A SOP Template for Production Line Management provides a standardized framework to ensure consistent and efficient operations on the production floor. It outlines step-by-step procedures, safety protocols, and quality control measures to streamline workflow and minimize errors. This template enhances communication among team members and supports compliance with industry regulations.

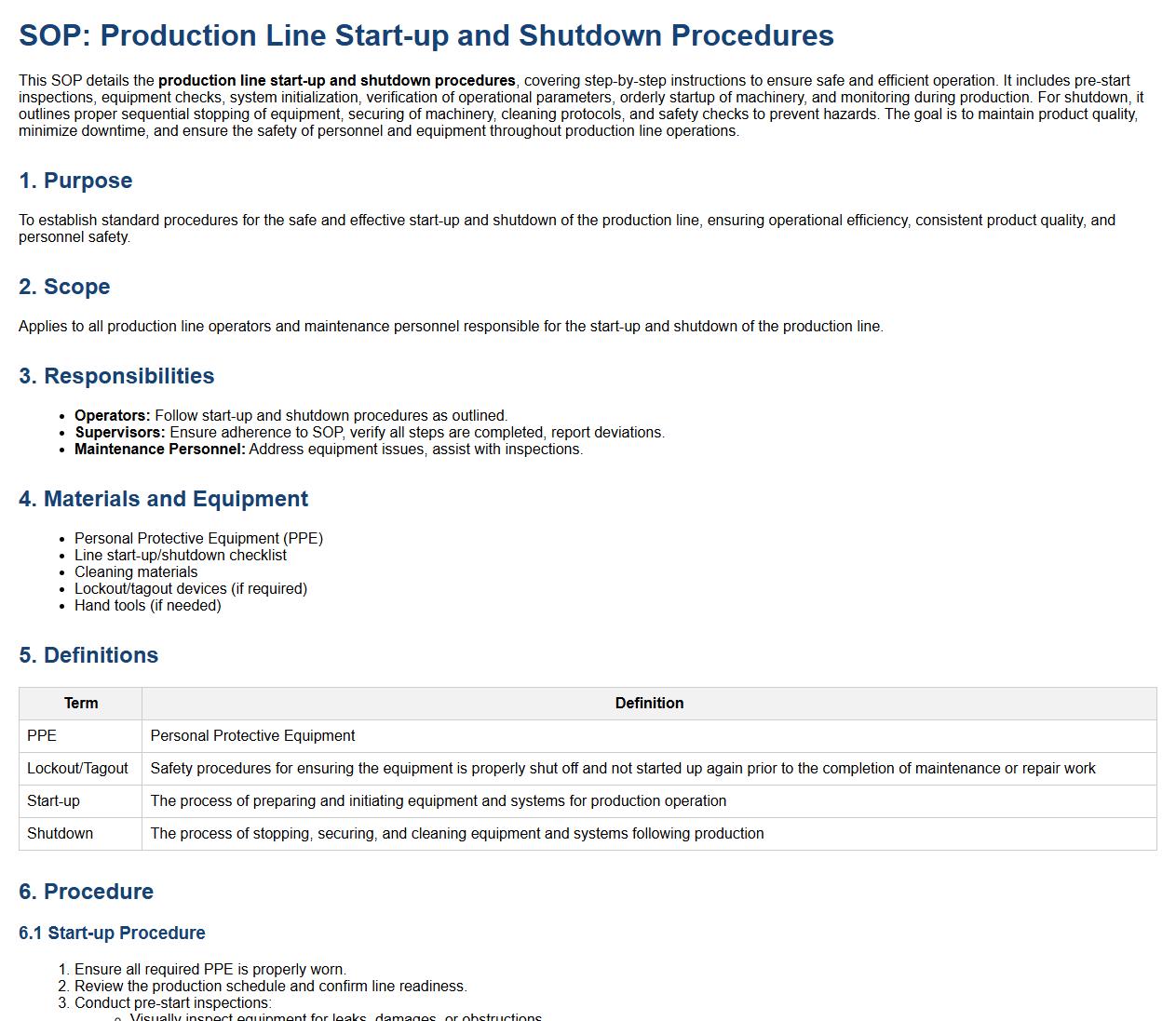

Production line start-up and shutdown procedures.

This SOP details the production line start-up and shutdown procedures, covering step-by-step instructions to ensure safe and efficient operation. It includes pre-start inspections, equipment checks, system initialization, verification of operational parameters, orderly startup of machinery, and monitoring during production. For shutdown, it outlines proper sequential stopping of equipment, securing of machinery, cleaning protocols, and safety checks to prevent hazards. The goal is to maintain product quality, minimize downtime, and ensure the safety of personnel and equipment throughout production line operations.

