A SOP Template for Manufacturing Staff Training ensures consistent and effective onboarding by outlining clear procedures and safety protocols. This template helps standardize training processes, improving employee competency and compliance with industry regulations. It serves as a practical guide for supervisors to deliver structured and measurable training sessions.

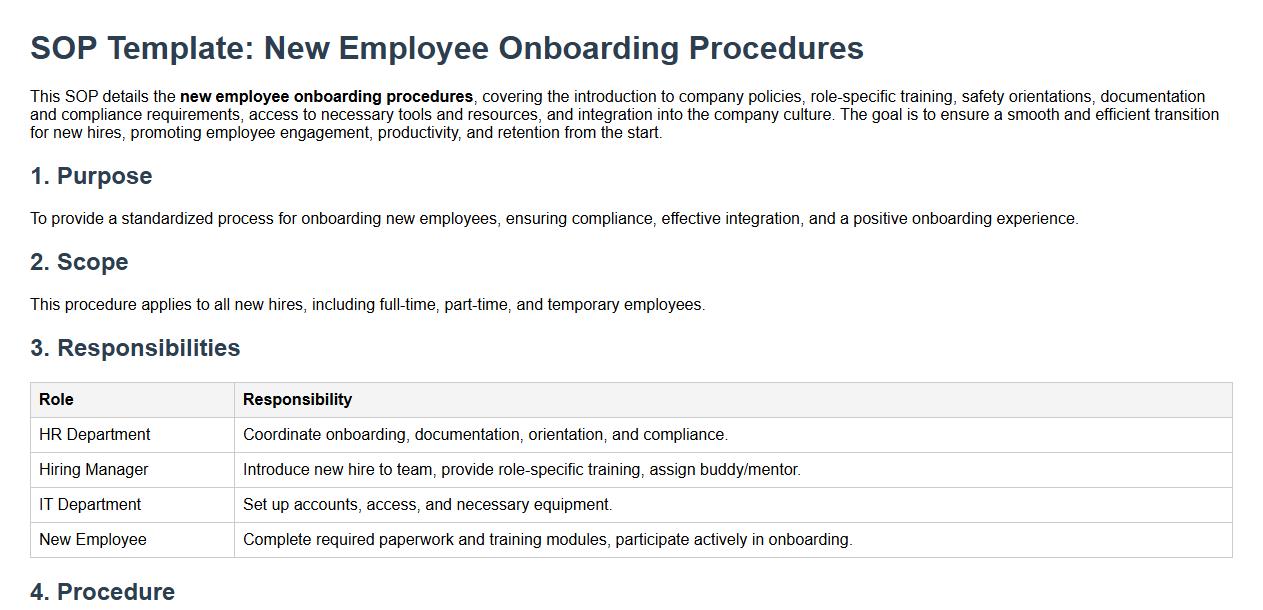

New employee onboarding procedures.

This SOP details the new employee onboarding procedures, covering the introduction to company policies, role-specific training, safety orientations, documentation and compliance requirements, access to necessary tools and resources, and integration into the company culture. The goal is to ensure a smooth and efficient transition for new hires, promoting employee engagement, productivity, and retention from the start.

