A SOP Template for Lean Manufacturing Process streamlines workflow by providing clear, step-by-step instructions to eliminate waste and enhance efficiency. This template ensures consistent implementation of lean principles, promoting continuous improvement and reducing production costs. Using a well-structured SOP helps maintain quality standards while optimizing resource utilization.

Process mapping and workflow documentation.

This SOP defines the standards for process mapping and workflow documentation, detailing the steps for identifying, analyzing, and visually representing business processes. It emphasizes the importance of accurate documentation to improve operational efficiency, consistency, and communication across teams. The procedure covers selecting appropriate mapping tools, defining process boundaries, capturing workflows, validating information with stakeholders, and maintaining updates to ensure continuous process improvement and clarity in organizational operations.

Standardized work instructions development.

This SOP details the process for developing standardized work instructions, encompassing the creation, review, validation, and continuous improvement of clear and concise work procedures. It ensures consistency, quality, and efficiency across operations by providing employees with precise guidelines to perform tasks safely and effectively, reducing variability and enhancing productivity.

Daily 5S workplace organization procedures.

This SOP details the Daily 5S workplace organization procedures, which include sorting, setting in order, shining, standardizing, and sustaining. The purpose is to maintain a clean, organized, and efficient work environment by eliminating clutter, arranging tools and materials systematically, performing regular cleaning, establishing standard practices, and promoting sustained workplace discipline. Implementing these procedures enhances productivity, safety, and workplace morale.

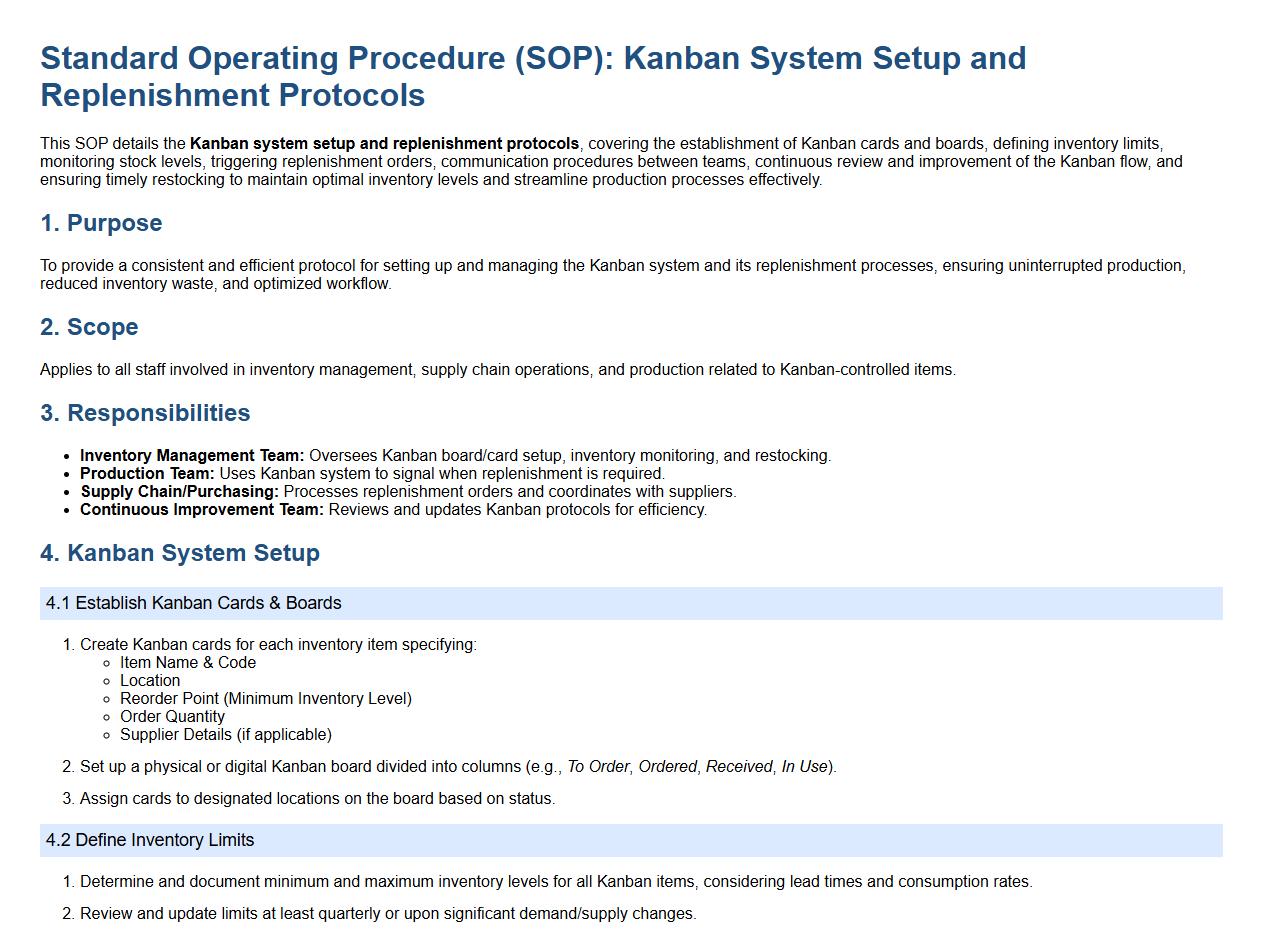

Kanban system setup and replenishment protocols.