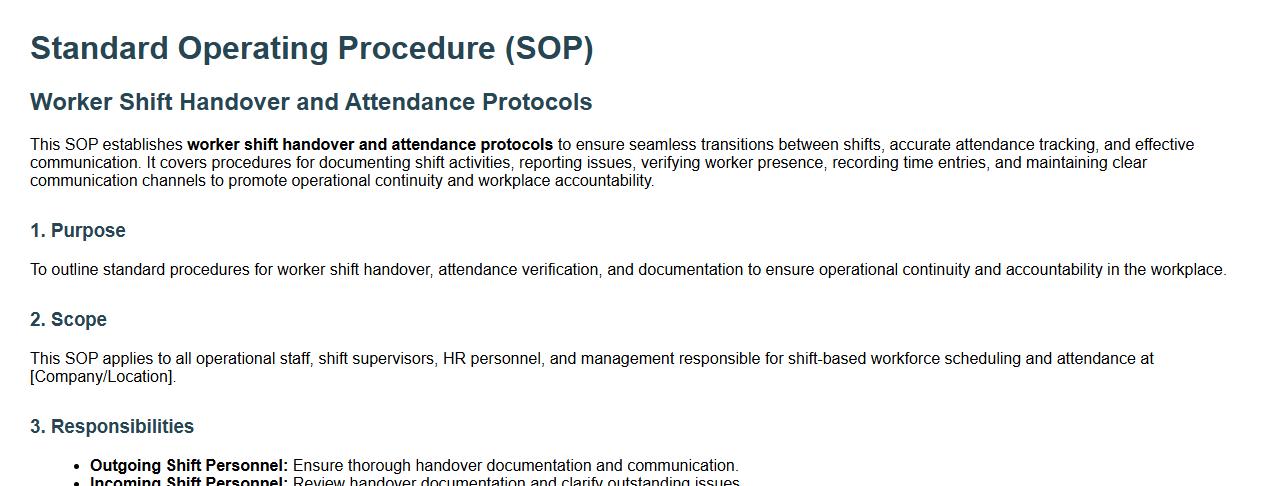

Worker shift handover and attendance protocols.

This SOP establishes worker shift handover and attendance protocols to ensure seamless transitions between shifts, accurate attendance tracking, and effective communication. It covers procedures for documenting shift activities, reporting issues, verifying worker presence, recording time entries, and maintaining clear communication channels to promote operational continuity and workplace accountability.

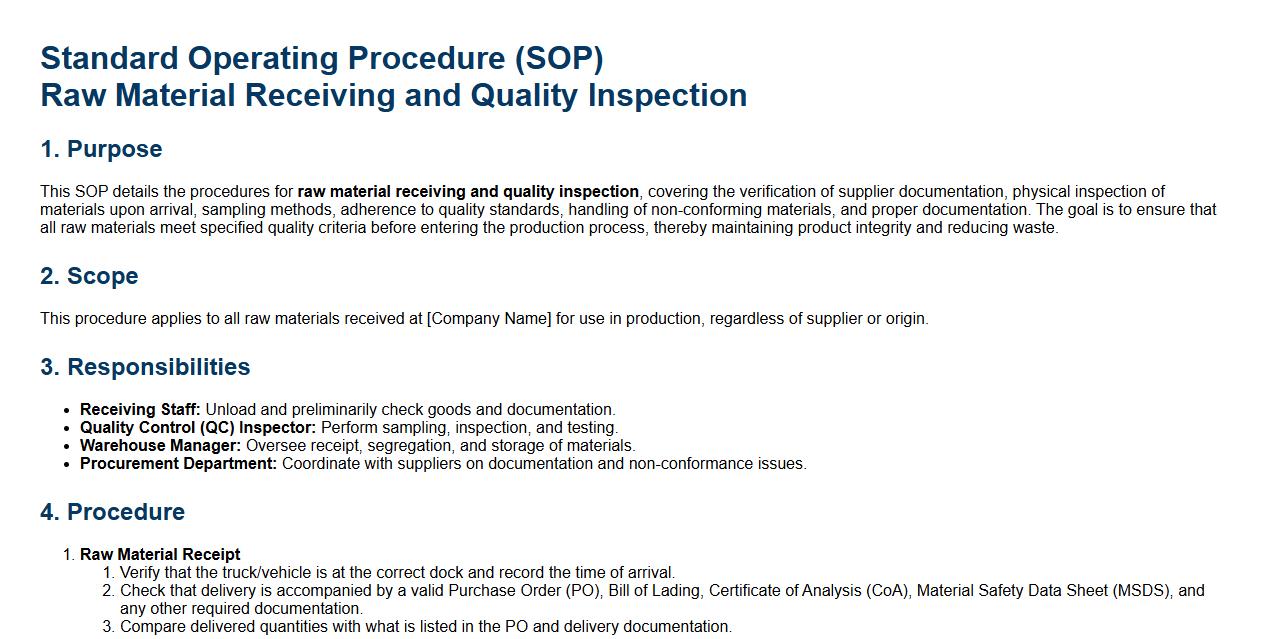

Raw material receiving and quality inspection.

