A SOP Template for Workplace Safety in Manufacturing provides a clear and structured guideline to ensure consistent safety practices on the production floor. This template outlines essential procedures for hazard identification, equipment operation, and emergency response to minimize risks and enhance worker protection. Implementing such a standardized document helps maintain compliance with safety regulations and fosters a culture of continuous safety improvement.

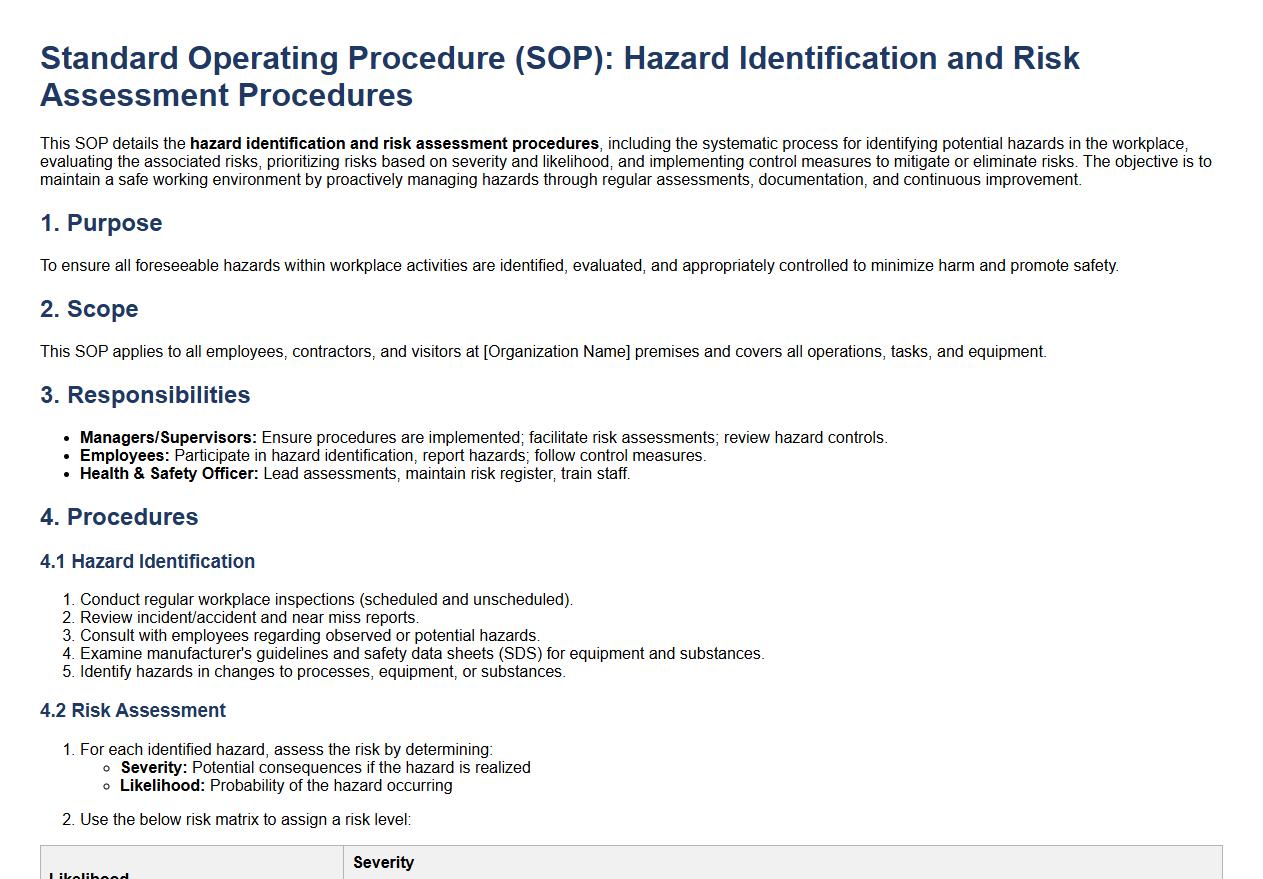

Hazard identification and risk assessment procedures.

This SOP details the hazard identification and risk assessment procedures, including the systematic process for identifying potential hazards in the workplace, evaluating the associated risks, prioritizing risks based on severity and likelihood, and implementing control measures to mitigate or eliminate risks. The objective is to maintain a safe working environment by proactively managing hazards through regular assessments, documentation, and continuous improvement.