This SOP details the Kanban system setup and replenishment protocols, covering the establishment of Kanban cards and boards, defining inventory limits, monitoring stock levels, triggering replenishment orders, communication procedures between teams, continuous review and improvement of the Kanban flow, and ensuring timely restocking to maintain optimal inventory levels and streamline production processes effectively.

Root cause analysis and problem-solving routines.

This SOP details the root cause analysis and problem-solving routines, focusing on systematic identification of underlying issues, effective troubleshooting methodologies, data collection and analysis techniques, implementation of corrective actions, and continuous improvement practices. The objective is to enhance organizational problem-solving capabilities, prevent recurrence of issues, and promote efficient resolution of operational challenges.

Quality control and defect management guidelines.

This SOP establishes quality control and defect management guidelines to ensure the consistent production of high-quality products. It covers inspection processes, defect identification and classification, corrective and preventive actions, documentation of quality issues, and continuous improvement strategies. The goal is to minimize defects, enhance product reliability, and maintain customer satisfaction through systematic quality assurance practices.

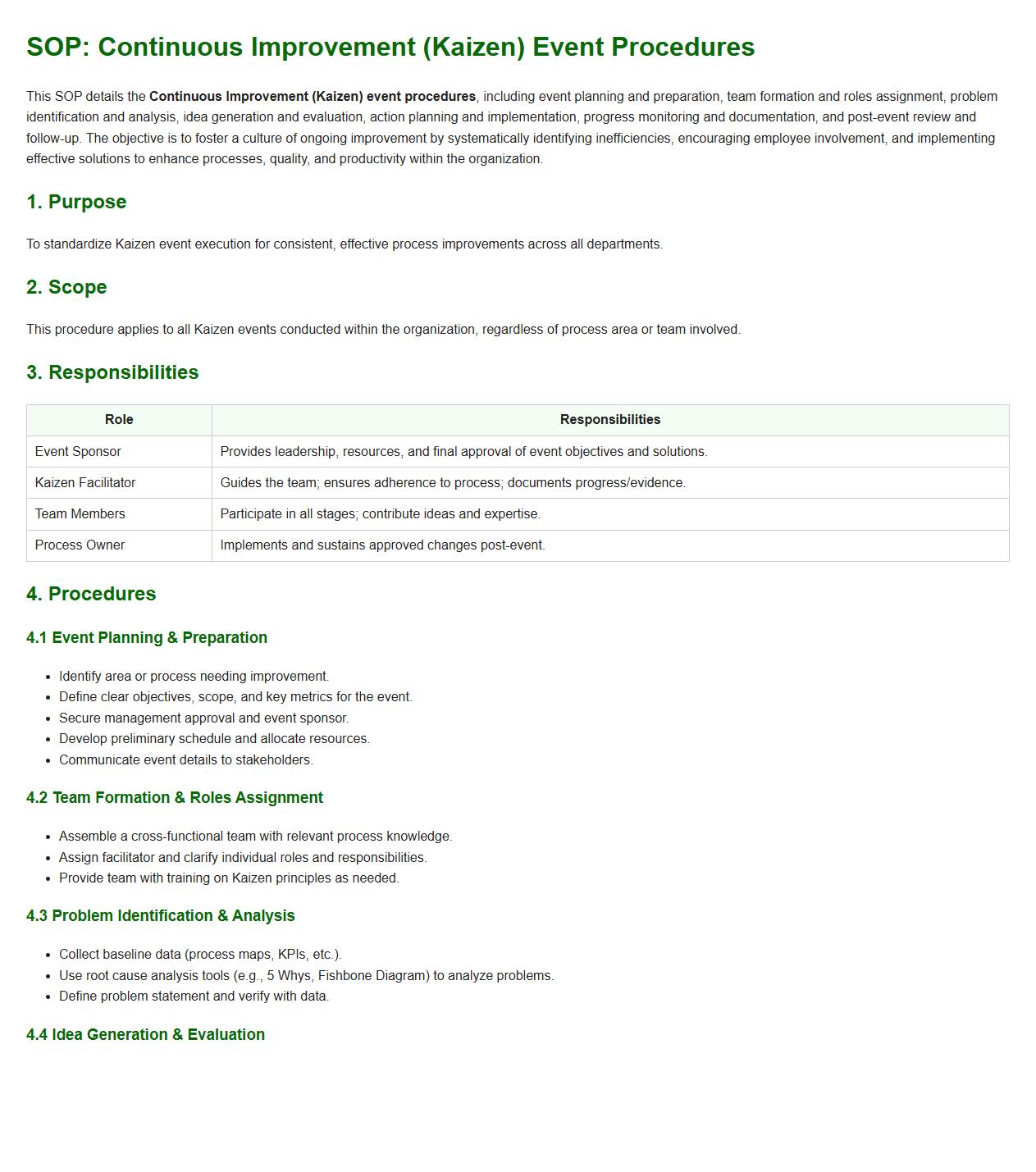

Continuous improvement (Kaizen) event procedures.

