A SOP Template for Product Assembly Process provides a clear, standardized framework to ensure consistent and efficient assembly of products. It outlines step-by-step instructions, necessary tools, and safety measures to improve quality control and reduce errors. Using this template enhances workflow organization and supports training for new employees.

Raw material inspection and acceptance criteria.

This SOP defines the raw material inspection and acceptance criteria to ensure that all incoming materials meet specified quality standards. It includes procedures for verifying supplier documentation, conducting visual and physical inspections, sampling methods for testing, criteria for acceptance or rejection, and recording inspection results. The objective is to guarantee that only raw materials conforming to quality requirements are accepted, thereby preventing defects in the production process and ensuring product consistency and safety.

Workstation preparation and tool setup procedures.

This SOP details workstation preparation and tool setup procedures to ensure an organized, safe, and efficient work environment. It covers steps for cleaning and arranging the workstation, selecting and inspecting necessary tools, proper tool placement, calibration and maintenance requirements, and safety checks prior to starting work. The goal is to optimize productivity, minimize hazards, and maintain consistent quality by following standardized setup protocols.

Component verification and pre-assembly checks.

This SOP details the procedures for component verification and pre-assembly checks, including the inspection of parts for quality and conformity, verification against specifications and design documents, identification of defects or damages, and ensuring all components are properly prepared for assembly. The purpose is to prevent assembly errors, ensure product quality, and enhance overall manufacturing efficiency by implementing thorough verification and inspection steps prior to assembly.

Step-by-step assembly instructions.

This SOP provides step-by-step assembly instructions to guide users through the systematic process of assembling products or equipment. It includes detailed, sequential steps to ensure accurate, efficient, and safe assembly, reducing errors and improving product quality and consistency.

Quality control checkpoints during assembly.

This SOP defines quality control checkpoints during assembly to ensure products meet specified standards at every stage. It includes inspection procedures, verification of components, in-process testing, defect identification and documentation, corrective actions, and final product evaluation. The goal is to maintain consistent quality, reduce errors, and enhance customer satisfaction through systematic monitoring and control throughout the assembly process.

Handling of non-conforming parts or assemblies.

This SOP details the process for handling of non-conforming parts or assemblies, including identification, segregation, documentation, evaluation, and disposition of non-conforming items. It ensures that defective or non-compliant parts are properly managed to prevent unintended use, maintain product quality, and comply with regulatory requirements. The procedure also covers roles and responsibilities, corrective actions, and continuous improvement measures to minimize recurrence and uphold manufacturing standards.