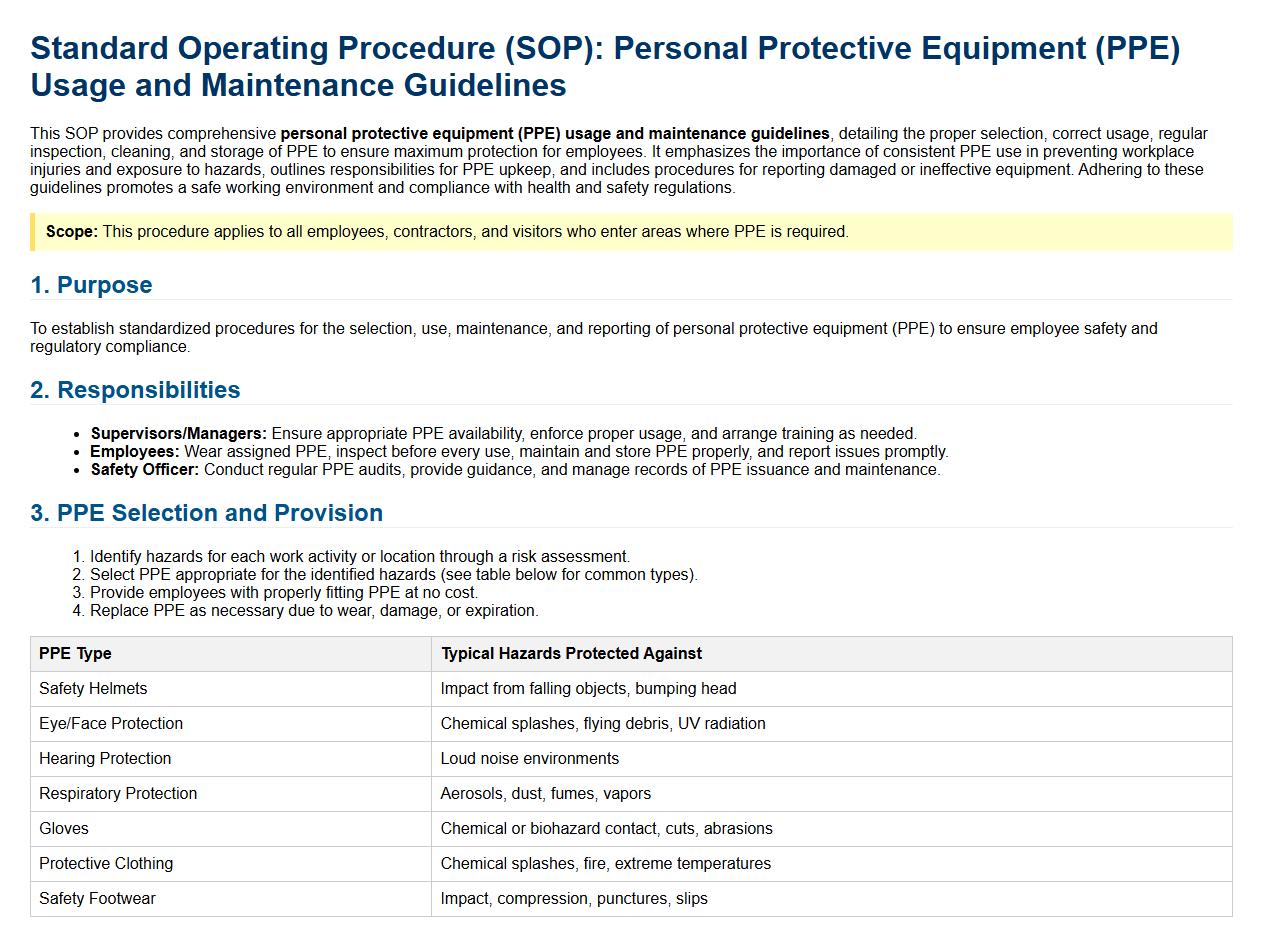

Personal protective equipment (PPE) usage and maintenance guidelines.

This SOP provides comprehensive personal protective equipment (PPE) usage and maintenance guidelines, detailing the proper selection, correct usage, regular inspection, cleaning, and storage of PPE to ensure maximum protection for employees. It emphasizes the importance of consistent PPE use in preventing workplace injuries and exposure to hazards, outlines responsibilities for PPE upkeep, and includes procedures for reporting damaged or ineffective equipment. Adhering to these guidelines promotes a safe working environment and compliance with health and safety regulations.