This SOP details the Continuous Improvement (Kaizen) event procedures, including event planning and preparation, team formation and roles assignment, problem identification and analysis, idea generation and evaluation, action planning and implementation, progress monitoring and documentation, and post-event review and follow-up. The objective is to foster a culture of ongoing improvement by systematically identifying inefficiencies, encouraging employee involvement, and implementing effective solutions to enhance processes, quality, and productivity within the organization.

Equipment cleaning, inspection, and maintenance schedules.

This SOP defines the procedures for equipment cleaning, inspection, and maintenance schedules, including regular cleaning protocols, detailed inspection checklists, routine maintenance tasks, and timely repairs to ensure equipment efficiency and longevity. It aims to minimize downtime, prevent equipment failures, and maintain a safe working environment by adhering to standardized maintenance schedules and documenting all activities accurately.

Visual management and performance tracking.

This SOP defines the processes for visual management and performance tracking, including establishing visual indicators, setting performance benchmarks, monitoring key performance indicators (KPIs), utilizing dashboards and visual tools, conducting regular reviews, and implementing continuous improvement strategies. The goal is to enhance transparency, improve operational efficiency, and facilitate data-driven decision-making through clear and effective visual communication methods.

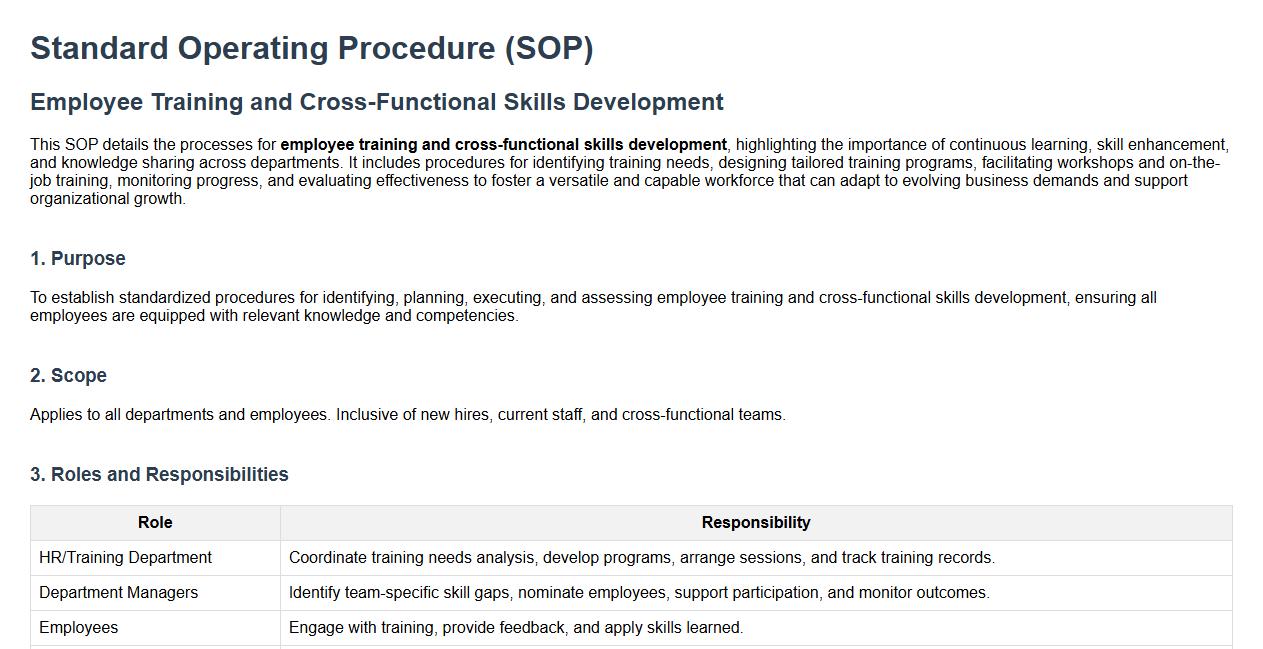

Employee training and cross-functional skills development.