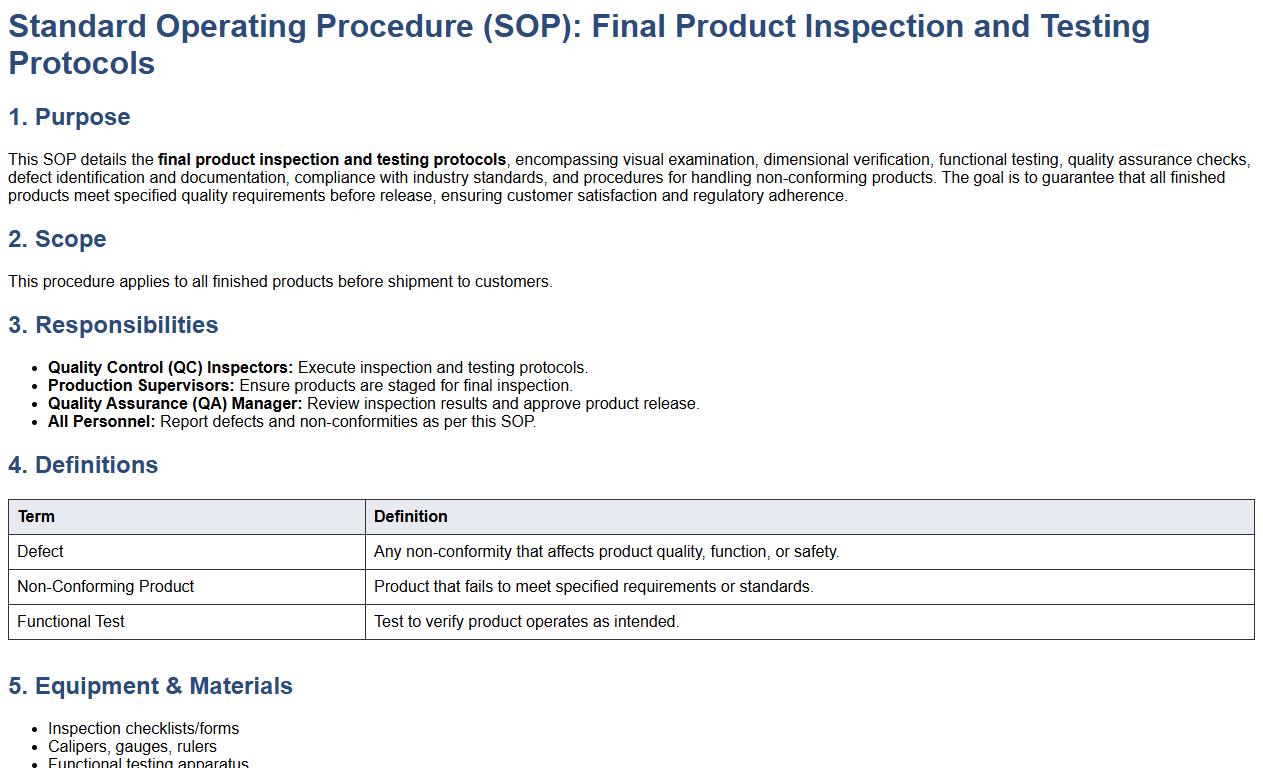

Final product inspection and testing protocols.

This SOP details the final product inspection and testing protocols, encompassing visual examination, dimensional verification, functional testing, quality assurance checks, defect identification and documentation, compliance with industry standards, and procedures for handling non-conforming products. The goal is to guarantee that all finished products meet specified quality requirements before release, ensuring customer satisfaction and regulatory adherence.

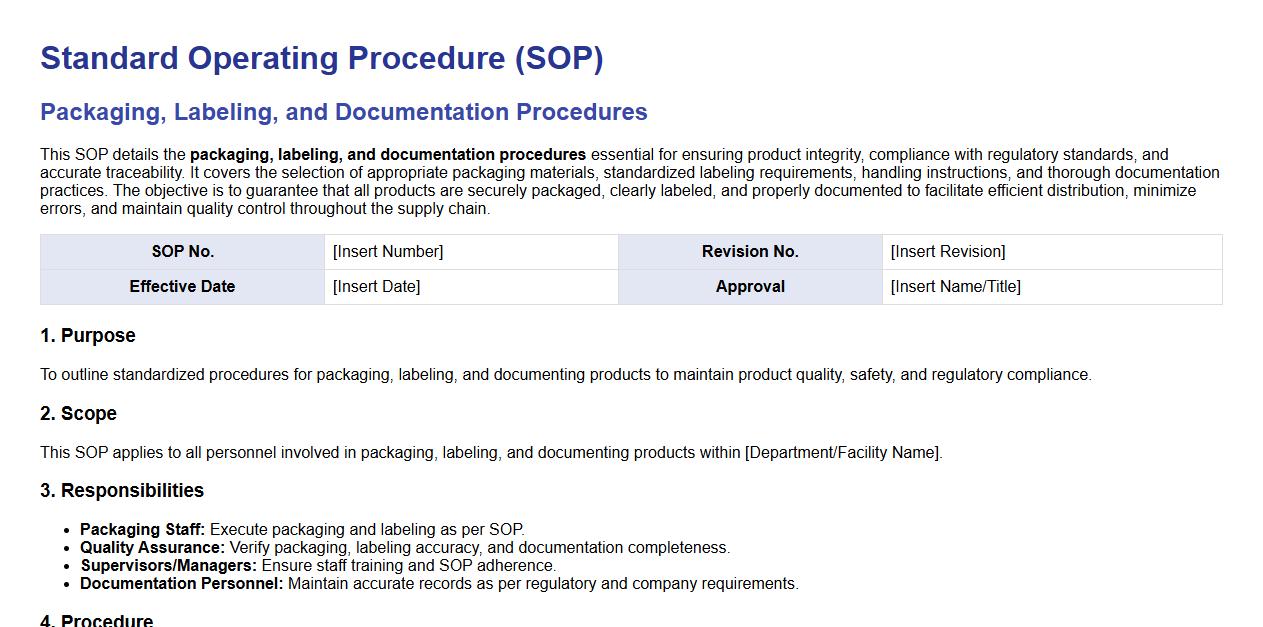

Packaging, labeling, and documentation procedures.

This SOP details the packaging, labeling, and documentation procedures essential for ensuring product integrity, compliance with regulatory standards, and accurate traceability. It covers the selection of appropriate packaging materials, standardized labeling requirements, handling instructions, and thorough documentation practices. The objective is to guarantee that all products are securely packaged, clearly labeled, and properly documented to facilitate efficient distribution, minimize errors, and maintain quality control throughout the supply chain.