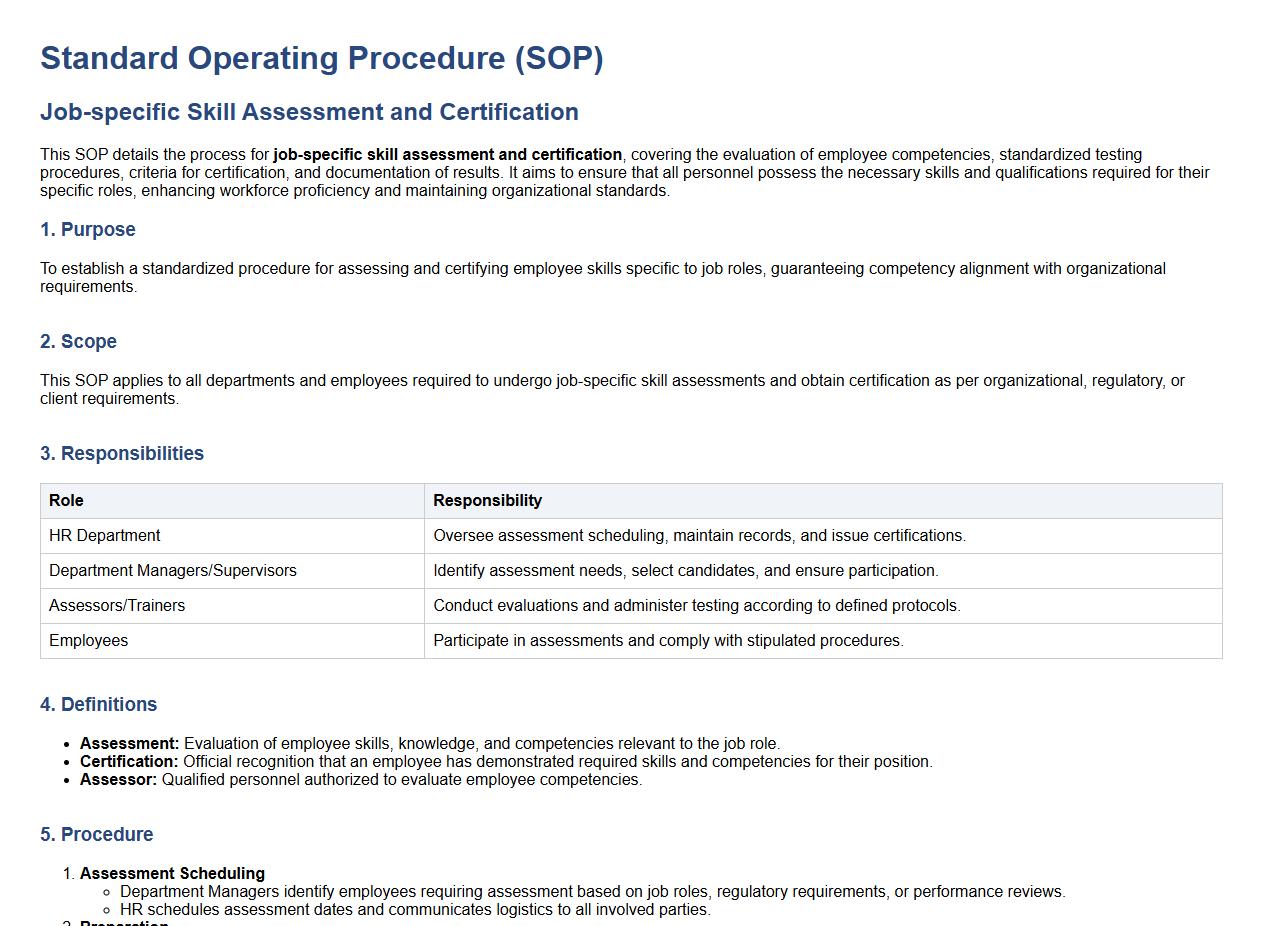

Job-specific skill assessment and certification.

This SOP details the process for job-specific skill assessment and certification, covering the evaluation of employee competencies, standardized testing procedures, criteria for certification, and documentation of results. It aims to ensure that all personnel possess the necessary skills and qualifications required for their specific roles, enhancing workforce proficiency and maintaining organizational standards.