This SOP details the procedures for raw material receiving and quality inspection, covering the verification of supplier documentation, physical inspection of materials upon arrival, sampling methods, adherence to quality standards, handling of non-conforming materials, and proper documentation. The goal is to ensure that all raw materials meet specified quality criteria before entering the production process, thereby maintaining product integrity and reducing waste.

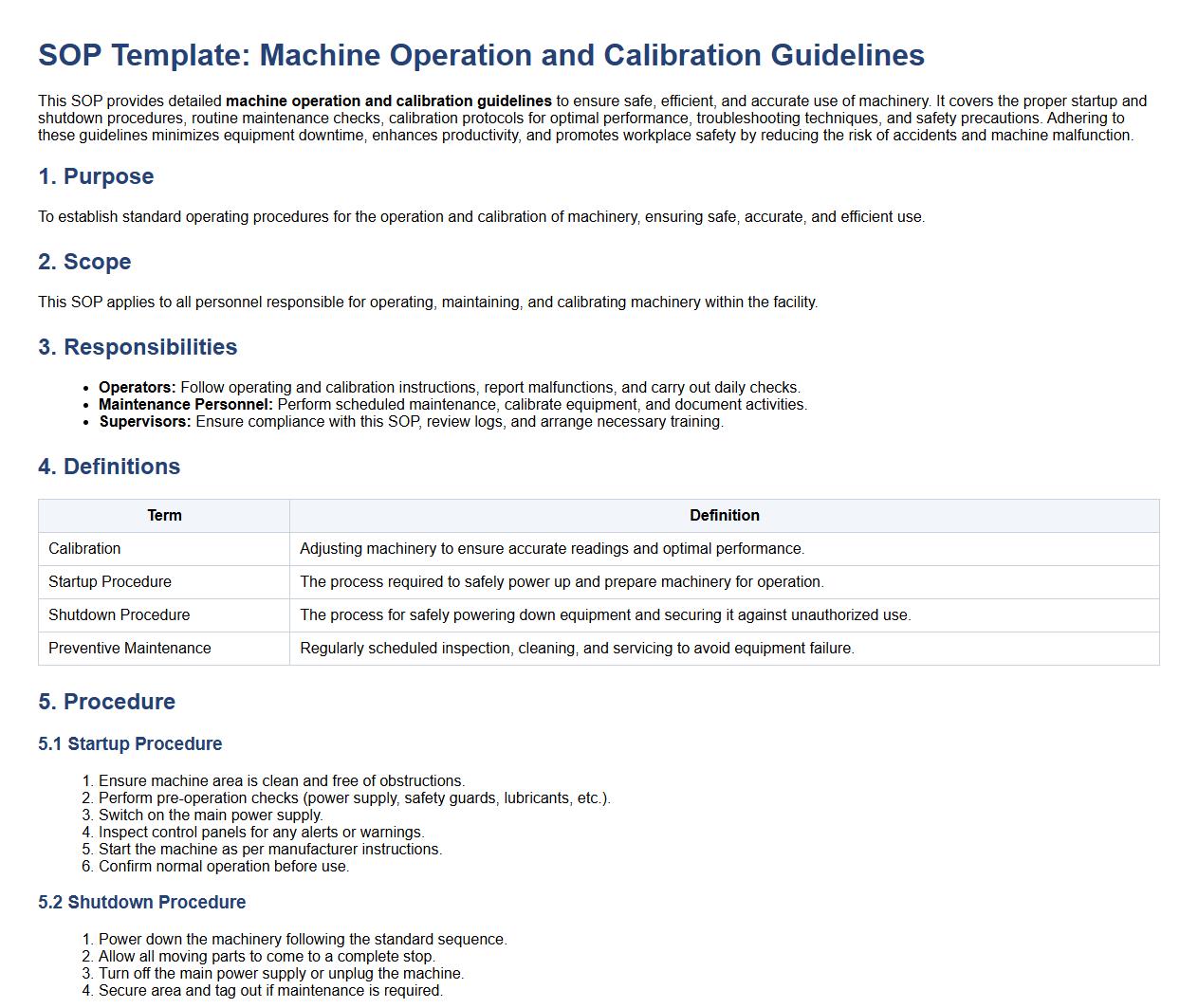

Machine operation and calibration guidelines.

