A SOP Template for Standardized Work Instructions ensures consistent and clear documentation of procedures across an organization. It provides a structured format to outline step-by-step tasks, responsibilities, and quality standards, enhancing efficiency and compliance. This template simplifies training, reduces errors, and supports continuous improvement initiatives.

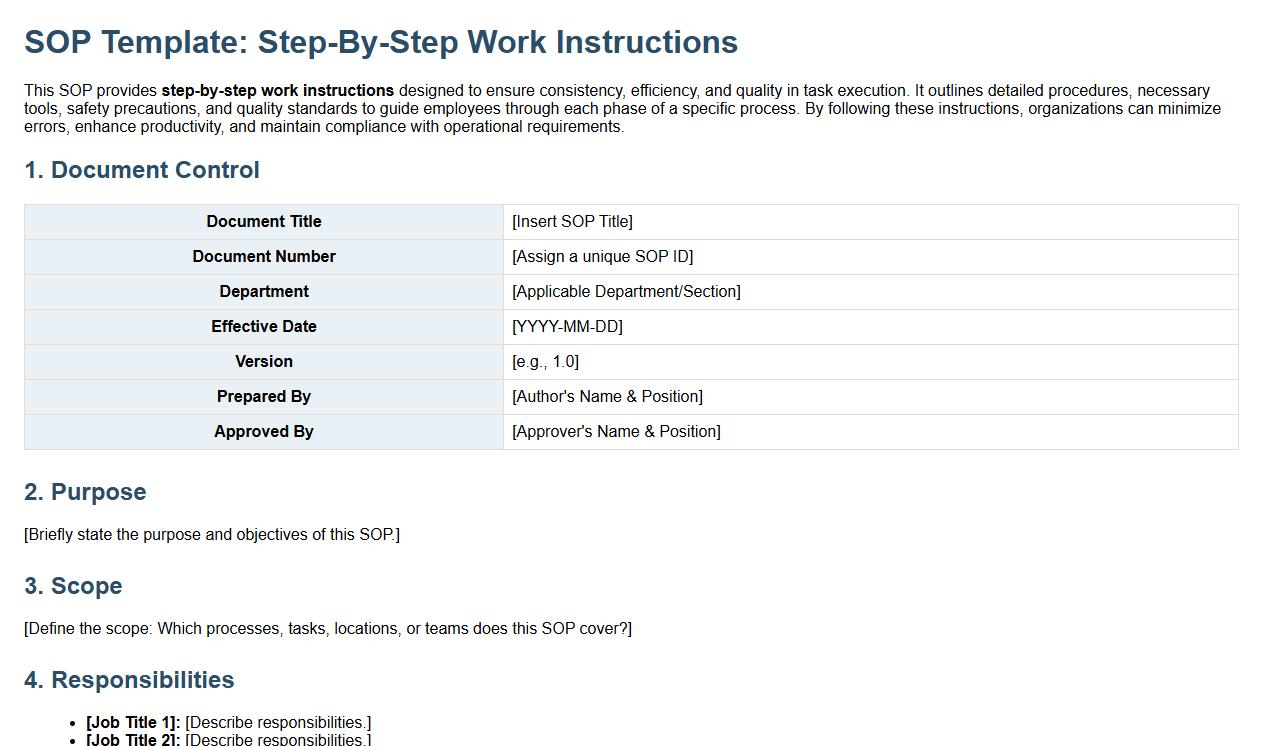

Document title and identification details.

This SOP describes the document title and identification details, specifying the standardized format for naming documents, including the title, unique identification code, version number, and effective date. It ensures consistency, easy retrieval, and accurate tracking of document revisions across the organization.

Purpose and scope of the procedure.

This SOP defines the purpose and scope of the procedure, outlining the objectives, applicability, and boundaries of the process to ensure clarity and consistent implementation. It establishes the framework for the procedure's use, detailing the specific activities covered, involved personnel, and operational limits to maintain effectiveness and compliance within the organization.

Roles and responsibilities defined.

This SOP clearly defines the roles and responsibilities of all personnel involved in the organization's operations, ensuring accountability and clarity in task assignments. It outlines specific duties, reporting structures, and authority levels to promote efficient workflow, effective communication, and successful achievement of organizational goals.

Required materials and equipment list.