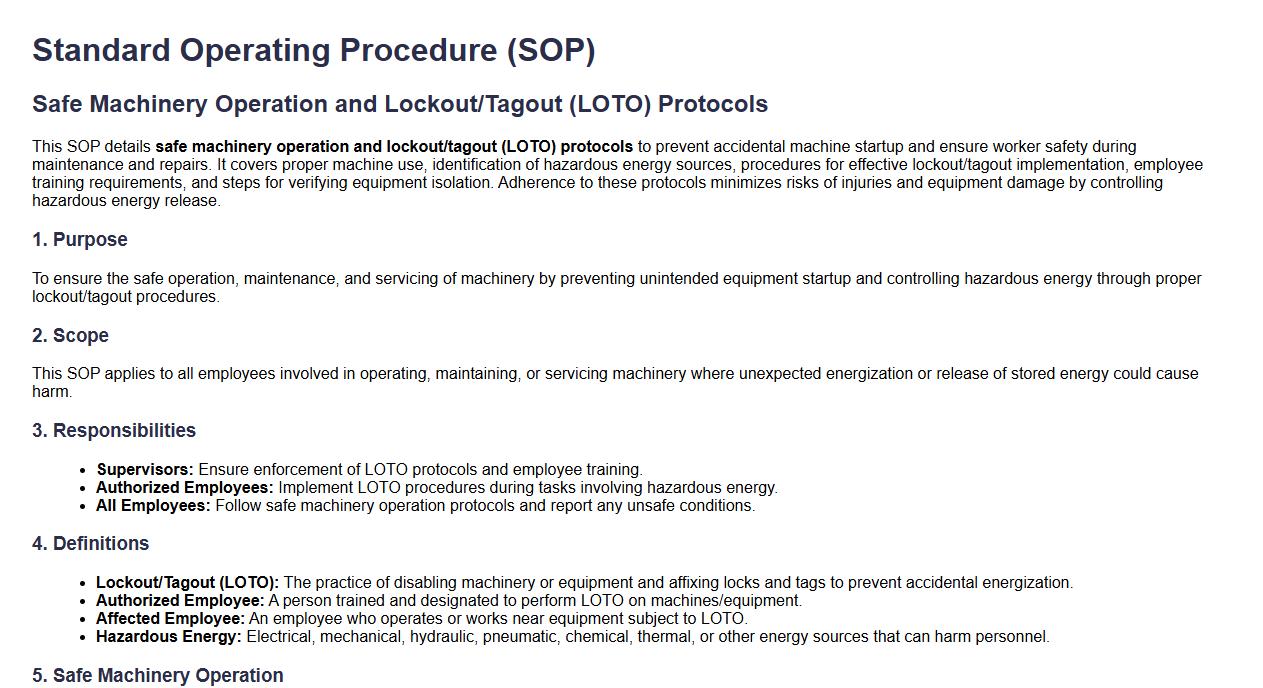

Safe machinery operation and lockout/tagout (LOTO) protocols.

This SOP details safe machinery operation and lockout/tagout (LOTO) protocols to prevent accidental machine startup and ensure worker safety during maintenance and repairs. It covers proper machine use, identification of hazardous energy sources, procedures for effective lockout/tagout implementation, employee training requirements, and steps for verifying equipment isolation. Adherence to these protocols minimizes risks of injuries and equipment damage by controlling hazardous energy release.