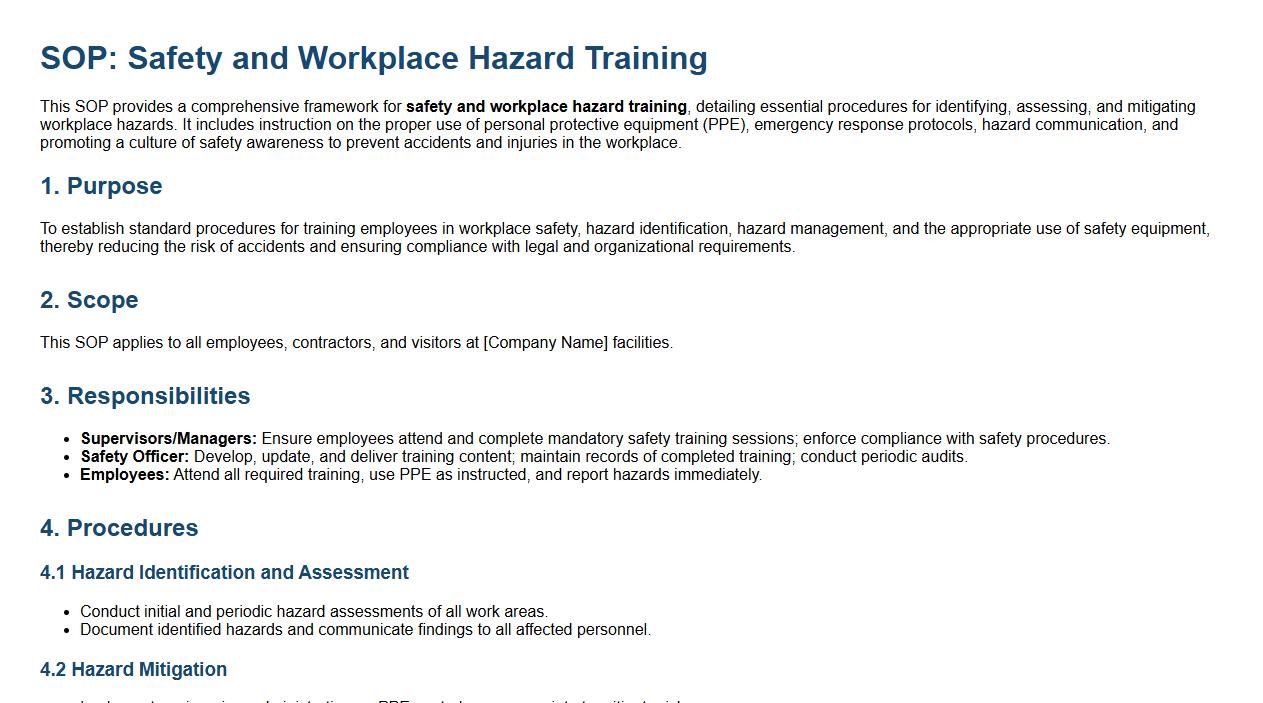

Safety and workplace hazard training.

This SOP provides a comprehensive framework for safety and workplace hazard training, detailing essential procedures for identifying, assessing, and mitigating workplace hazards. It includes instruction on the proper use of personal protective equipment (PPE), emergency response protocols, hazard communication, and promoting a culture of safety awareness to prevent accidents and injuries in the workplace.

