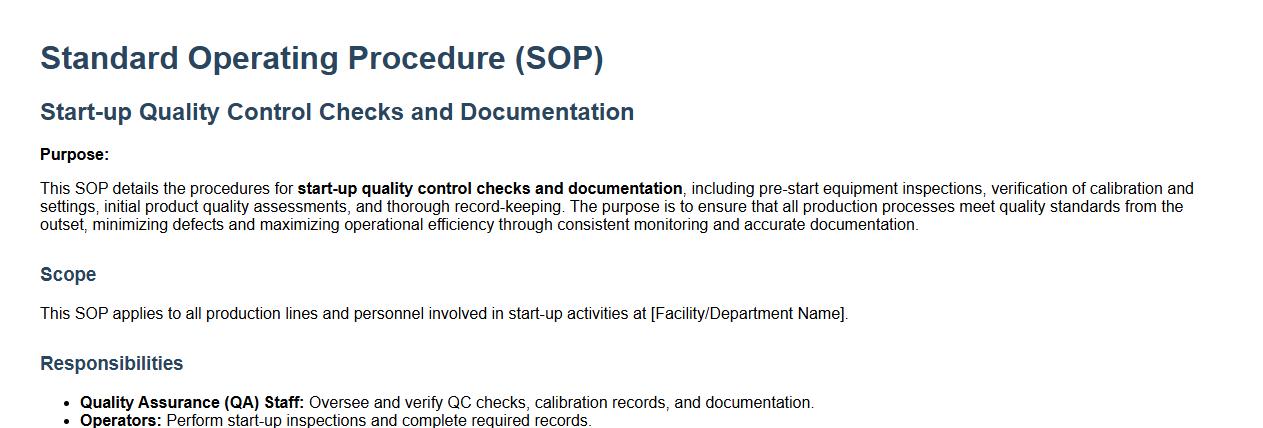

Start-up quality control checks and documentation.

This SOP details the procedures for start-up quality control checks and documentation, including pre-start equipment inspections, verification of calibration and settings, initial product quality assessments, and thorough record-keeping. The purpose is to ensure that all production processes meet quality standards from the outset, minimizing defects and maximizing operational efficiency through consistent monitoring and accurate documentation.

Production schedule review and shift handover.

This SOP details the production schedule review and shift handover process, ensuring seamless communication and continuity between shifts. It covers the procedures for reviewing the current production schedule, updating progress, addressing deviations, and effectively handing over critical information to incoming shift personnel. The aim is to maintain production efficiency, minimize errors, and support operational consistency across all shifts.

Initial batch testing and process sign-off.

This SOP defines the procedures for initial batch testing and process sign-off, ensuring that all production batches undergo rigorous quality and safety checks before full-scale manufacturing. It covers sample collection, laboratory analysis, compliance verification, documentation requirements, and final approval criteria, facilitating consistent product quality and regulatory adherence.

What are the essential steps outlined in the SOP for preparing a new production line for operation?

The SOP emphasizes initial planning and layout design as the first crucial step in preparing a new production line. Next, it specifies the installation of machinery followed by thorough testing to ensure full operational readiness. Lastly, the SOP mandates training staff on the new equipment to ensure smooth workflow and efficiency from day one.

Which safety protocols must be strictly followed during the manufacturing line setup as per the SOP?

Adherence to personal protective equipment (PPE) guidelines is mandatory for all team members during setup. The SOP also requires strict compliance with lockout/tagout procedures to prevent accidental equipment startup. Additionally, regular safety audits are conducted to ensure the environment remains hazard-free throughout the setup process.

How does the SOP define the responsibilities of team members involved in the production line setup?

The SOP outlines clear roles including a designated line supervisor responsible for overseeing the entire setup operation. Technicians are tasked with machinery assembly and calibration while quality inspectors conduct ongoing checks. Communication protocols between team members are defined to ensure accountability and timely resolution of issues.

What documentation and approvals are required before commencing the setup process according to the SOP?

The SOP requires detailed setup plans and risk assessments to be documented and reviewed. Formal approval from the quality assurance and safety departments must be obtained before any physical installation begins. Additionally, equipment certification and compliance reports are compiled to meet internal and regulatory standards.

How does the SOP ensure quality control during and after the production line installation?

Continuous monitoring through predefined quality checkpoints is integrated into the setup timeline to detect and mitigate issues early. Post-installation, the SOP enforces a commissioning phase with rigorous performance testing to verify production standards. Finally, documentation of all quality control measures is maintained for traceability and future audits.