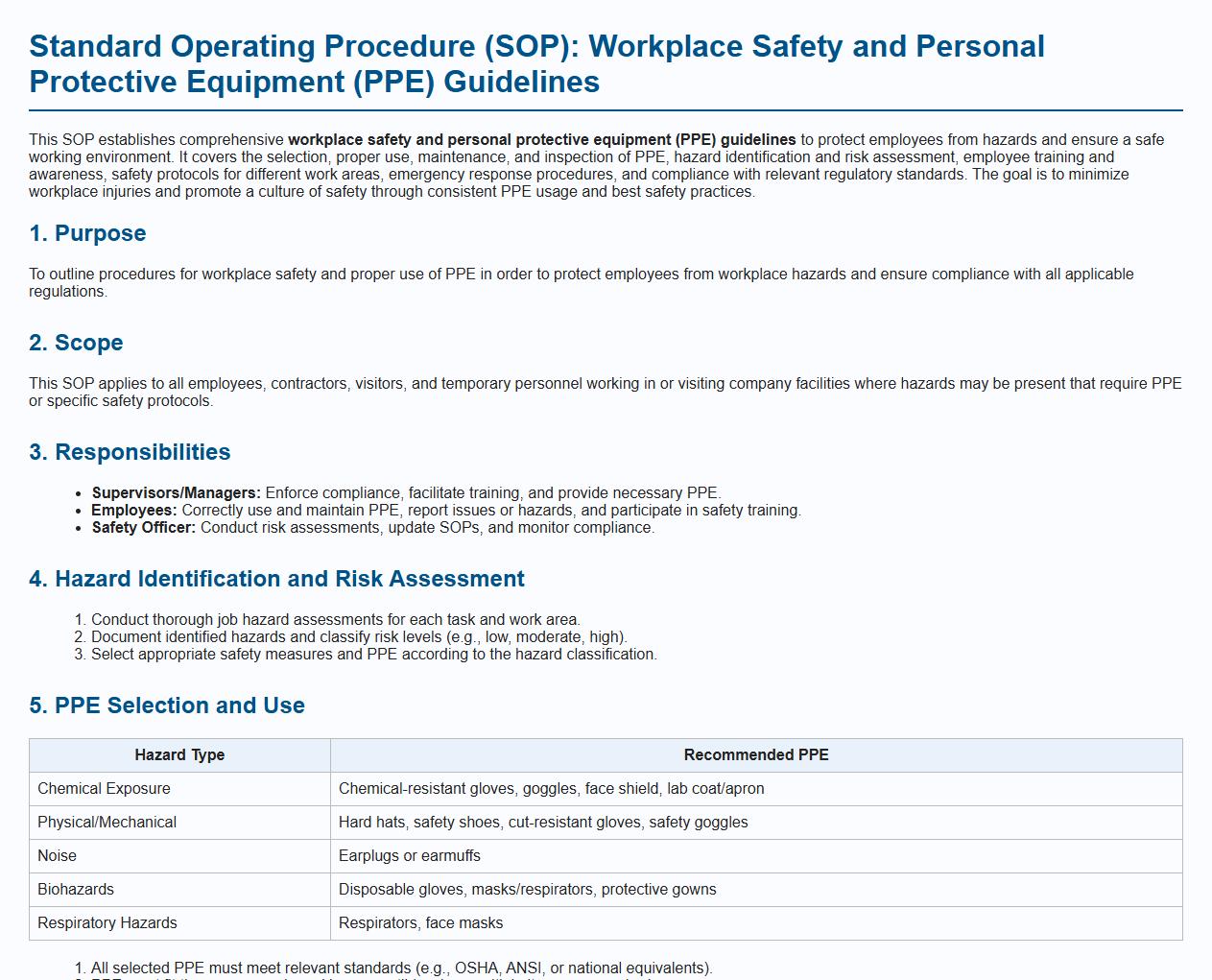

Workplace safety and personal protective equipment (PPE) guidelines.

This SOP establishes comprehensive workplace safety and personal protective equipment (PPE) guidelines to protect employees from hazards and ensure a safe working environment. It covers the selection, proper use, maintenance, and inspection of PPE, hazard identification and risk assessment, employee training and awareness, safety protocols for different work areas, emergency response procedures, and compliance with relevant regulatory standards. The goal is to minimize workplace injuries and promote a culture of safety through consistent PPE usage and best safety practices.