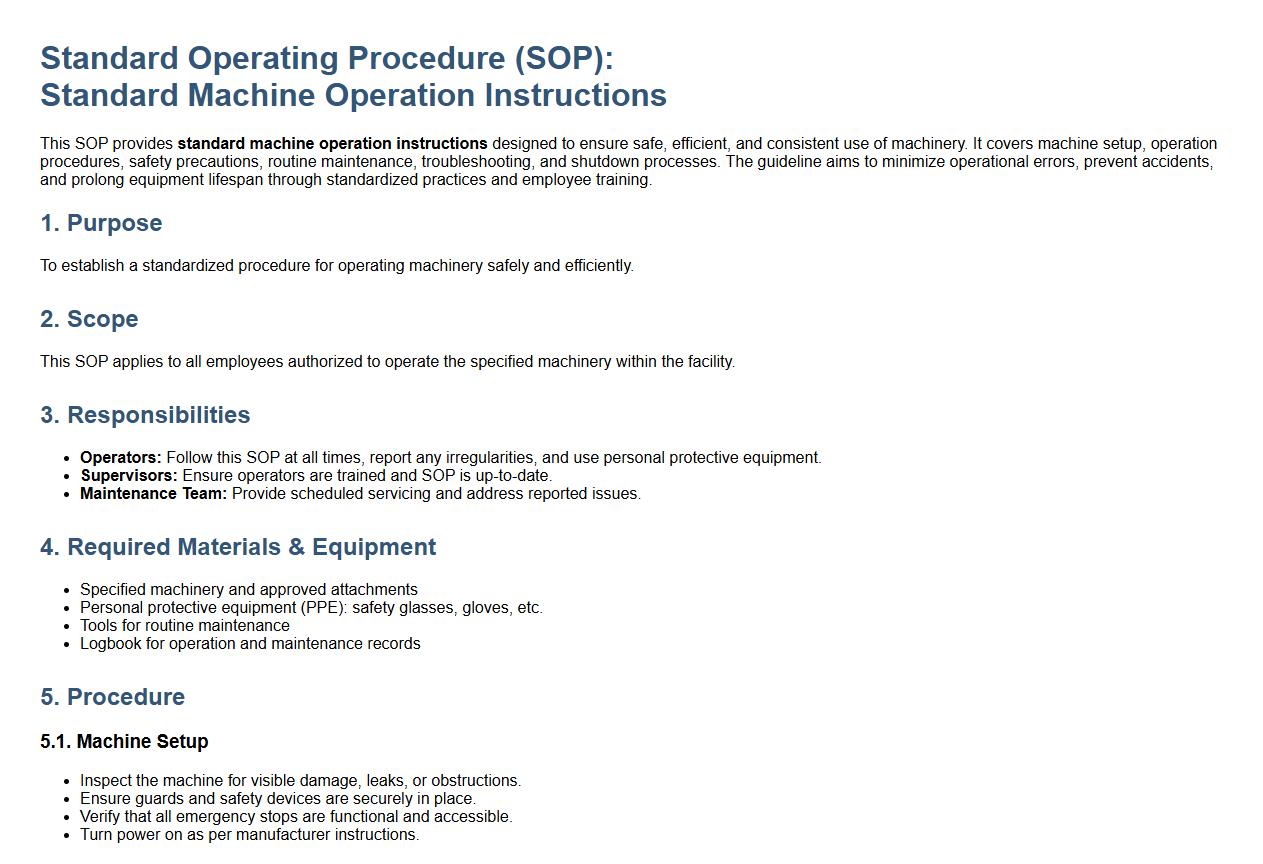

Standard machine operation instructions.

This SOP provides standard machine operation instructions designed to ensure safe, efficient, and consistent use of machinery. It covers machine setup, operation procedures, safety precautions, routine maintenance, troubleshooting, and shutdown processes. The guideline aims to minimize operational errors, prevent accidents, and prolong equipment lifespan through standardized practices and employee training.

