A SOP Template for Machine Maintenance provides a structured format to document standard procedures for inspecting, servicing, and repairing machinery. This template ensures consistency, improves efficiency, and reduces downtime by outlining step-by-step maintenance tasks and safety protocols. Regular use of the SOP template helps in maintaining equipment longevity and operational reliability.

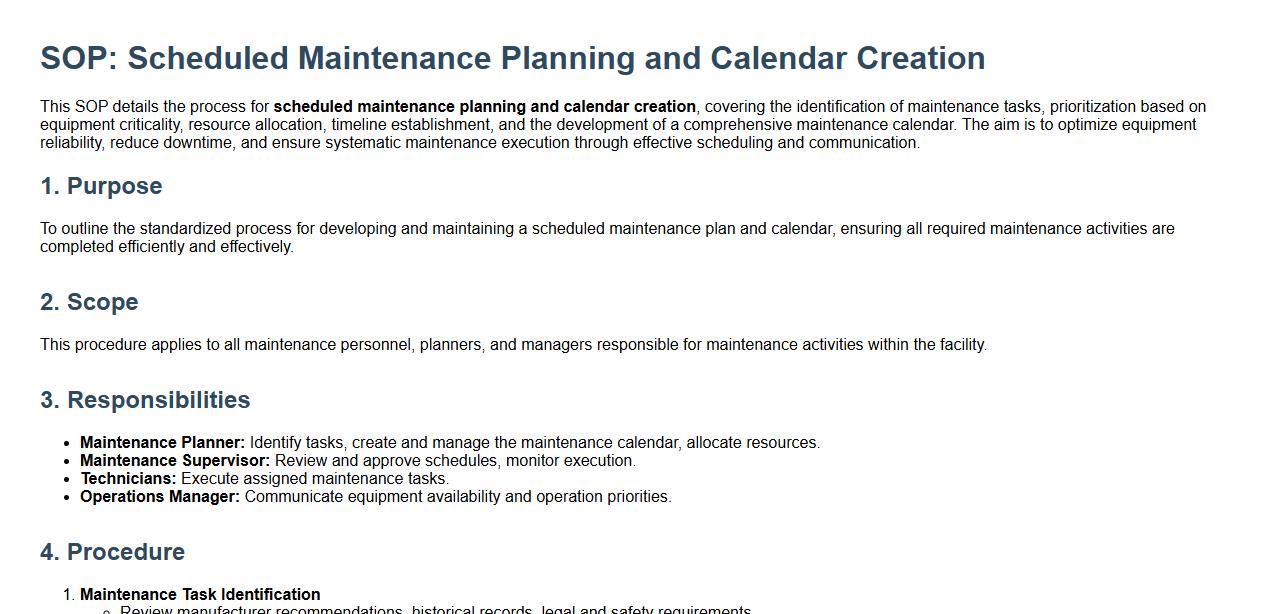

Scheduled maintenance planning and calendar creation.

This SOP details the process for scheduled maintenance planning and calendar creation, covering the identification of maintenance tasks, prioritization based on equipment criticality, resource allocation, timeline establishment, and the development of a comprehensive maintenance calendar. The aim is to optimize equipment reliability, reduce downtime, and ensure systematic maintenance execution through effective scheduling and communication.