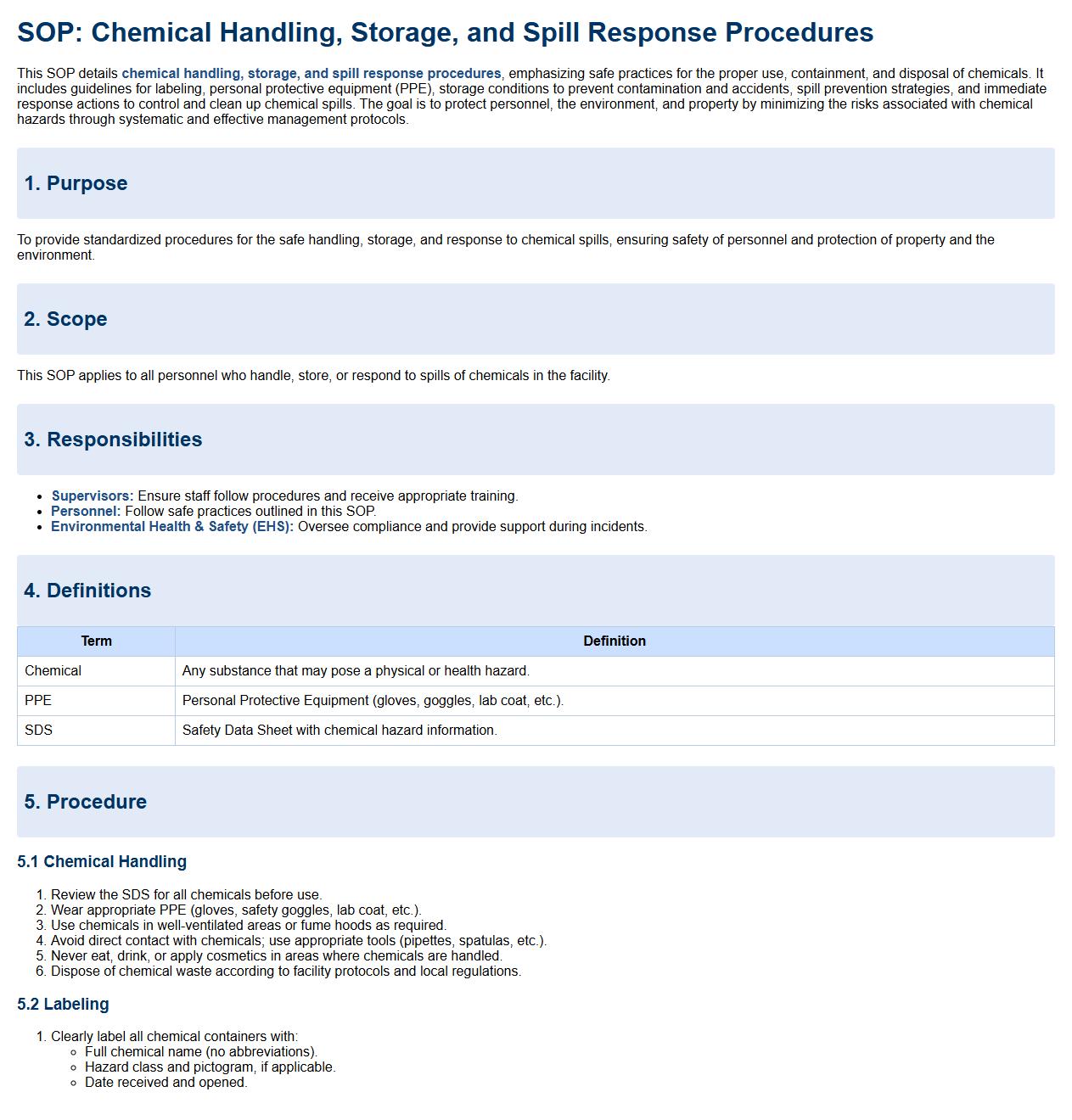

Chemical handling, storage, and spill response procedures.

This SOP details chemical handling, storage, and spill response procedures, emphasizing safe practices for the proper use, containment, and disposal of chemicals. It includes guidelines for labeling, personal protective equipment (PPE), storage conditions to prevent contamination and accidents, spill prevention strategies, and immediate response actions to control and clean up chemical spills. The goal is to protect personnel, the environment, and property by minimizing the risks associated with chemical hazards through systematic and effective management protocols.