This SOP details the processes for employee training and cross-functional skills development, highlighting the importance of continuous learning, skill enhancement, and knowledge sharing across departments. It includes procedures for identifying training needs, designing tailored training programs, facilitating workshops and on-the-job training, monitoring progress, and evaluating effectiveness to foster a versatile and capable workforce that can adapt to evolving business demands and support organizational growth.

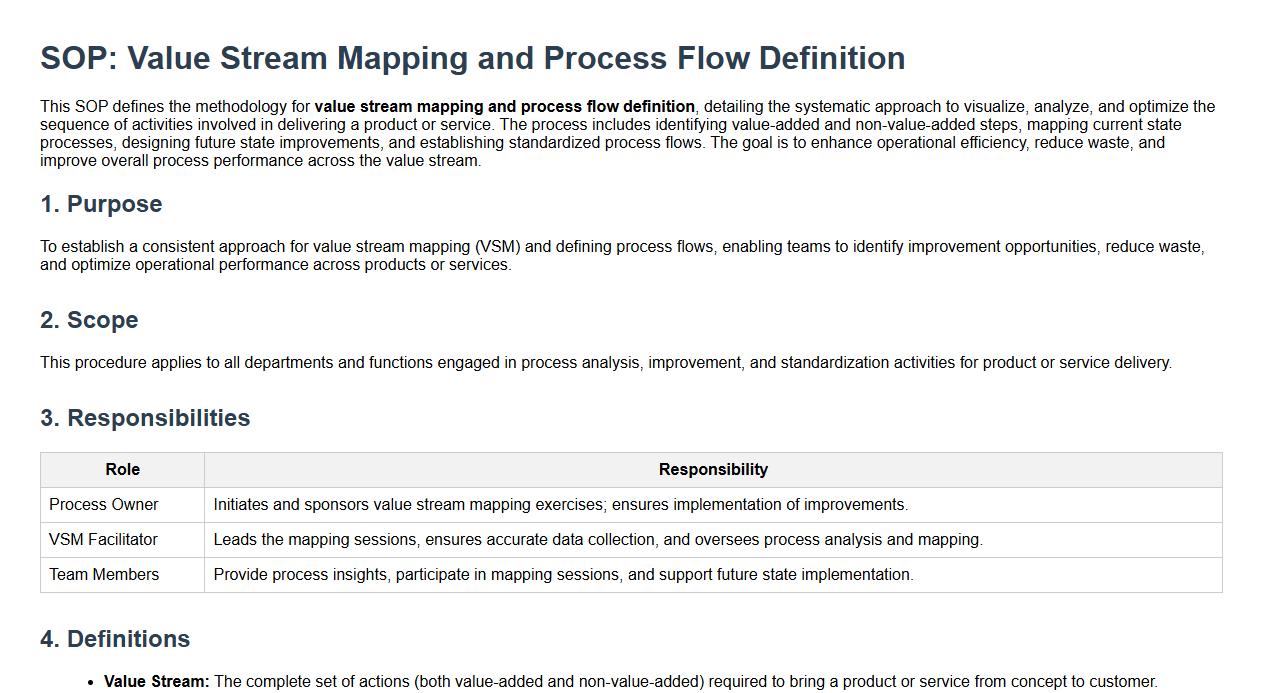

Value stream mapping and process flow definition.

This SOP defines the methodology for value stream mapping and process flow definition, detailing the systematic approach to visualize, analyze, and optimize the sequence of activities involved in delivering a product or service. The process includes identifying value-added and non-value-added steps, mapping current state processes, designing future state improvements, and establishing standardized process flows. The goal is to enhance operational efficiency, reduce waste, and improve overall process performance across the value stream.