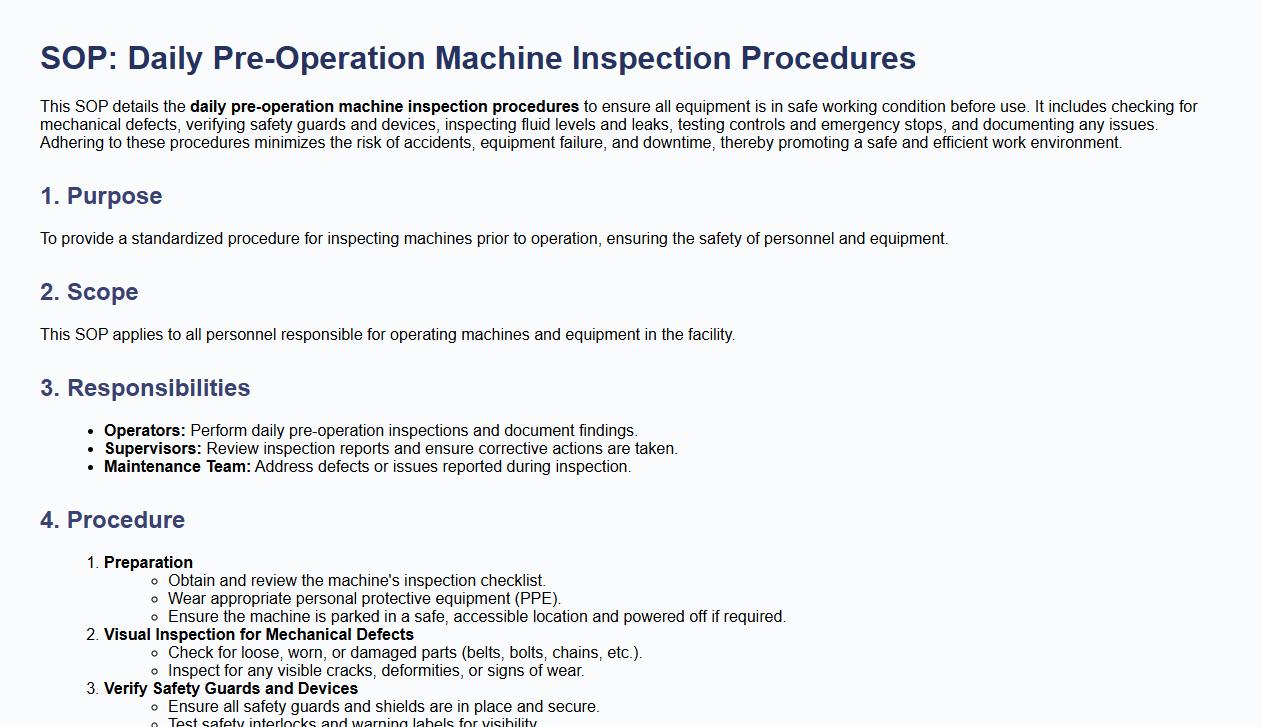

Daily pre-operation machine inspection procedures.

This SOP details the daily pre-operation machine inspection procedures to ensure all equipment is in safe working condition before use. It includes checking for mechanical defects, verifying safety guards and devices, inspecting fluid levels and leaks, testing controls and emergency stops, and documenting any issues. Adhering to these procedures minimizes the risk of accidents, equipment failure, and downtime, thereby promoting a safe and efficient work environment.