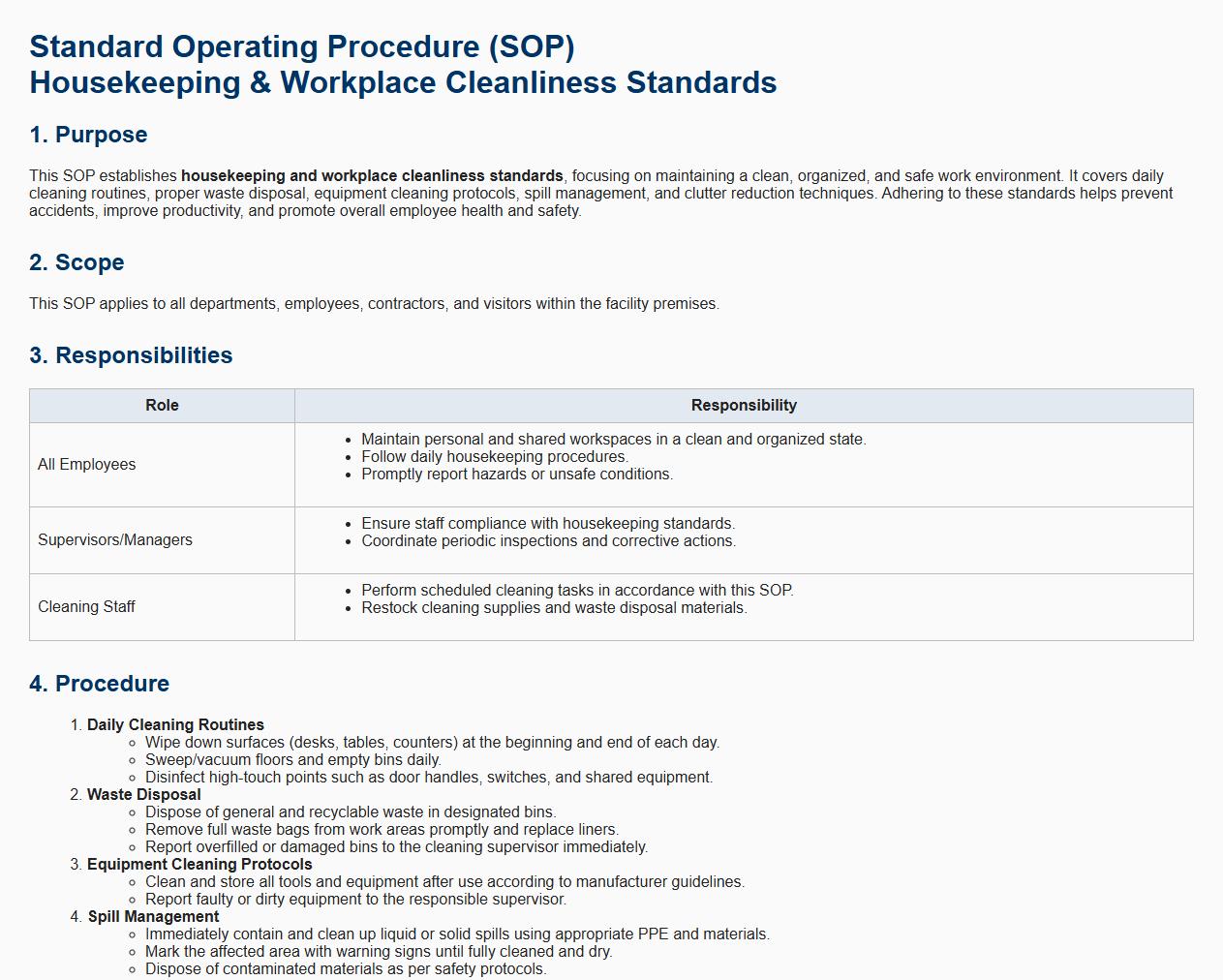

Housekeeping and workplace cleanliness standards.

This SOP establishes housekeeping and workplace cleanliness standards, focusing on maintaining a clean, organized, and safe work environment. It covers daily cleaning routines, proper waste disposal, equipment cleaning protocols, spill management, and clutter reduction techniques. Adhering to these standards helps prevent accidents, improve productivity, and promote overall employee health and safety.