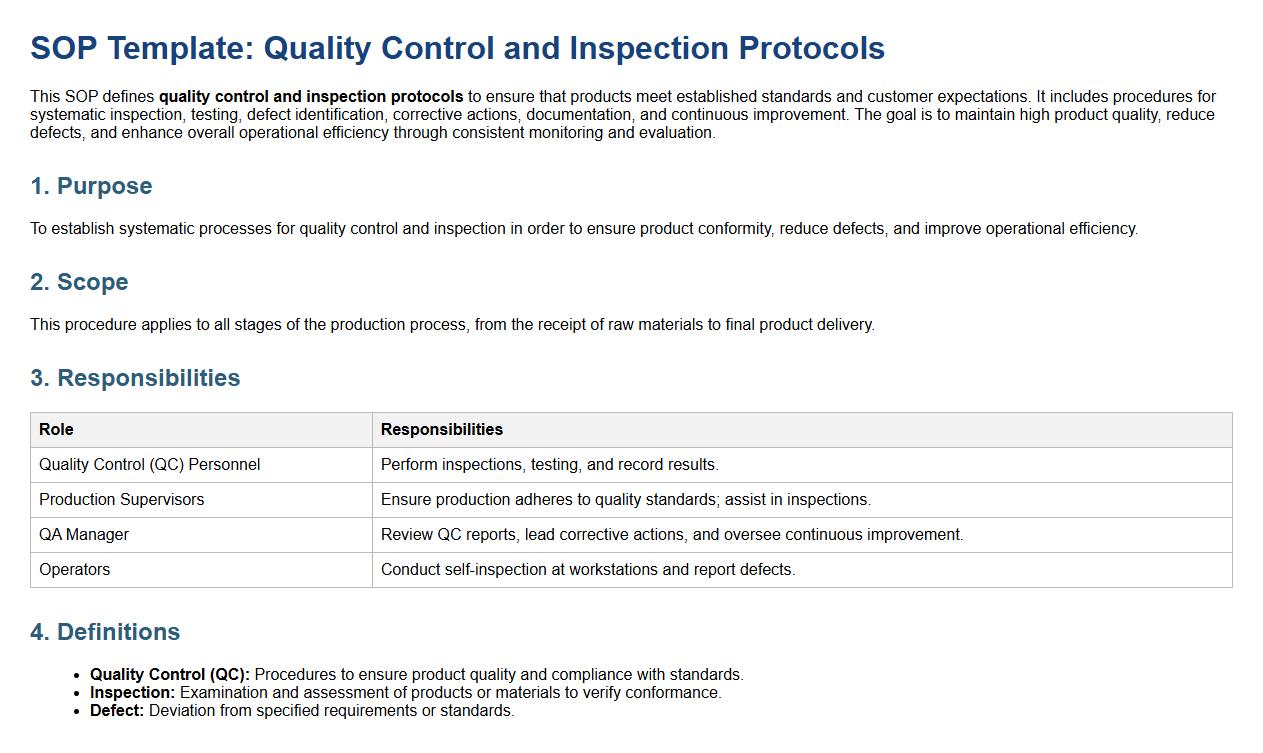

Quality control and inspection protocols.

This SOP defines quality control and inspection protocols to ensure that products meet established standards and customer expectations. It includes procedures for systematic inspection, testing, defect identification, corrective actions, documentation, and continuous improvement. The goal is to maintain high product quality, reduce defects, and enhance overall operational efficiency through consistent monitoring and evaluation.

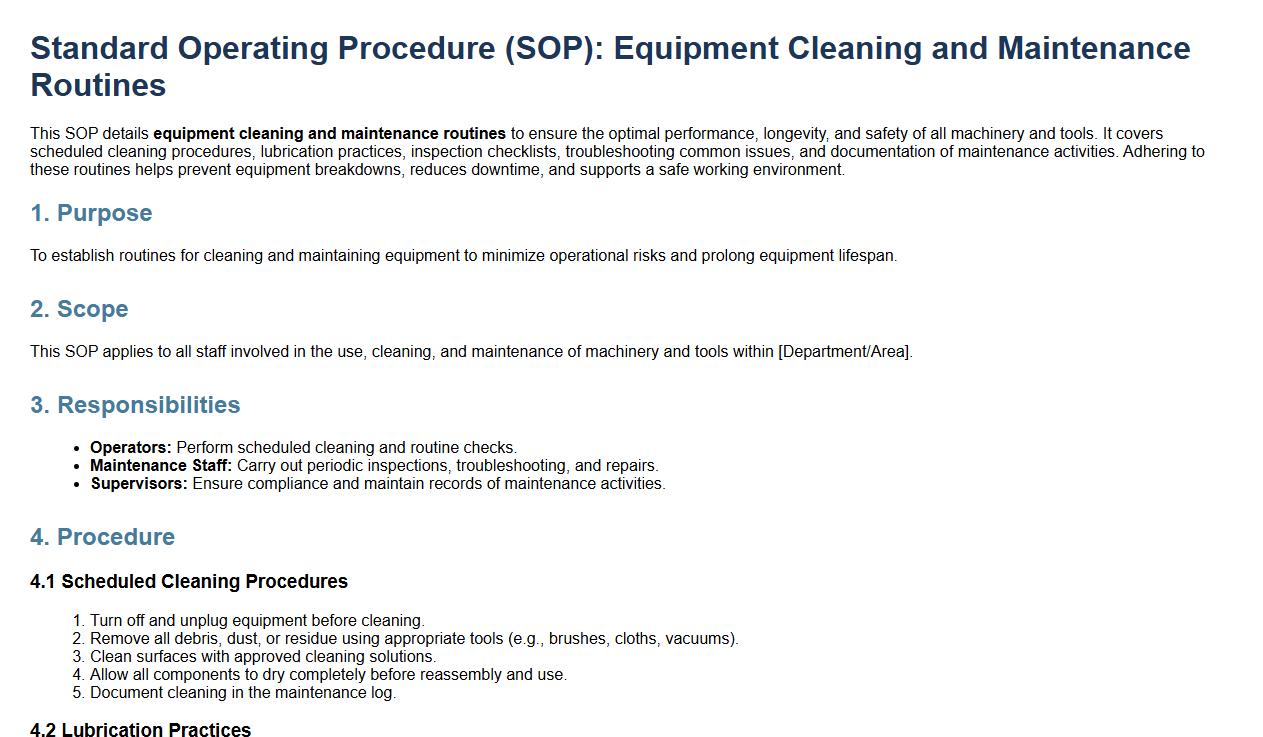

Equipment cleaning and maintenance routines.