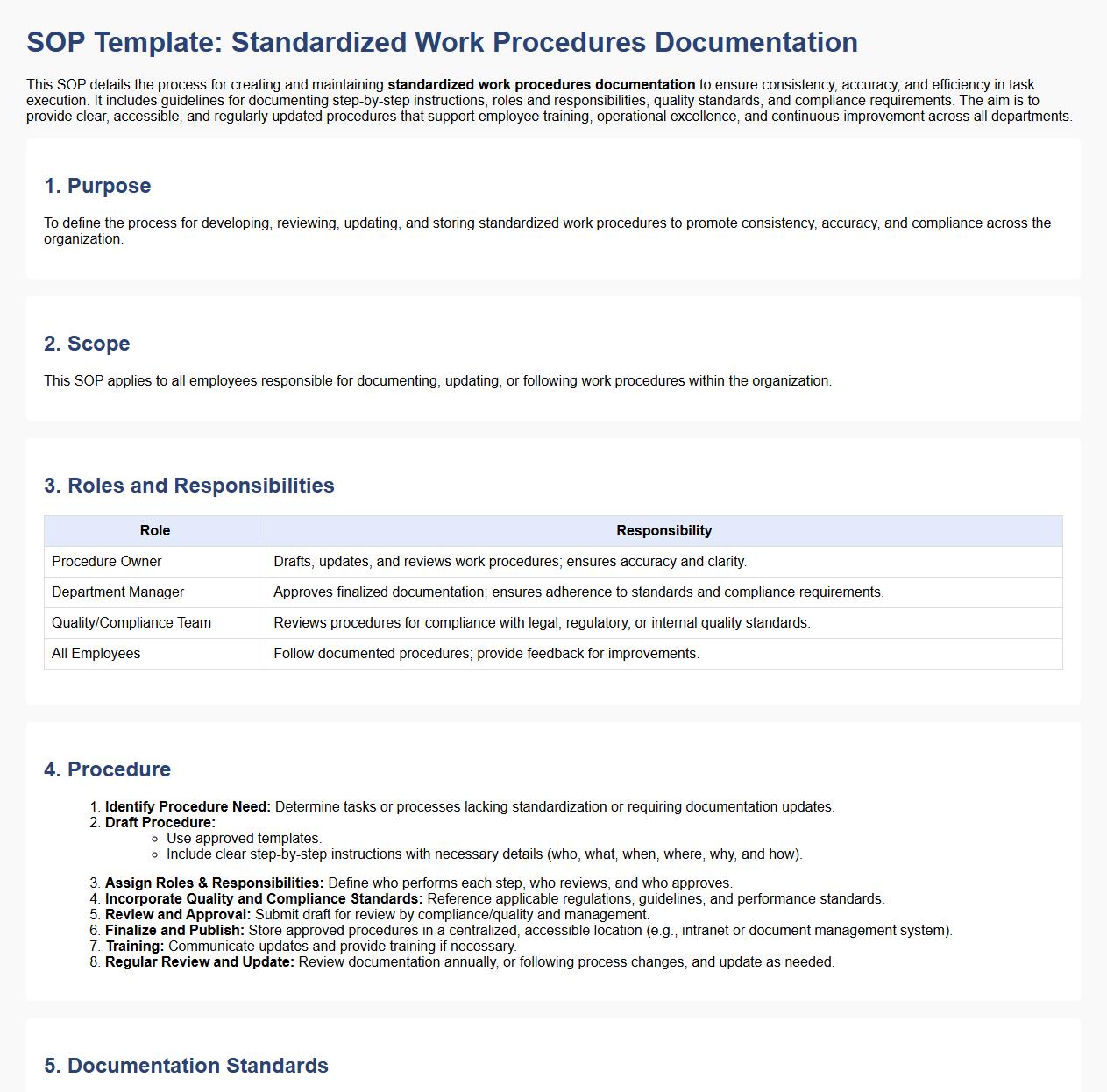

Standardized work procedures documentation.

This SOP details the process for creating and maintaining standardized work procedures documentation to ensure consistency, accuracy, and efficiency in task execution. It includes guidelines for documenting step-by-step instructions, roles and responsibilities, quality standards, and compliance requirements. The aim is to provide clear, accessible, and regularly updated procedures that support employee training, operational excellence, and continuous improvement across all departments.