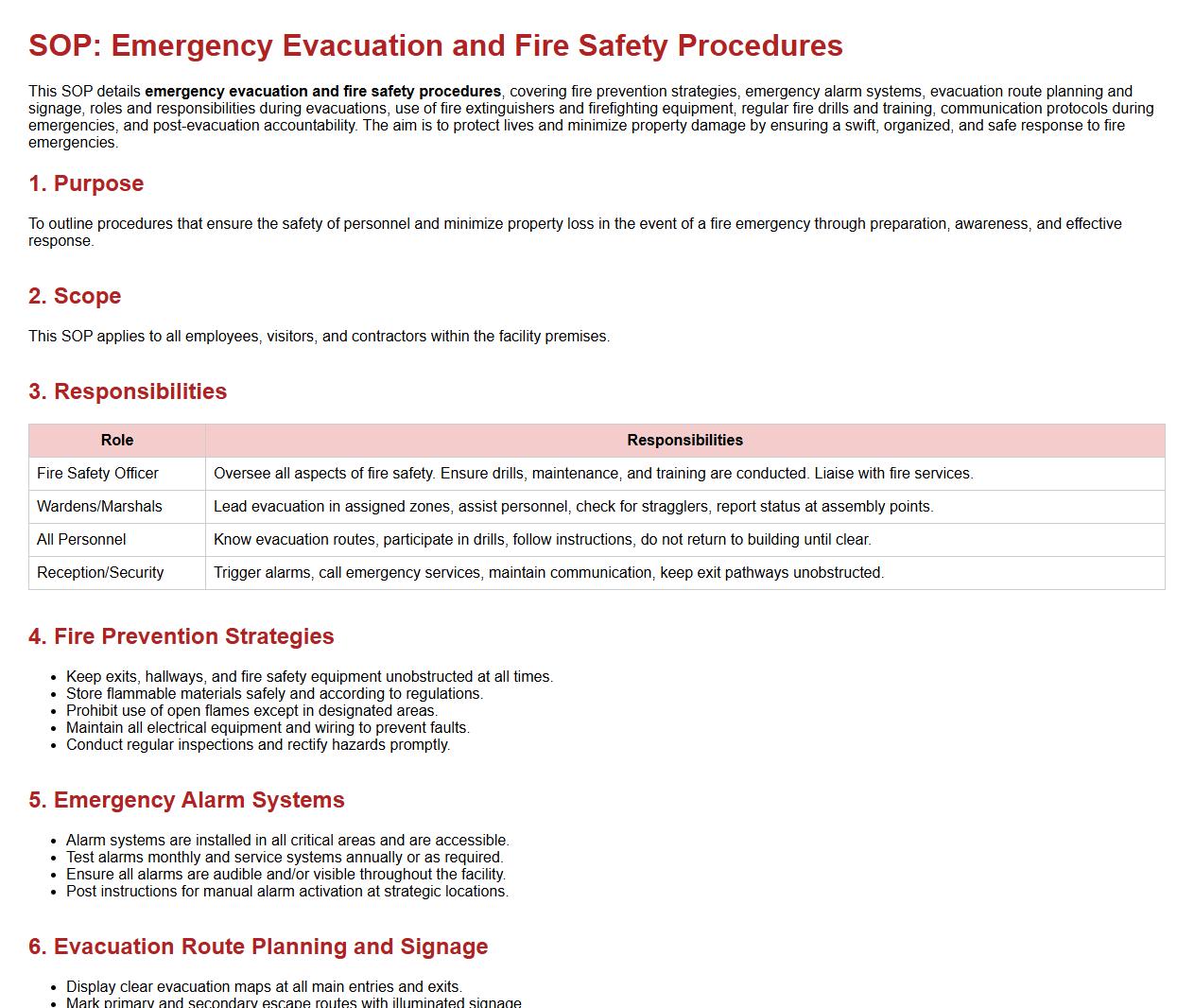

Emergency evacuation and fire safety procedures.

This SOP details emergency evacuation and fire safety procedures, covering fire prevention strategies, emergency alarm systems, evacuation route planning and signage, roles and responsibilities during evacuations, use of fire extinguishers and firefighting equipment, regular fire drills and training, communication protocols during emergencies, and post-evacuation accountability. The aim is to protect lives and minimize property damage by ensuring a swift, organized, and safe response to fire emergencies.