This SOP provides detailed machine operation and calibration guidelines to ensure safe, efficient, and accurate use of machinery. It covers the proper startup and shutdown procedures, routine maintenance checks, calibration protocols for optimal performance, troubleshooting techniques, and safety precautions. Adhering to these guidelines minimizes equipment downtime, enhances productivity, and promotes workplace safety by reducing the risk of accidents and machine malfunction.

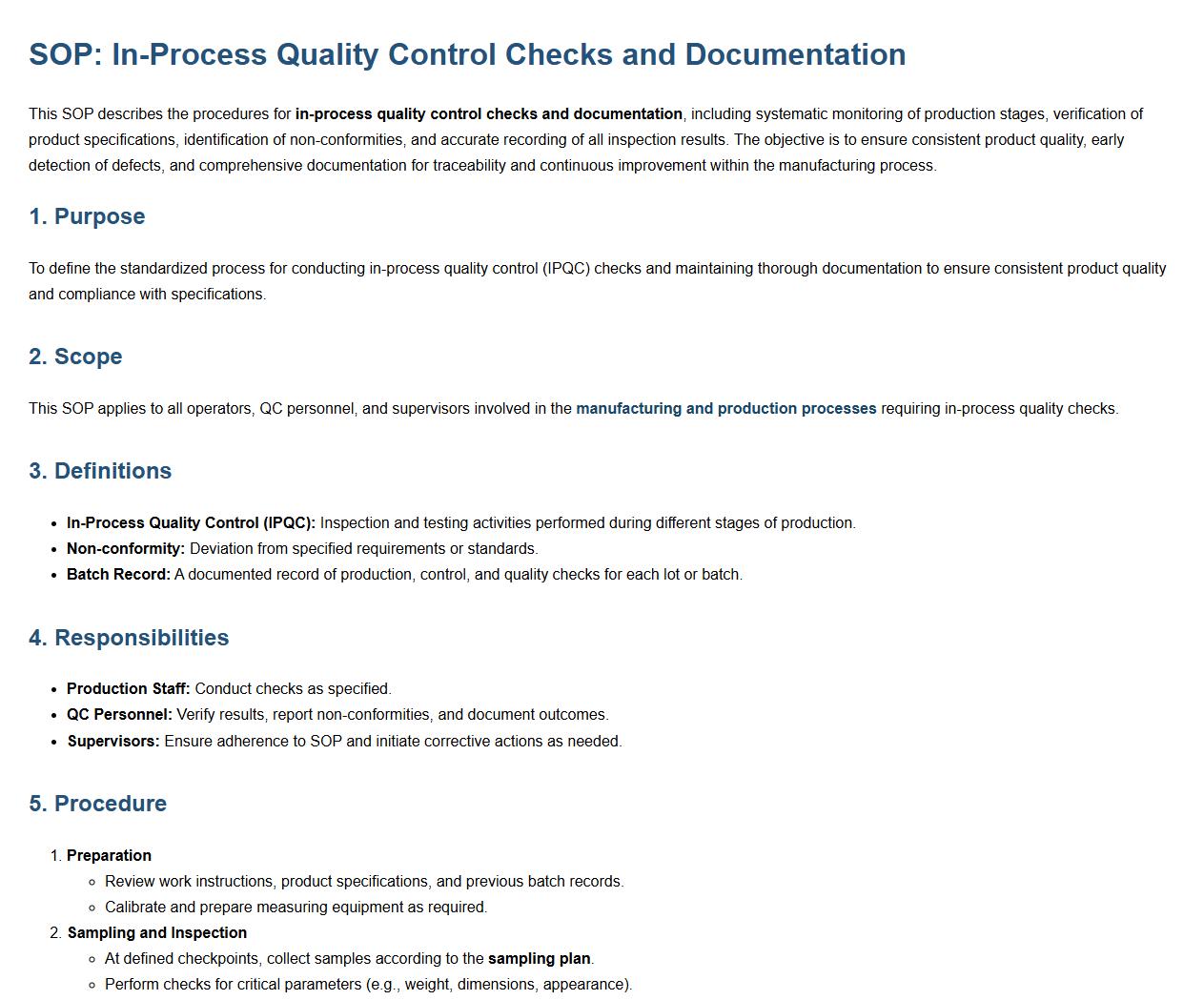

In-process quality control checks and documentation.

This SOP describes the procedures for in-process quality control checks and documentation, including systematic monitoring of production stages, verification of product specifications, identification of non-conformities, and accurate recording of all inspection results. The objective is to ensure consistent product quality, early detection of defects, and comprehensive documentation for traceability and continuous improvement within the manufacturing process.