This SOP details the required materials and equipment list necessary for efficient operations, ensuring all tools, supplies, and devices are identified, available, and maintained. It covers specifications, quantities, storage requirements, and usage guidelines to support smooth workflow and safety compliance.

Step-by-step work instructions.

This SOP provides step-by-step work instructions designed to ensure consistency, efficiency, and quality in task execution. It outlines detailed procedures, necessary tools, safety precautions, and quality standards to guide employees through each phase of a specific process. By following these instructions, organizations can minimize errors, enhance productivity, and maintain compliance with operational requirements.

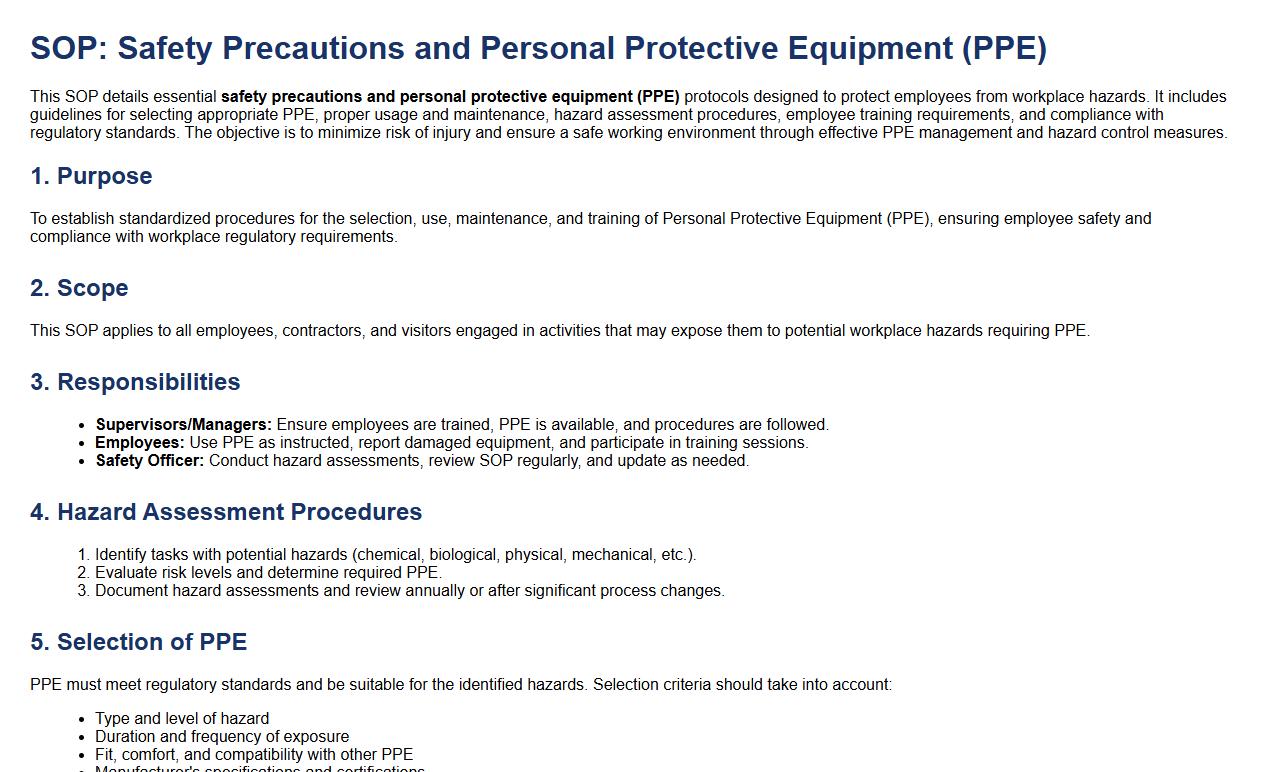

Safety precautions and personal protective equipment (PPE).

This SOP details essential safety precautions and personal protective equipment (PPE) protocols designed to protect employees from workplace hazards. It includes guidelines for selecting appropriate PPE, proper usage and maintenance, hazard assessment procedures, employee training requirements, and compliance with regulatory standards. The objective is to minimize risk of injury and ensure a safe working environment through effective PPE management and hazard control measures.