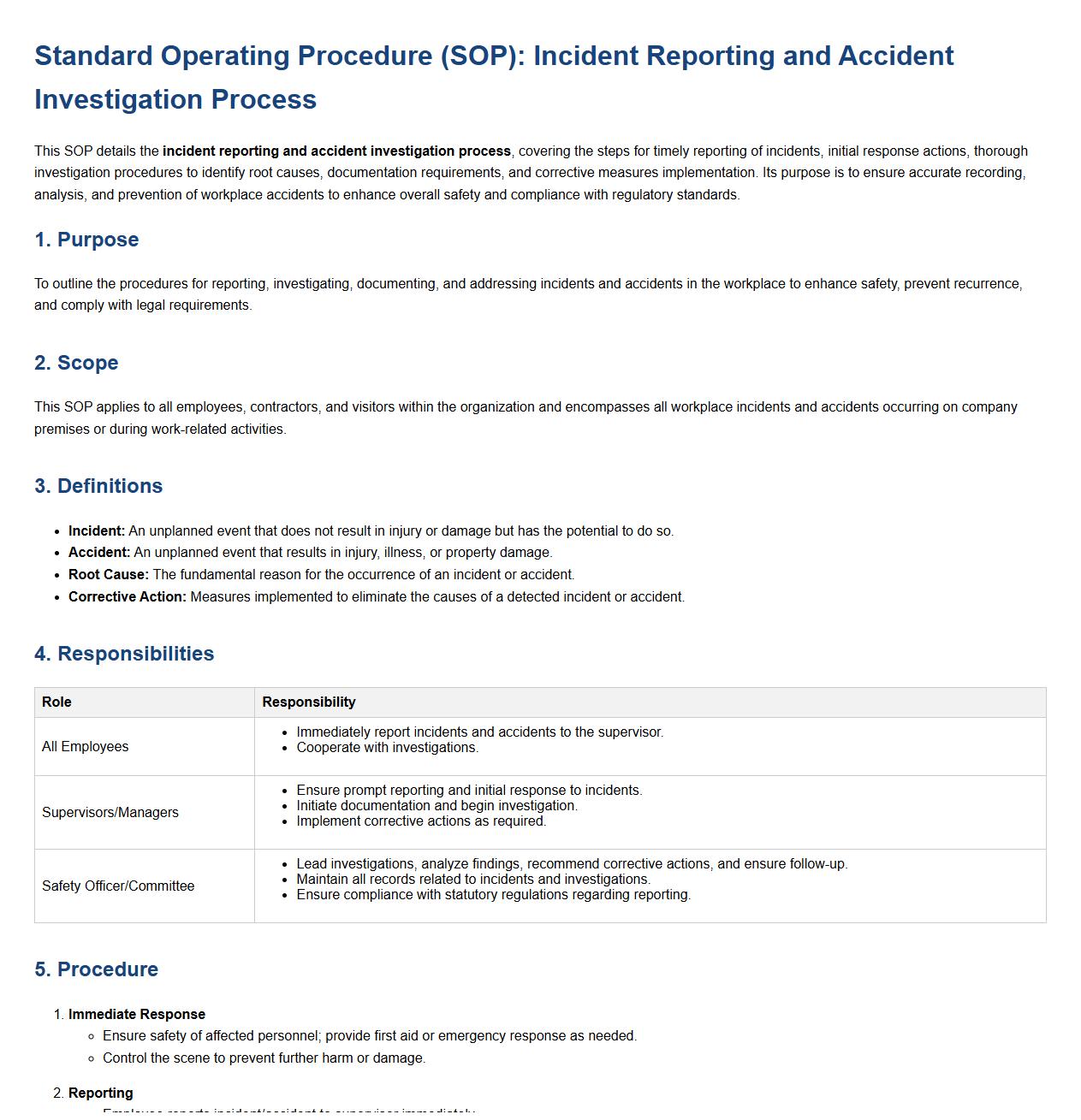

Incident reporting and accident investigation process.

This SOP details the incident reporting and accident investigation process, covering the steps for timely reporting of incidents, initial response actions, thorough investigation procedures to identify root causes, documentation requirements, and corrective measures implementation. Its purpose is to ensure accurate recording, analysis, and prevention of workplace accidents to enhance overall safety and compliance with regulatory standards.