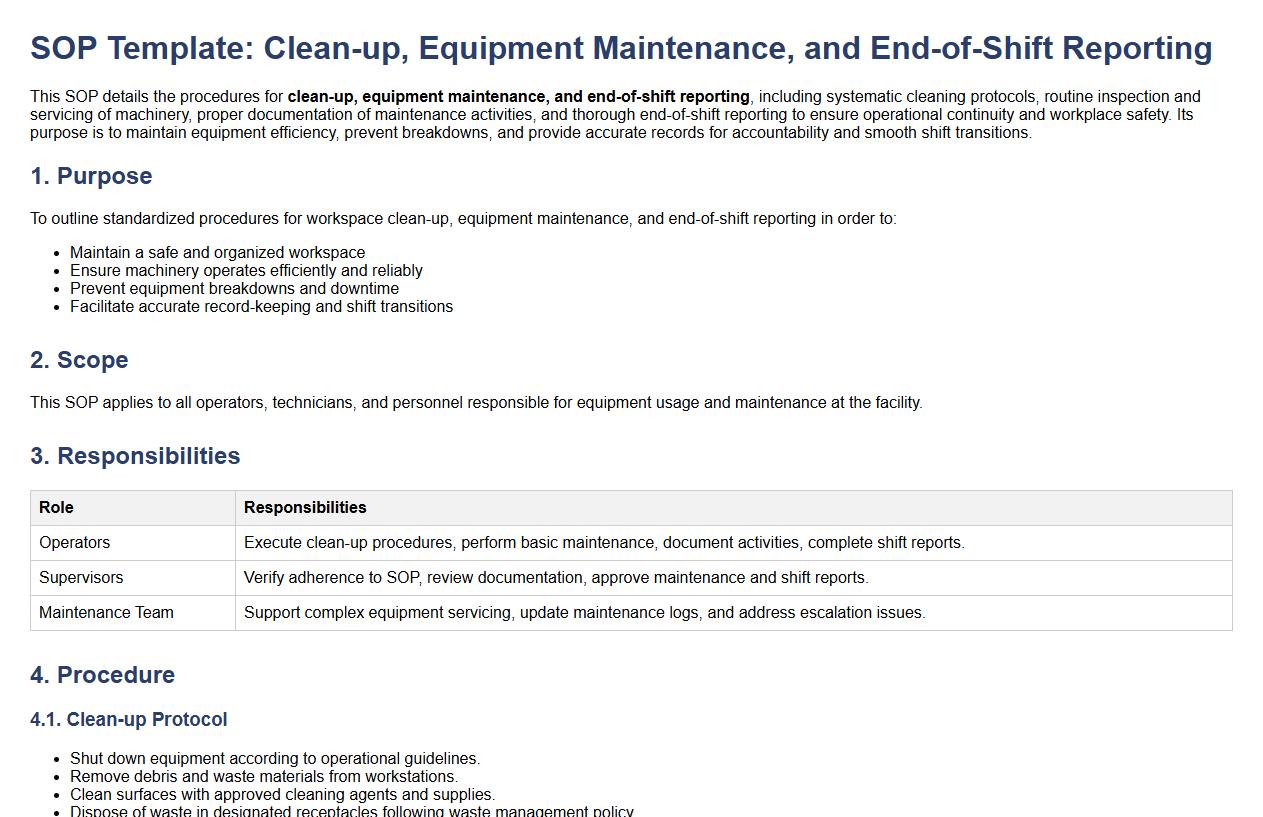

Clean-up, equipment maintenance, and end-of-shift reporting.

This SOP details the procedures for clean-up, equipment maintenance, and end-of-shift reporting, including systematic cleaning protocols, routine inspection and servicing of machinery, proper documentation of maintenance activities, and thorough end-of-shift reporting to ensure operational continuity and workplace safety. Its purpose is to maintain equipment efficiency, prevent breakdowns, and provide accurate records for accountability and smooth shift transitions.

What are the key steps outlined in the SOP for the Product Assembly Process?

The SOP details the assembly sequence starting from component preparation to final product inspection. Each step is designed to ensure systematic progression and minimize errors during production. Proper adherence to these steps guarantees consistent product quality and operational efficiency.

Which personnel or departments are responsible for each assembly stage according to the SOP?

The SOP assigns specific responsibilities to designated personnel and departments at every stage of the assembly. Production teams handle initial assembly, while quality control inspectors oversee verification phases. Coordination between departments is crucial for smooth workflow and accountability.

What safety measures and PPE requirements are specified in the SOP for product assembly?

The SOP emphasizes strict compliance with safety protocols including the use of personal protective equipment (PPE) such as gloves, goggles, and helmets. It outlines hazard identification procedures to prevent accidents during assembly. Regular safety training is also mandated to maintain a safe working environment.

How does the SOP define quality control checkpoints within the assembly process?

Quality control checkpoints are strategically integrated at critical stages of the assembly to detect defects early. The SOP specifies inspection criteria and documentation requirements for each checkpoint. This ensures that only products meeting quality standards move forward to subsequent phases.

What documentation or records are mandated by the SOP during and after product assembly?

The SOP requires comprehensive documentation including assembly logs, quality inspection reports, and deviation records. These documents serve as traceability tools for audit and continuous improvement processes. Maintaining accurate records supports compliance and enhances product accountability.