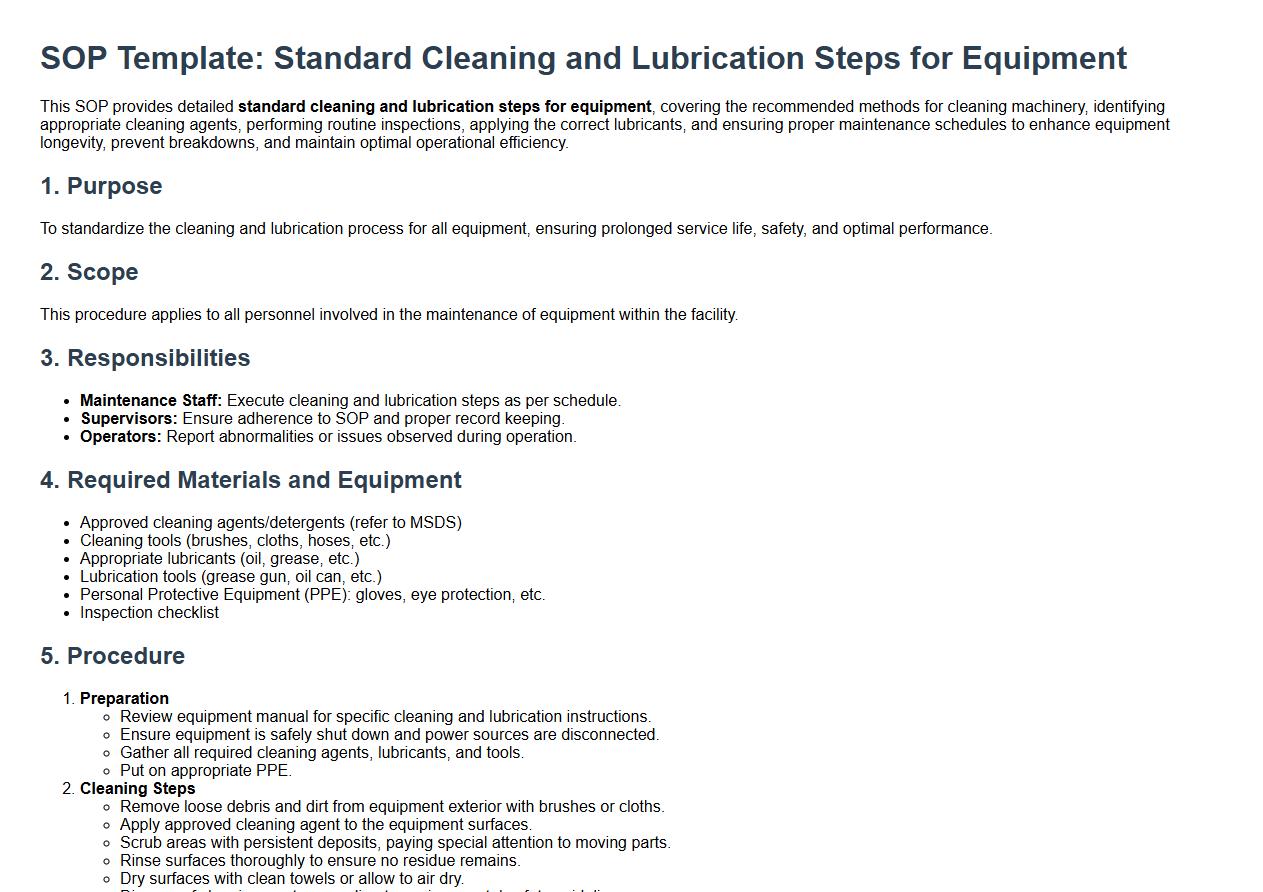

Standard cleaning and lubrication steps for equipment.

This SOP provides detailed standard cleaning and lubrication steps for equipment, covering the recommended methods for cleaning machinery, identifying appropriate cleaning agents, performing routine inspections, applying the correct lubricants, and ensuring proper maintenance schedules to enhance equipment longevity, prevent breakdowns, and maintain optimal operational efficiency.

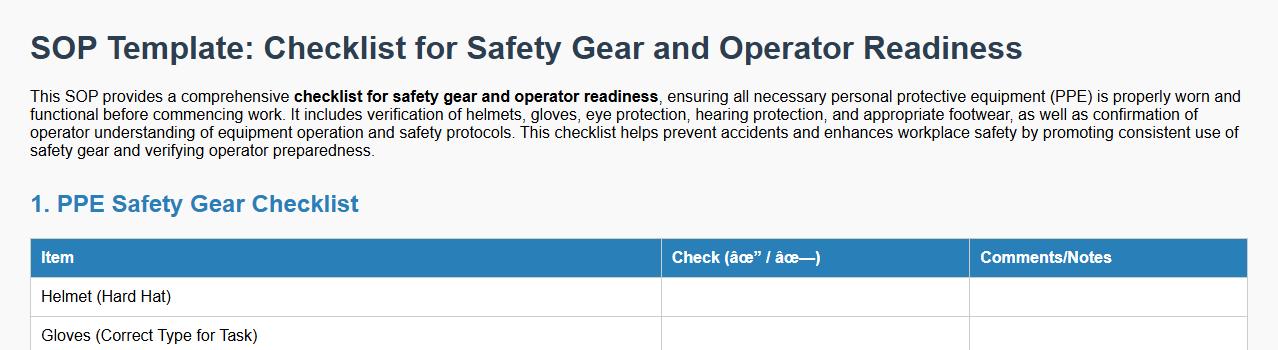

Checklist for safety gear and operator readiness.

This SOP provides a comprehensive checklist for safety gear and operator readiness, ensuring all necessary personal protective equipment (PPE) is properly worn and functional before commencing work. It includes verification of helmets, gloves, eye protection, hearing protection, and appropriate footwear, as well as confirmation of operator understanding of equipment operation and safety protocols. This checklist helps prevent accidents and enhances workplace safety by promoting consistent use of safety gear and verifying operator preparedness.