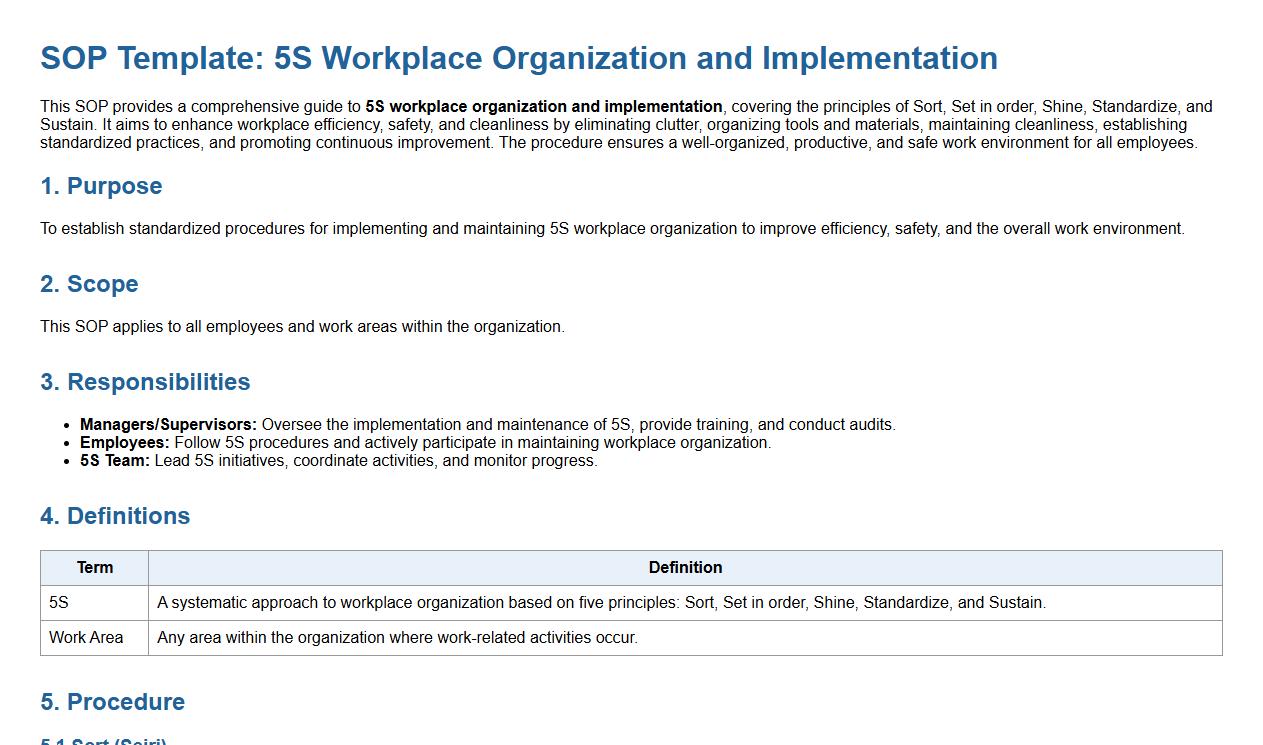

5S workplace organization and implementation.

This SOP provides a comprehensive guide to 5S workplace organization and implementation, covering the principles of Sort, Set in order, Shine, Standardize, and Sustain. It aims to enhance workplace efficiency, safety, and cleanliness by eliminating clutter, organizing tools and materials, maintaining cleanliness, establishing standardized practices, and promoting continuous improvement. The procedure ensures a well-organized, productive, and safe work environment for all employees.

Setup reduction and changeover process steps.

This SOP details the setup reduction and changeover process steps designed to minimize downtime and improve efficiency during equipment or production line transitions. It covers preparation and planning, cleaning and inspection procedures, tool and part replacement techniques, testing and verification methods, and continuous improvement practices to streamline operations and enhance productivity.

Visual management systems and signage use.

This SOP establishes guidelines for the effective implementation and use of visual management systems and signage within the workplace. It covers the design, placement, maintenance, and standardization of visual aids to enhance communication, improve safety, streamline workflow, and ensure clear identification of key areas, hazards, and processes. Proper visual management supports a more organized environment, reduces errors, and promotes compliance with operational and safety standards.

Kanban inventory and material replenishment process.

This SOP details the Kanban inventory and material replenishment process, outlining the steps for managing inventory levels, triggering replenishment signals, and maintaining optimal stock availability. It covers the design and use of Kanban cards, monitoring inventory status, communication between production and supply teams, and timely ordering and delivery of materials to prevent shortages and overstock. The objective is to streamline inventory management, reduce waste, and ensure a smooth production workflow through effective material replenishment practices.

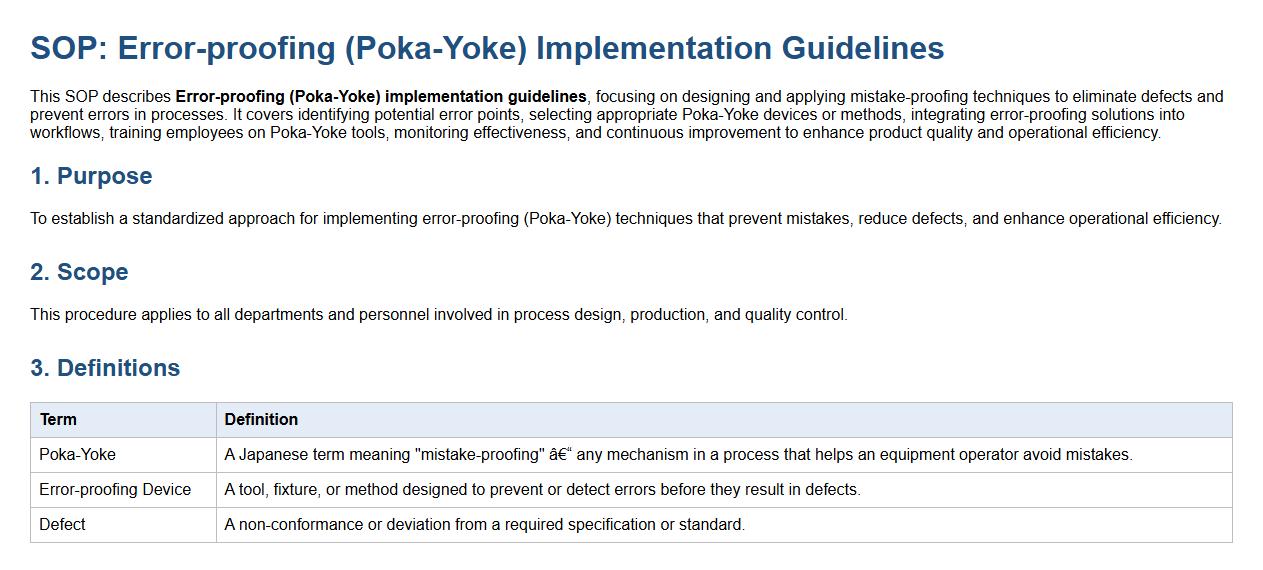

Error-proofing (Poka-Yoke) implementation guidelines.