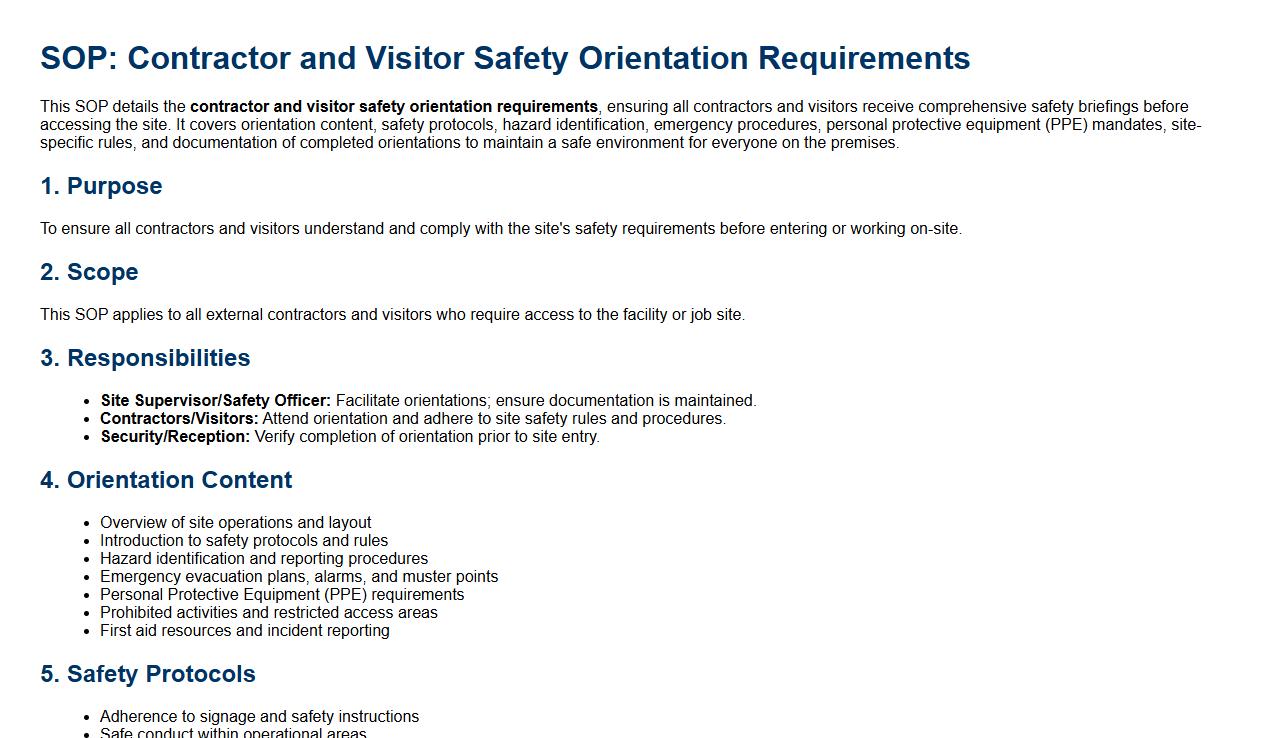

Contractor and visitor safety orientation requirements.

This SOP details the contractor and visitor safety orientation requirements, ensuring all contractors and visitors receive comprehensive safety briefings before accessing the site. It covers orientation content, safety protocols, hazard identification, emergency procedures, personal protective equipment (PPE) mandates, site-specific rules, and documentation of completed orientations to maintain a safe environment for everyone on the premises.

Employee safety training and competency assessment.

This SOP defines the procedures for employee safety training and competency assessment to ensure all staff are adequately trained and competent in their roles. It covers the identification of training needs, development and delivery of safety training programs, evaluation of employee understanding, and regular competency assessments. The objective is to maintain a safe workplace by promoting continuous learning, compliance with safety standards, and minimizing workplace risks through verified employee skills and knowledge.

First aid and medical emergency response procedures.

This SOP details first aid and medical emergency response procedures, including immediate assessment of injuries, provision of basic first aid treatment, communication protocols for summoning advanced medical help, use of emergency medical equipment, documentation of incidents, and training requirements for personnel. The objective is to ensure timely and effective response to medical emergencies, minimizing harm and promoting safety within the workplace.

Key Objectives for Ensuring Workplace Safety in Manufacturing

The SOP's primary objective is to minimize workplace accidents through systematic safety protocols. It emphasizes creating a hazard-free environment by identifying and controlling risks. Ensuring employee awareness and compliance with safety standards is also a crucial goal.

Personal Protective Equipment (PPE) Requirements Specified in the SOP

The SOP mandates the use of PPE tailored to specific tasks, such as gloves, helmets, and eye protection. It details criteria for selecting appropriate PPE based on the hazards involved. Regular inspection and proper maintenance of PPE are also strongly emphasized.

Emergency Procedures and Reporting Protocols Detailed in the SOP

The SOP outlines clear emergency response steps including evacuation routes and first aid measures. It requires immediate reporting of incidents to designated authorities for swift action. Documentation of all emergencies ensures continuous improvement in safety practices.

Machine Safety and Lockout/Tagout Procedures Addressed by the SOP

The SOP enforces strict machine lockout/tagout protocols to prevent accidental startup during maintenance. It mandates thorough inspection before and after repairs to ensure operator safety. Training workers on these procedures is critical to avoid mechanical hazards.

Regular Training and Safety Audit Measures Mandated by the SOP

The SOP requires periodic safety training sessions to keep employees updated on best practices. Scheduled safety audits help identify and rectify potential hazards promptly. Continuous evaluation ensures sustained compliance with workplace safety standards.