A SOP Template for Surgical Instrument Inventory provides a structured framework to ensure accurate tracking, maintenance, and sterilization of surgical tools. It outlines standardized procedures for inventory checks, documentation, and handling to minimize instrument loss and contamination risks. Following this template enhances operational efficiency and compliance with healthcare regulations.

Instrument receiving and inspection procedures.

This SOP details the instrument receiving and inspection procedures, including the steps for verifying delivered items against purchase orders, inspecting instruments for damage or defects, ensuring proper calibration and certification, documenting inspection results, and managing the acceptance or rejection of instruments. The purpose is to guarantee that all received instruments meet quality standards and specifications before being integrated into operational use, thereby maintaining accuracy, safety, and compliance.

Instrument cleaning and sterilization guidelines.

This SOP details the instrument cleaning and sterilization guidelines, covering the proper procedures for cleaning, disinfecting, and sterilizing medical and laboratory instruments. It includes steps for pre-cleaning, choosing appropriate cleaning agents, using sterilization equipment, maintaining sterility during storage, and ensuring compliance with health and safety standards. The goal is to prevent contamination, reduce the risk of infection, and ensure the safety and effectiveness of all instruments used in patient care or laboratory work.

Daily and weekly inventory audits.

This SOP establishes the procedures for conducting daily and weekly inventory audits to ensure accurate tracking of stock levels, minimize discrepancies, and maintain optimal inventory management. It includes steps for verifying incoming and outgoing inventory, recording adjustments, identifying variances, and reporting findings to relevant departments. The goal is to enhance inventory accuracy, improve supply chain efficiency, and support informed decision-making through regular and systematic audits.

Instrument labeling and tracking protocols.

This SOP details instrument labeling and tracking protocols, including standardized labeling procedures, unique identification codes, inventory management, tracking throughout usage, cleaning and maintenance documentation, and secure storage guidelines. The aim is to ensure accurate identification, proper usage, and traceability of all instruments to enhance operational efficiency and compliance with regulatory standards.

Proper storage and organization of instruments.

This SOP details the proper storage and organization of instruments to ensure their longevity, maintain functionality, and enhance workplace efficiency. It includes guidelines for cleaning, categorizing, labeling, and safely storing instruments in designated areas to prevent damage, contamination, and misplacement. Effective implementation promotes a safe and organized environment, facilitating easy access and accountability of all instruments used in daily operations.

Issuance and return process for surgical sets.

This SOP details the issuance and return process for surgical sets, covering the standardized procedures for tracking, handling, and managing surgical instruments. It ensures proper sterilization verification, accurate documentation during issuance, timely return of used sets, inspection for damage or contamination, and secure storage. The process aims to maintain surgical instrument integrity, enhance operating room efficiency, and uphold patient safety by preventing infection and instrument shortages.

Damaged or missing instrument reporting procedures.

This SOP details the damaged or missing instrument reporting procedures to ensure prompt identification, reporting, and resolution of any instrument discrepancies. It includes steps for employees to report damaged or missing instruments, documentation requirements, notification protocols to supervisors or responsible departments, investigation processes, and corrective actions to prevent recurrence. The goal is to maintain accurate inventory, ensure operational efficiency, and uphold safety and compliance standards.