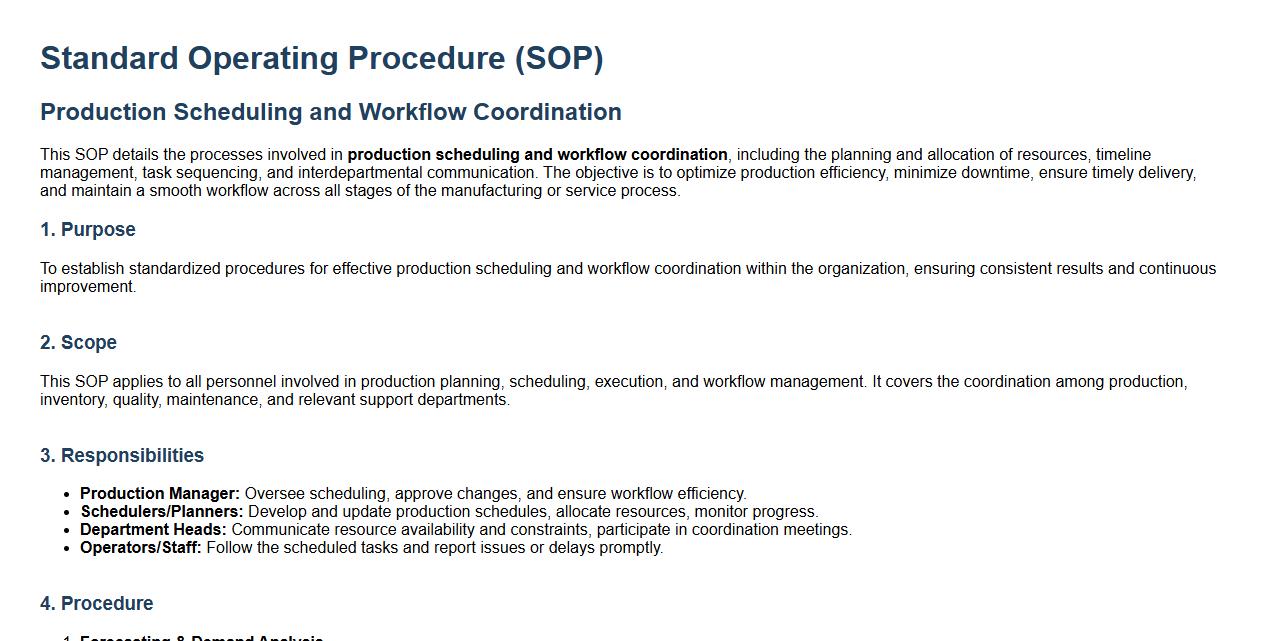

Production scheduling and workflow coordination.

This SOP details the processes involved in production scheduling and workflow coordination, including the planning and allocation of resources, timeline management, task sequencing, and interdepartmental communication. The objective is to optimize production efficiency, minimize downtime, ensure timely delivery, and maintain a smooth workflow across all stages of the manufacturing or service process.