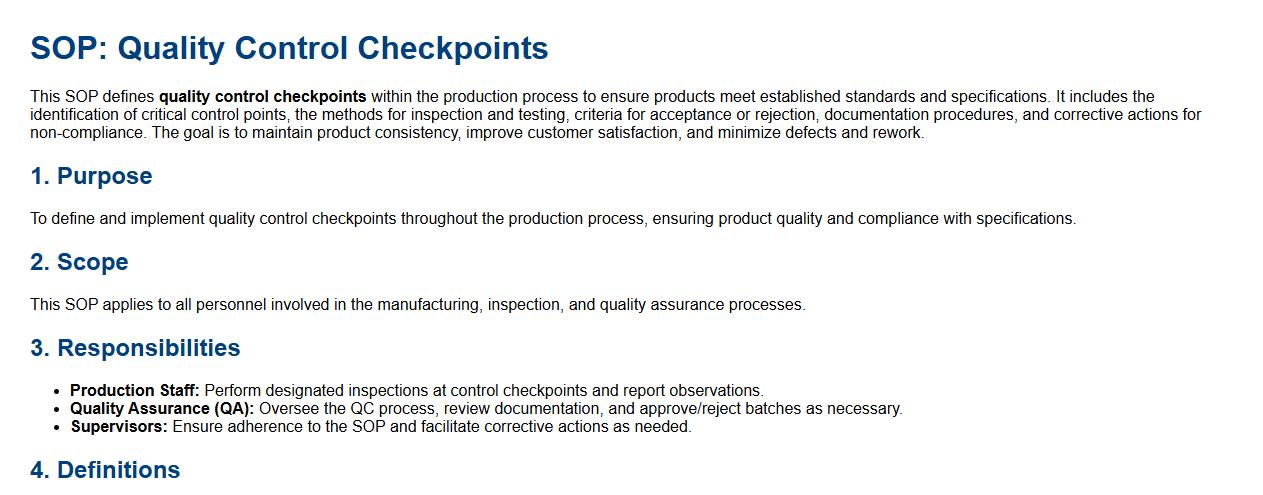

Quality control checkpoints.

This SOP defines quality control checkpoints within the production process to ensure products meet established standards and specifications. It includes the identification of critical control points, the methods for inspection and testing, criteria for acceptance or rejection, documentation procedures, and corrective actions for non-compliance. The goal is to maintain product consistency, improve customer satisfaction, and minimize defects and rework.