This SOP details equipment cleaning and maintenance routines to ensure the optimal performance, longevity, and safety of all machinery and tools. It covers scheduled cleaning procedures, lubrication practices, inspection checklists, troubleshooting common issues, and documentation of maintenance activities. Adhering to these routines helps prevent equipment breakdowns, reduces downtime, and supports a safe working environment.

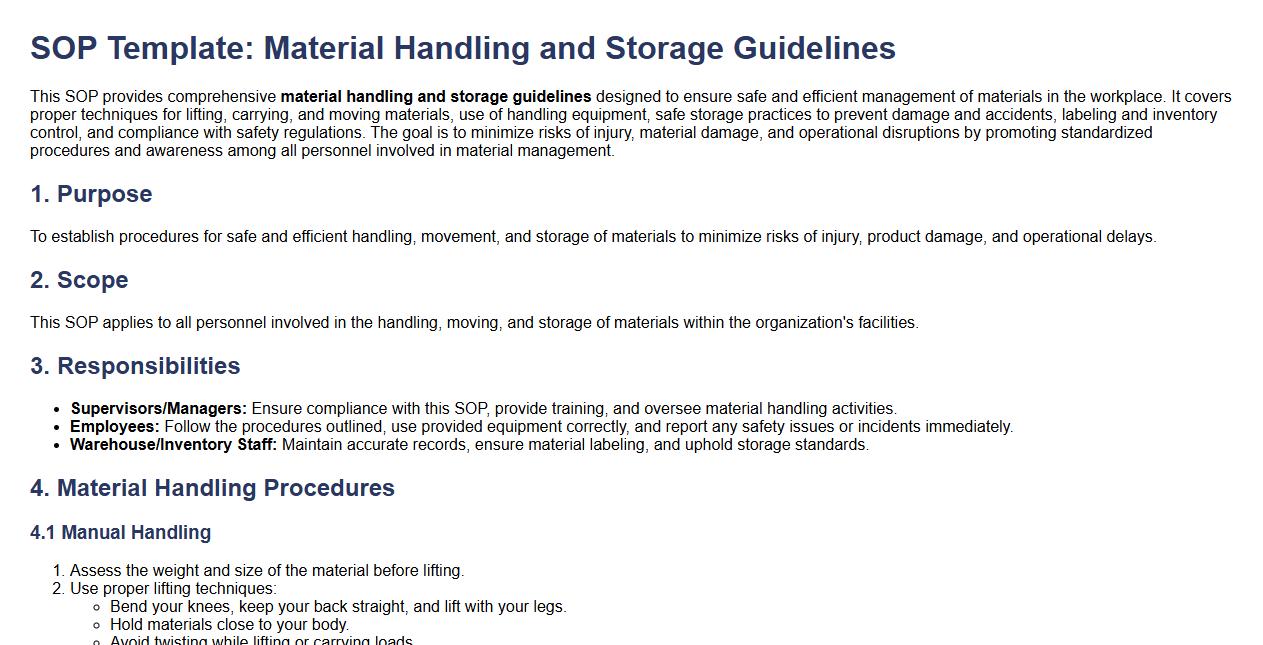

Material handling and storage guidelines.

This SOP provides comprehensive material handling and storage guidelines designed to ensure safe and efficient management of materials in the workplace. It covers proper techniques for lifting, carrying, and moving materials, use of handling equipment, safe storage practices to prevent damage and accidents, labeling and inventory control, and compliance with safety regulations. The goal is to minimize risks of injury, material damage, and operational disruptions by promoting standardized procedures and awareness among all personnel involved in material management.