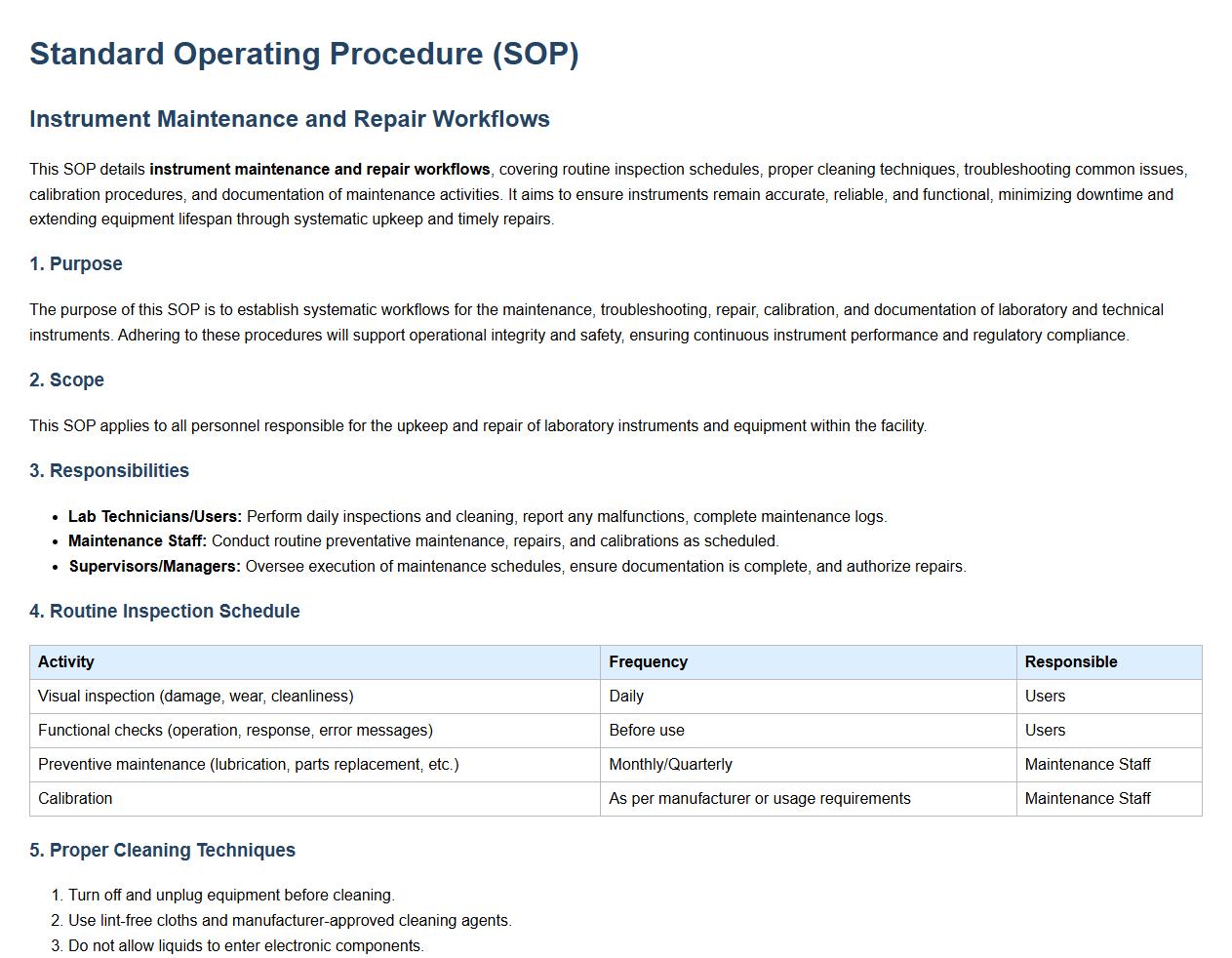

Instrument maintenance and repair workflows.

This SOP details instrument maintenance and repair workflows, covering routine inspection schedules, proper cleaning techniques, troubleshooting common issues, calibration procedures, and documentation of maintenance activities. It aims to ensure instruments remain accurate, reliable, and functional, minimizing downtime and extending equipment lifespan through systematic upkeep and timely repairs.

Documentation and record-keeping standards.

This SOP details documentation and record-keeping standards to ensure accurate, consistent, and secure management of all organizational records. It covers record creation, classification, retention, storage, retrieval, and disposal procedures, emphasizing compliance with legal and regulatory requirements. The objective is to maintain data integrity, facilitate efficient access, support operational transparency, and enable effective auditing and reporting across all departments.