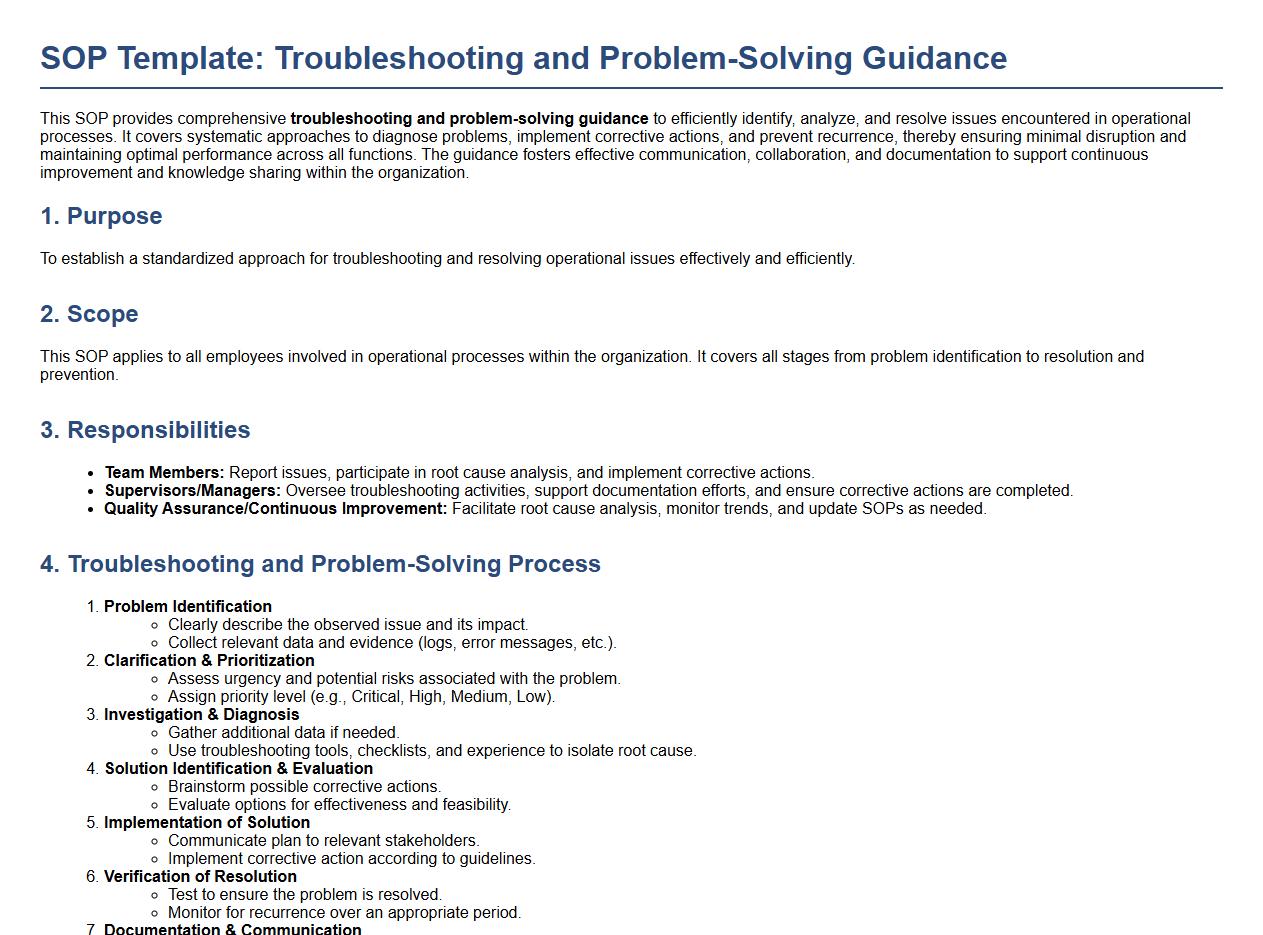

Troubleshooting and problem-solving guidance.

This SOP provides comprehensive troubleshooting and problem-solving guidance to efficiently identify, analyze, and resolve issues encountered in operational processes. It covers systematic approaches to diagnose problems, implement corrective actions, and prevent recurrence, thereby ensuring minimal disruption and maintaining optimal performance across all functions. The guidance fosters effective communication, collaboration, and documentation to support continuous improvement and knowledge sharing within the organization.