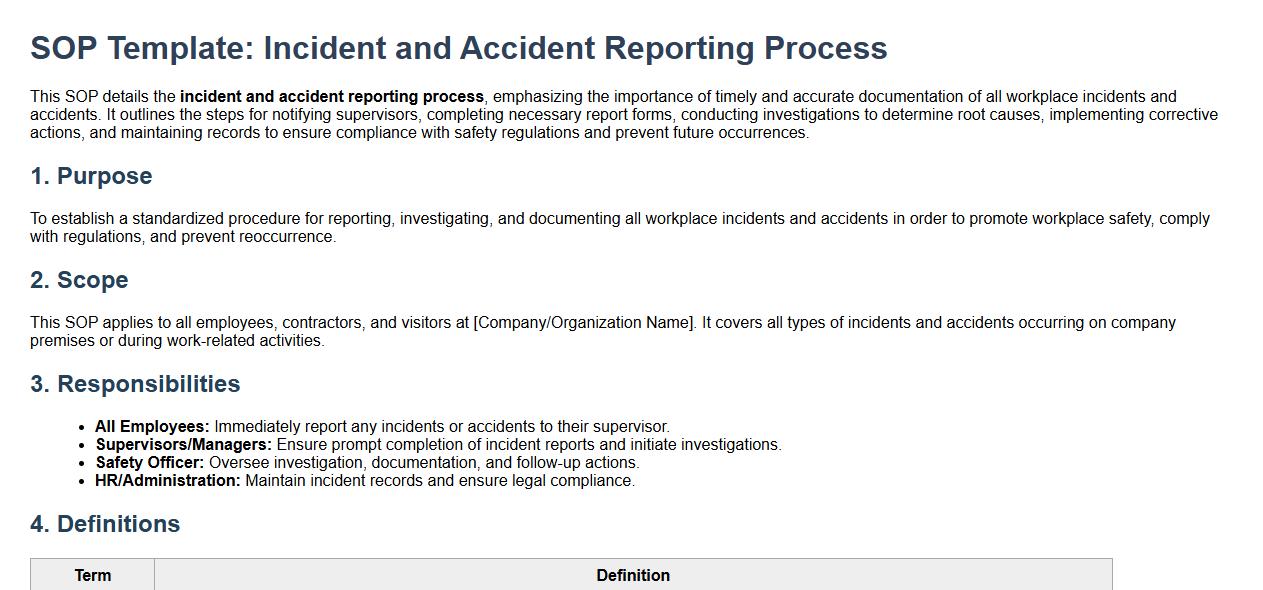

Incident and accident reporting process.

This SOP details the incident and accident reporting process, emphasizing the importance of timely and accurate documentation of all workplace incidents and accidents. It outlines the steps for notifying supervisors, completing necessary report forms, conducting investigations to determine root causes, implementing corrective actions, and maintaining records to ensure compliance with safety regulations and prevent future occurrences.

Continuous improvement and feedback sessions.

This SOP describes the process for continuous improvement and feedback sessions, including the scheduling of regular meetings, methods for gathering constructive feedback from team members, analyzing performance data, identifying areas for enhancement, implementing improvement strategies, monitoring progress, and fostering a culture of open communication and collaboration. The goal is to ensure ongoing organizational development and increased efficiency through systematic evaluation and responsive action.

Documentation and training record management.

This SOP details the documentation and training record management process, ensuring accurate maintenance, secure storage, and timely updating of all training records and related documents. It covers the procedures for documenting employee training activities, tracking certifications and compliance, managing record retention schedules, and facilitating easy retrieval of records for audits and reviews. The goal is to maintain organized and reliable documentation that supports workforce development and regulatory compliance.

What are the key objectives outlined in the SOP for Manufacturing Staff Training?

The SOP emphasizes comprehensive skill development to enhance staff efficiency and product quality. It aims to ensure all manufacturing personnel understand safety protocols and operational procedures thoroughly. Additionally, the SOP seeks to standardize training processes across all departments to maintain consistency.

Which specific training methods are mandated by the SOP for different staff roles?

The SOP mandates a mix of hands-on practical training, classroom sessions, and e-learning modules tailored to role-specific requirements. Supervisory roles require advanced technical workshops while entry-level staff participate in basic operational training. This structured approach ensures relevant competency development for each position.

How does the SOP ensure competency evaluation and knowledge retention among manufacturing staff?

The SOP includes regular assessments and performance reviews to evaluate staff competency effectively. It mandates periodic refresher courses and on-the-job evaluations to reinforce knowledge retention. Feedback mechanisms are integrated to identify knowledge gaps and implement corrective training promptly.

What documentation and record-keeping processes are required by the SOP?

The SOP requires detailed training records including attendance, assessment results, and certification status for each employee. It ensures documentation is securely stored and easily accessible for audits and compliance checks. Proper record-keeping supports continuous improvement and regulatory adherence.

What frequency and intervals for training updates are defined within the SOP?

The SOP specifies that training must be updated at least annually or whenever there are changes in procedures or regulations. It also requires interim refresher sessions based on competency evaluation outcomes. This ensures manufacturing staff remain current with best practices and compliance standards.