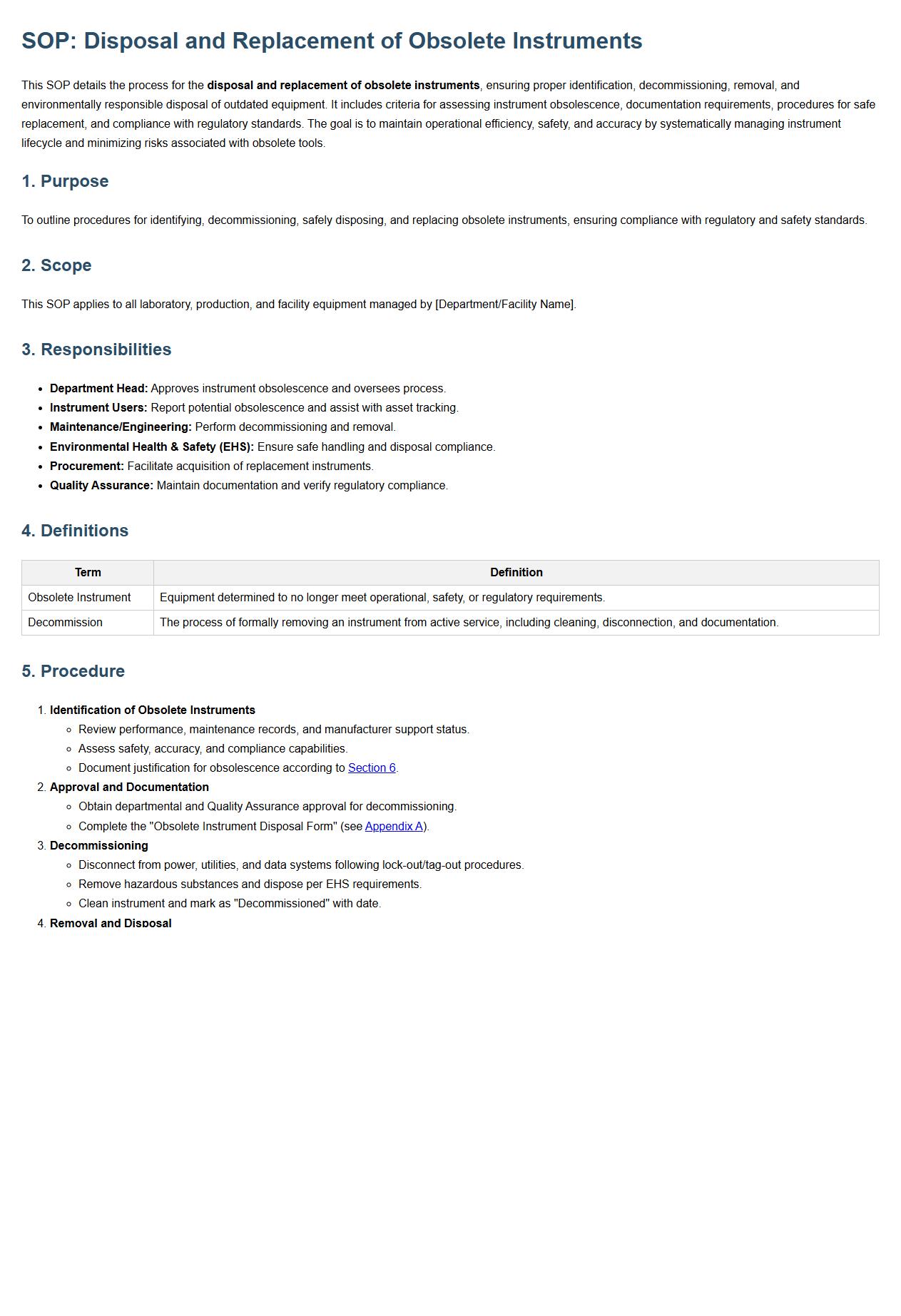

Disposal and replacement of obsolete instruments.

This SOP details the process for the disposal and replacement of obsolete instruments, ensuring proper identification, decommissioning, removal, and environmentally responsible disposal of outdated equipment. It includes criteria for assessing instrument obsolescence, documentation requirements, procedures for safe replacement, and compliance with regulatory standards. The goal is to maintain operational efficiency, safety, and accuracy by systematically managing instrument lifecycle and minimizing risks associated with obsolete tools.

What is the primary purpose of maintaining a Surgical Instrument Inventory as stated in the SOP?

The primary purpose of maintaining a Surgical Instrument Inventory is to ensure accurate tracking of all surgical tools. This helps prevent loss and facilitates timely replacement of instruments. It also promotes surgical safety and operational efficiency.

Which personnel are responsible for updating and verifying the surgical instrument inventory records?

The responsibility for updating and verifying the surgical instrument inventory lies with trained sterile processing and surgical staff. These individuals ensure all records are accurate and current. Regular collaboration between departments is essential for maintaining inventory integrity.

How does the SOP define the process for reporting and documenting lost or damaged surgical instruments?

The SOP mandates immediate reporting of any lost or damaged surgical instruments to the supervising authority. Detailed documentation, including incident descriptions and corrective actions, must be recorded. This procedure helps in accountability and timely resolution.

What are the key steps outlined for performing routine inventory audits according to the SOP?

Routine inventory audits involve systematic counting, inspecting, and verifying surgical instruments. Discrepancies are flagged and investigated promptly. Documentation of audit results ensures transparency and continuous improvement.

Which procedures are specified for handling and storing sterilized versus non-sterilized surgical instruments in the inventory?

The SOP specifies distinct protocols for handling sterilized and non-sterilized surgical instruments. Sterilized instruments must be stored in designated sterile areas to maintain asepsis. Non-sterilized instruments require secure, separate storage until proper sterilization is completed.