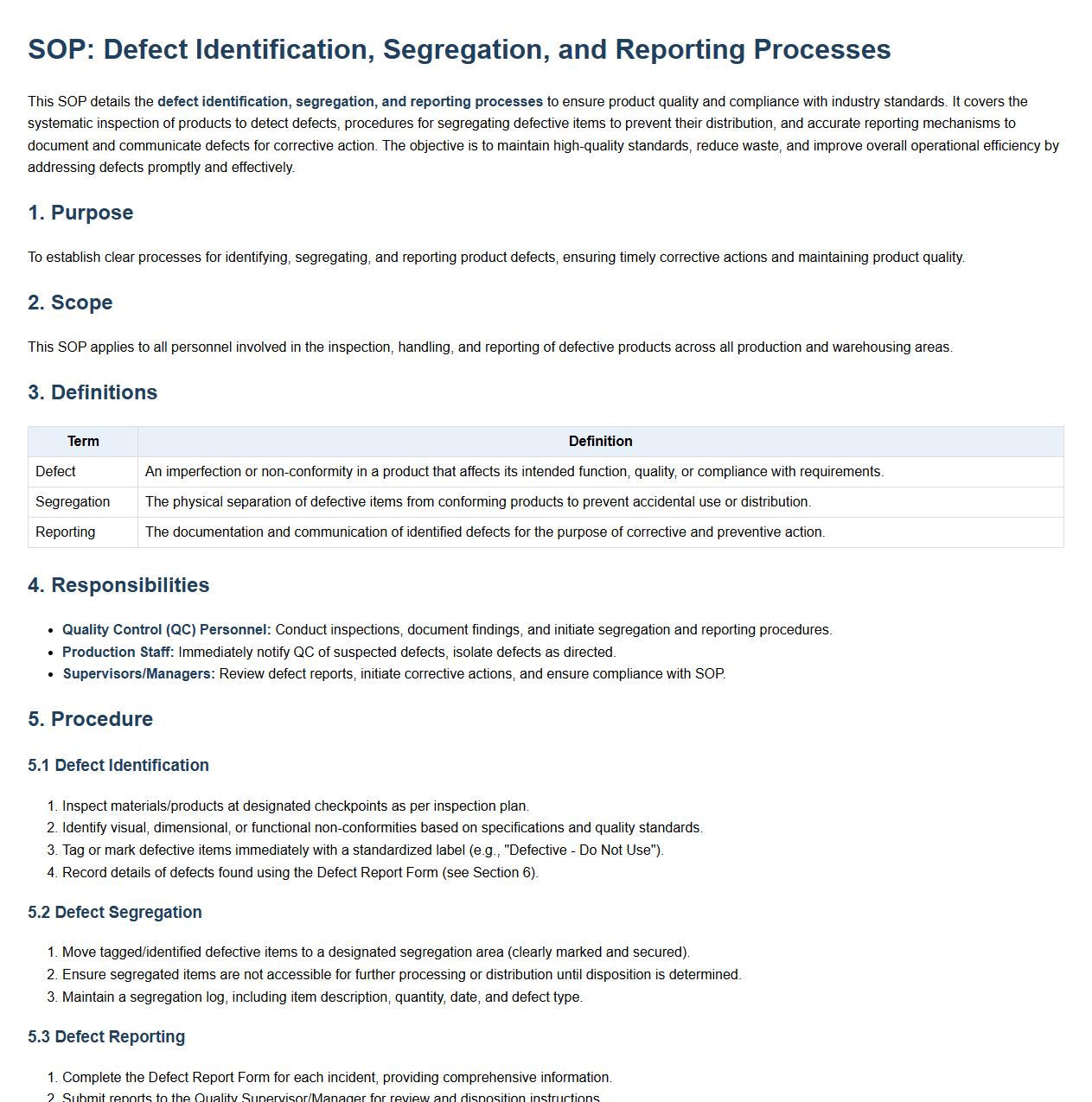

Defect identification, segregation, and reporting processes.

This SOP details the defect identification, segregation, and reporting processes to ensure product quality and compliance with industry standards. It covers the systematic inspection of products to detect defects, procedures for segregating defective items to prevent their distribution, and accurate reporting mechanisms to document and communicate defects for corrective action. The objective is to maintain high-quality standards, reduce waste, and improve overall operational efficiency by addressing defects promptly and effectively.

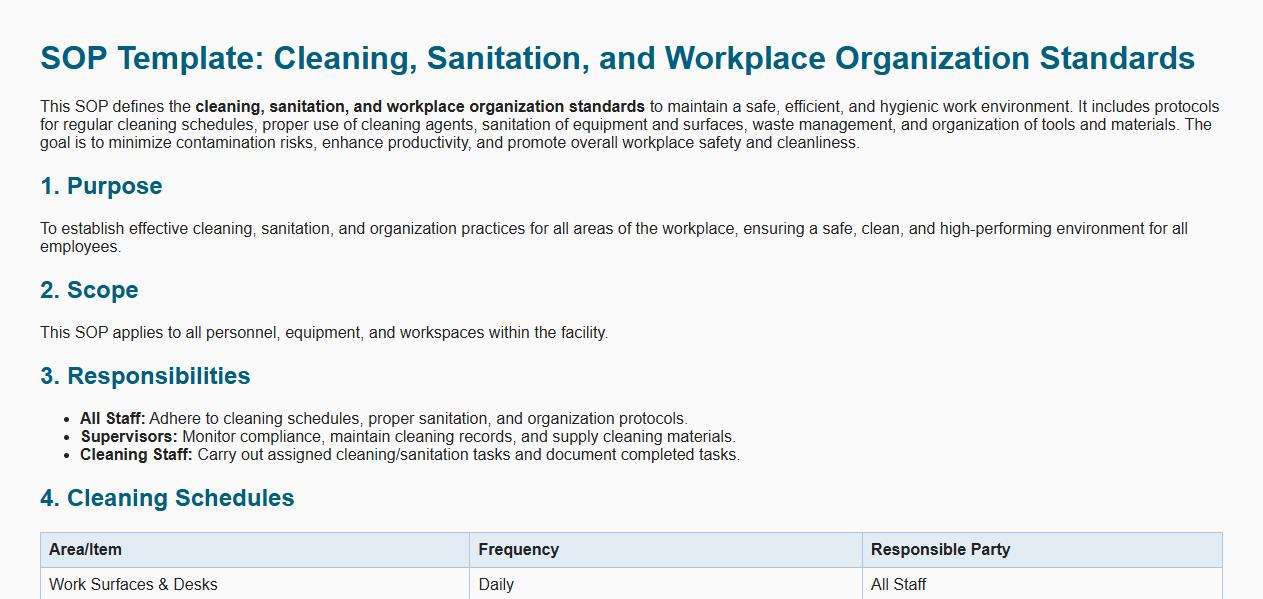

Cleaning, sanitation, and workplace organization standards.