This SOP describes Error-proofing (Poka-Yoke) implementation guidelines, focusing on designing and applying mistake-proofing techniques to eliminate defects and prevent errors in processes. It covers identifying potential error points, selecting appropriate Poka-Yoke devices or methods, integrating error-proofing solutions into workflows, training employees on Poka-Yoke tools, monitoring effectiveness, and continuous improvement to enhance product quality and operational efficiency.

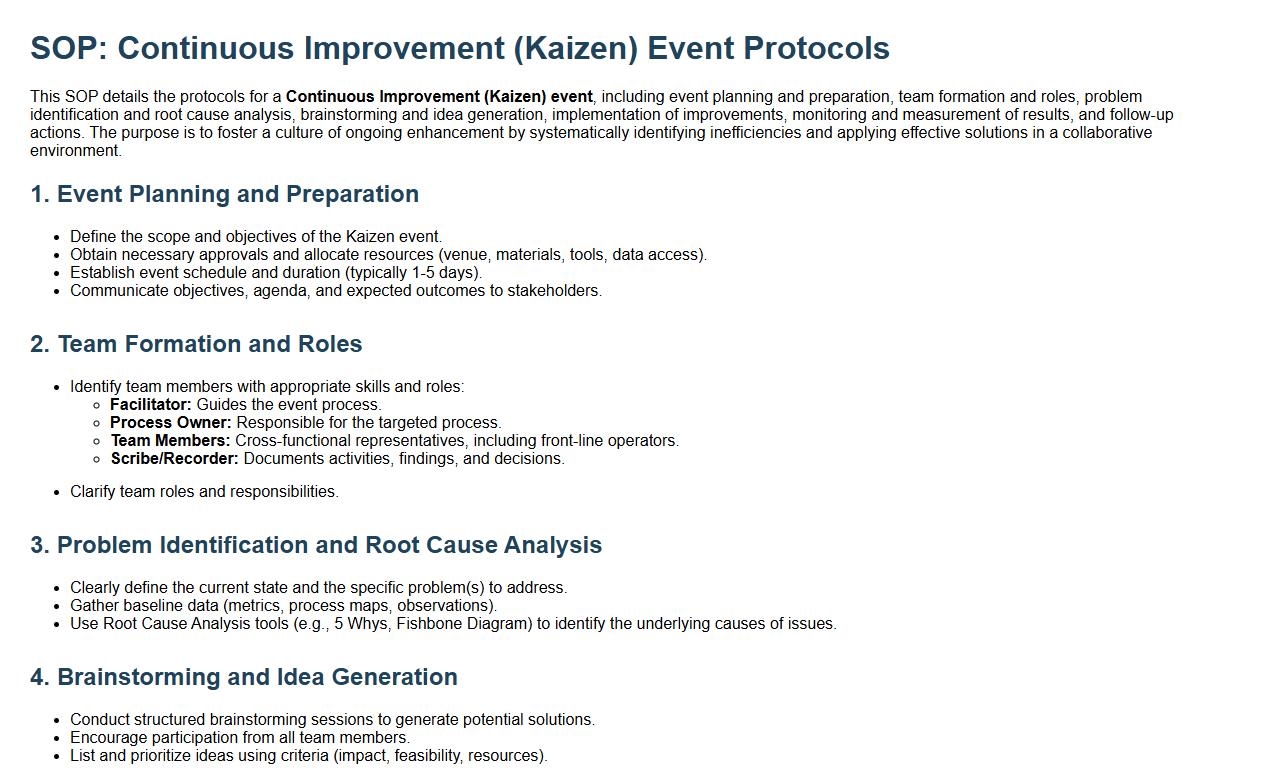

Continuous improvement (Kaizen) event protocols.

This SOP details the protocols for a Continuous Improvement (Kaizen) event, including event planning and preparation, team formation and roles, problem identification and root cause analysis, brainstorming and idea generation, implementation of improvements, monitoring and measurement of results, and follow-up actions. The purpose is to foster a culture of ongoing enhancement by systematically identifying inefficiencies and applying effective solutions in a collaborative environment.