Guidelines for identifying and reporting machine faults.

This SOP provides comprehensive guidelines for identifying and reporting machine faults, detailing the steps for regular machine inspections, recognizing common fault indicators, documenting issues accurately, and communicating faults to maintenance teams promptly. The objective is to enhance machine reliability, prevent operational downtime, and ensure workplace safety through efficient fault management processes.

Step-by-step instructions for minor repairs and adjustments.

This SOP provides step-by-step instructions for minor repairs and adjustments, detailing precise and systematic procedures to safely and effectively address common equipment and facility issues. It includes guidelines for identifying problems, selecting appropriate tools, executing repairs, performing quality checks, and documenting the work completed to ensure operational continuity and reduce downtime.

Documentation and logging of maintenance activities.

This SOP details the documentation and logging of maintenance activities, emphasizing accurate recording of all maintenance tasks, scheduling preventive maintenance, tracking repairs and replacements, maintaining equipment service histories, ensuring compliance with safety standards, and facilitating efficient asset management. The objective is to enhance operational reliability, reduce downtime, and provide clear maintenance records for auditing and continuous improvement purposes.

Procedures for inventory management of spare parts.

This SOP details the procedures for inventory management of spare parts, encompassing parts identification and categorization, inventory tracking and record-keeping, stock level monitoring and reorder point determination, storage organization and handling protocols, periodic inventory audits and reconciliation, supplier coordination and procurement processes, and documentation of inventory transactions. The goal is to maintain optimal spare parts availability, minimize downtime, reduce excess inventory costs, and ensure efficient and accurate inventory control throughout the maintenance and operational cycles.

Protocols for engaging external service technicians.

This SOP details the protocols for engaging external service technicians, encompassing the selection criteria, verification of qualifications, scheduling and communication procedures, safety and compliance requirements, confidentiality agreements, on-site access and supervision guidelines, performance monitoring, and post-service evaluation. The objective is to ensure that all external technicians are properly vetted, effectively coordinated, and managed to maintain operational efficiency and workplace safety.

Emergency response and shutdown procedures for equipment failures.

This SOP details emergency response and shutdown procedures for equipment failures, including immediate actions to safely stop malfunctioning machinery, protocols for alerting supervisors and maintenance teams, steps to secure the work area, guidelines for assessing and documenting the failure, and measures to prevent further damage or injury. The goal is to ensure employee safety, minimize equipment downtime, and maintain operational continuity through effective and timely response strategies.

What specific safety procedures must be followed during machine maintenance according to the SOP?

The SOP mandates strict adherence to lockout/tagout procedures to ensure the machine is fully de-energized before maintenance begins. Personnel must wear appropriate PPE (Personal Protective Equipment), including gloves, safety glasses, and protective footwear. Additionally, clear communication protocols must be followed to prevent accidental machine startup during maintenance.

Which maintenance tasks and frequency are outlined in the SOP for optimal machine performance?

The SOP specifies routine tasks such as lubrication of moving parts every 500 operational hours and inspection of electrical systems monthly. Cleaning of filters and replacement of worn components should be conducted quarterly to maintain efficiency. Preventive maintenance schedules are clearly defined to minimize downtime and extend machine lifespan.

Who is authorized and responsible for performing each step in the machine maintenance SOP?

Only certified maintenance technicians are authorized to perform mechanical inspections and repairs, ensuring expertise in handling complex machinery. Operators may conduct daily visual checks and basic cleaning under supervision. Supervisors are responsible for verifying task completion and compliance with safety standards.

What documentation and reporting requirements are specified in the SOP after maintenance is completed?

The SOP requires detailed recording of all maintenance activities in the maintenance logbook, including date, tasks performed, and personnel involved. Any replaced parts must be documented with serial numbers and reasons for replacement. A formal report must be submitted to the maintenance supervisor for review and approval to ensure accountability.

What actions does the SOP specify in case of detection of faults or abnormalities during maintenance?

Upon detection of faults or abnormalities, the SOP mandates immediate cessation of machine operation to prevent further damage. The issue must be reported to the maintenance supervisor for a thorough diagnosis and corrective planning. If necessary, the machine is tagged as out of service until proper repairs are completed and verified.