This SOP defines the cleaning, sanitation, and workplace organization standards to maintain a safe, efficient, and hygienic work environment. It includes protocols for regular cleaning schedules, proper use of cleaning agents, sanitation of equipment and surfaces, waste management, and organization of tools and materials. The goal is to minimize contamination risks, enhance productivity, and promote overall workplace safety and cleanliness.

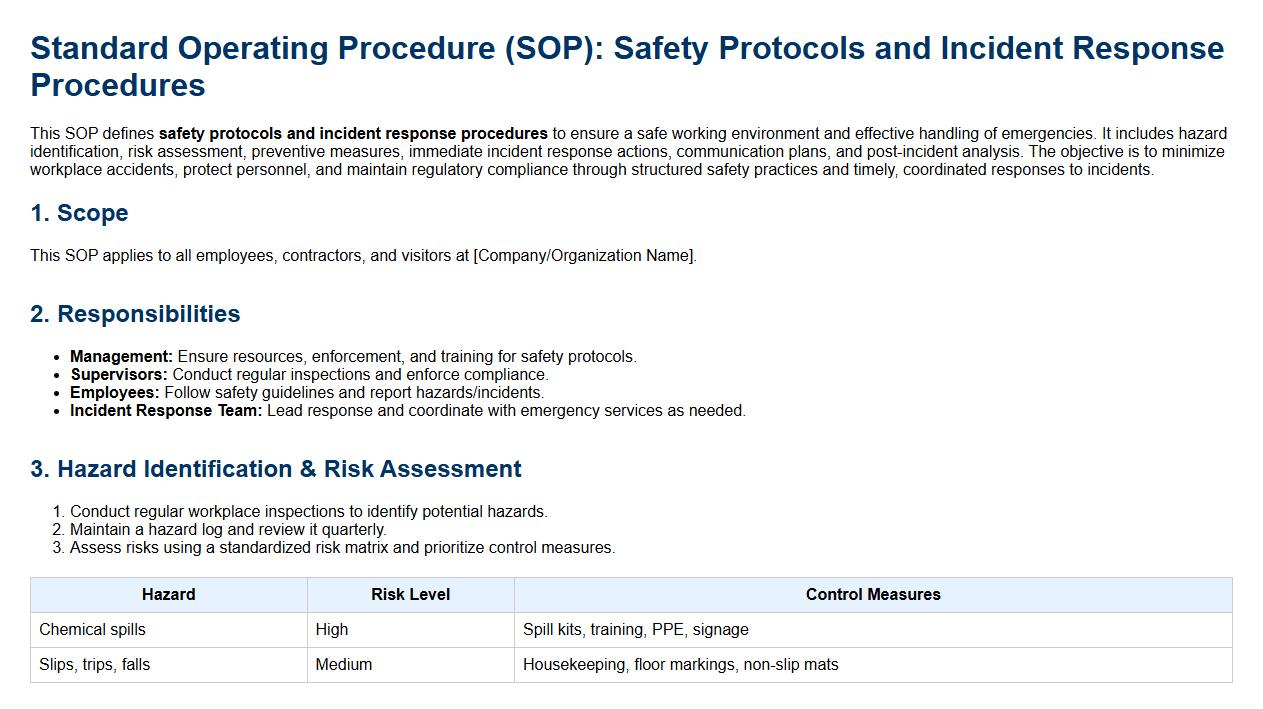

Safety protocols and incident response procedures.

This SOP defines safety protocols and incident response procedures to ensure a safe working environment and effective handling of emergencies. It includes hazard identification, risk assessment, preventive measures, immediate incident response actions, communication plans, and post-incident analysis. The objective is to minimize workplace accidents, protect personnel, and maintain regulatory compliance through structured safety practices and timely, coordinated responses to incidents.