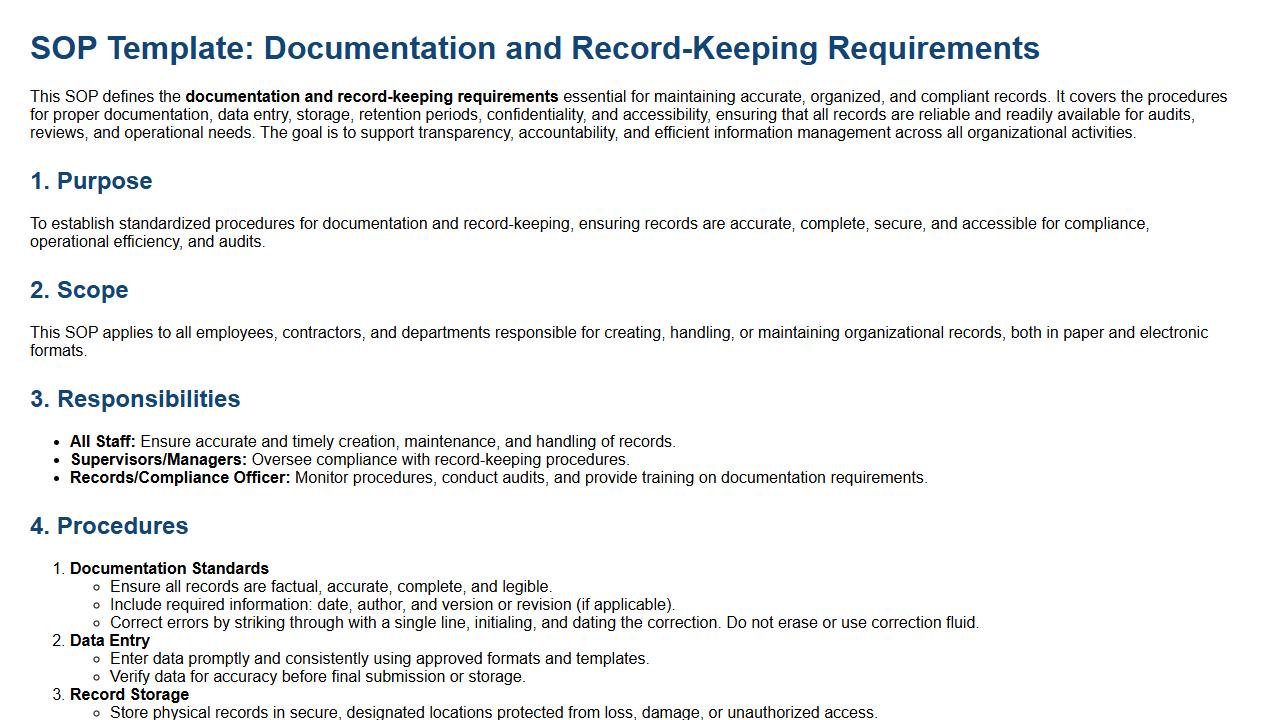

Documentation and record-keeping requirements.

This SOP defines the documentation and record-keeping requirements essential for maintaining accurate, organized, and compliant records. It covers the procedures for proper documentation, data entry, storage, retention periods, confidentiality, and accessibility, ensuring that all records are reliable and readily available for audits, reviews, and operational needs. The goal is to support transparency, accountability, and efficient information management across all organizational activities.

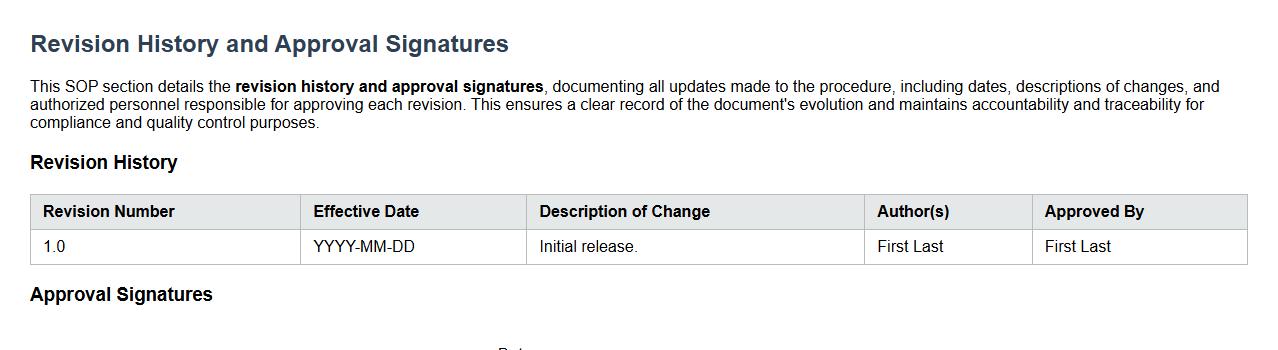

Revision history and approval signatures.

This SOP section details the revision history and approval signatures, documenting all updates made to the procedure, including dates, descriptions of changes, and authorized personnel responsible for approving each revision. This ensures a clear record of the document's evolution and maintains accountability and traceability for compliance and quality control purposes.

What are the key objectives outlined in the SOP for Standardized Work Instructions?

The SOP aims to establish clear and consistent standardized work instructions to enhance operational efficiency. It focuses on reducing variability and ensuring quality outcomes across all processes. The primary objective is to provide a reliable reference that supports employee training and performance.

Which roles and responsibilities are defined within the SOP for creating and maintaining work instructions?

The SOP assigns responsibility to process owners for developing and updating work instructions. Quality assurance teams are tasked with validating the accuracy and compliance of these documents. Additionally, employees must adhere to instructions and provide feedback for continuous improvement.

What process steps are required for reviewing and approving standardized work instructions in the SOP?

The SOP includes a structured review process involving subject matter experts and supervisors for thorough evaluation. After review, designated approvers must formally approve the work instructions before implementation. This ensures accuracy, compliance, and readiness for use on the production floor.

How does the SOP ensure version control and document management for work instructions?

The SOP mandates maintaining a version control system that tracks all revisions of work instructions. Only the latest approved version is accessible to employees to prevent confusion. Document management protocols ensure secure storage and easy retrieval of all documents.

What criteria does the SOP specify for training and competency assessment related to standardized work instructions?

The SOP requires structured training programs to ensure employees understand the work instructions. Competency assessments are conducted periodically to verify that employees can accurately execute tasks. Results of these assessments guide any necessary re-training or updates to the instructions.