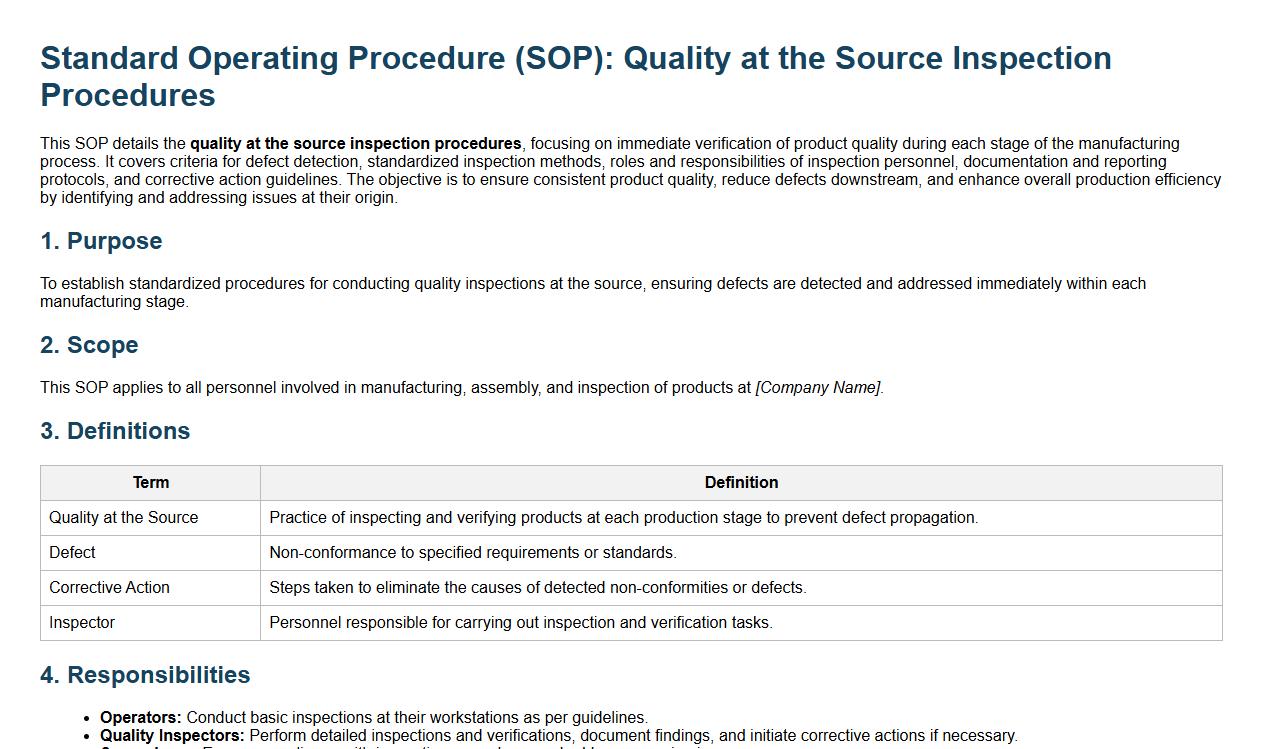

Quality at the source inspection procedures.

This SOP details the quality at the source inspection procedures, focusing on immediate verification of product quality during each stage of the manufacturing process. It covers criteria for defect detection, standardized inspection methods, roles and responsibilities of inspection personnel, documentation and reporting protocols, and corrective action guidelines. The objective is to ensure consistent product quality, reduce defects downstream, and enhance overall production efficiency by identifying and addressing issues at their origin.

Daily performance tracking and reporting routines.

This SOP details daily performance tracking and reporting routines, encompassing data collection methods, key performance indicators monitoring, timely documentation, accuracy verification, routine analysis, and reporting protocols. The objective is to ensure consistent evaluation of operational efficiency, facilitate informed decision-making, and promote transparency across departments through systematic performance tracking and clear, concise reporting.

Key Steps for Initiating a Lean Manufacturing Process

The SOP emphasizes identifying value streams to map out all critical processes. Next, it guides the elimination of non-value-added activities to streamline production. Finally, the process involves continuous monitoring to ensure sustained efficiency gains.

Waste Types Targeted for Elimination

The SOP targets the elimination of the seven wastes: overproduction, waiting, transport, extra processing, inventory, motion, and defects. Each waste type is addressed with specific strategies to minimize its occurrence. This approach helps in maximizing operational efficiency and reducing costs.

Role Definition in Sustaining Lean Practices

The SOP clearly outlines roles and responsibilities for all team members to maintain lean practices. Managers are tasked with oversight and continuous improvement leadership. Operators are responsible for adhering to standardized procedures and reporting inefficiencies.

Standard Procedures for Continuous Improvement

Standard procedures include regular Kaizen events and root cause analysis sessions. The SOP mandates periodic review meetings to assess process performance and identify improvement opportunities. Documentation of improvements ensures visibility and accountability.

Ensuring Compliance and Documentation

The SOP mandates strict adherence to documented protocols during all stages of Lean implementation. Compliance is verified through audits and performance metrics tracking. Accurate documentation provides transparency and supports ongoing process refinement.