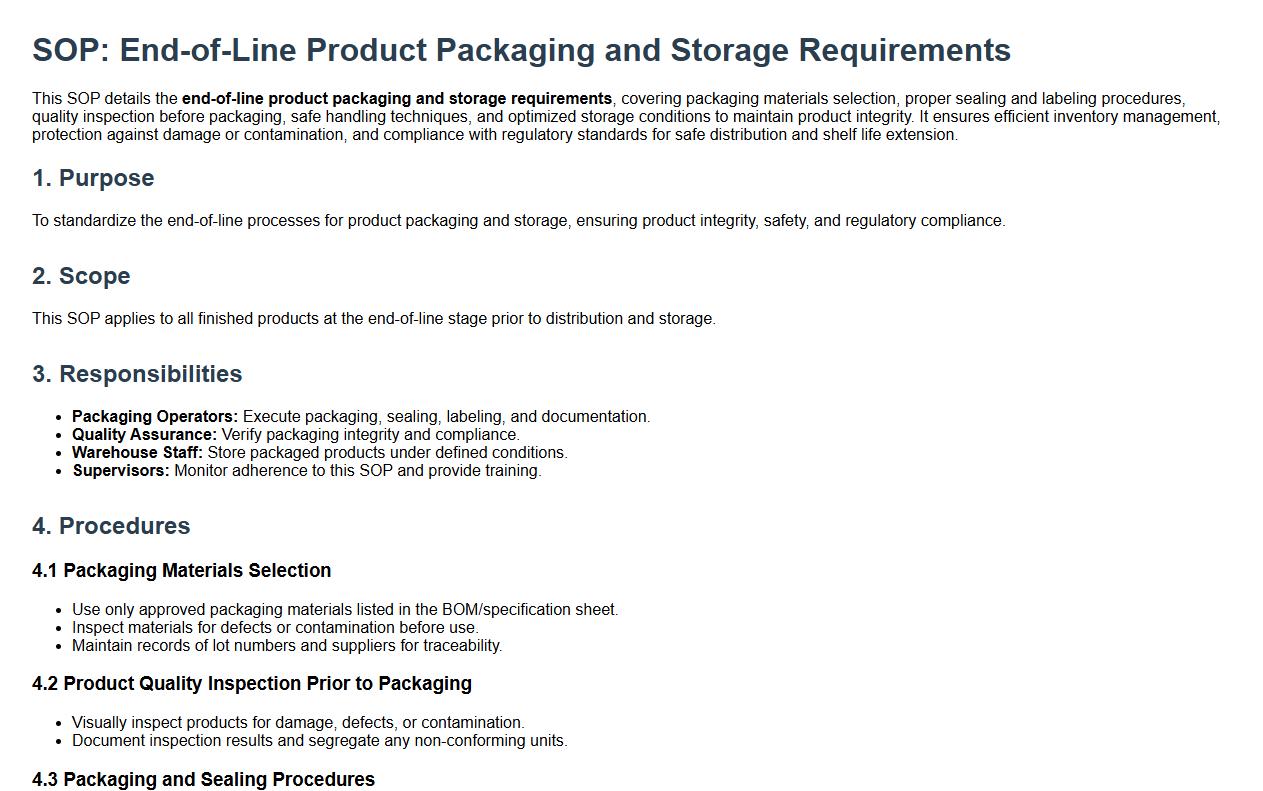

End-of-line product packaging and storage requirements.

This SOP details the end-of-line product packaging and storage requirements, covering packaging materials selection, proper sealing and labeling procedures, quality inspection before packaging, safe handling techniques, and optimized storage conditions to maintain product integrity. It ensures efficient inventory management, protection against damage or contamination, and compliance with regulatory standards for safe distribution and shelf life extension.

What are the key objectives and scope defined in the SOP for Production Line Management?

The key objectives of the SOP for Production Line Management focus on ensuring efficient, safe, and consistent production processes. It aims to optimize workflow, reduce waste, and maintain high-quality output across all stages of production. The scope typically covers all activities from raw material handling to final product packaging within the production line environment.

Which roles and responsibilities are outlined for personnel in the production line SOP?

The SOP clearly defines the roles and responsibilities of each team member to ensure accountability and smooth operations. Operators are responsible for machine operation and monitoring, while supervisors oversee compliance and production targets. Quality control personnel are tasked with inspection and reporting, ensuring adherence to established standards.

What are the critical steps and sequence specified for standard production line operations in the SOP?

The SOP details the critical steps starting from raw material inspection to final product packaging in a sequential manner. It emphasizes precise machine setup, regular monitoring, and timely adjustments to maintain consistency. Each step is designed to minimize errors and ensure a streamlined production flow.

What quality control measures and documentation requirements are mandated by the SOP?

The SOP mandates strict quality control measures including regular inspections, sampling, and testing at various stages. Documentation requirements include maintaining production logs, quality check reports, and traceability records to ensure transparency. These measures help in early detection of issues and continuous improvement.

What procedures does the SOP prescribe for handling deviations, non-conformances, and emergency situations?

The SOP prescribes clear procedures for identifying, documenting, and addressing deviations and non-conformances promptly. It includes steps for root cause analysis and corrective actions to prevent recurrence. Emergency protocols ensure personnel safety and minimize impact on production through immediate response plans.